Patents

Literature

38results about How to "Winding will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

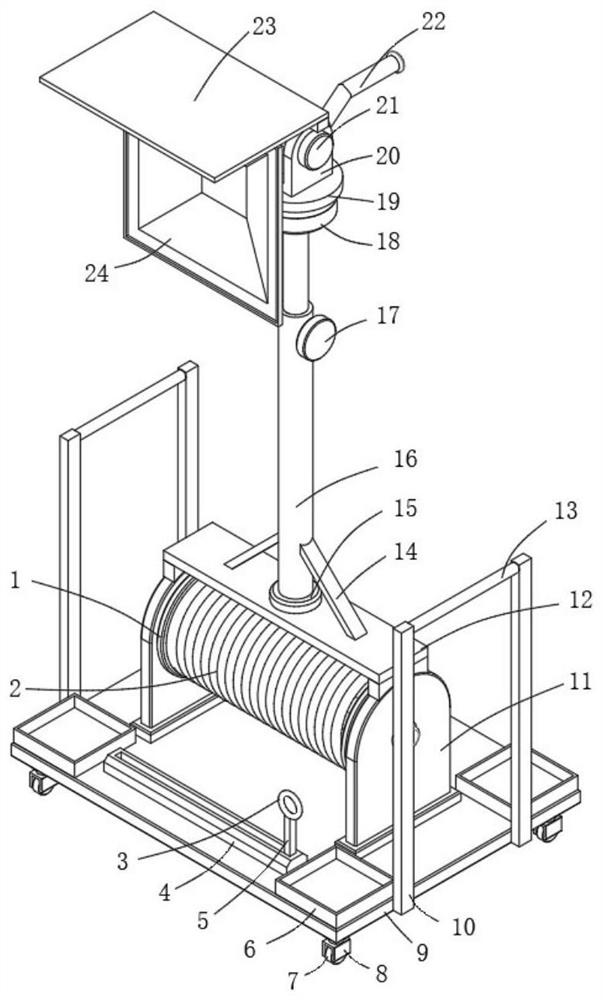

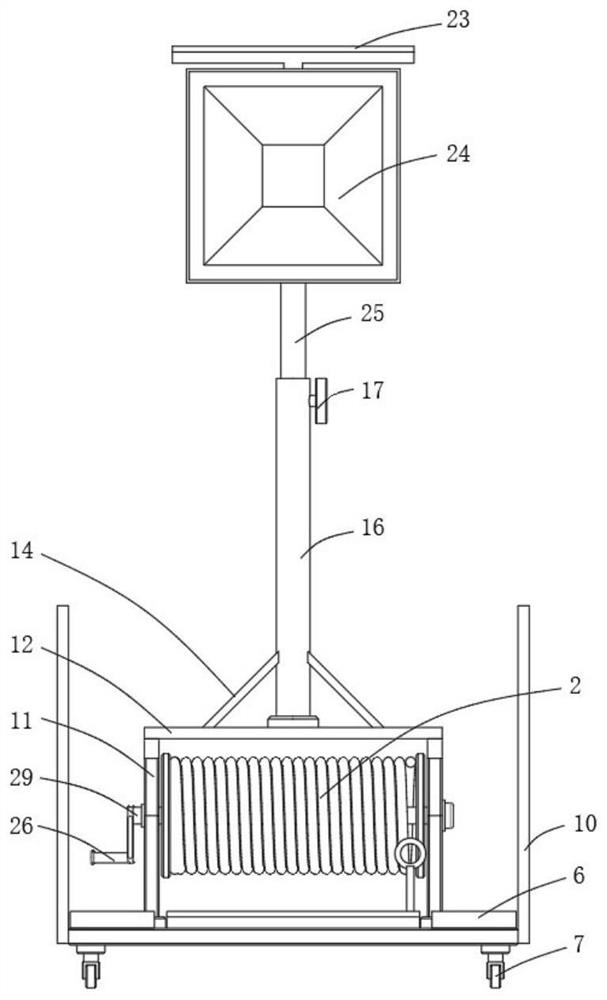

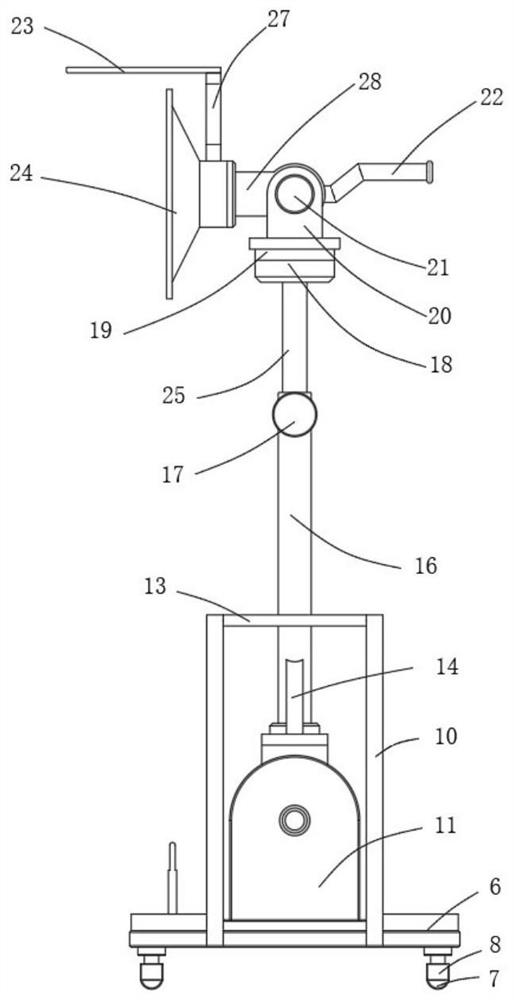

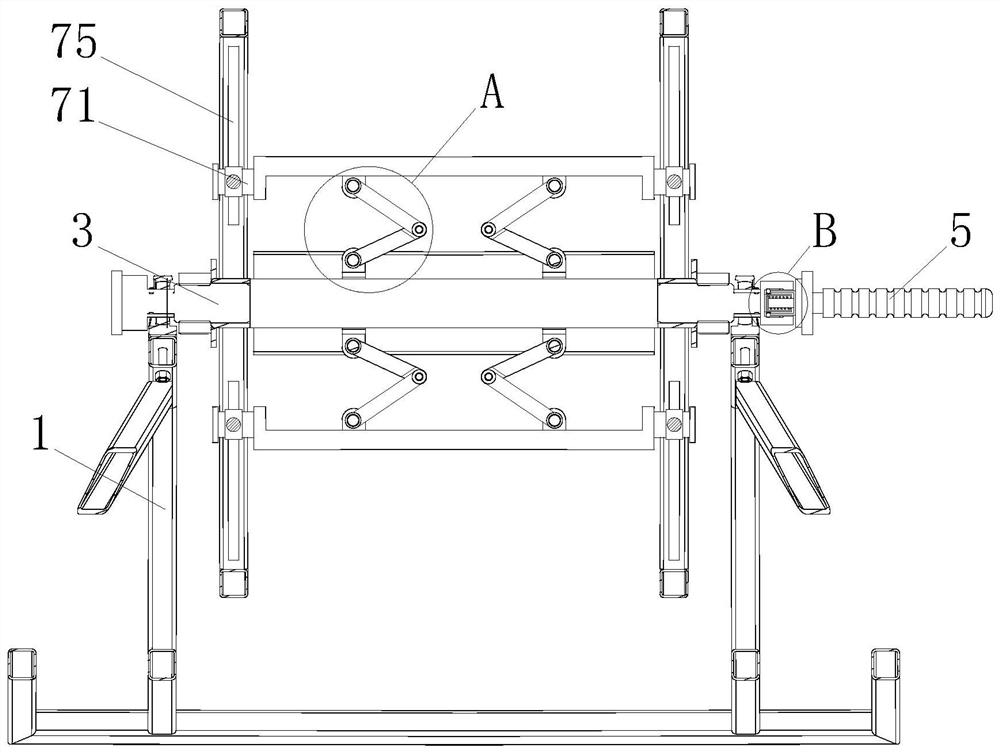

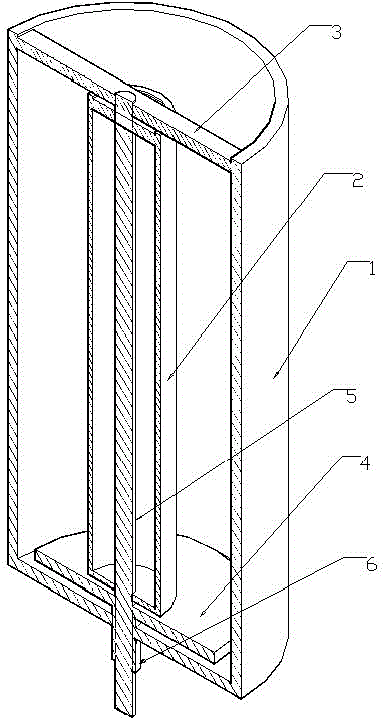

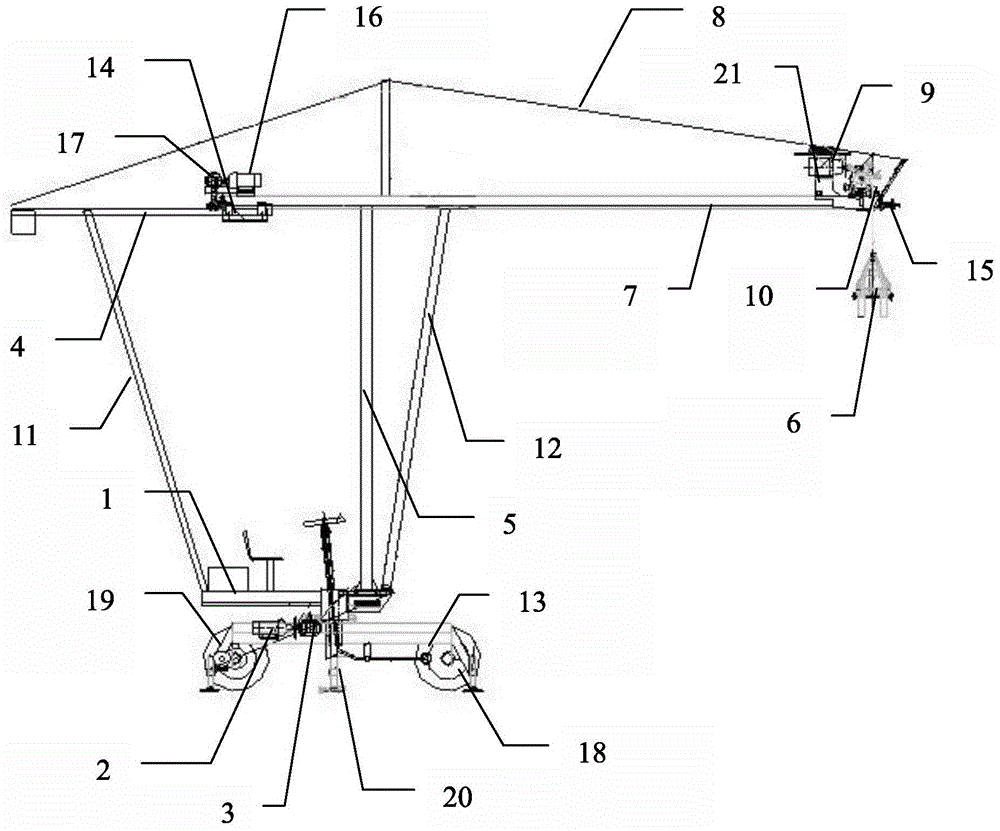

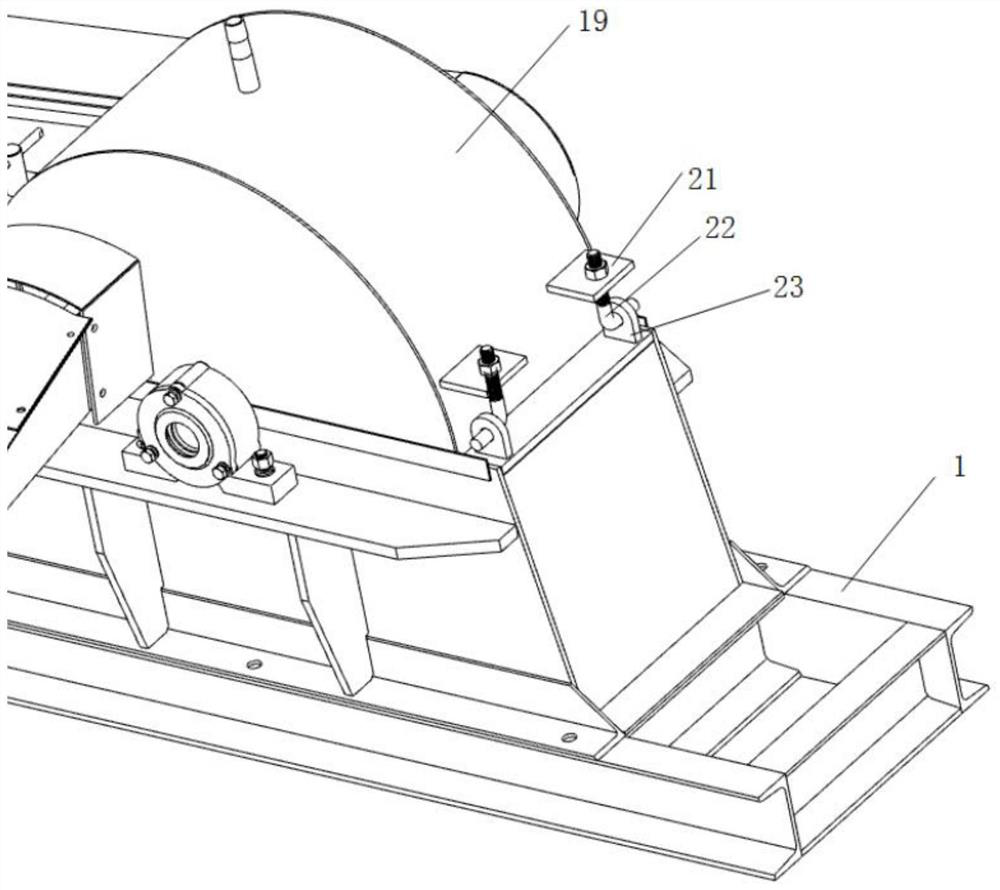

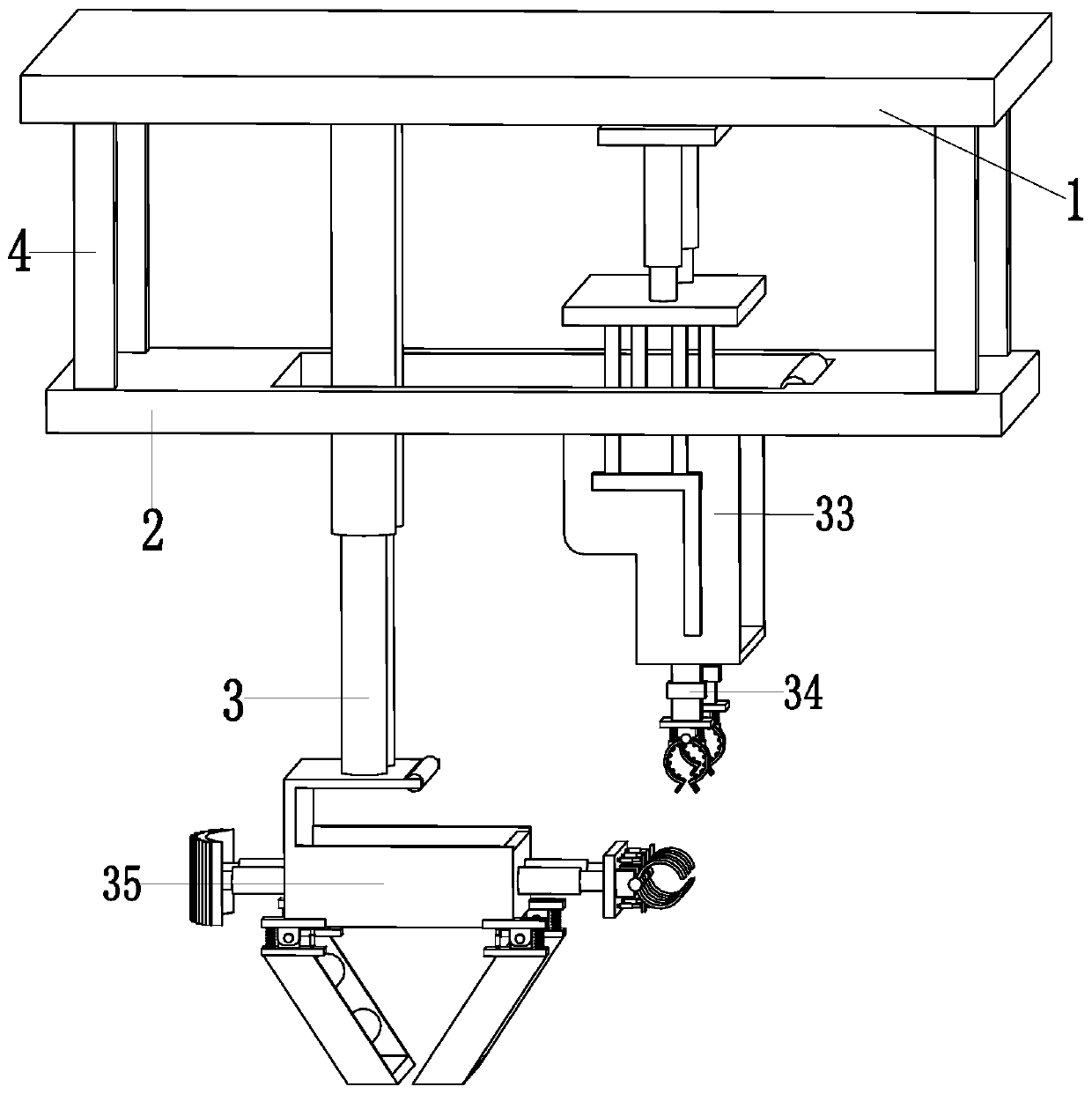

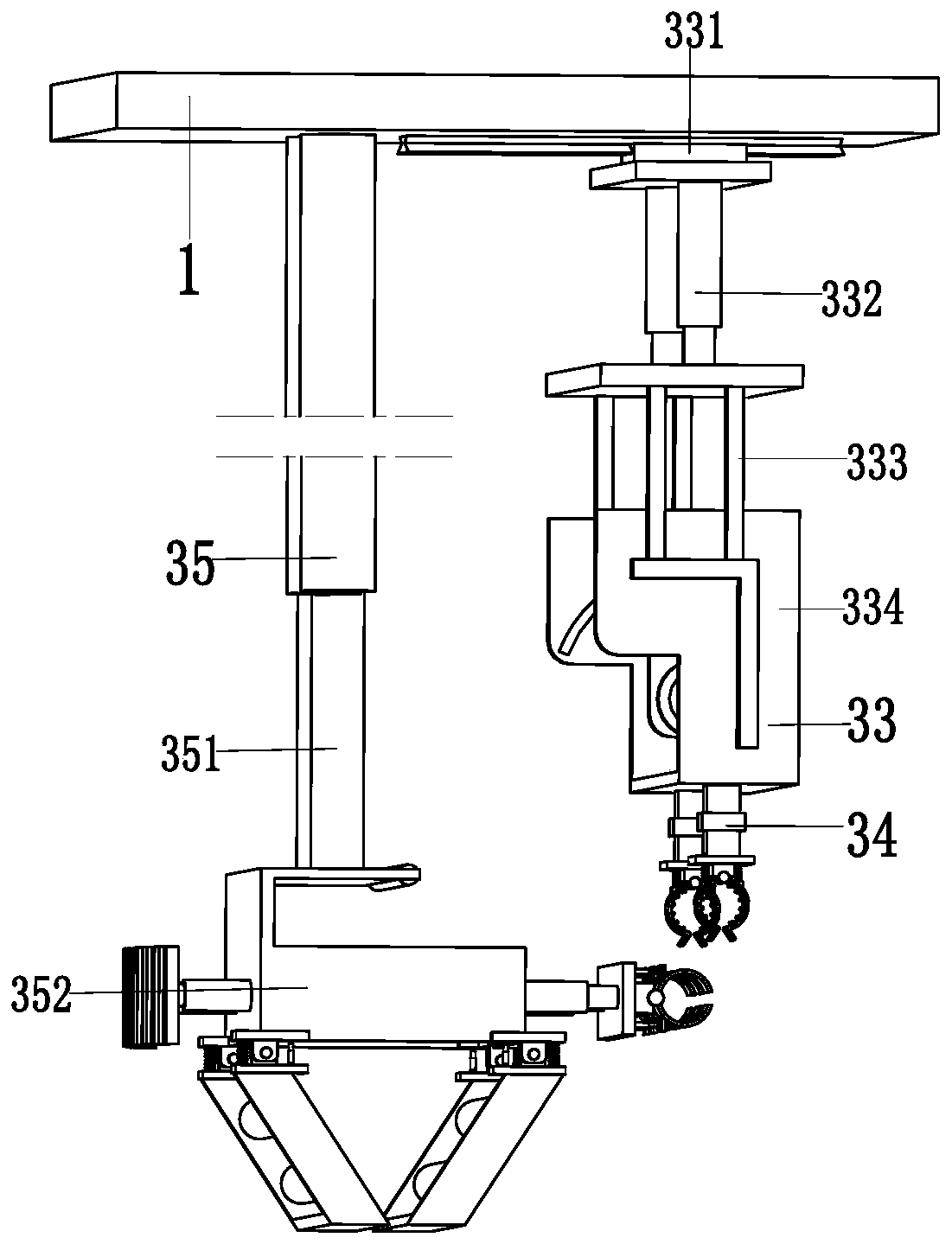

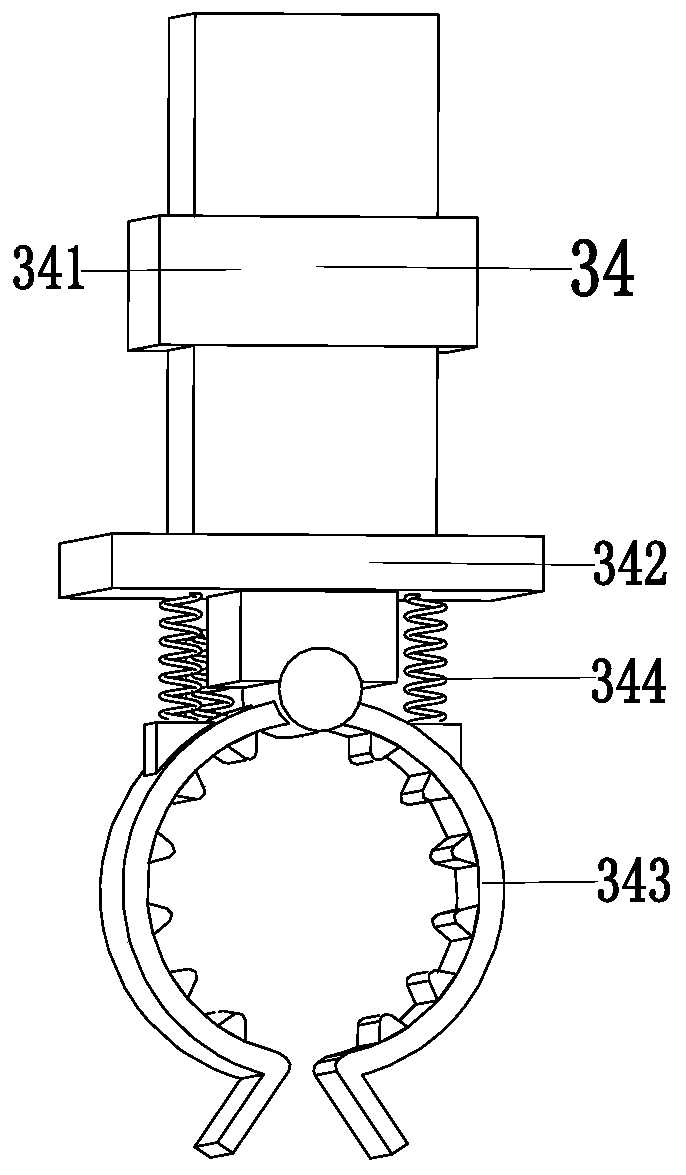

Cable multi-angle laying scaffold

ActiveCN108711787AEliminate damage to cablesAvoid shakingFilament handlingApparatus for laying cablesEngineering

