Reciprocating compressor of refrigerating machine

A refrigerating machine and reciprocating technology, which is applied in the field of refrigerating compressors, can solve problems such as easy decomposition and double bonds are easy to break, and achieve the effects of improving energy efficiency, improving compression efficiency, and preventing global warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

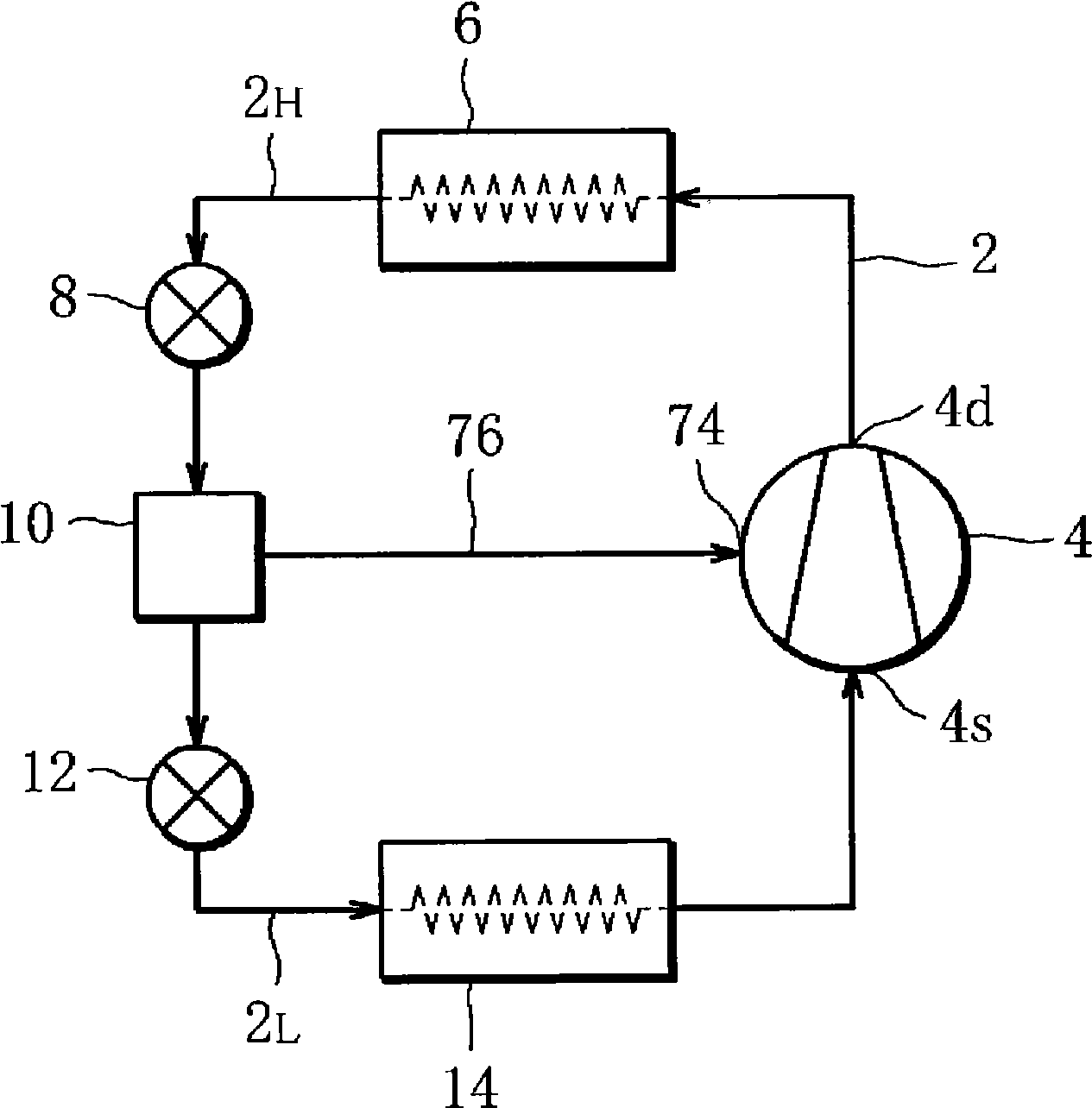

[0020] figure 1 The refrigerating machine is installed in the air-conditioning system for the vehicle, and includes the circulation path 2 for the refrigerant. A compressor 4 , a condenser 6 , a first expansion valve 8 , a gas-liquid separator 10 , a second expansion valve 12 , and an evaporator 14 are sequentially inserted into the circulation path 2 . The compressor 4 compresses and discharges the refrigerant, and the discharged refrigerant is supplied to the condenser 6 and circulates in the circulation path 2 .

