A kind of nano polytetrafluoroethylene coating and its preparation method and application

A technology of polytetrafluoroethylene and polyvinyl alcohol, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of cumbersome drawing process, large friction coefficient, environmental pollution, etc., to improve quality and service life, excellent Lubrication performance, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

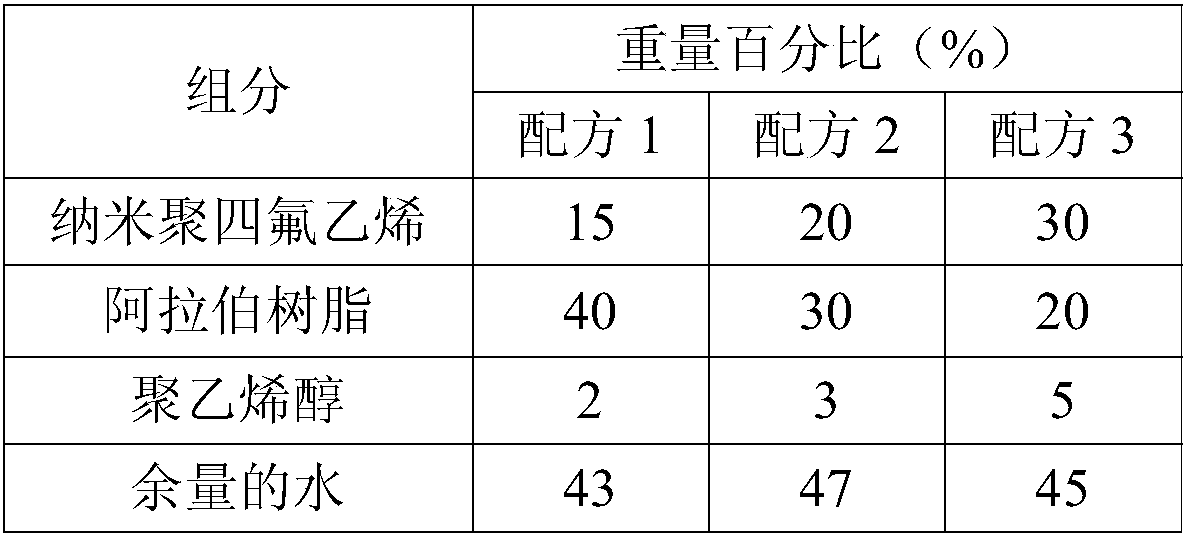

[0046] Prepare the nano-polytetrafluoroethylene coating of Example 1-3 according to formula 1-3 and specific preparation method.

[0047] The obtained nano-polytetrafluoroethylene coating samples are further used in subsequent examples.

Embodiment 4

[0048] Example 4: Application of nano-polytetrafluoroethylene coating in drawing process of titanium metal wire

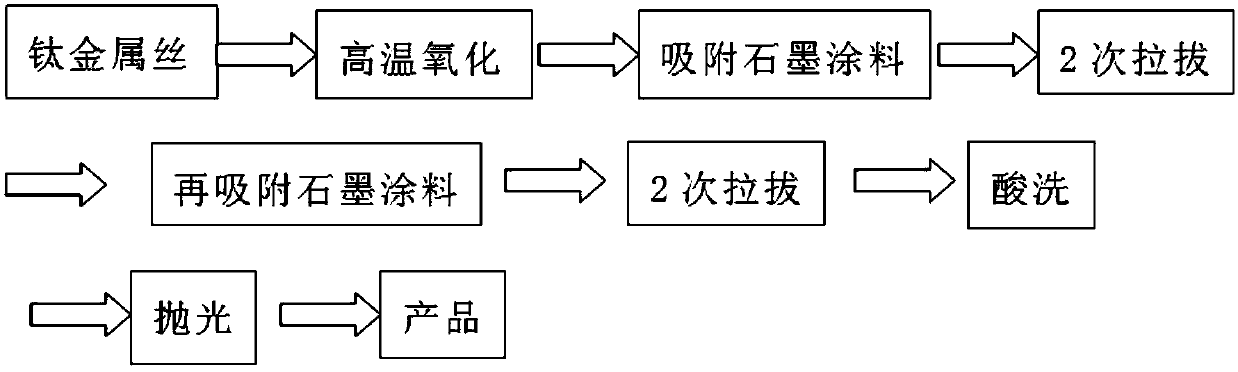

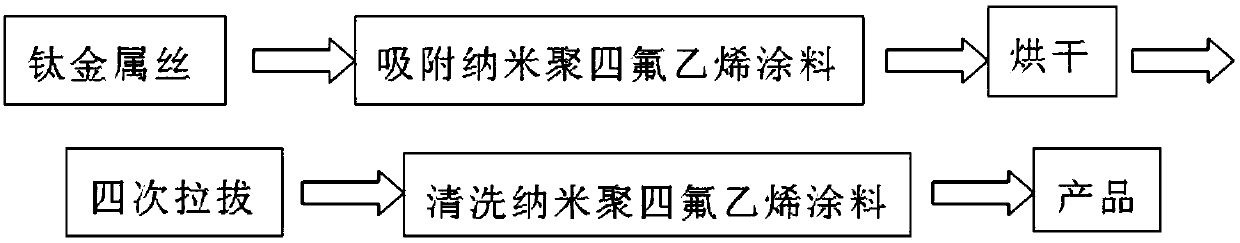

[0049] The traditional titanium wire drawing process using graphite powder coating is as follows: figure 1 Shown, nano polytetrafluoroethylene coating of the present invention is coated on the concrete technological process of application in titanium metal wire drawing process as figure 2 As shown, the specific process steps are as follows:

[0050] 1) Dip the titanium metal wire in the nano-polytetrafluoroethylene coating for 1-5 minutes;

[0051] 2) Drying the titanium wire dipped in the nano-polytetrafluoroethylene coating at 30-80° C. for 1-30 minutes;

[0052] 3) drawing the dried titanium wire four times;

[0053] 4) Clean the nano-polytetrafluoroethylene coating on the surface of the drawn titanium wire with 40-80°C hot water;

[0054] 5) drying.

[0055] After testing, the obtained titanium wire is qualified.

Embodiment 5

[0056] Example 5: Application of nano-polytetrafluoroethylene coating in drawing process of titanium metal wire

[0057] Nano polytetrafluoroethylene coating of the present invention is coated with the specific technological process of application in titanium metal wire drawing process as figure 2 As shown, the specific process steps are as follows:

[0058] 1) Apply the nano-PTFE coating directly on the titanium wire;

[0059] 2) drying the titanium metal wire coated with nano-polytetrafluoroethylene coating at 30-80°C for 1-30 minutes;

[0060] 3) drawing the dried titanium wire four times;

[0061] 4) Clean the nano-polytetrafluoroethylene coating on the surface of the drawn titanium wire with 40-80°C hot water;

[0062] 5) drying.

[0063] After testing, the obtained titanium wire is qualified.

[0064] In summary, the nano-polytetrafluoroethylene coating of the present invention has excellent lubricating properties, and can be well dip-coated on the smooth surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com