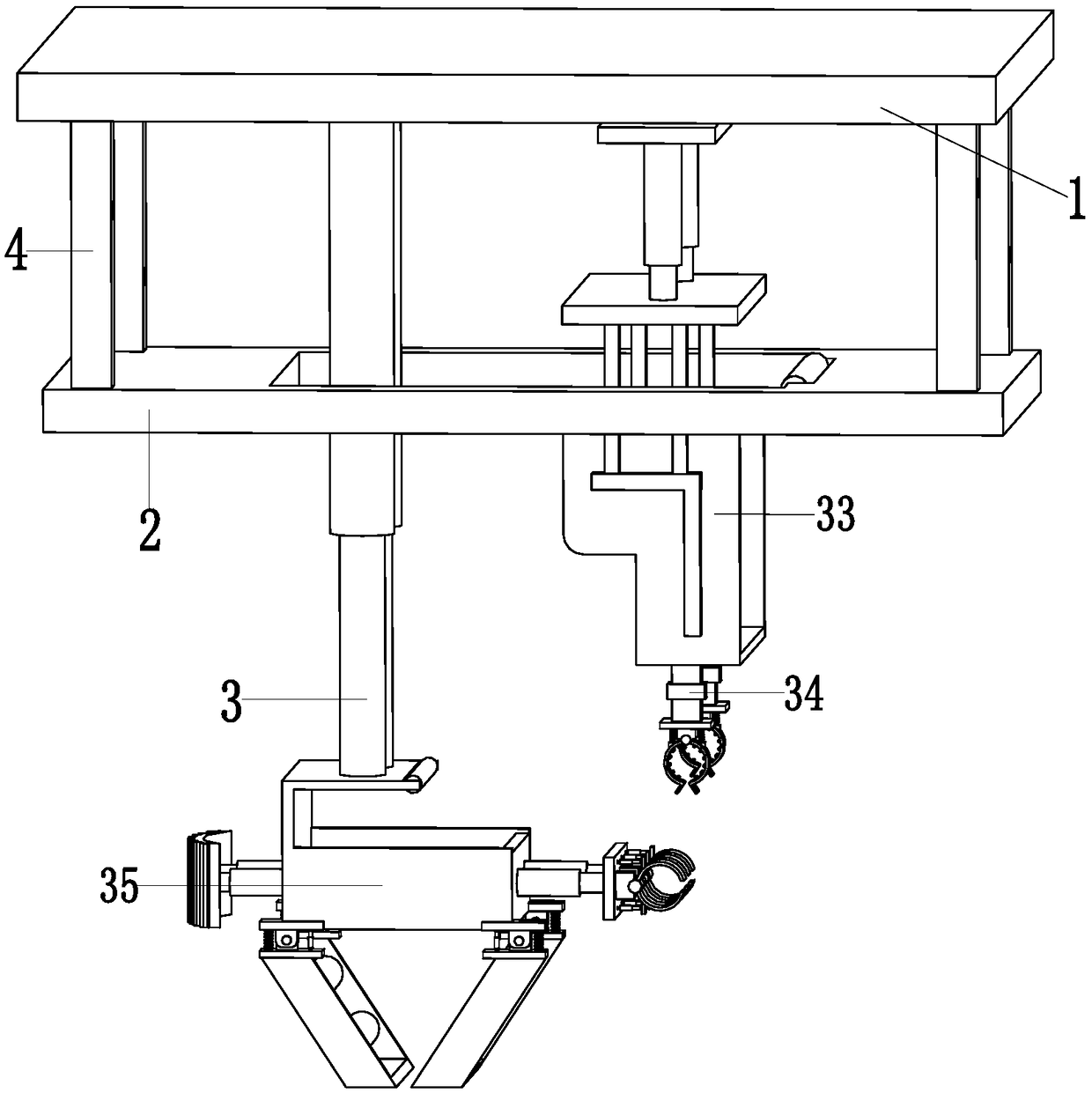

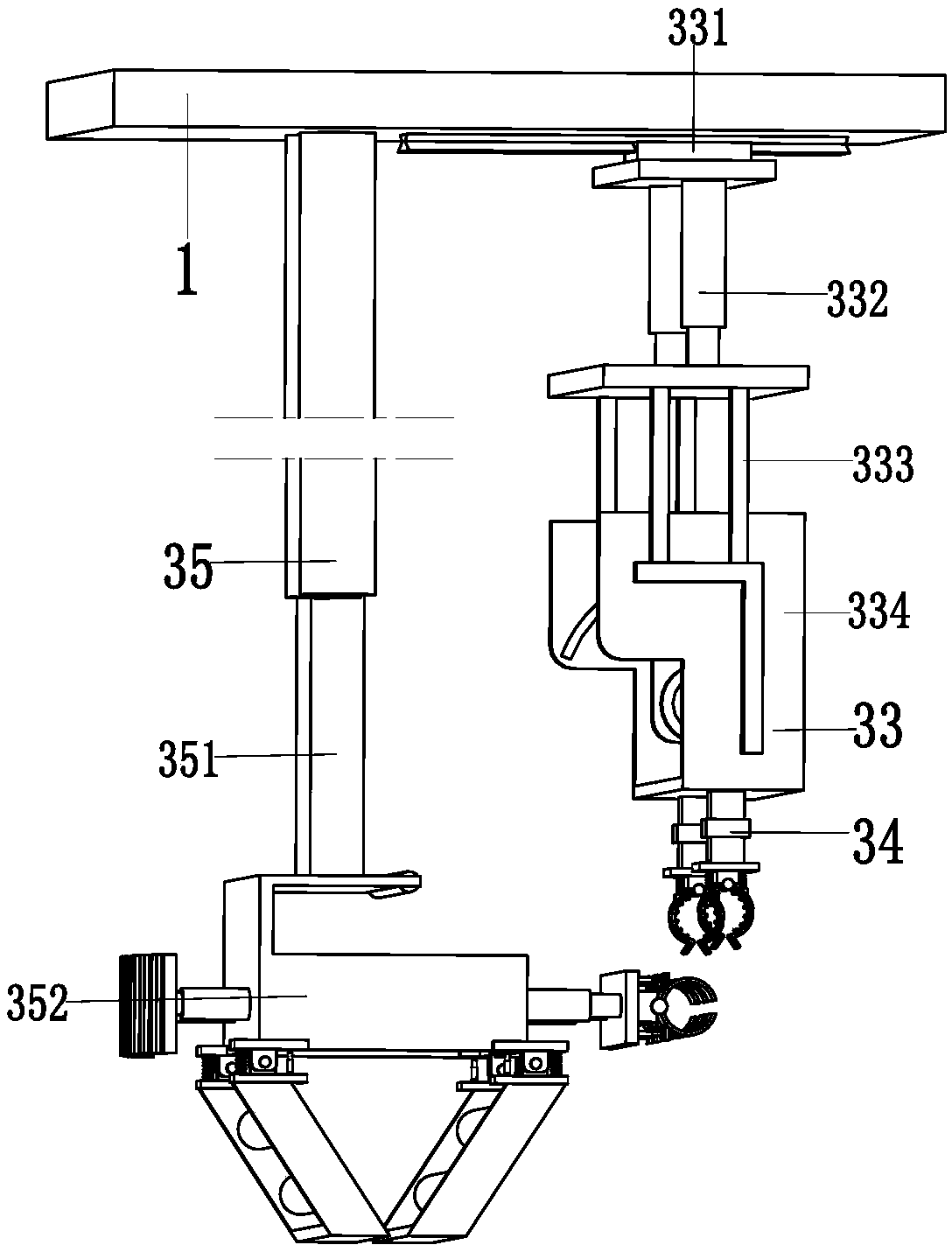

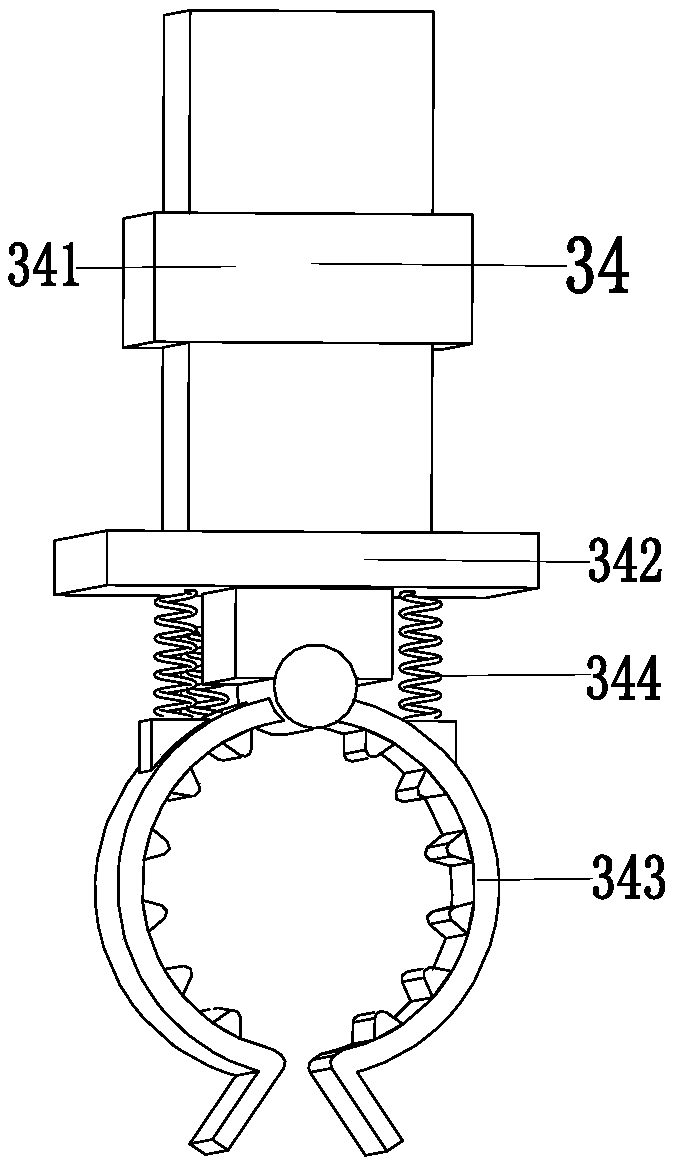

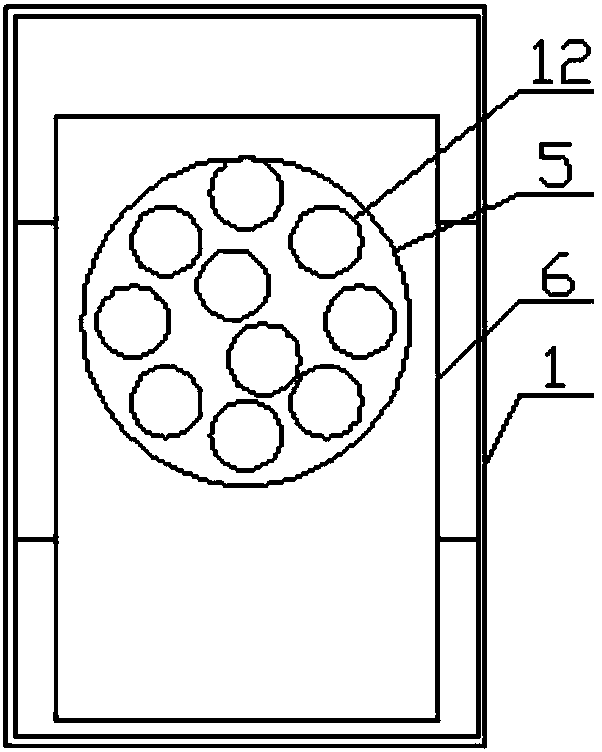

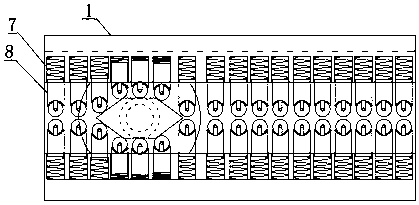

The invention relates to a cable multi-angle laying scaffold. The cable multi-angle laying scaffold comprises a support roof, a support bottom plate, a paying-off device and a support connecting column; a square slot is arranged in the middle part of the support bottom plate, the support roof is arranged on the top of the support bottom plate through the support connecting column, and the paying-off device is connected with the bottom of the support roof; the paying-off device comprises a guiding mechanism, a clamping mechanism and a distributing mechanism; the clamping mechanism comprises a clamping telescopic column, a clamping connecting rack, a clamping claw and a clamping spring. The problems that the cable can produce friction with the sidewall of a cable well when the existing cablerack performs the cable pay-off, the cable has the hidden danger of twisting on the escalator of the cable well, the twining can occur when the cable is conveyed in two directions, and a transmissionrack can shake when the cable is conveyed in the cable well can be solved, and the function of performing angle-adjustable conveying of the cable in the cable well can be realized.

Owner:湘潭潭州电力建设有限公司

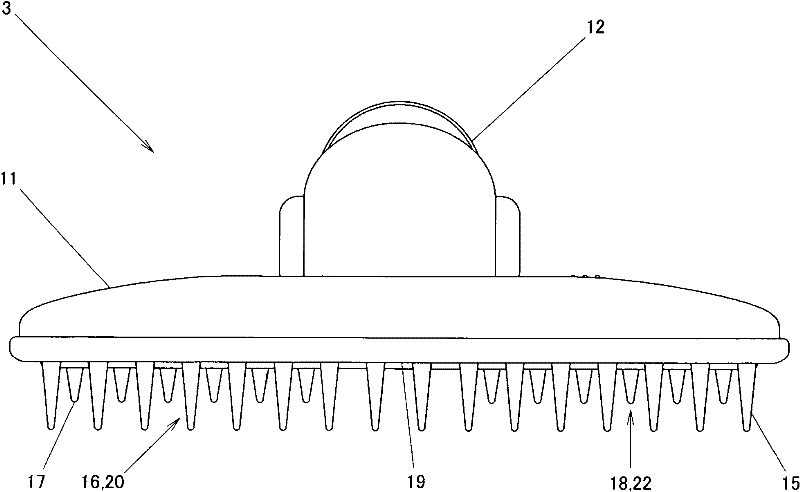

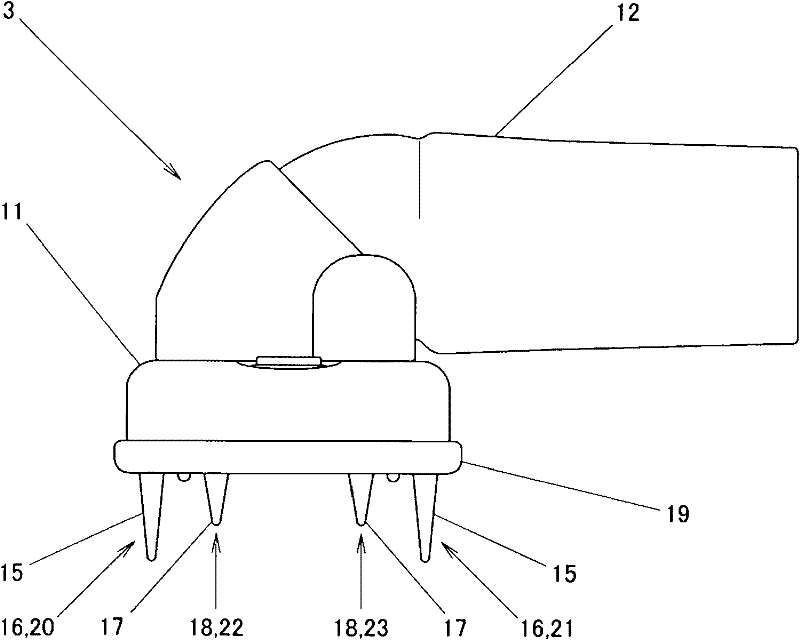

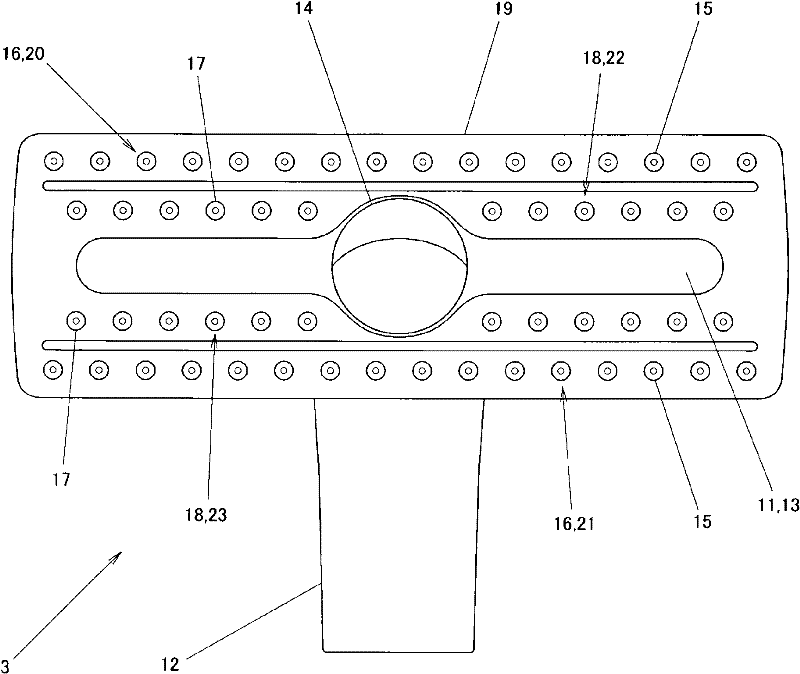

Suction Nozzle Used For Electric Cleaner

The invention discloses a suction nozzle used for an electric cleaner. The invention provides the suction nozzle used for the electric cleaner that does not damage carpet and the like and capable of cleaning hairs and furs adhering on the carpet and pads well in a gentle manner. In the invention, a long project group formed by a plurality of long projects (15) and a short project group (18) formed by a plurality of short projects (17) are arranged near a suction opening (14) of a suction nozzle body (16). The projects (15)(17) are made of flexible materials. One face of the long project group (16) bends and the other face cleans the furs and hairs deep in the carpet (c). The short project group (18) cleans furs and hairs in the surface of the carpet (c). Thus, not only the carpet (c)is damaged, but also the furs and the hairs adhered on the carpet (c) can be collected effectively. And the short project group (18) cleans the surface of the project group (18) in a rubbing manner. Thus, resistance between the project group (18) and the carpet (c) can be reduced. Therefore, even when the project number is increased, the furs and the hairs can be cleaned from the carpet(c) well in a gentle manner.

Owner:TWINBIRD CORP

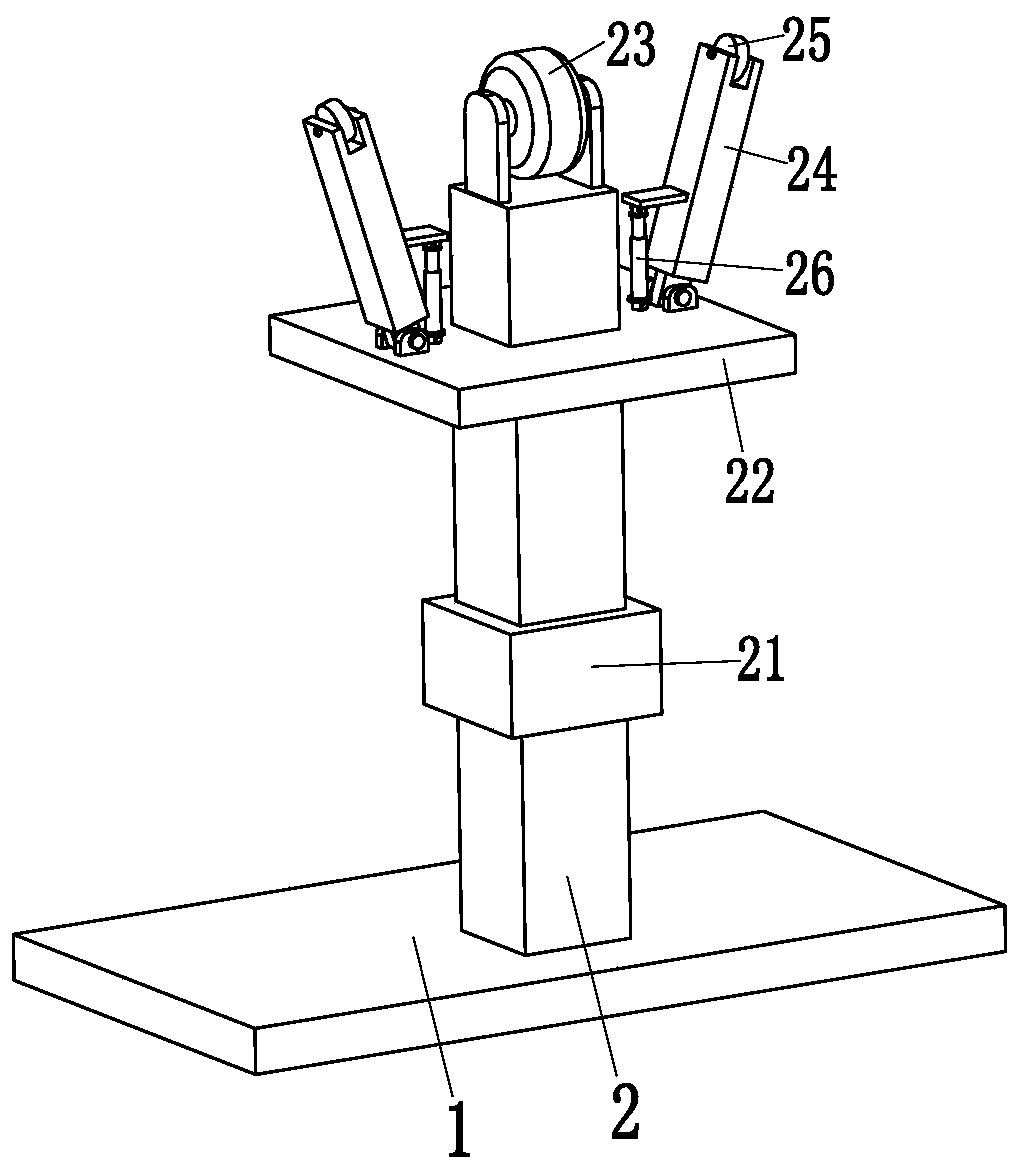

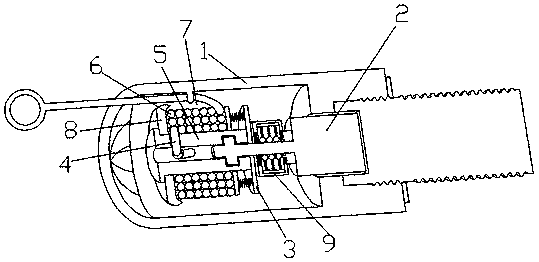

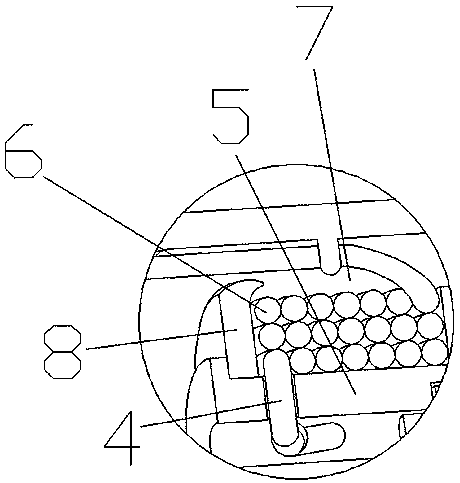

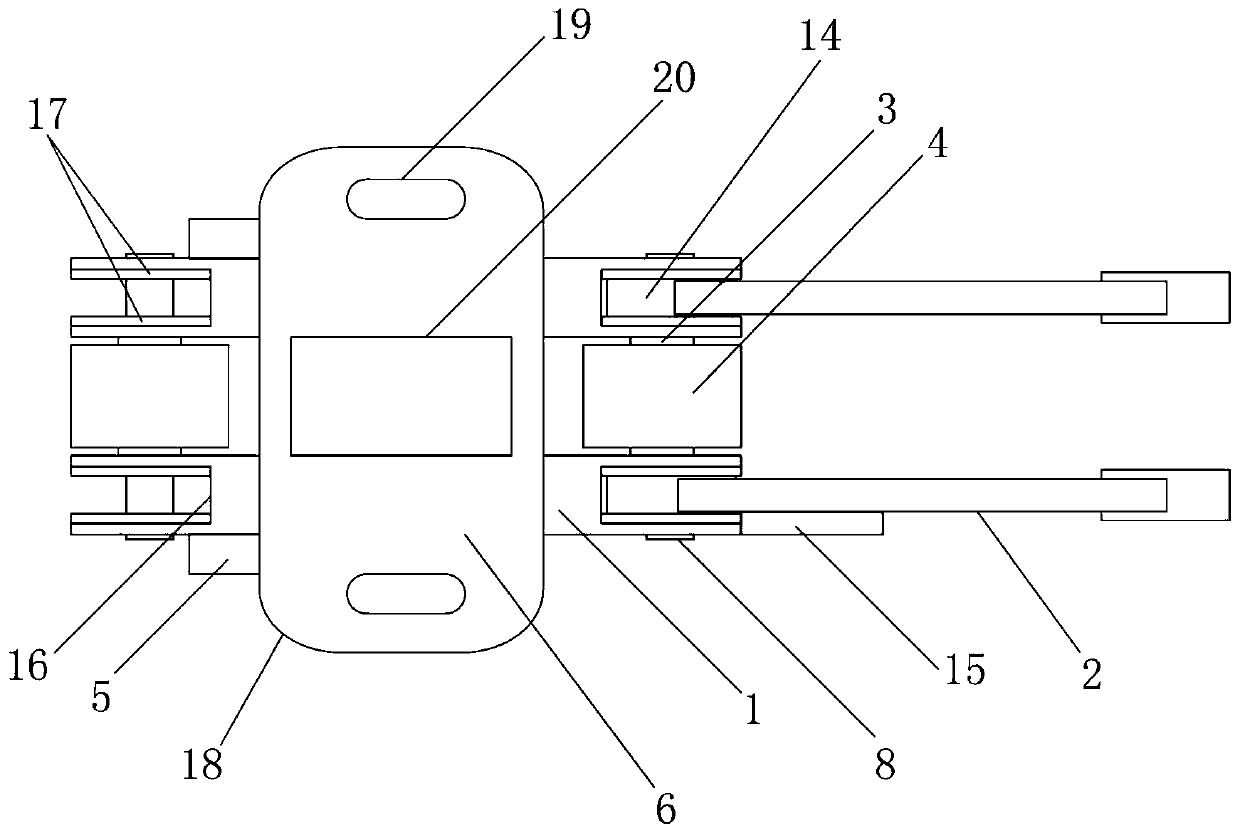

Automatic collecting device of electrocardiograph lead wires

PendingCN107758452AAvoid pullingAvoid slackDiagnostic recording/measuringSensorsElectrocardiograph leadHuman body

The invention discloses an automatic collecting device of electrocardiograph lead wires, and belongs to the technical field of medical apparatuses. The device comprises a main body with a box structure; a fixed plate, a left wire separating cylinder, a wire storage container, a right wire separating cylinder and a rotating shaft are fixed in the main body in sequence from left to right; the lead wires are started from an electrocardiograph to penetrate through the internal structures of the main body in sequence, and are connected to a human body; the ends, connected with the electrocardiograph, of the lead wires are fixed on the fixed plate; the left wire separating cylinder and the right wire separating cylinder are provided with separate through holes for enabling the lead wires to penetrate through; a side panel of the main body at the end of the rotating shaft is provided with through holes 2 corresponding to the lead wires one to one; weight blocks are arranged at the middle parts of the lead wires in the storage container; and the lead wires are respectively encircled by one lap on the rotating shaft. The device prevents and effectively solves the traction and looseness problems of the ends, connected with the electrocardiograph, of the lead wires, solves the problem of easy disordered winding of the lead wires, solves the problem of easy looseness of the lead wires therein, and is better in application and operation quality and effect.