[0021] Here, the circulation path 2 has a high-pressure region 2H from the discharge port 4d of the compressor 4 to the first expansion valve 8 via the condenser 6 and from the first expansion valve 8 via the gas-liquid separator 10, the second expansion valve 12, and the evaporator. The filter 14 reaches the low-pressure region 2L of the suction port 4s of the compressor 4 .

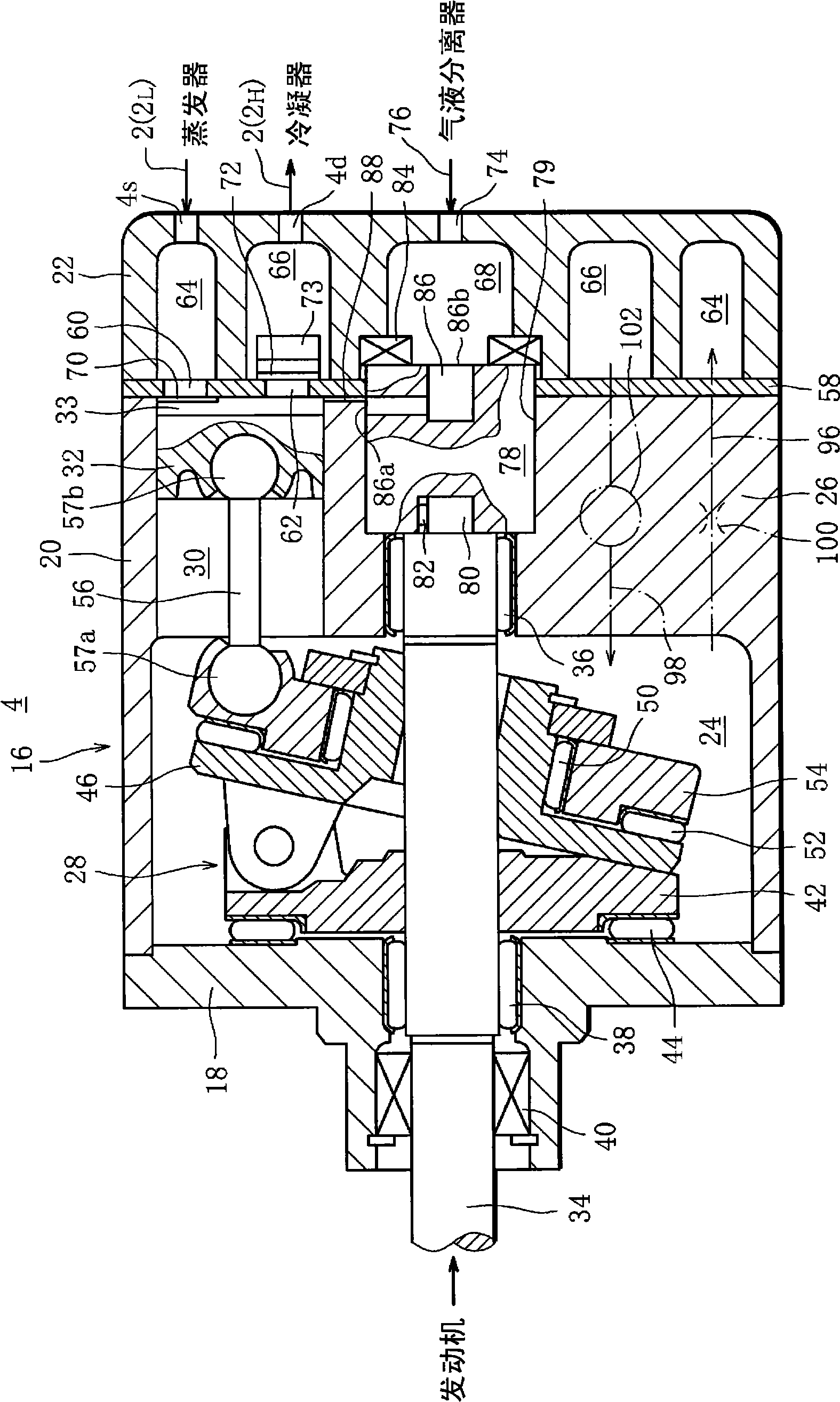

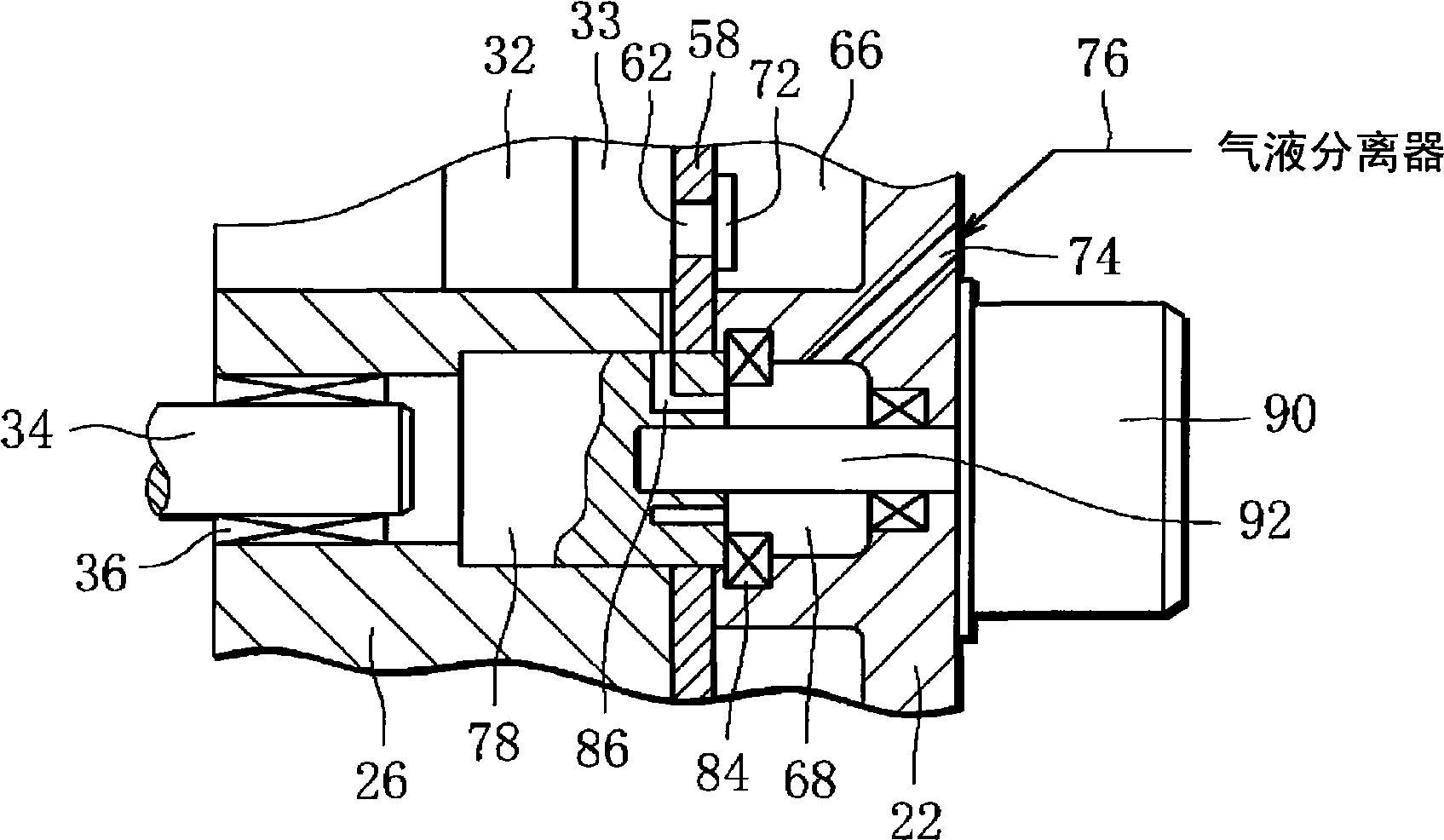

[0022] figure 2 The details of the compressor 4 are shown.

[0023] The compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com