Owner:刘功来

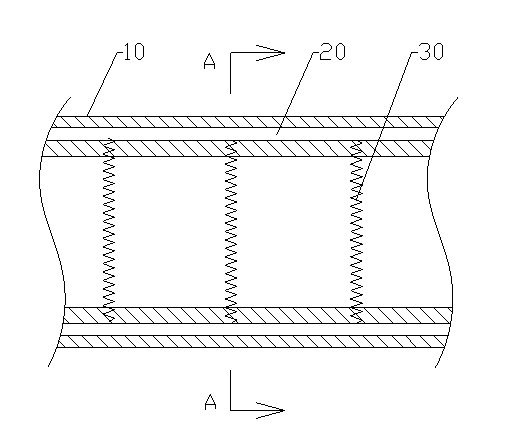

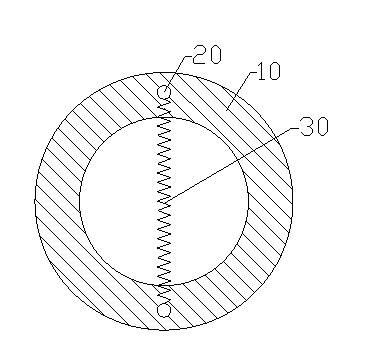

Damping oil suction hose and manufacturing process thereof

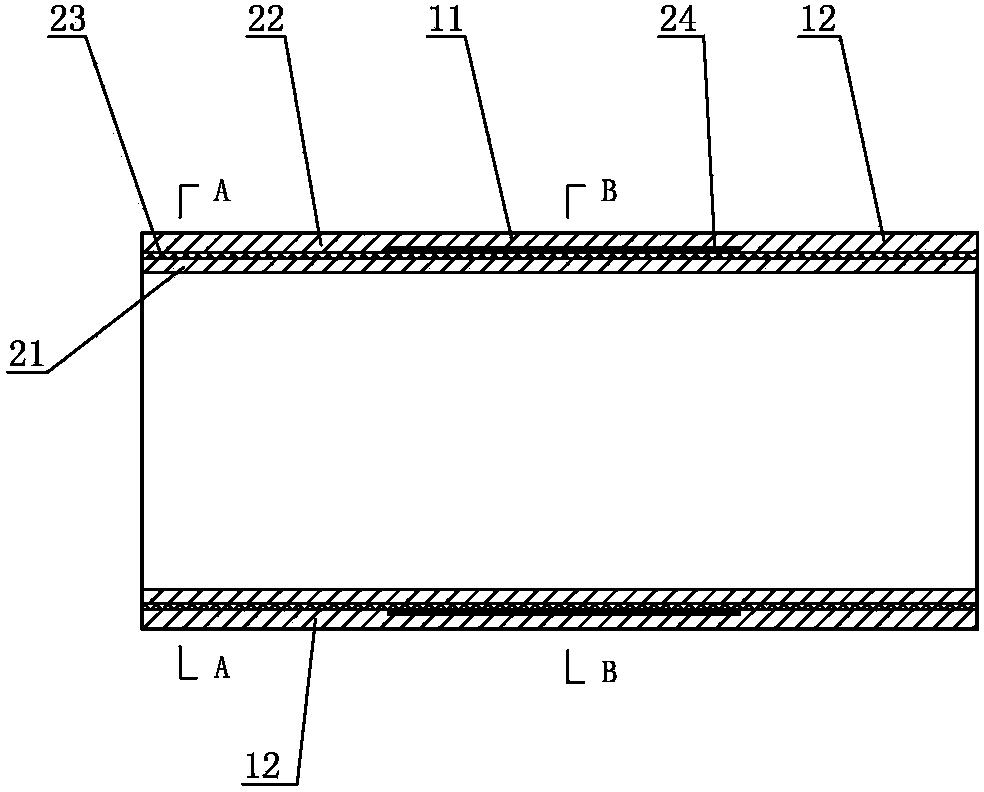

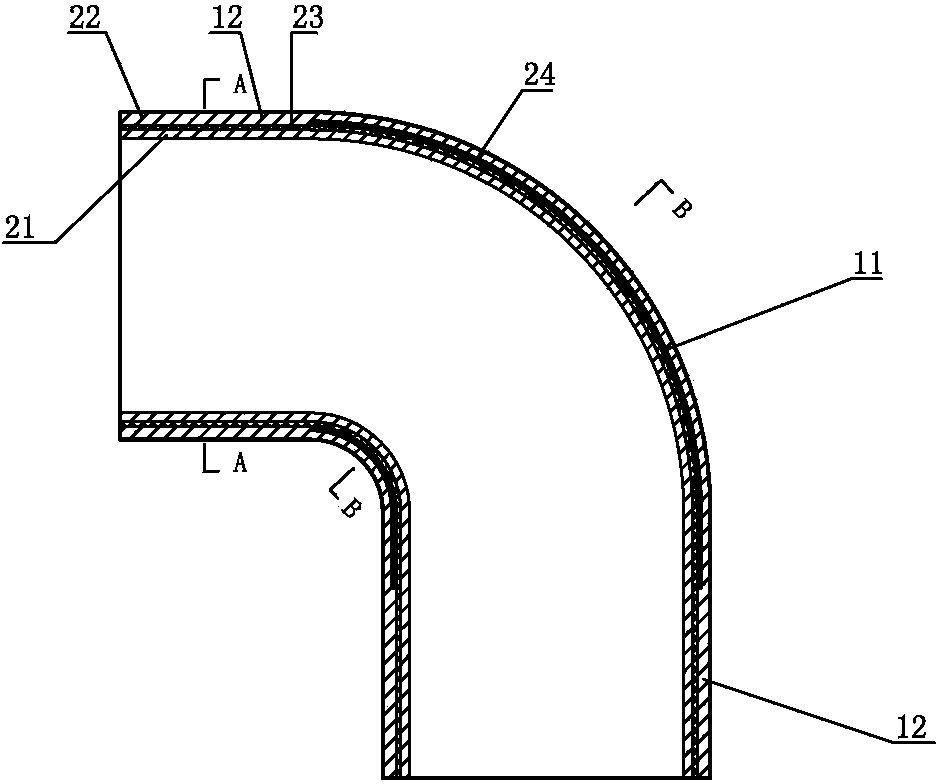

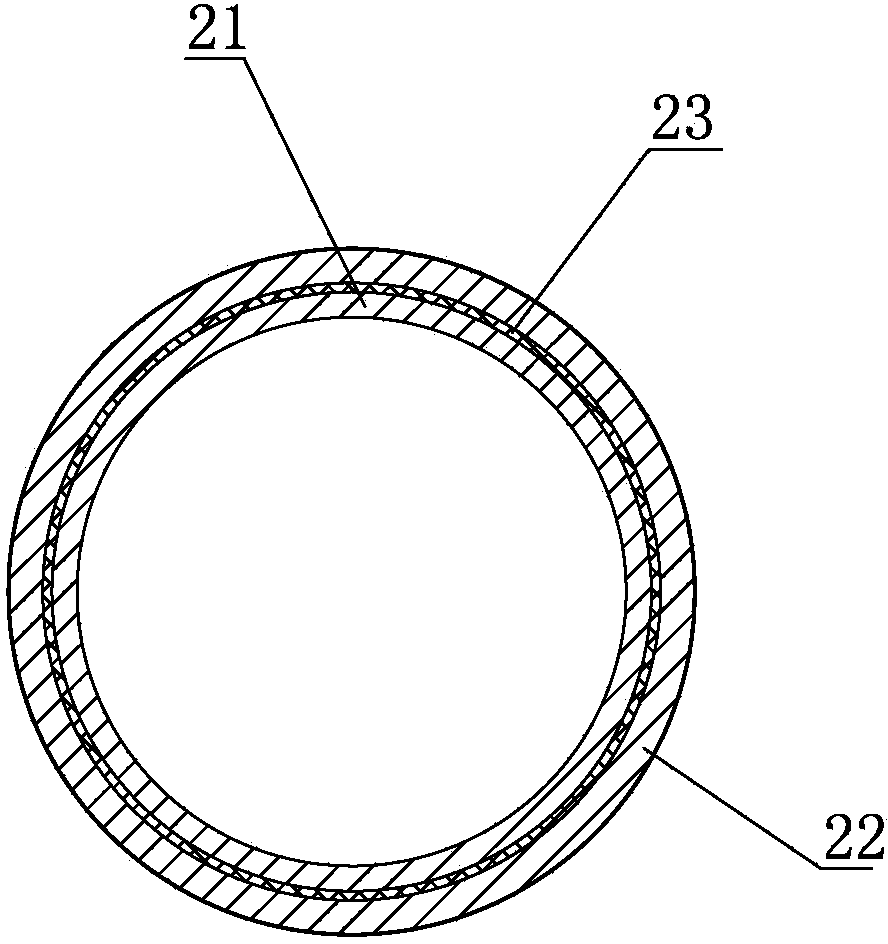

ActiveCN103527869AEasy to plug inHigh strengthFlexible pipesSiphonsUltimate tensile strengthPetroleum engineering

The invention discloses a damping oil suction hose and a manufacturing process thereof. The damping oil suction hose comprises an inner rubber layer, an outer rubber layer and a fiber layer. The fiber layer is disposed between the inner rubber layer and the outer rubber layer. In the axial direction, the damping oil suction hose comprises a middle section and connectors connected to two ends of the middle section. A steel wire is wound on the middle section between the fiber layer and the outer rubber layer. The manufacturing process includes: forming the inner rubber layer, winding fiber mesh cloth, winding the steel wire with the assistance of a ruler, and winding the outer rubber layer. The damping oil suction hose is good in strength, rigidity and suction flatness resistance.

Owner:GUANGZHOU LIANG SOFT TUBE

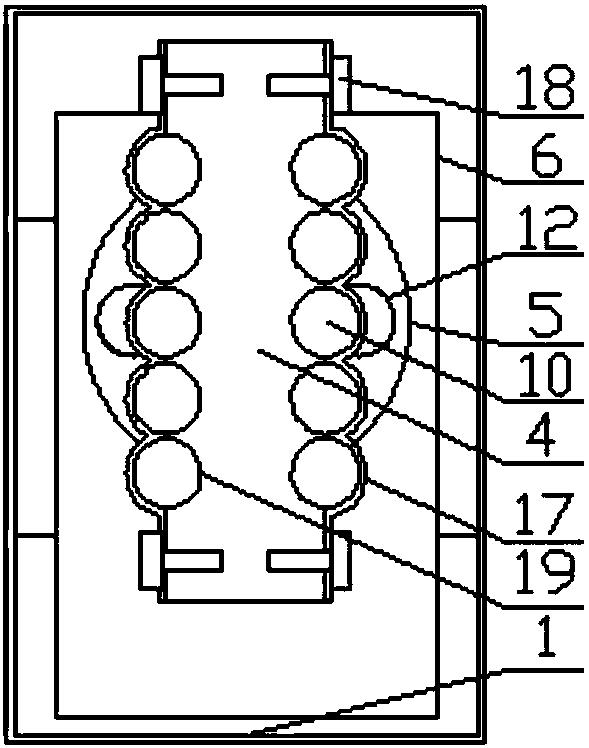

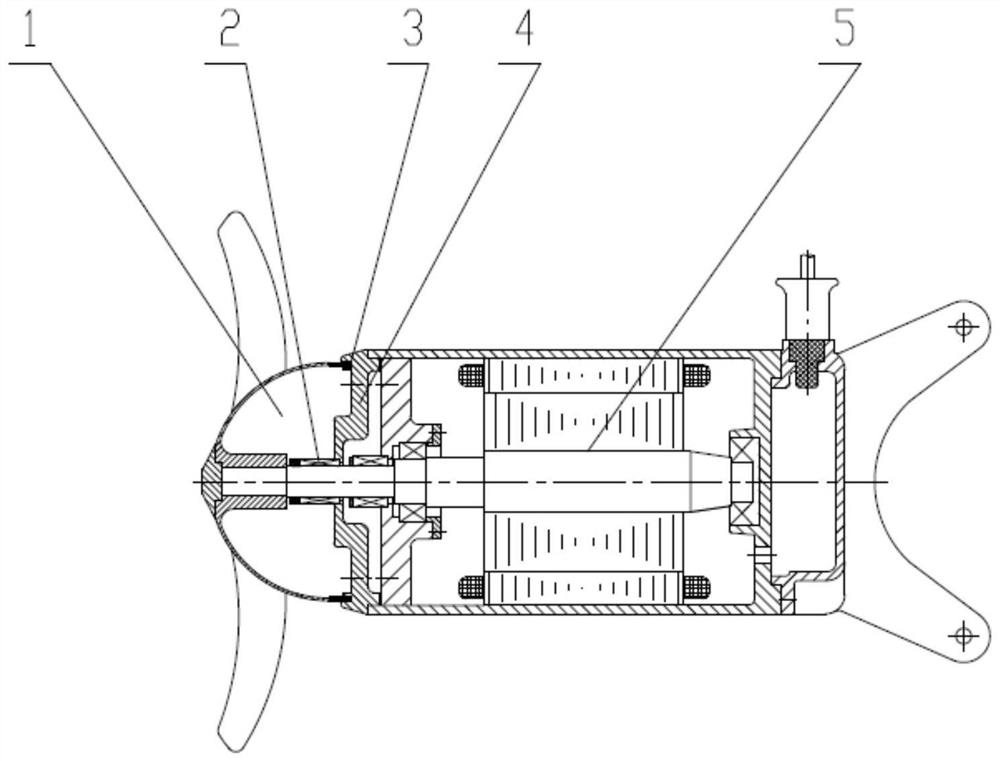

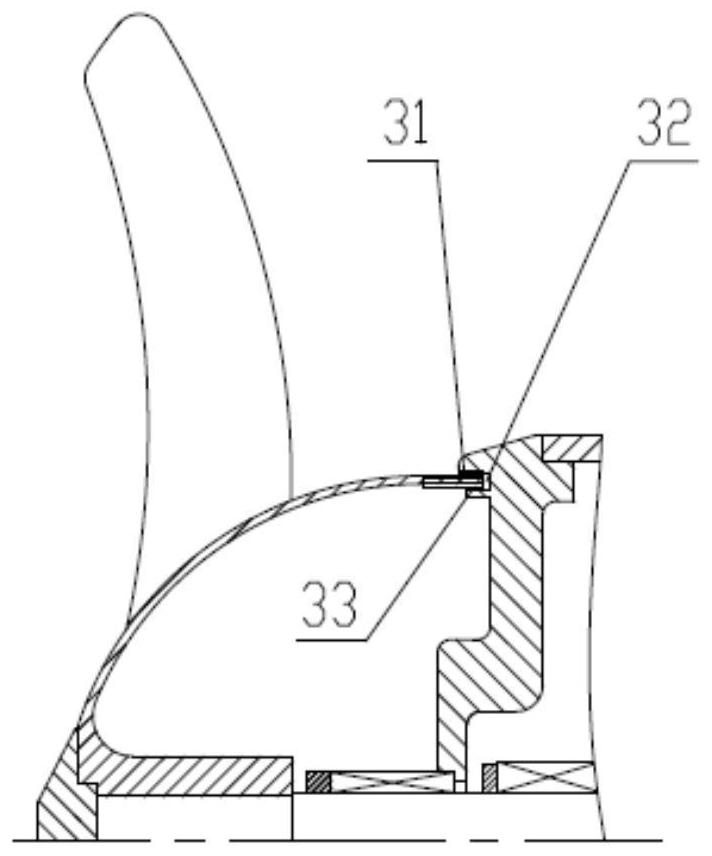

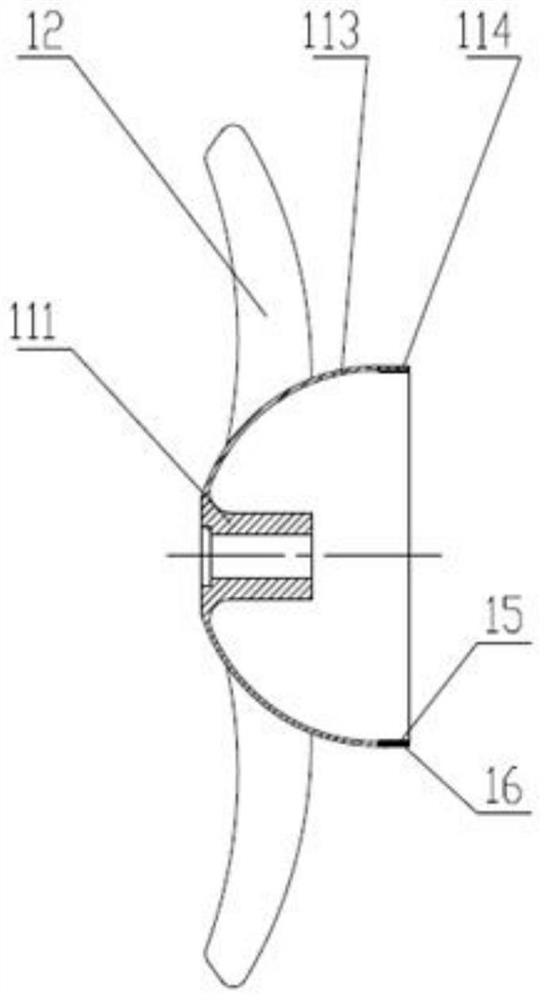

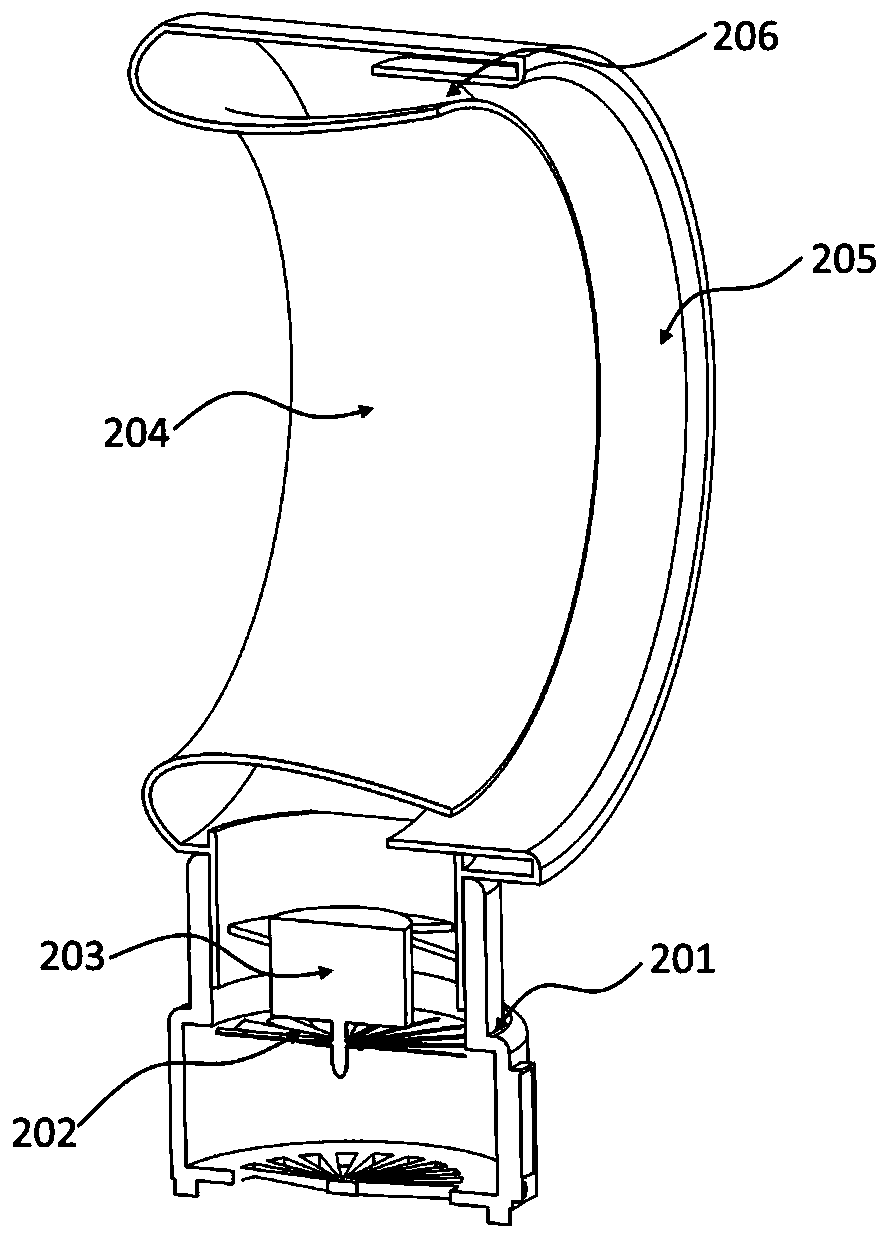

Efficient permanent magnet submersible mixer with anti-winding function

ActiveCN114367230AGuaranteed long-term safe useMaintain balance accuracyTransportation and packagingMixer accessoriesPhysicsWinding function

The invention provides an efficient permanent magnet submersible mixer with an anti-winding function, which comprises an impeller and a mechanical sealing seat, the mechanical sealing seat is provided with an annular sealing groove, and the hub end part of the impeller is in clearance fit with the sealing groove; a first spiral body is arranged on the periphery of the outer side face of the end of the hub, and water flow generated by rotation of the first spiral body flows from the direction close to the mechanical sealing seat to the direction away from the mechanical sealing seat. According to the efficient permanent magnet submersible mixer with the anti-winding function, fiber materials can be effectively prevented from entering the cavity of the hub, fibers can be prevented from being wound on the impeller, and the mixer can run reliably for a long time.

Owner:NANJING POLYTECHNIC INSITUTE

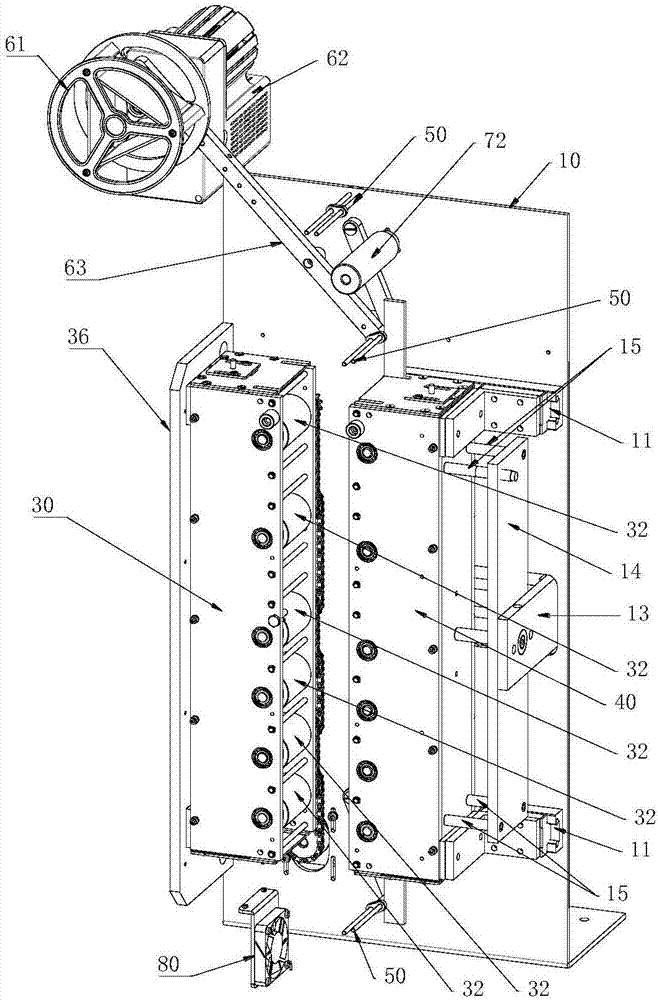

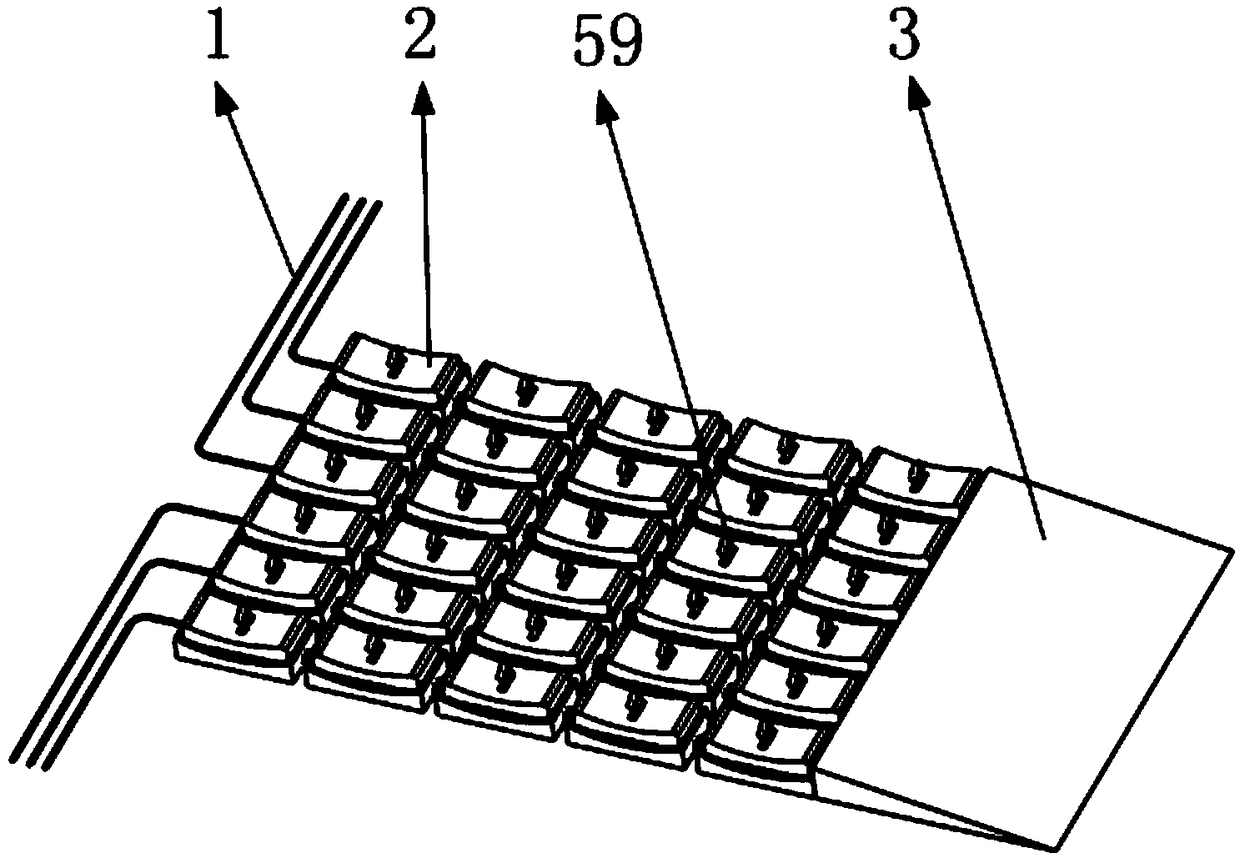

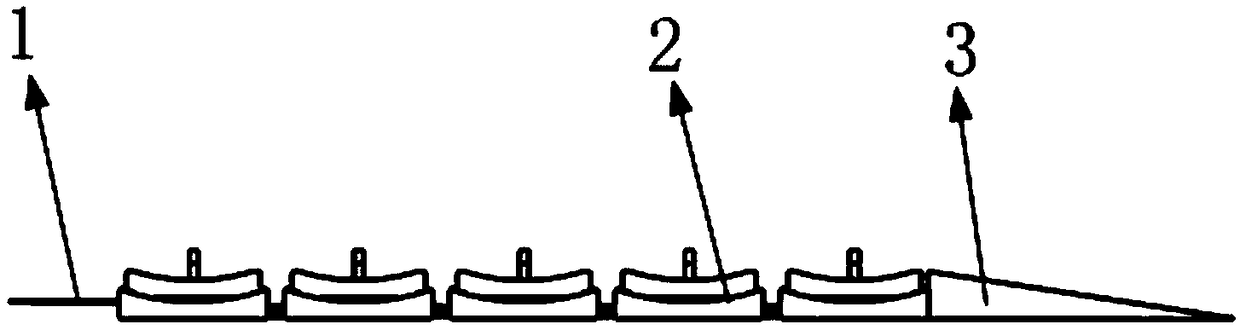

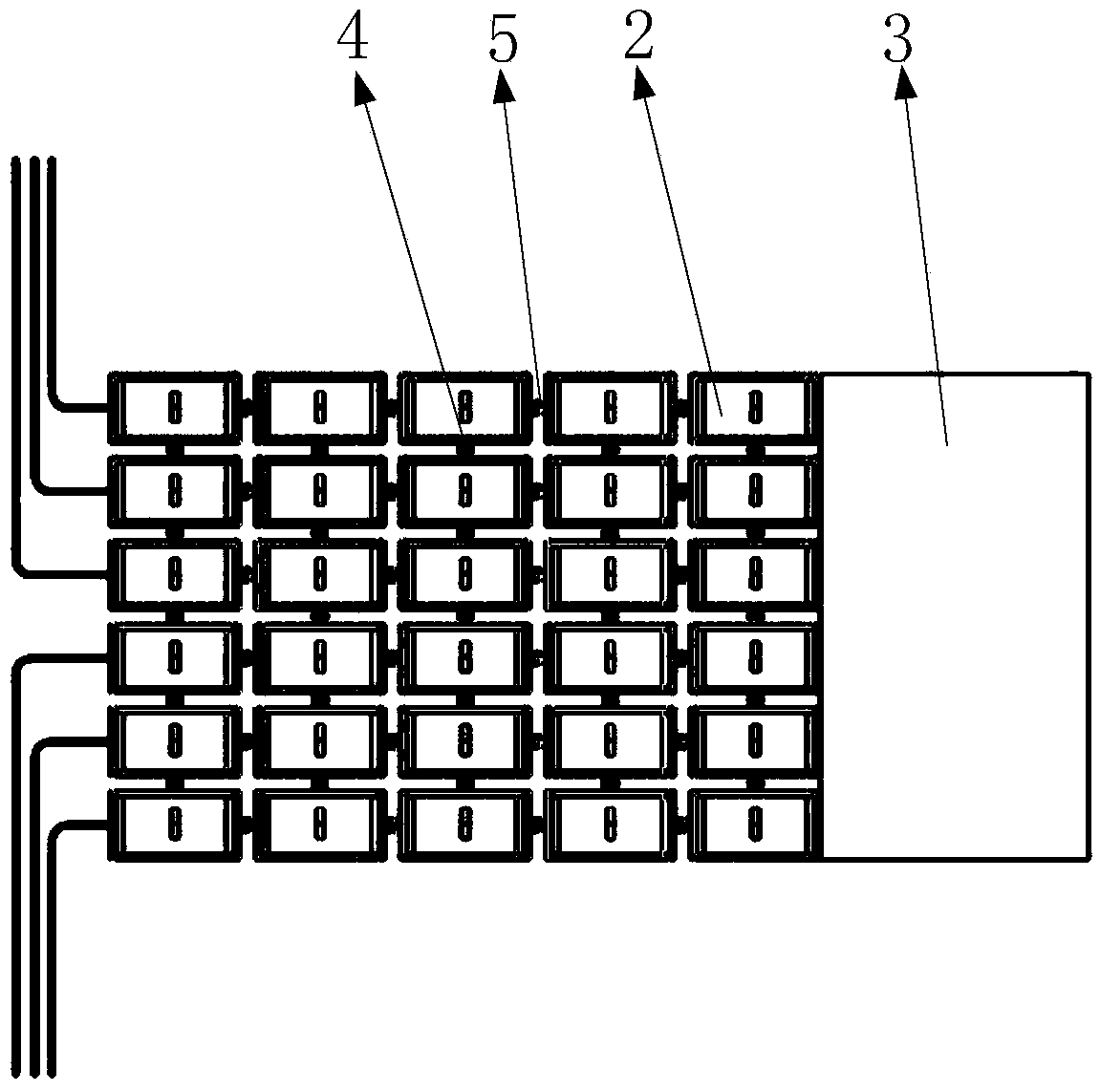

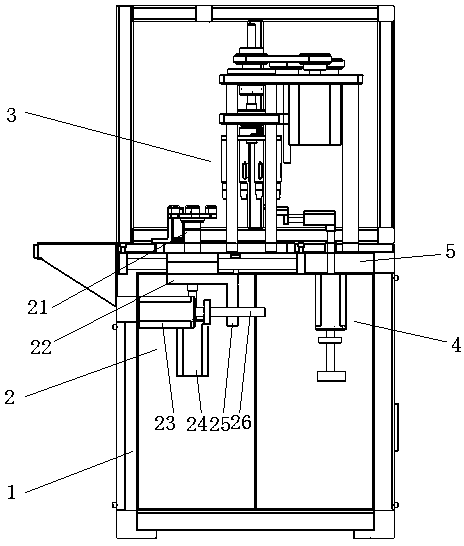

Ironing device

ActiveCN107099966APlay the role of ironingWinding will notFinal product manufactureTextile shapingAutomationElectrical and Electronics engineering

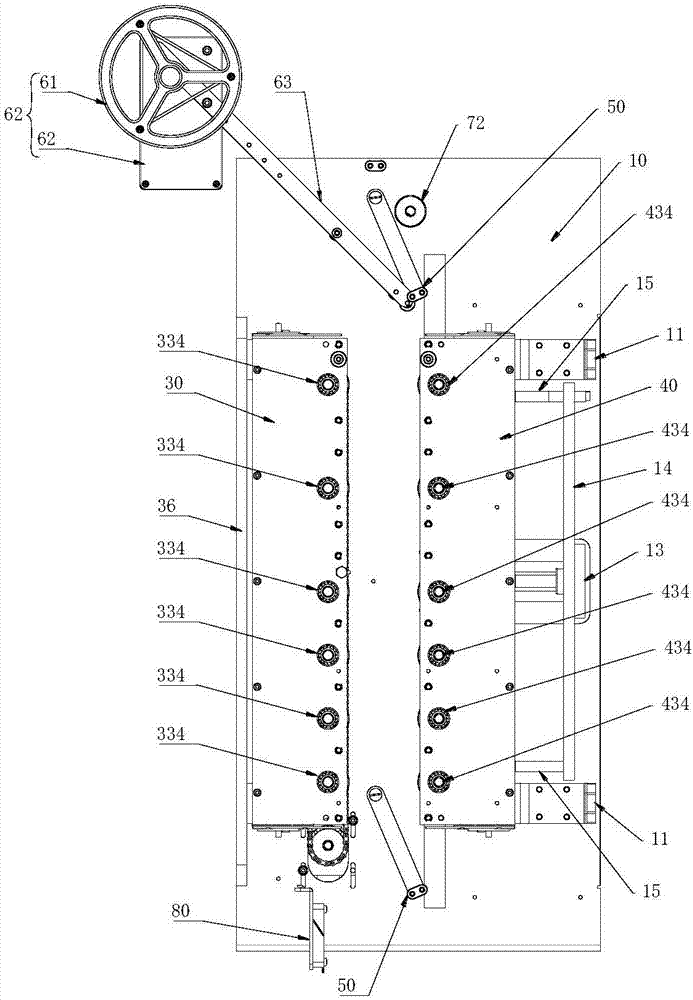

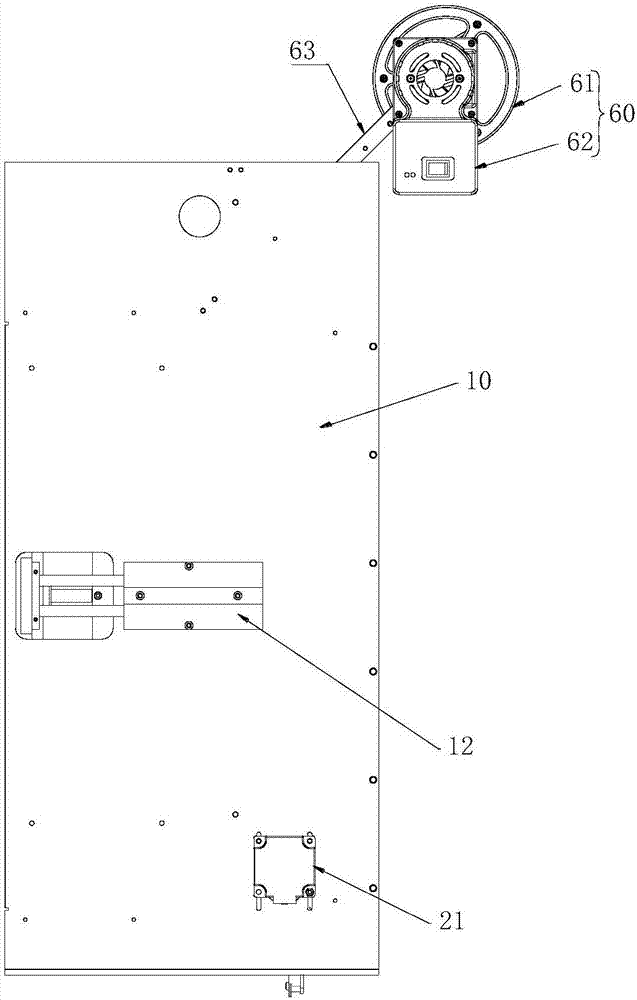

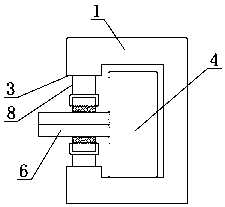

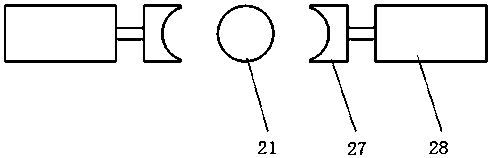

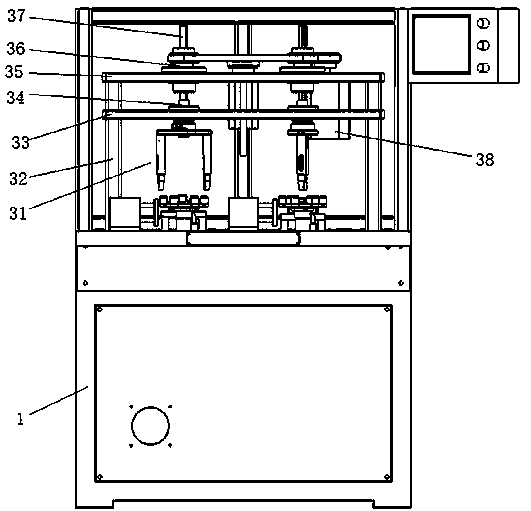

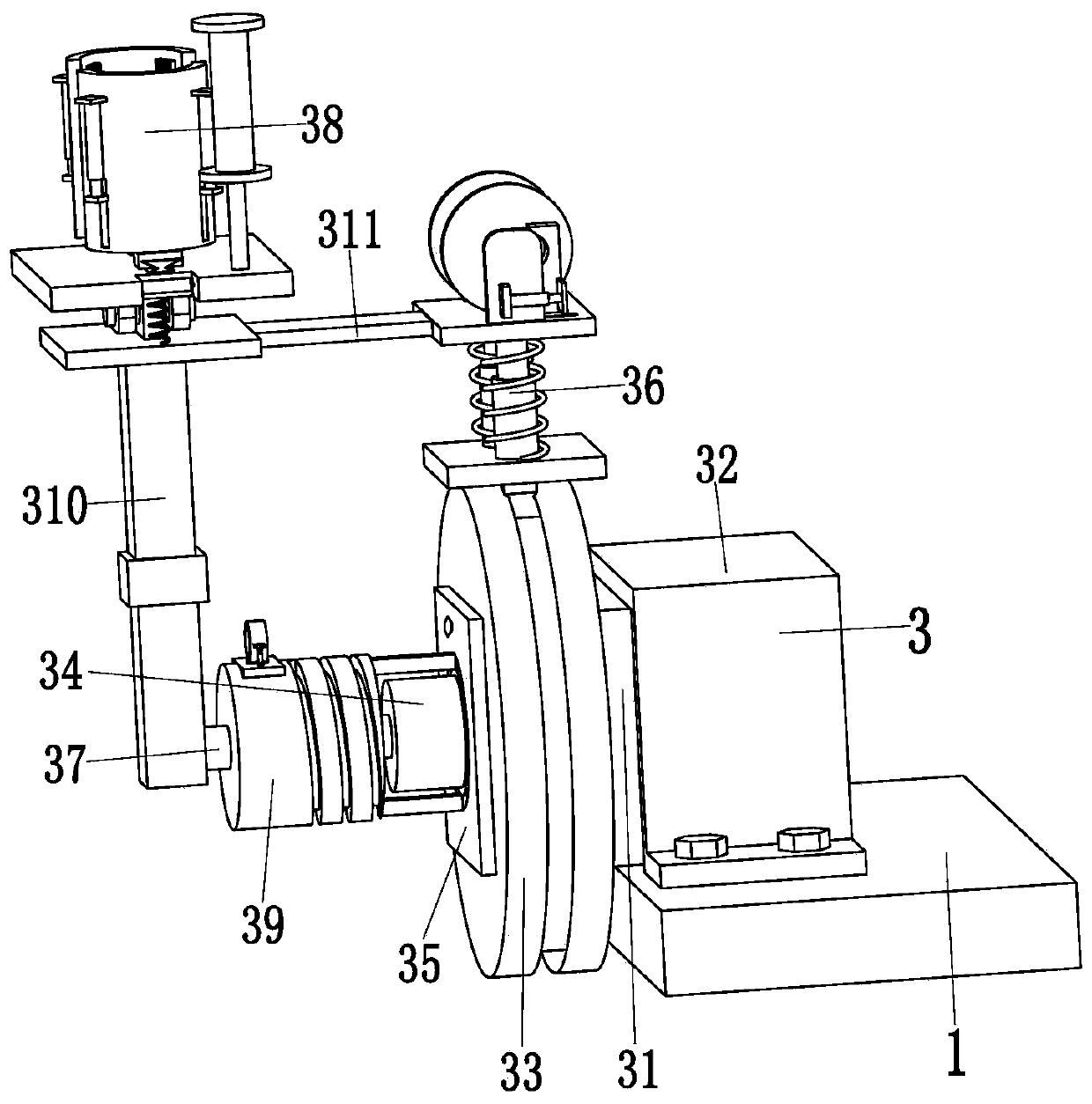

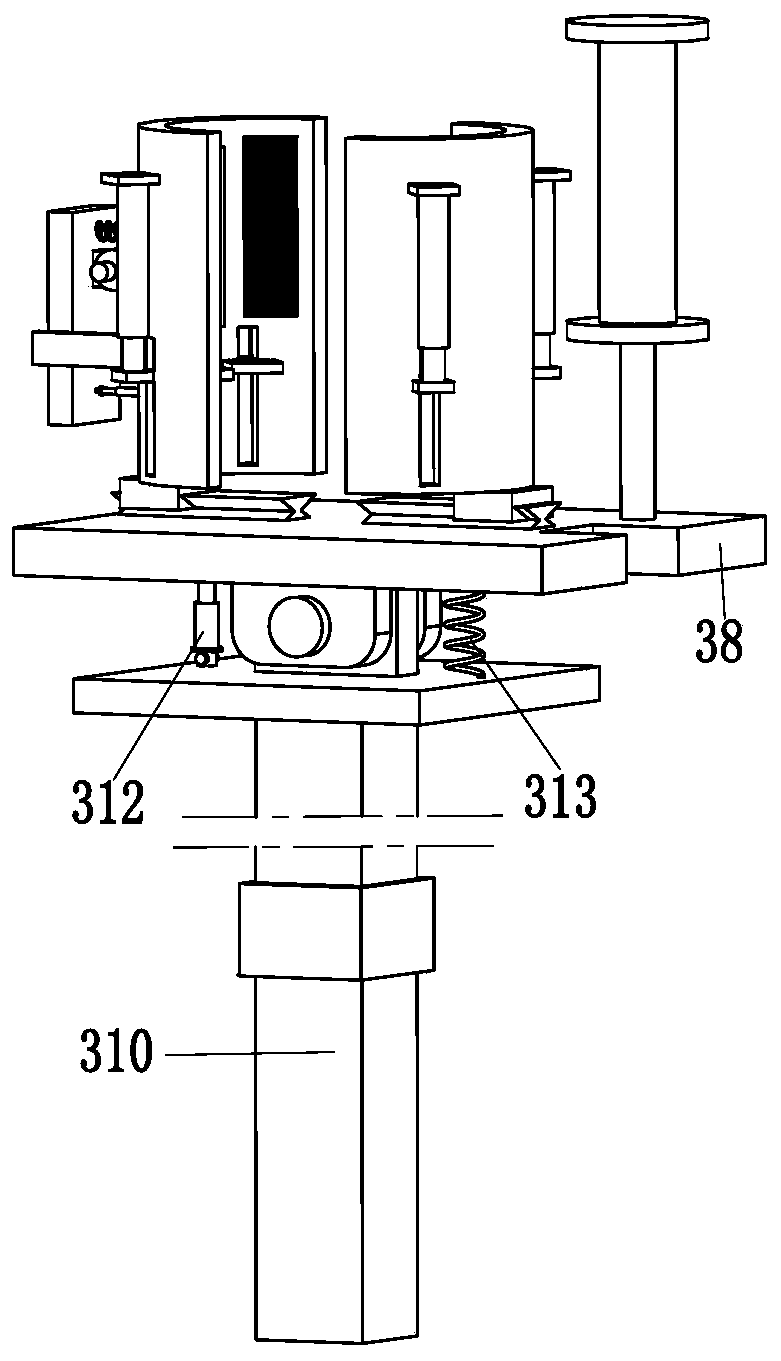

The invention provides an ironing device which comprises a substrate, a transmission mechanism and a first ironing assembly and a second ironing assembly which are arranged on the substrate. The first ironing assembly and the second ironing assembly are symmetrically arranged, the second ironing assembly can move relative to the first ironing assembly to adjust the distance between the first ironing assembly and the second ironing assembly, and the transmission mechanism is arranged on the first ironing assembly or the second ironing assembly; each of the first ironing assembly and the second ironing assembly comprises a heating device and a plurality of rollers, the rollers are linearly arrayed along a certain direction, and the heating device is located on one side of the linearly arrayed rollers; the transmission mechanism is connected with the rollers in the first ironing assembly or the second ironing assembly. The ironing device is good in ironing effect and high in automation degree.

Owner:上海富山精密机械科技有限公司

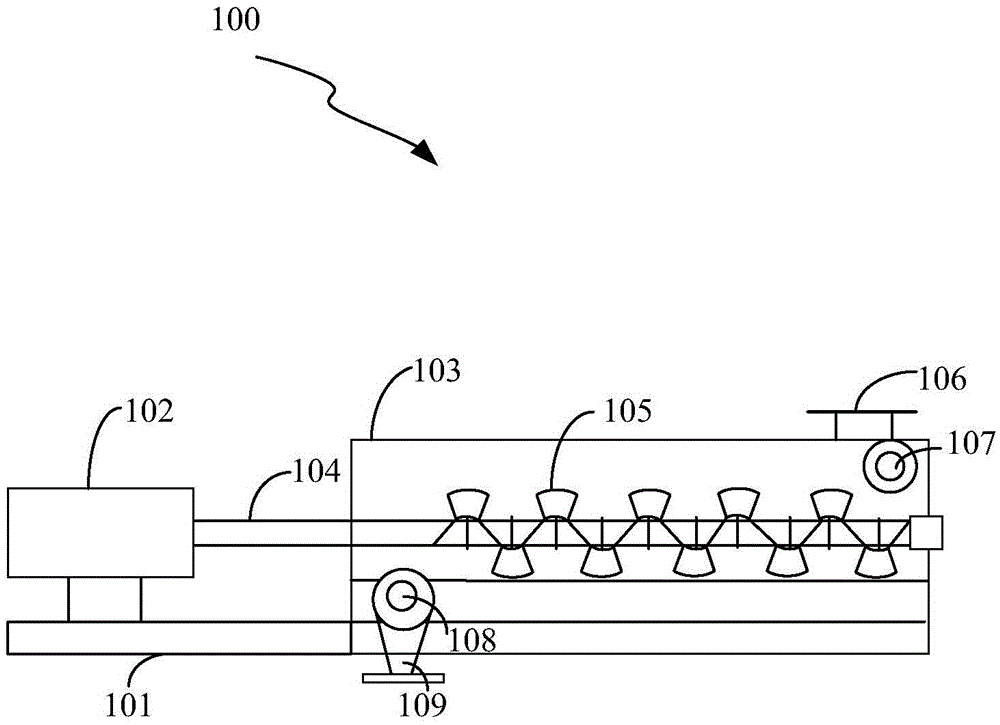

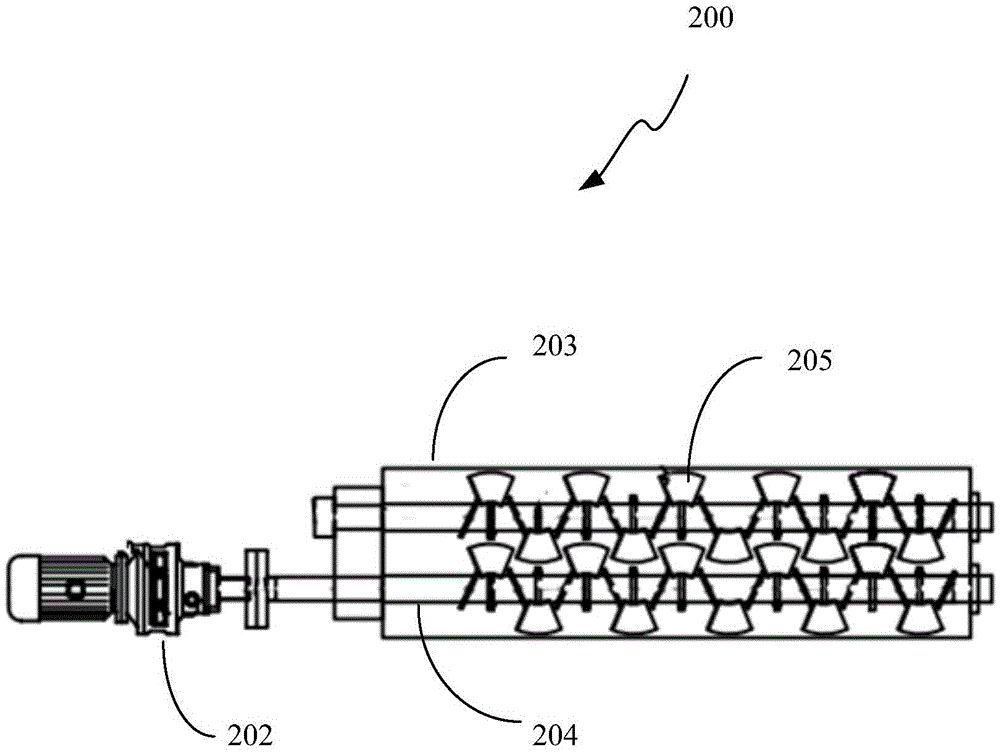

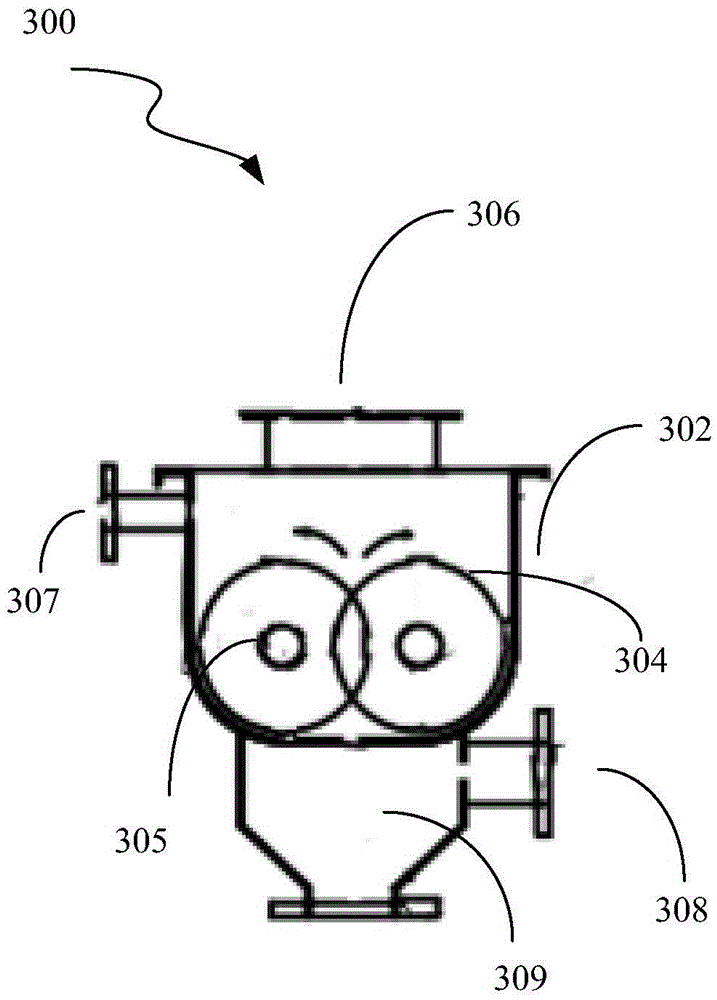

Sludge slurrying machine

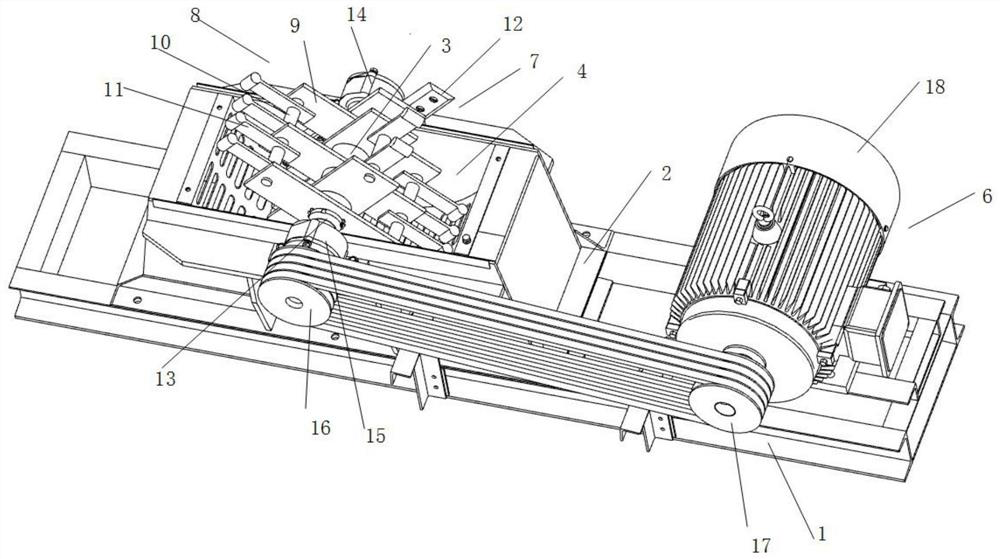

InactiveCN105536596AAchieve stirring effectRealize the conveying effectSludge treatmentRotary stirring mixersDrive shaftEngineering

The invention provides a sludge slurrying machine. The sludge slurrying machine comprises a transmission device, a transmission shaft, paddles, a casing and a base, wherein the transmission device and the casing are mounted on the base; the transmission device is connected with the transmission shaft and used for driving the transmission shaft to rotate; one end of the transmission shaft is connected with the transmission device, and the other end extends into the casing and is provided with the paddles; the paddles and the transmission shaft are set to form angles and are used for stirring and conveying sludge; a sludge addition port is formed in the upper end of the casing and used for addition of dewatered sludge to the casing; a discharging end is arranged at the bottom end of the casing and used for outputting a mixed and slurried material out of the sludge slurrying machine; the base is connected with the casing and used for supporting the sludge slurrying machine.

Owner:CSD BEIJING E P DEV CO LTD

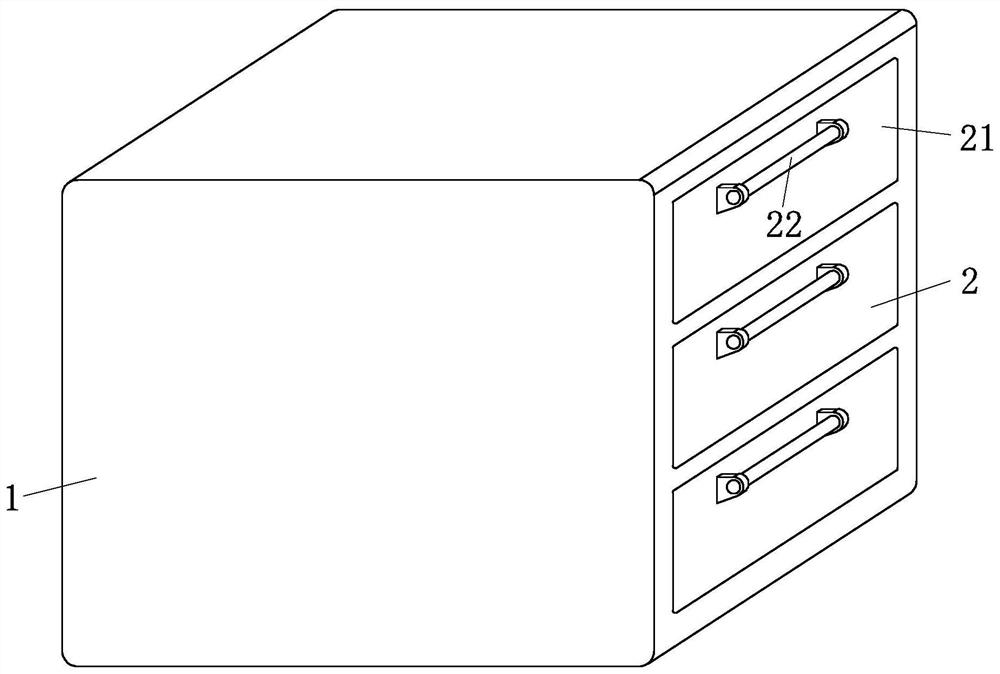

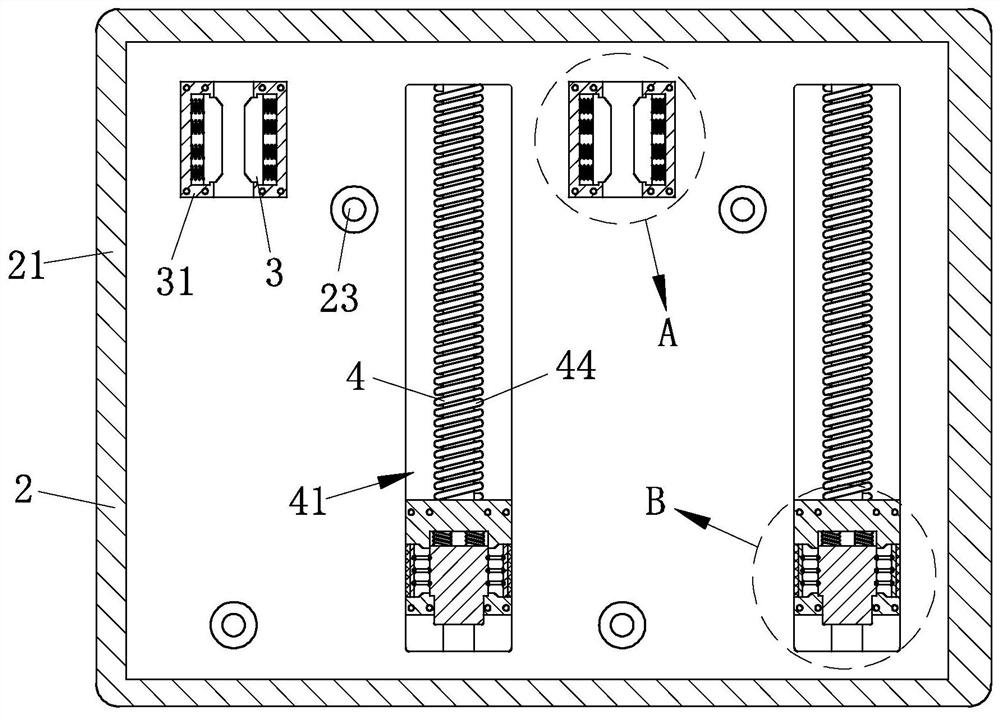

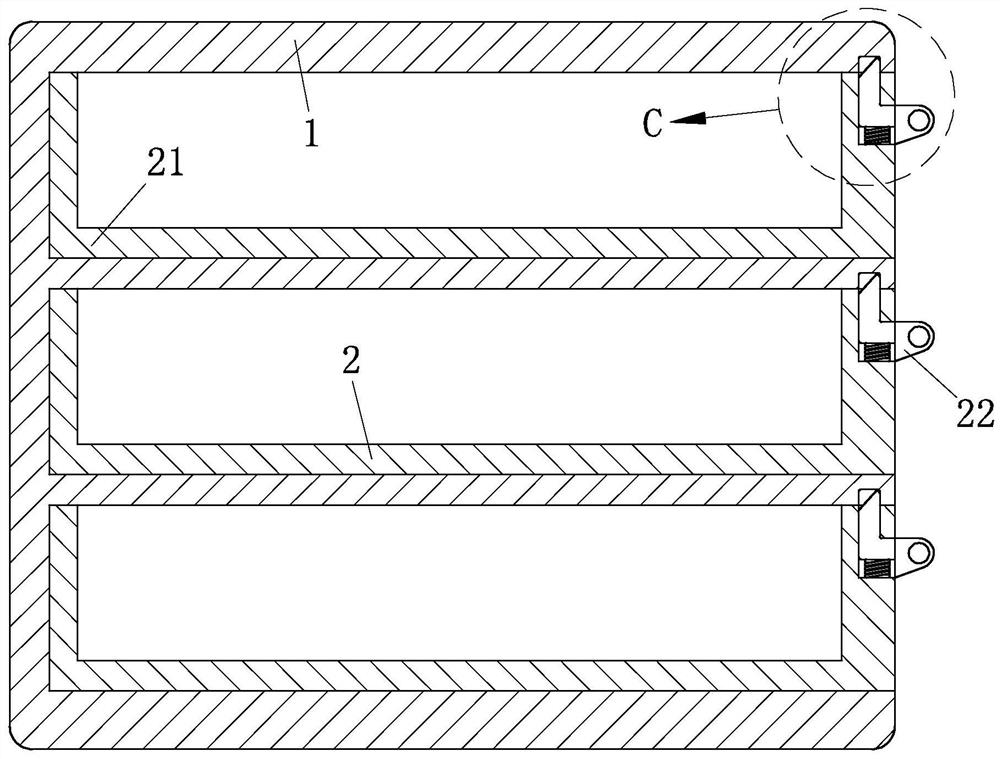

Sports equipment storage device

ActiveCN112619106ANot easy to fall offPromote withdrawalSport apparatusStructural engineeringJumping rope

The invention discloses a sports equipmentstorage device which comprises a box body, a storage mechanism, a storage box, a handle, a fixing rod, a clamping mechanism, a fixing block, a clamping block, a first spring, a driving mechanism, a sliding groove, a guide rod, a sliding block and a second spring. The storage device has the beneficial effects that the storage box can be conveniently pulled out by pressing the handle, so that a skipping rope can be conveniently placed in the storage box to be stored, a grip at one end of the skipping rope is placed in the center of one of the fixing blocks to be clamped during placement, and the two clamping blocks abut against and tightly clamp the grip of the skipping rope under the action of the first spring, thus preventing falling off of the grips; then the skipping rope is wound and rolled up through the two fixing rods, after rolling up is completed, the sliding block slides with the guide rod without the action of a second spring, the fixing block at the top of the sliding block can be moved, and therefore the grip at the other end of the skipping rope can be clamped conveniently; therefore, the skipping rope is prevented from being wound to bring inconvenience to subsequent exercises when used next time.

Owner:澧县第一中学

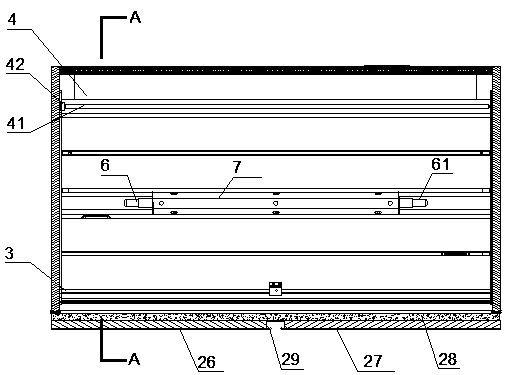

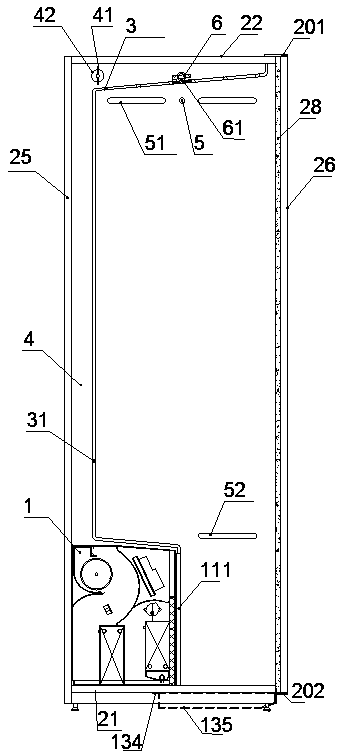

Multifunctional cabinet type heat pump clothes dryer

PendingCN111041797ASolve the problem of easy windingWinding will notDispersed particle separationLavatory sanitoryThermodynamicsEngineering

The invention discloses a multifunctional cabinet type heat pump clothes dryer. The multifunctional cabinet type heat pump clothes dryer comprises a cabinet body and a dehumidification main machine arranged in the cabinet body, wherein a combined air duct is arranged in the cabinet body through a partition plate; an air supply outlet is further formed in the top of the cabinet body; an air outletof the dehumidification main machine and the air supply outlet in the top of the cabinet body communicate with the combined air duct respectively; and a clothes airing rod is arranged below the air supply outlet. The multifunctional cabinet type heat pump clothes dryer can effectively solve a series of problems that an existing clothes dryer is limited in clothes drying capacity, clothes are proneto being wound, different types of clothes cannot be dried synchronously, clothes which are not resistant to abrasion cannot be dried, clothes which are not resistant to high temperature cannot be dried, and electric heating clothes drying energy consumption is too large.

Owner:成都佳阳智能家居有限公司

Fire hose

Owner:SUZHOU WEILANG INTELLIGENT SYST INTEGRATION

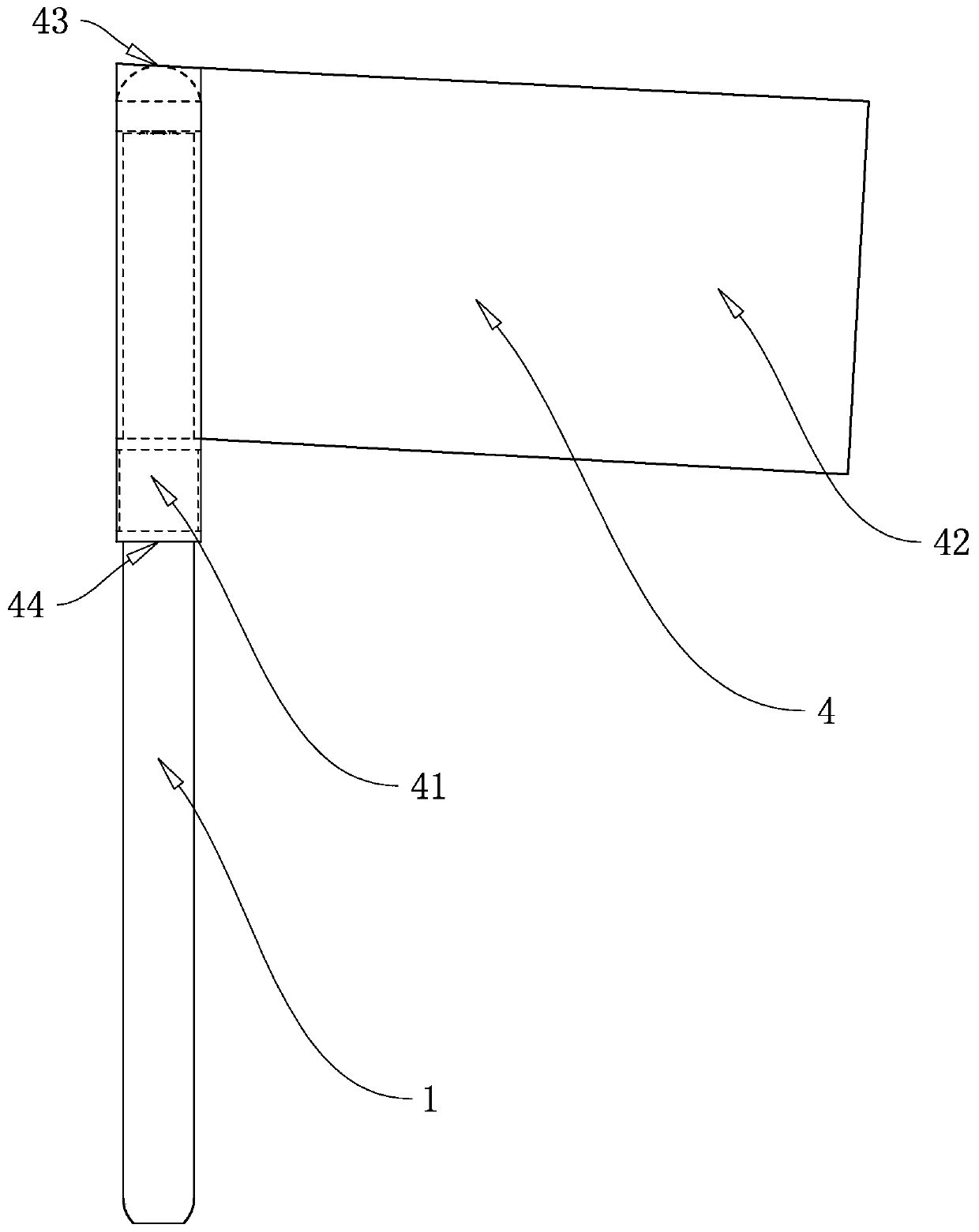

Non-lifting type winding prevention flagpole

InactiveCN110644842AReasonable designWinding will notTowersClassical mechanicsStructural engineering

The invention relates to the technical field of flagpoles and particularly provides a non-lifting type winding prevention flagpole. The flagpole is provided with a flagpole sleeve pole. The flagpole sleeve pole comprises an upper movable cover and a lower movable sleeve. The upper movable cover is located at the upper end of the flagpole sleeve pole. The upper end of the flagpole sleeve pole is provided with an inverted clamp matched with the upper movable cover. The upper movable cover is provided with an inner support hole matched with the inverted clamp of the flagpole sleeve pole. An uppermovable cover round head of the upper movable cover is provided with rough points. The lower movable sleeve is located at the lower end of the flagpole sleeve pole and is provided with an inner hole.The inner hole is provided with a lug. A groove matched with the lug is formed between the flagpole sleeve pole and the flagpole. According to the technical scheme, the upper end of a flagpole sleeveabuts against the upper movable cover, the lower end of the flagpole sleeve is bound to the lower movable sleeve, thus a flag waves with wind on the flagpole and is not wound around the flagpole, thedefect that a flag is wound around a previous non-lifting type flagpole can be overcome, and high popularization value is achieved.

Owner:玉环派盛科技有限公司

Efficient energy-saving LED lamp

InactiveCN112902034AWinding will notEasy to carryLighting support devicesPortable electric lightingCircular discLight equipment

The invention provides an efficient energy-saving LED lamp, and belongs to the technical field of lighting equipment. The efficient energy-saving LED lamp comprises a bottom plate, the lower surface of the bottom plate is fixedly connected with a wheel support, the two sides of the bottom plate are fixedly connected with fixing rods, the upper surface of the bottom plate is fixedly connected with a base and a fixed guide rail in sequence from back to front, a movable rod is movably connected to the inner wall of the fixed guide rail, a rotating shaft is movably connected to the inner wall of the base, and discs are fixedly connected to the two ends of the outer surface of the rotating shaft. Through the arranged rotating shaft, cables can be wound, the cables are more convenient to carry, the cables cannot be wound together, and the problem that the cables are difficult to unwind due to the fact that the cables are wound together is solved. A crank is arranged, the crank can be rocked to drive the rotating shaft to take up the cables, the working time of manual take-up is shortened, and therefore, the problem that in the prior art, during night construction, lighting equipment is inconvenient to install and carry and single in function is solved.

Owner:张铀

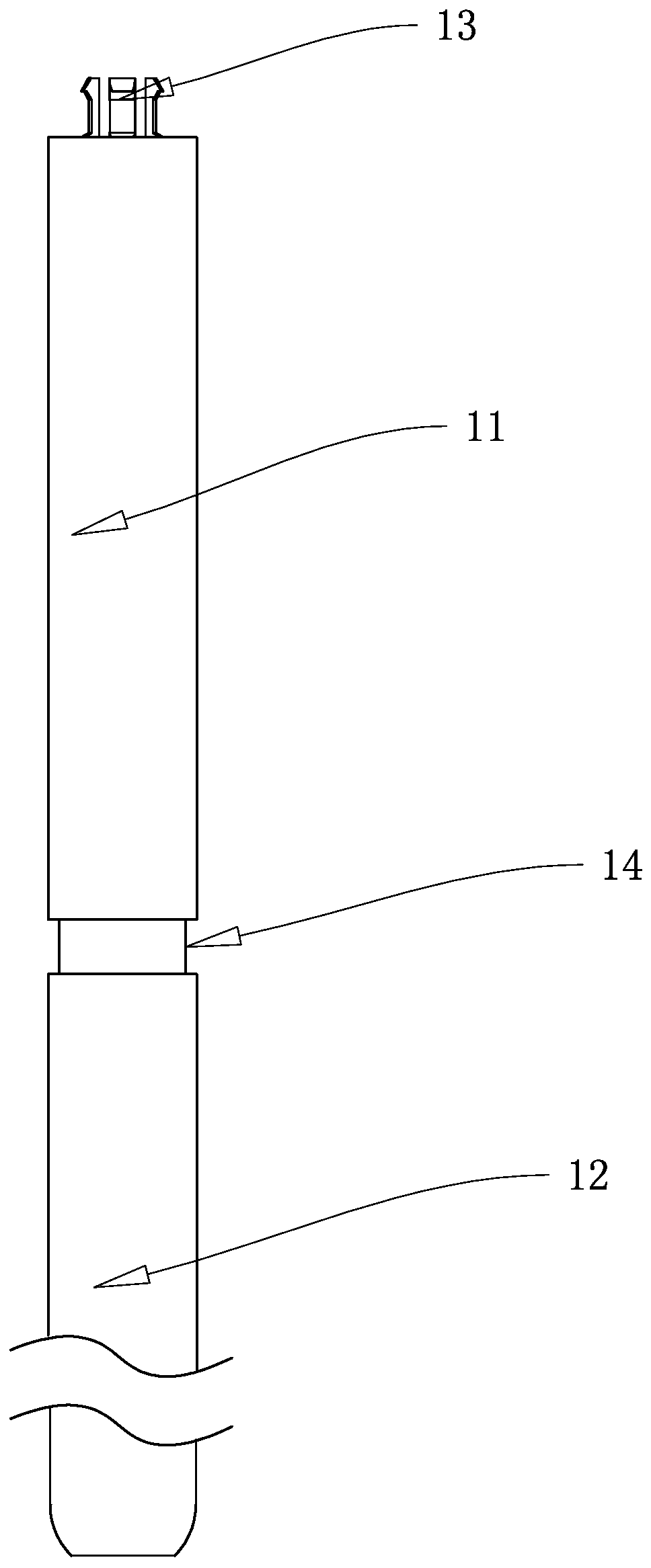

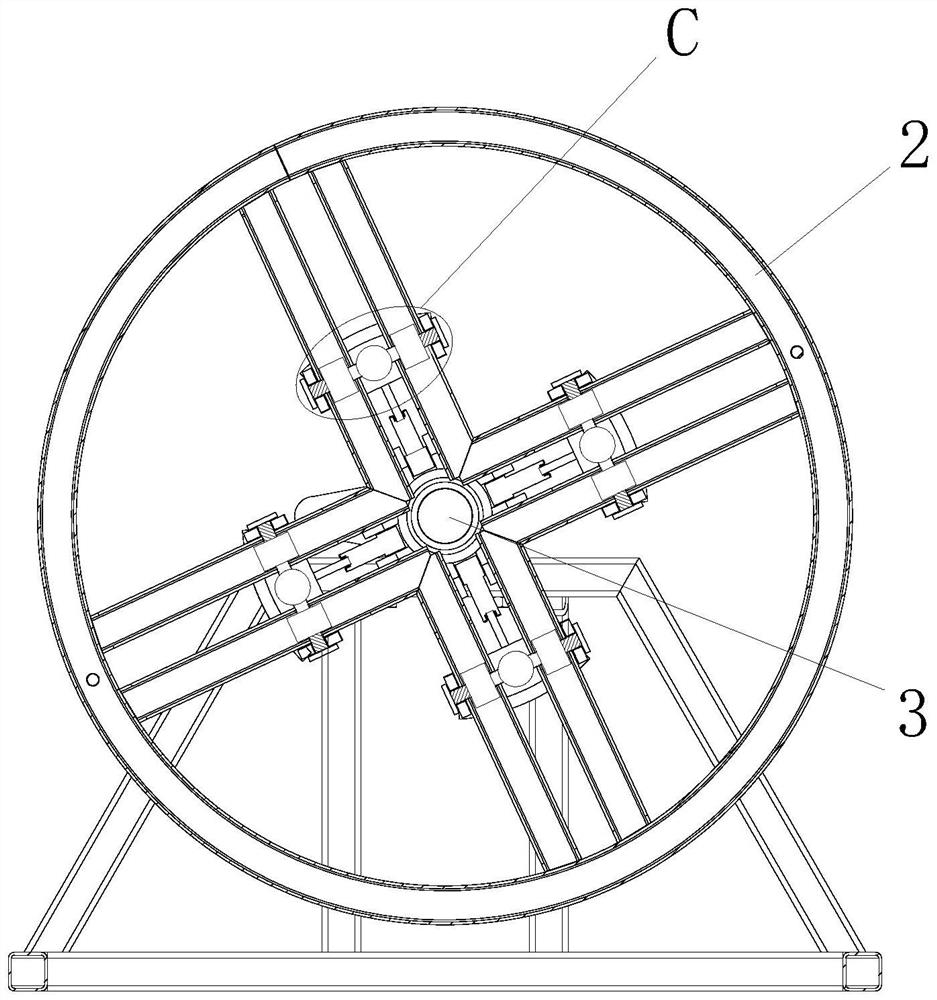

High-stability superconductor electromagnetic wire pay-off device

PendingCN114572756AEasy to wrapWinding will notFilament handlingSuperconductor elements usageEngineeringLantern

The invention discloses a high-stability superconductor electromagnetic wire pay-off device which comprises a frame, a rotating ring, a shaft rod, four sets of adjusting plates and a rotating handle, and the surface of the shaft rod is provided with the four sets of adjusting plates through two sets of adjusting structures. The adjusting structure comprises two sets of lantern rings arranged on the surface of the shaft rod in a sleeving mode, four sets of first hinge pieces arranged on the surfaces of the outer walls of the lantern rings, a third rotating shaft penetrating through the other end of the second connecting rod and second hinge pieces arranged at the two ends of the third rotating shaft. By arranging an adjusting plate, an adjusting structure and the like, the problems that the diameter of a rotating roller cannot be changed, when an electromagnetic wire with the large diameter is wound, the bending amplitude of the electromagnetic wire is large when the electromagnetic wire is wound on the rotating roller, plastic deformation of a metal wire in the electromagnetic wire is likely to happen, and the electromagnetic wire is damaged are effectively solved. And the problem that the released electromagnetic wire cannot be naturally recovered to a linear state, and additional straightening processing operation needs to be carried out is solved, and the convenience of the device is improved.

Owner:安徽聚虹电器有限公司

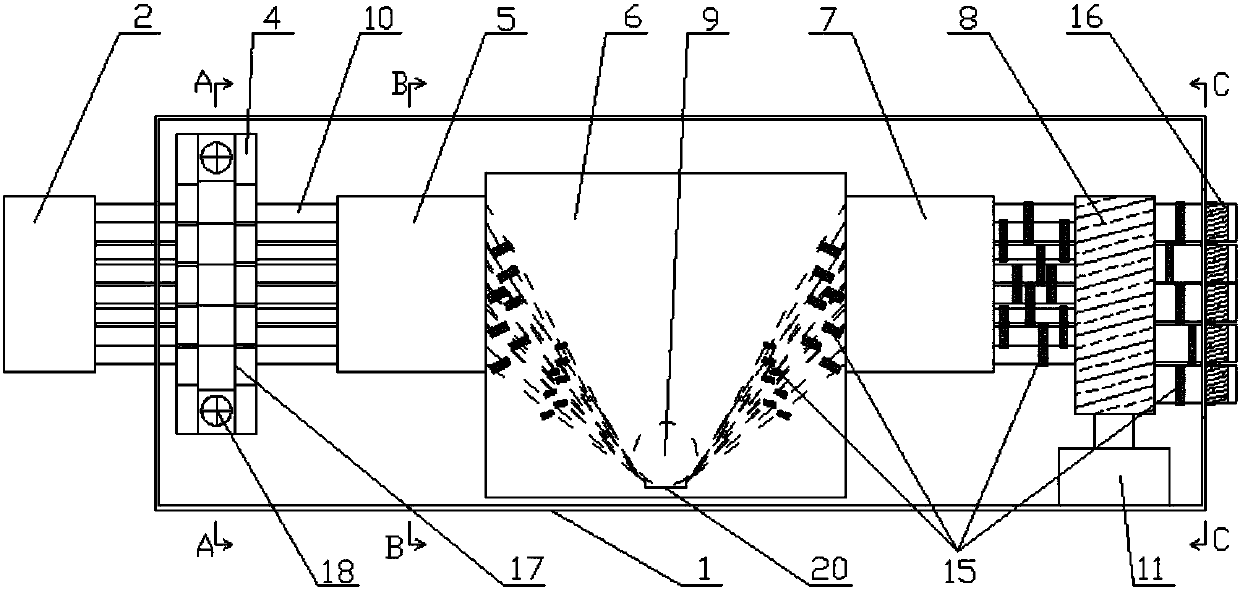

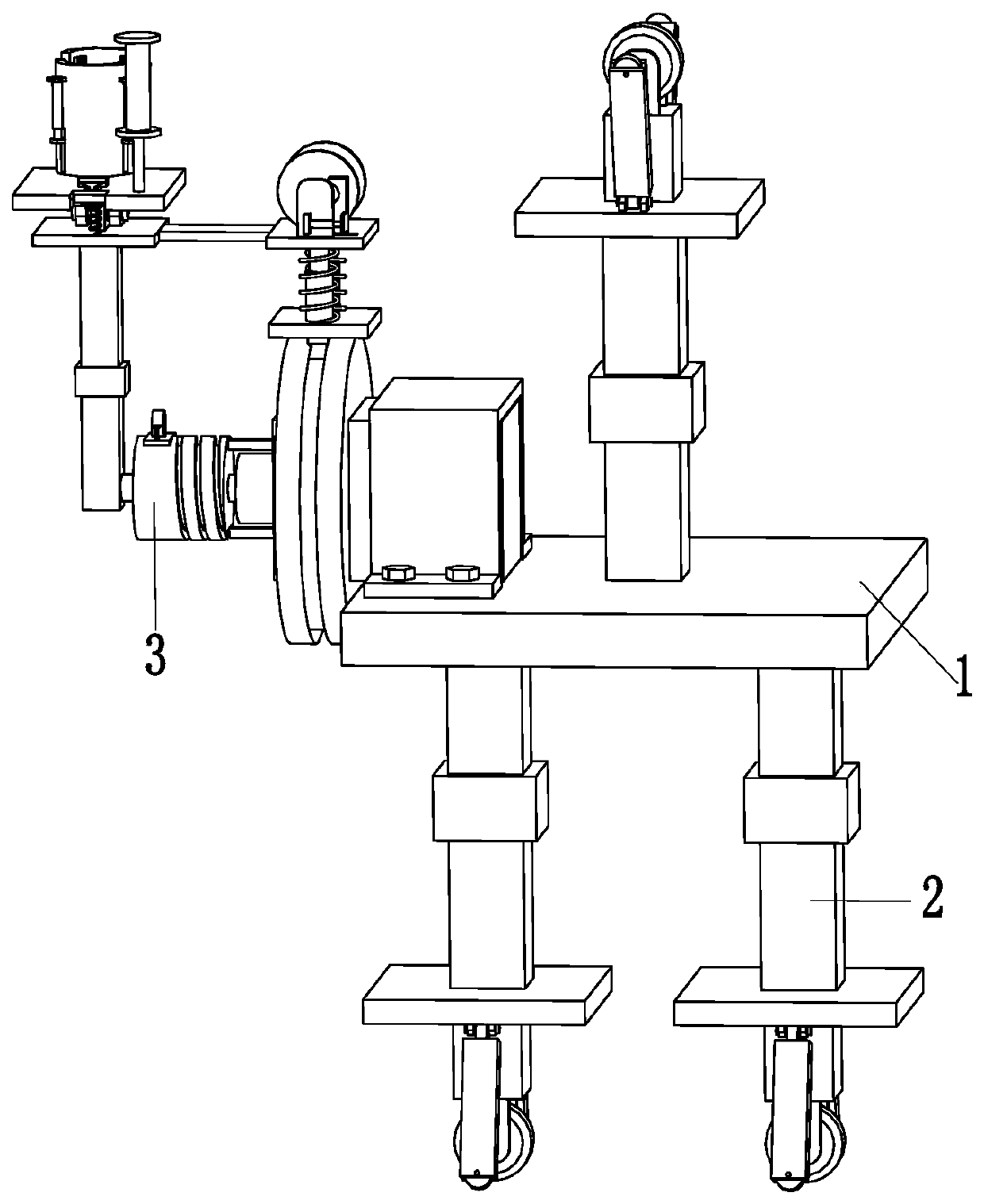

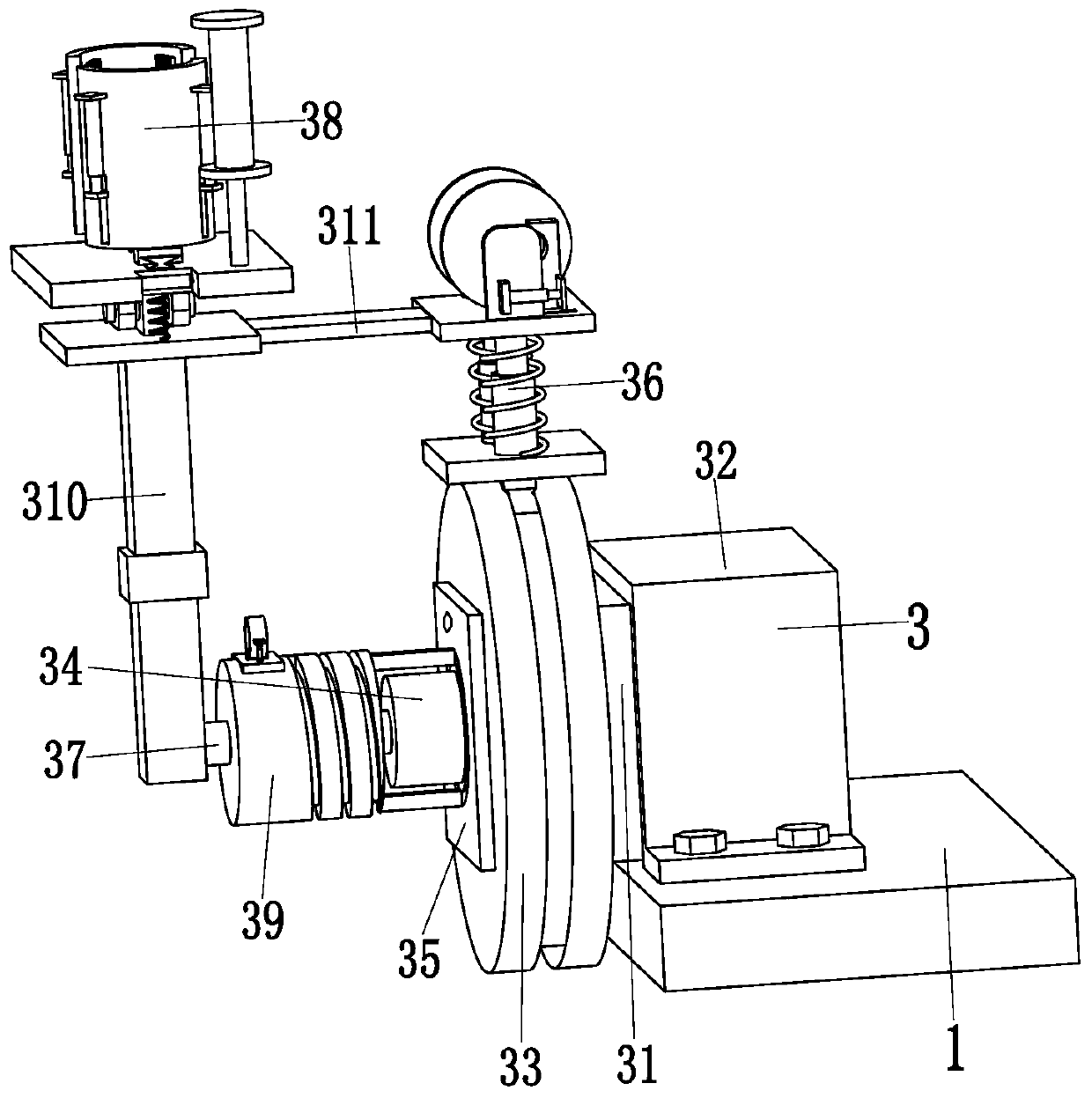

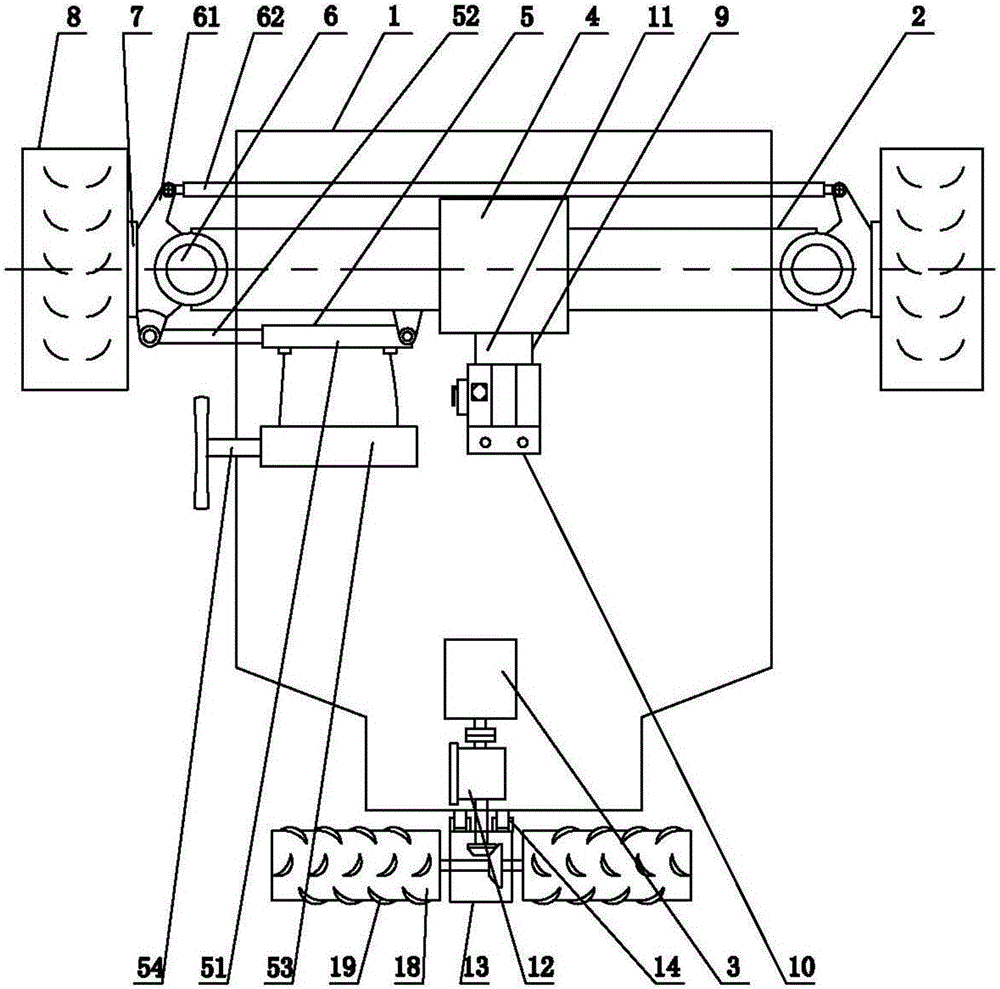

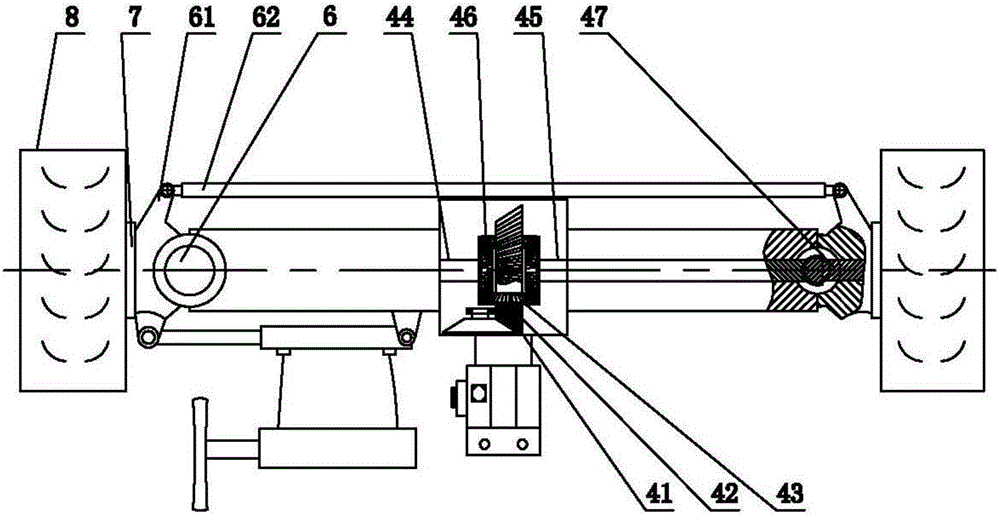

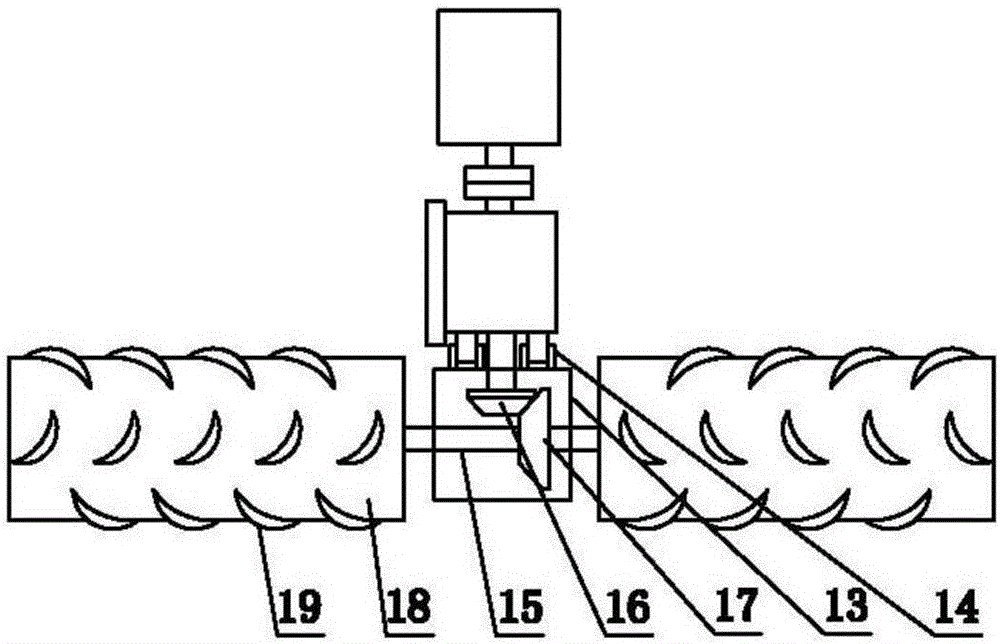

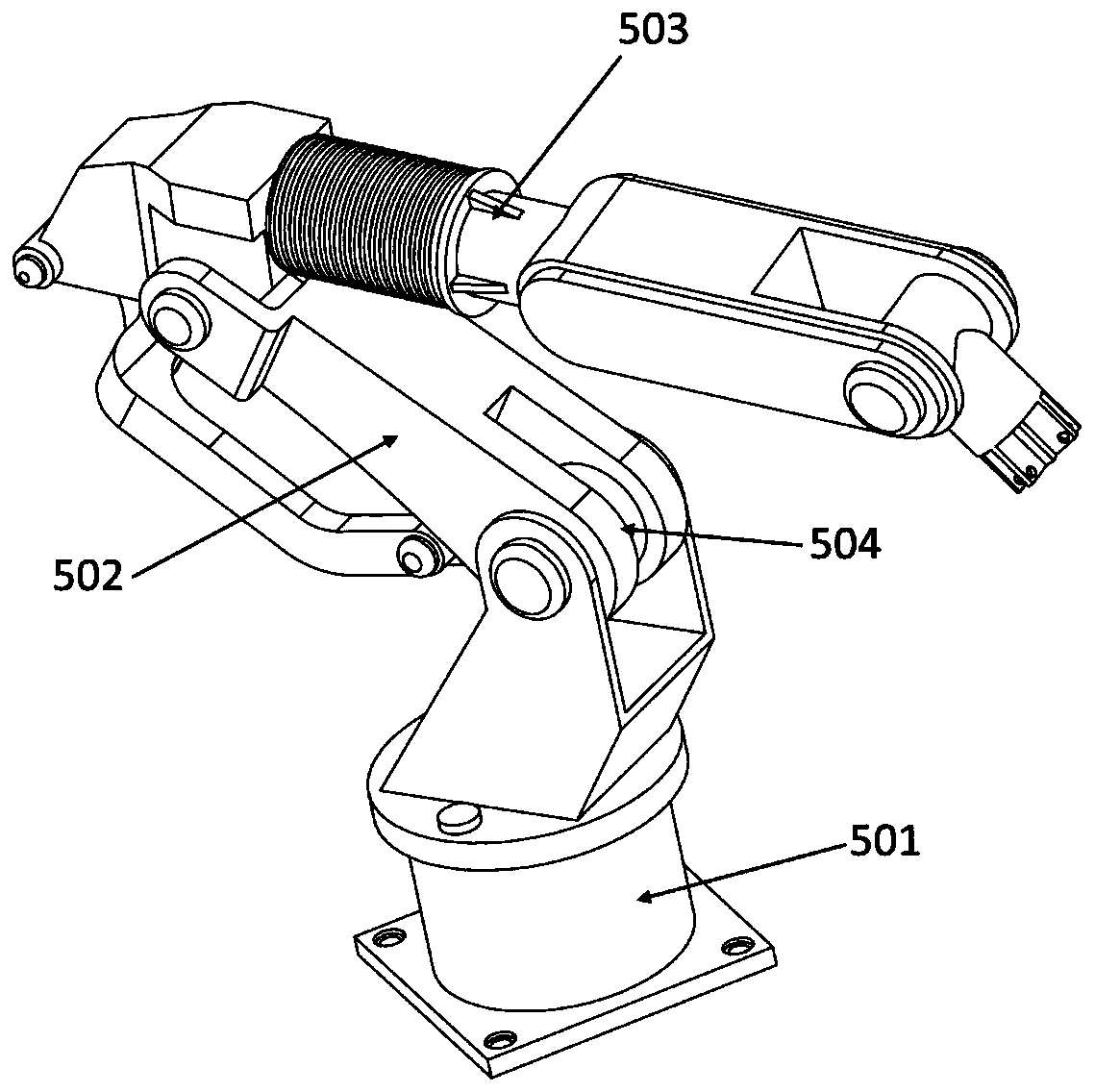

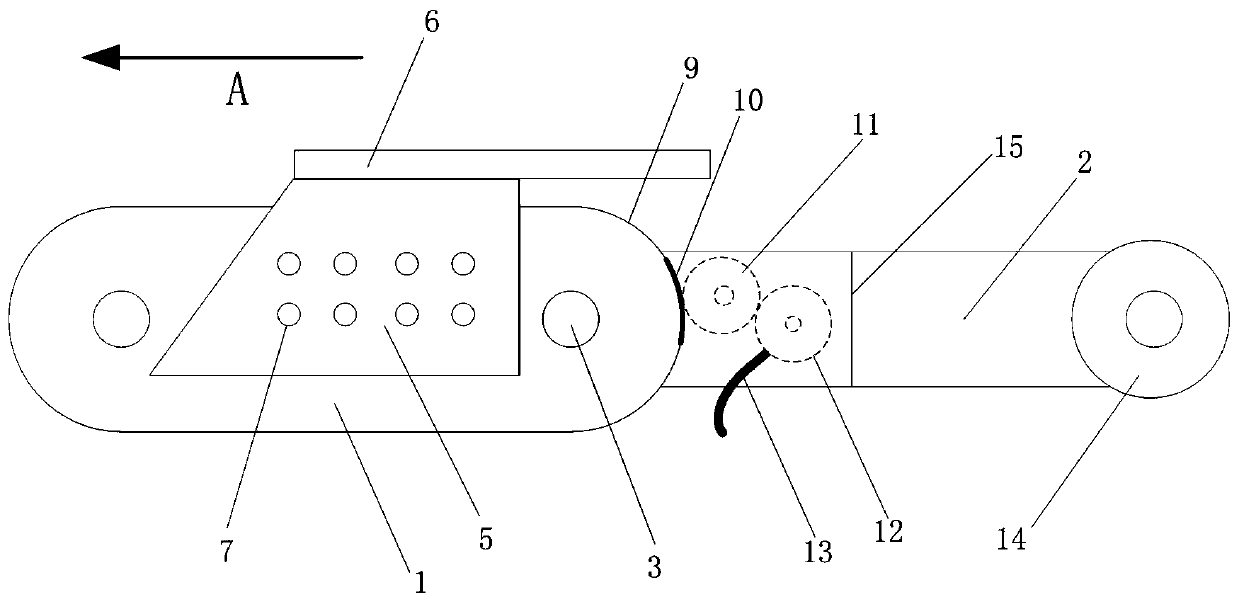

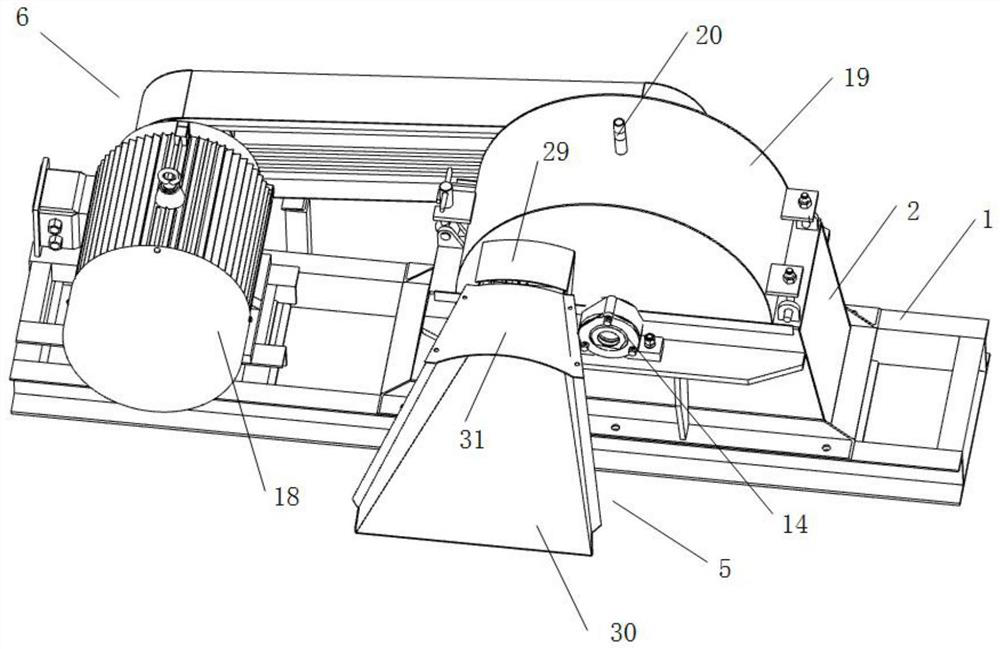

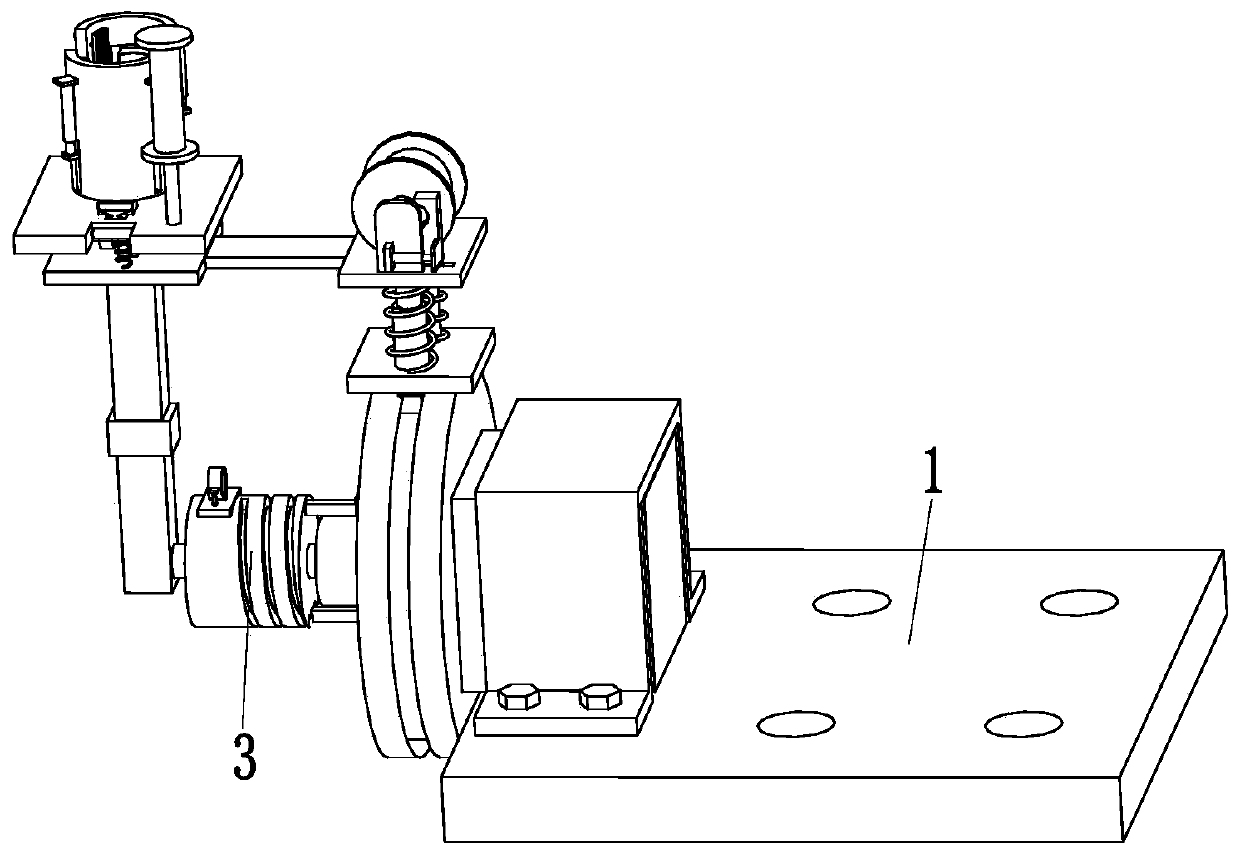

An intelligent robot for arc spraying of large steel pipes

ActiveCN109023214BAutomated Arc SprayingWinding will notMolten spray coatingEngineeringMechanical engineering

The invention relates to a large-scale steel pipe electric arc spraying intelligent robot. The robot comprises a supporting plate, three travelling devices and a spraying device. One traveling deviceis mounted on the upper end surface of the middle of the supporting plate, and the other two travelling devices are mounted at the left and right ends of the bottom of the supporting plate correspondingly. The spraying device is mounted at the top of the left end of the supporting plate. Each travelling device comprises a travelling telescopic column, a travelling support plate, a travelling wheel, supporting connecting columns, supporting rollers and supporting angle push rods. By means of the large-scale steel pipe electric arc spraying intelligent robot, the problems that when electric arcspraying is performed on existing blowdown pipes, a spray gun needs to be held manually to spray the blowdown pipes, manual operation has potential safety hazards, manual electric arc spraying is difficult when the sizes of the blowdown pipes are small, a power line of the spray gun is prone to being tangled during electric arc spraying, and a spraying welding stick is prone to fracturing during spraying can be solved.

Owner:湖南隆盛达钢管制造有限公司

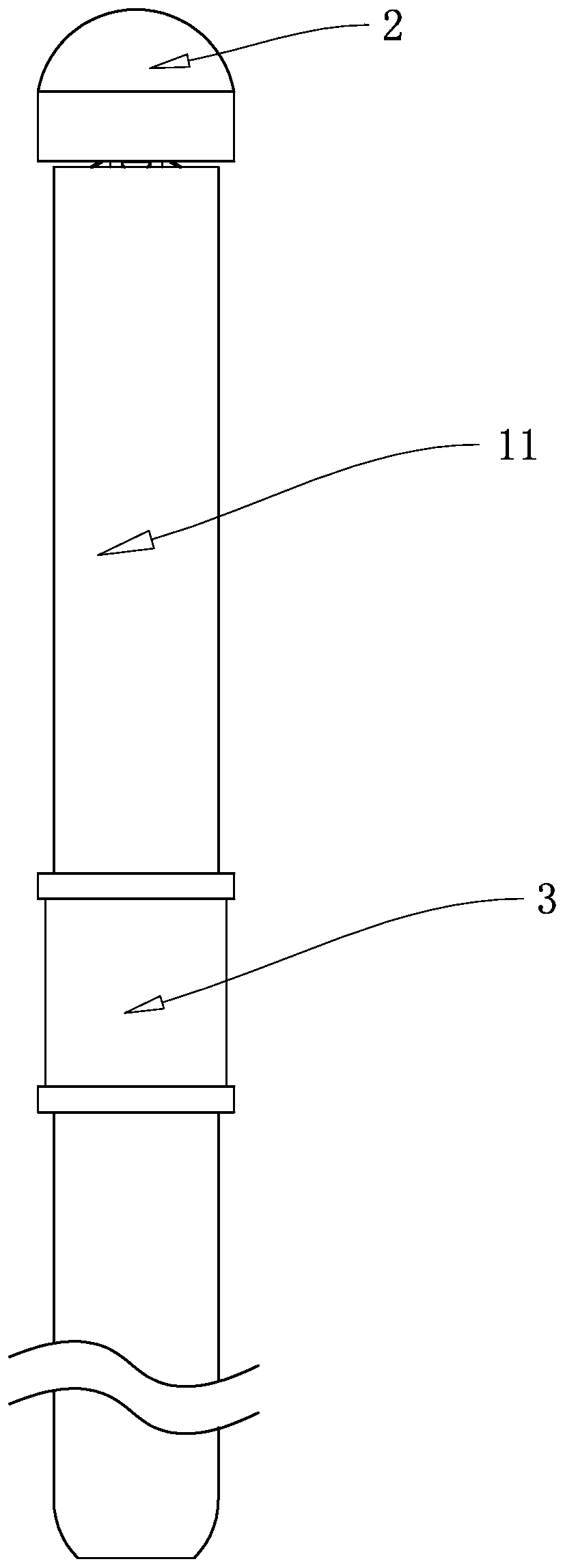

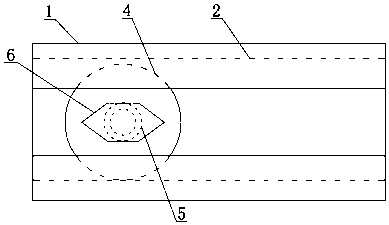

Winding-free washing machine with central rotating cylinder

InactiveCN104611877AWinding will notHigh speed washingOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention relates to a winding-free washing machine with a central rotating cylinder. The winding-free washing machine is characterized in that the rotating cylinder (2) is arranged at the center of the washing machine and the rotation axial-direction of the rotating cylinder (2) is the same as that of the washing machine. Due to the rotating cylinder, clothes cannot be rolled to the center by vortex to be wound mutually, and meanwhile the clothes are scoured, rubbed and squeezed, so that the washing effect is enhanced.

Owner:徐林波

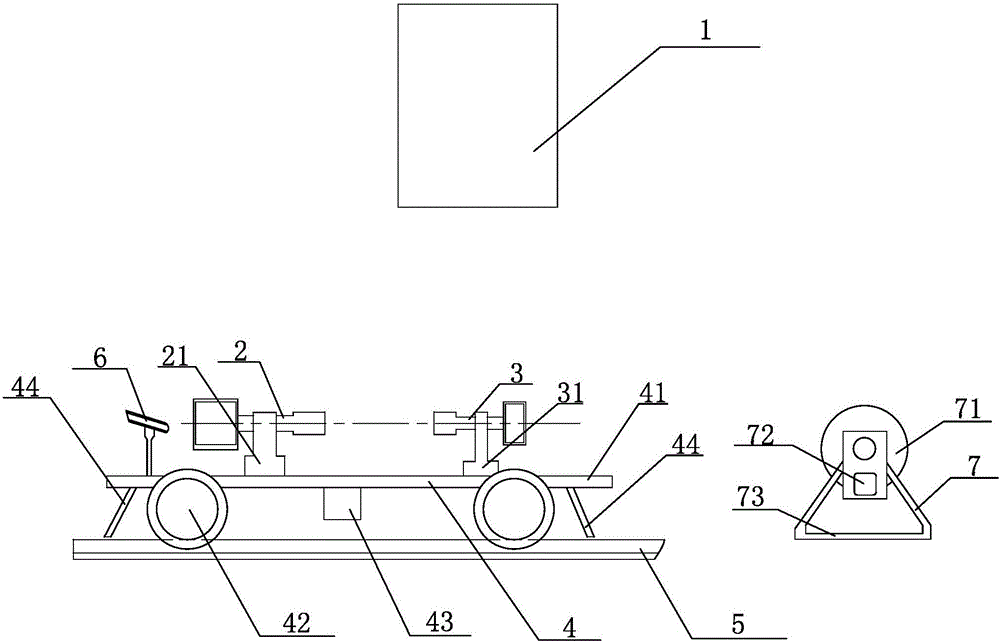

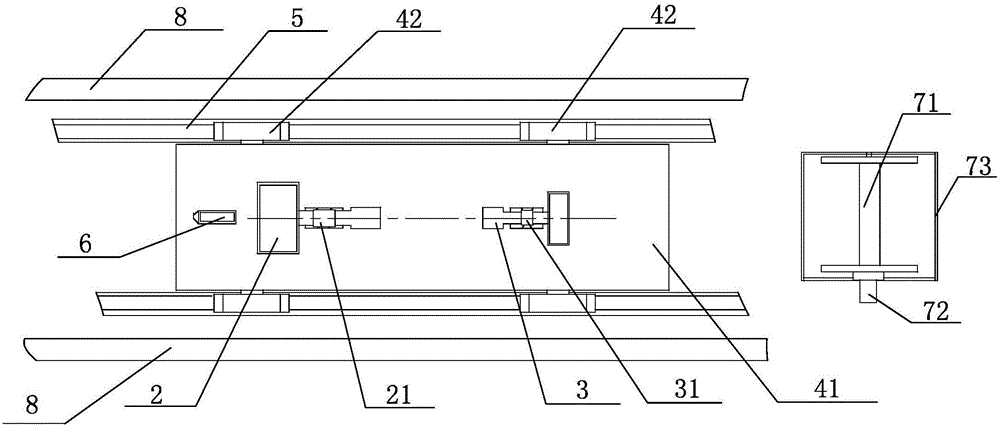

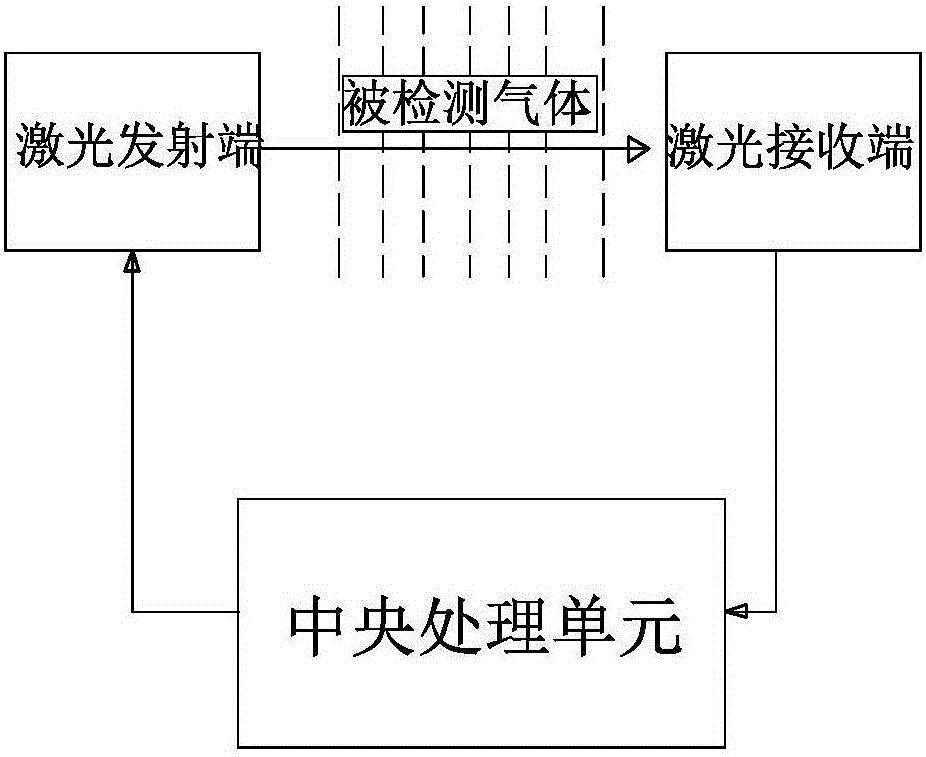

Laser spectrum cable trench gas detection system

InactiveCN105891134AHigh sensitivityReliable dataColor/spectral properties measurementsCritical positionComputer terminal

The invention discloses a laser spectrum cable trench gas detection system which comprises a laser emission end, a laser receiving end, a walking device and a remote monitoring terminal, wherein the walking device comprises two parallel tracks and a walking trolley; a motor can drive a track wheel so that the walking trolley walks along the track; the laser emission end and the laser receiving end are oppositely arranged on the walking trolley; the remote monitoring terminal comprises a central processing unit, a walking control unit and a display screen; the laser emission end and the laser receiving end are connected with the central processing unit through an optical cable; and the motor is connected with the walking control unit through a wire. In the invention, various harmful gases in the cable trench are detected by the laser spectrographic analysis, and the workflow of concentration detection of the harmful gases in the cable trench is simplified; and meanwhile, the concentration of the harmful gases on each key position in the cable trench can be detected anytime by using the walking trolley, and safety guarantee is provided for the cable conveying and inspection workers.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Four-wheeled differential driving friction tiller

InactiveCN105794336AGuaranteed uptimeAvoid entanglementTilling equipmentsDrive wheelDifferential transmission

The invention discloses a four-wheeled differential driving friction tiller.The friction tiller comprises a rack, an engine, an integrated front axle, rotary tillage wheels and the like.The integrated front axle and the engine are arranged at the tail end of the rack, a differential transmission device and a steering device are arranged on the integrated front axle, and swing bases are arranged at the two ends of the integrated front axle and each provided with a hub.Front-arranged driving wheels are driven by an oil pump and a hydraulic continuously variable transmission.An output shaft of the engine is connected with an input shaft of a speed change gear box, an output shaft of the speed change gear box drives a rotary tillage shaft to rotate, and the rotary tillage wheels are symmetrically arranged at the two ends of the rotary tillage shaft.The four-wheeled differential driving friction tiller rolls weeds into soil through the driving wheels and the rotary tillage wheels so that the weeds can die from suffocation, the weed killing effect is achieved, and the friction tiller is adaptive to a hard-board field and a deep-mud field and capable of rolling weeds.Smooth transition is achieved between Falcate cutters on the rotary tillage wheels and the driving wheels, soil penetration is stable in depth and free of dead angles, and weed winding is avoided.

Owner:彭宇良

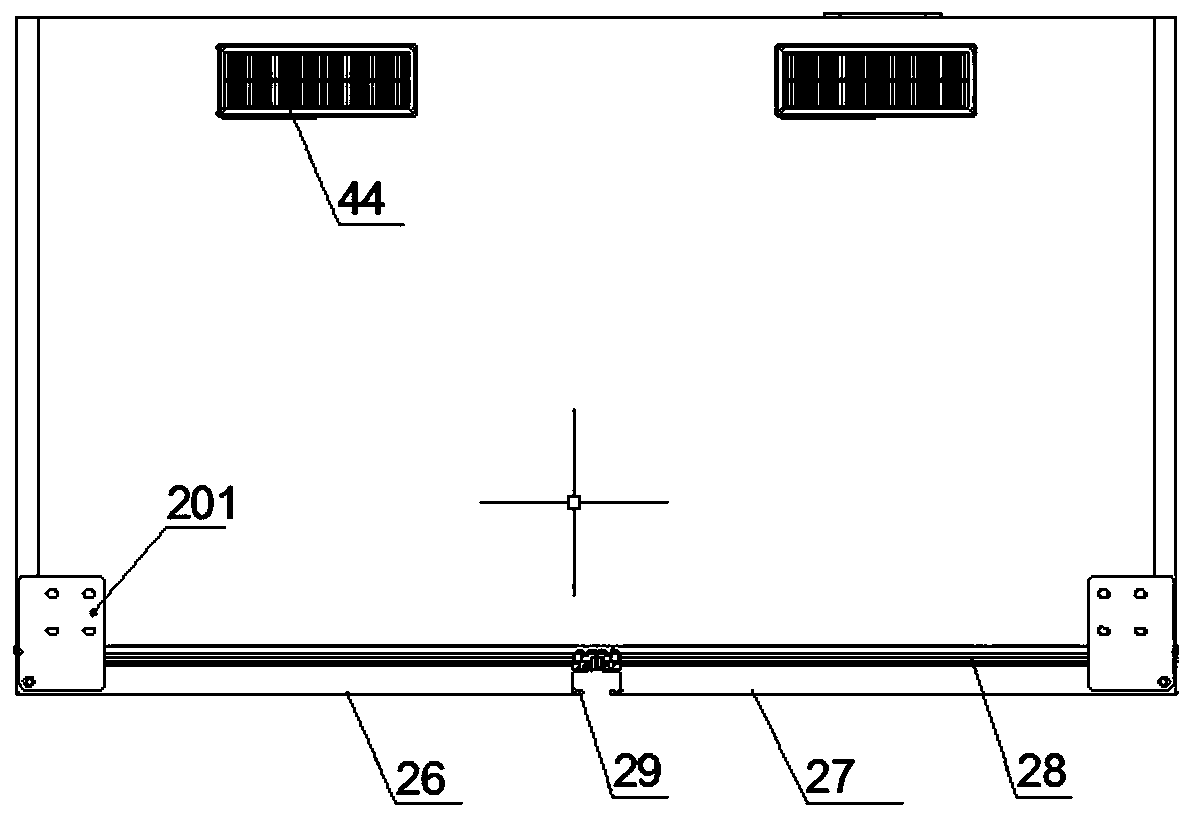

A Refrigerator Guide Rail That Can Avoid Entangling Foreign Objects

ActiveCN106052282BAvoid damageSimple structureLighting and heating apparatusSupportForeign matterEngineering

The invention discloses a refrigerator guide rail with the function of preventing twisting by foreign matter. The refrigerator guide rail comprises a guide rail shell. A guide rail groove is formed in the guide rail shell. An opening is formed in the left side of the guide rail shell, and a guide rail wheel is arranged in the guide rail groove. The middle portion of the guide rail wheel is rotationally connected with the right end of a bearing shaft through a bearing. The bearing shaft is located on the inner side of the opening. Containing grooves are formed in the upper side and the lower side of the opening. A foreign matter blocking device is arranged in each containing groove and comprises a spring, wherein the spring is fixedly connected with the upper portion of an inner cavity of the containing groove, the lower side of the spring is fixedly connected with the upper end of a telescopic support, the telescopic support is sleeved with the containing groove in a connected manner, and the outer end of the telescopic support is rotationally connected with a wheel. Generally speaking, the refrigerator guide rail is simple in structure and capable of effectively blocking the foreign matter and has the function of preventing twisting by the foreign matter and suitable for application and popularization.

Owner:CHUZHOU OUBOTE ELECTRONICS MFG

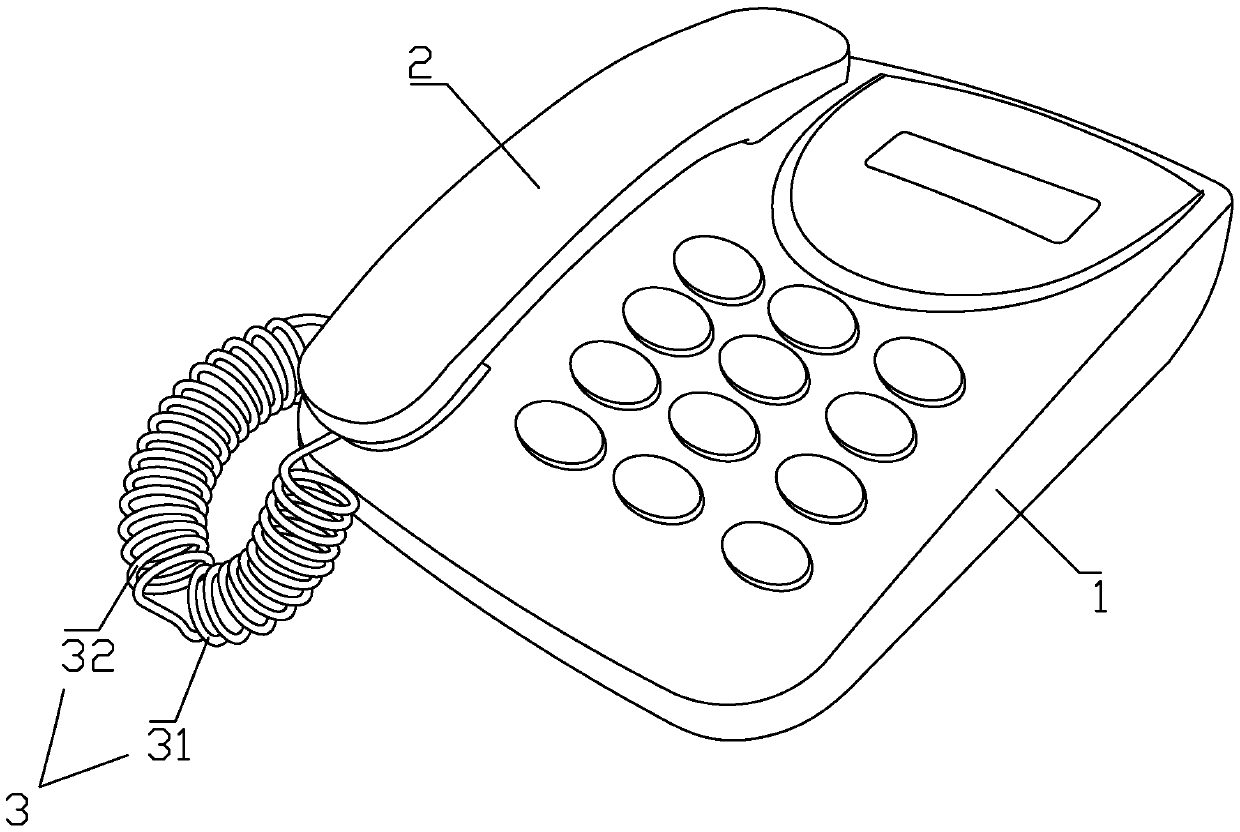

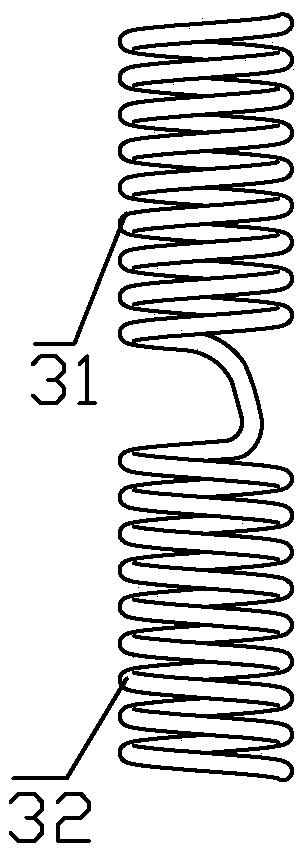

Telephone avoiding twining

The invention provides a telephone avoiding twining, comprising a telephone body, a microphone, and a telephone rope between the microphone and the telephone body. The telephone rope is provided with a first curling part and a second curling part which are in mutual connection and are curled in opposite directions. The invention also provides the telephone which can avoid telephone rope twining caused by switching between two sides of the face in a long-term use process.

Owner:郭佩琳

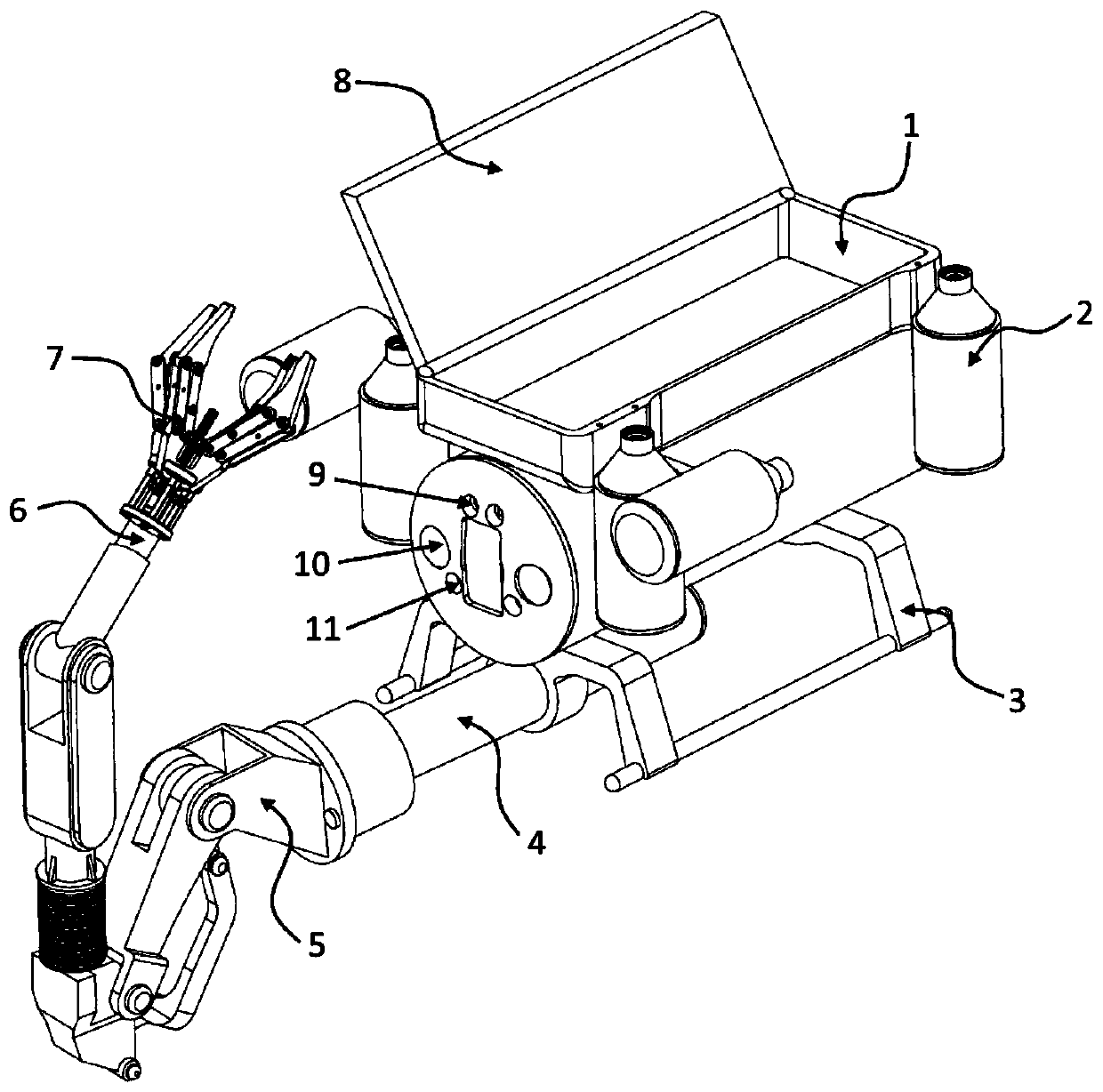

A collection method for an underwater collection robot that prevents the entanglement of aquatic plants

ActiveCN109878669BFlexible operationGuaranteed uptimePropulsive elementsUnderwater equipmentWater storageEngineering

The invention discloses an underwater collection robot and a collection method thereof which prevent aquatic plants from being entangled, and is characterized in that it comprises five parts: a basic assembly, a driving assembly, a grasping assembly, and a telemetry assembly. Wherein, the basic assembly includes a casing, a storage basket, a sealing cover, and an undercarriage; the drive assembly includes six blade hidden propellers installed at predetermined positions on the casing, and installed inside the casing, and two water storage compartments located at its head and tail ends; the grabbing assembly includes a mechanical arm telescopically connected to one side of the landing gear, and a mechanical claw telescopically connected to one end of the mechanical arm; the telemetry assembly includes An image acquisition unit on one side of the body, a control circuit installed inside the housing, and a user terminal wirelessly connected to the image acquisition unit. The present invention has abundant power and is not entangled by seaweeds and other seabed plants, and operates reliably.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

A vehicle-mounted brick loading machine

The invention relates to the field of brick loading machines and particularly relates to a vehicle-mounted type brick loading machine. The vehicle-mounted type brick loading machine comprises a brick loading machine platform and a lifting mechanism, wherein the brick loading machine is arranged on a vehicle body of a driving vehicle and comprises a rotary disc and a driving mechanism; the driving mechanism comprises a rotary disc motor and a rotary disc speed reducing machine; the rotary disc motor and the rotary disc speed reducing machine are arranged at the lower end of the rotary disc and drive the rotary disc to move; a supporting frame is fixed in the middle of the rotary disc; the lifting mechanism is fixed at the upper part of the brick loading machine platform by virtue of the supporting frame; one end of the lifting mechanism is connected with a brick grabbing device; the lifting mechanism is also provided with a driving wheel and a driven pulley which are respectively arranged at the two ends of the lifting mechanism; a steel wire rope is connected with the brick grabbing device by the driving wheel and the driven pulley; a main rod of the lifting mechanism is also provided with a track; a steel wire rope synchronizer is arranged on the track and is positioned between the driving wheel and the driven pulley; the steel wire rope penetrates through the steel wire rope synchronizer. The vehicle-mounted type brick loading machine provided by the invention is high in working efficiency, simple in structure and low in production cost.

Owner:NANNING YUANZHUO NEW ENERGY TECH CO LTD

A vehicle interceptor

ActiveCN106592467BProtection from damagePrevent disengagementTraffic restrictionsFlywheelHeavy weight

A pneumatic vehicle intercepting and stopping mechanism, comprising a housing (1), a triggering arc plate (3), a telescopic column (5), a top cover (12), pneumatic spike columns (15), and pneumatic spikes (29). The pneumatic vehicle intercepting and stopping mechanism is fixed together with a wheel as the pneumatic spikes (29) puncture the wheel. The pneumatic vehicle intercepting and stopping mechanism does not rotate along with the wheel due to large volume and heavy weight, and can instantly brake the wheel in order to intercept and stop a vehicle.

Owner:徐州天骋智能科技有限公司

Take-up and pay-off device

The invention relates to the field of take-up and pay-off devices, in particular to a take-up and pay-off device. The take-up and pay-off device comprises a fixed seat, a take-up and pay-off motor, alimiting elastic sheet, a wire outlet hole and a wire winding stand column where a wire is wound. The take-up and pay-off device further comprises an elastic protector. One end of the wire winding stand column is connected with the take-up and pay-off motor, and the other end of the wire winding stand column is connected with a hollow cavity on the fixed seat. The limiting elastic sheet is arranged at the joint of the take-up and pay-off motor and the wire winding stand column. The wire winding stand column is in a hollow shape. One end of the wire is located on the inner side of the wire winding stand column, and the other end of the wire penetrates the outer side of the wire winding stand column and is then connected with the wire outlet hole. The elastic protector is arranged on the outer side of the wire winding stand column in a surrounding manner and arranged below the limiting elastic sheet. According to the take-up and pay-off device, through forward operation of the take-up and pay-off motor, the wire is paid off through the wire outlet hole; when drawing-out force is reduced, the take-up and pay-off motor rotates reversely, and the wire is taken up to be wound around thewire winding stand column; and when the whole wire is drawn out, the elastic protector can achieve a protection and buffer function on the wire.

Owner:冯秉健

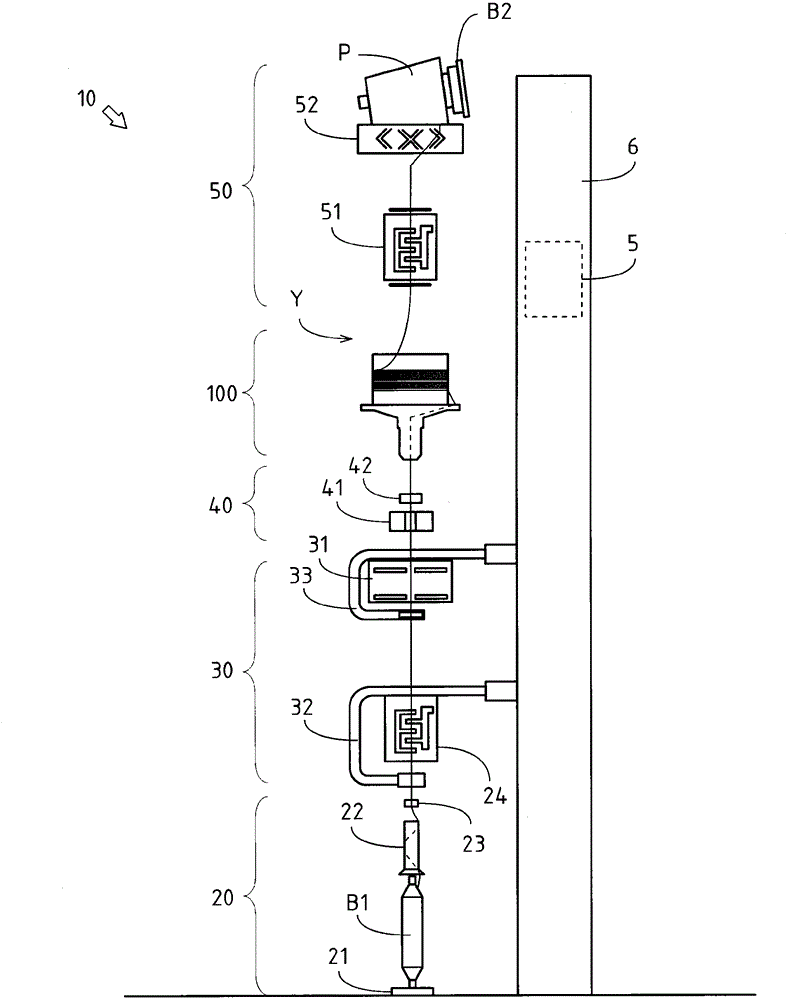

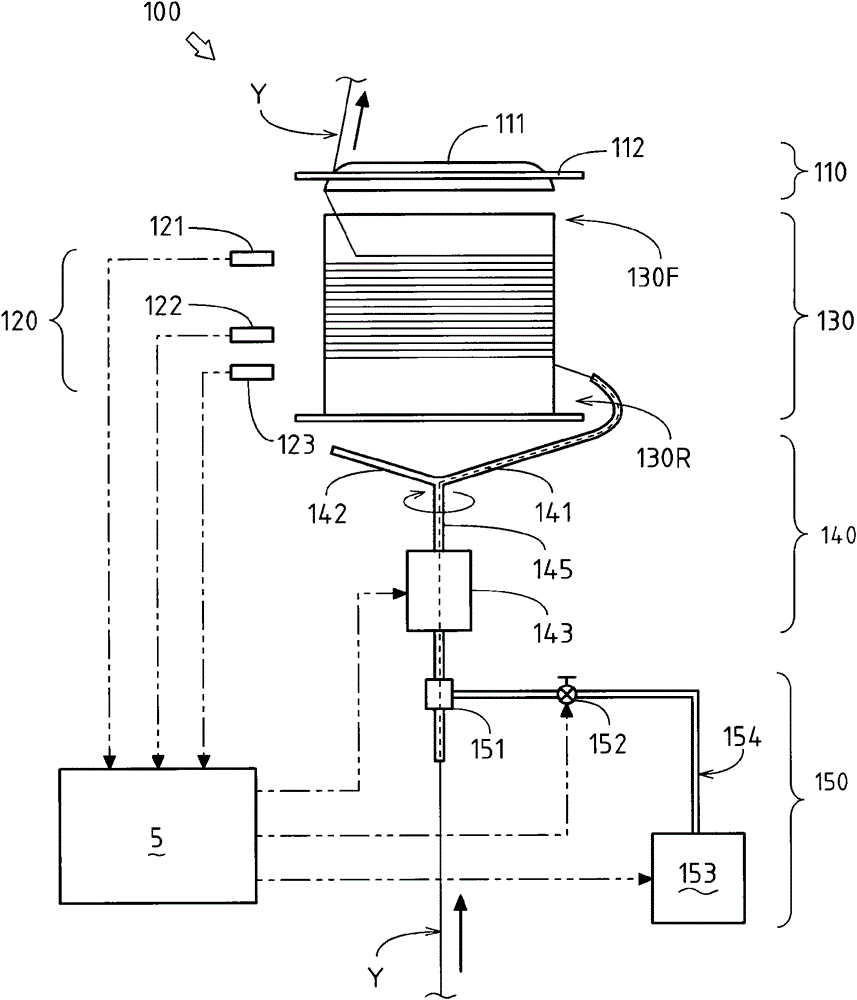

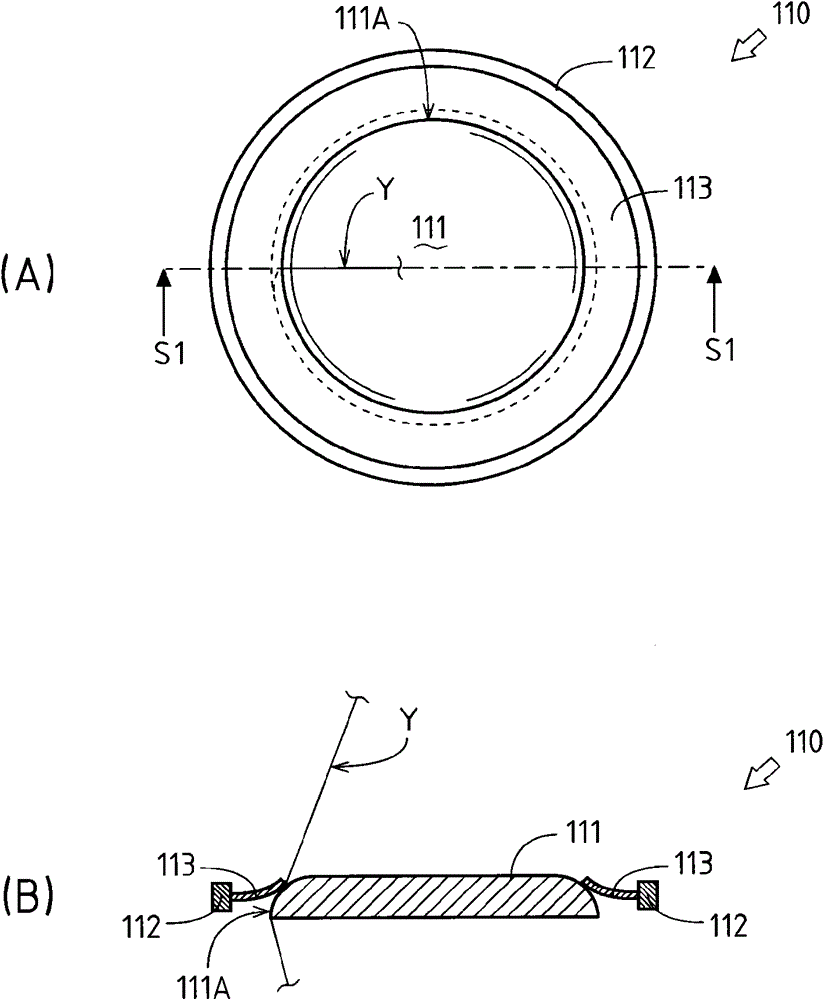

Yarn winding device

Provided is a yarn winding device that can prevent the occurrence of sluffing. A winding unit (10), while eliminating the threading defects of a yarn feeding bobbin (B1) around which is wound a yarn (Y) that is spun by a fine spinning machine, winds a package (P). The winding unit (10) comprises a yarn accumulating device (100) which winds the yarn (Y) from the yarn feeding bobbin (B1) and accumulates the wound yarn. The yarn accumulating device (100) comprises the following: a yarn accumulating part (130) which accumulates the yarn (Y); and a winding part (140) which, while rotating, winds the yarn (Y) around the yarn accumulating part (130). The yarn accumulating part (130) comprises the following: a yarn accumulating body (belt outer side) (132F) around which the yarn (Y) is wound; and a drive pulley (134) which maintains an equidistant space between yarns (Y) to be wound and supplies the yarn (Y) that is wound around the belt outer side (132F) from a winding side (130R) to a unwinding side (130F).

Owner:MURATA MASCH LTD

Conveyor chain for harvester

ActiveCN106321733BPrevent internal frictionExtended service lifeHarvestersChain linksSprocketEngineering

Owner:JIANGSU DONGFA CHAIN CO LTD

Winding machine

PendingCN108454077AEvenly distributedIncrease the number of lapsDomestic articlesFinal product manufactureWinding machineShortest distance

The invention discloses a winding machine. The winding machine comprises a machine board, magnetic tension devices arranged at the top of the machine board, a supporting plate arranged in the middle of the machine board, a sliding table assembly, an up-down floating winding assembly and a thread height control assembly. The winding machine is simple in structure; winding rotating shafts drive winding rods to move from bottom to top, so that nylon threads are uniformly distributed, and the winding quality of a connecting plate is ensured; in addition, the nylon threads are uniformly distributed, so that the circle number of the nylon threads can be improved to a certain degree; a lifting motor controls the height of thread outlet planes by a lead screw; in addition, an air cylinder pushes acorresponding height control board to beside of the buffer connecting plate; when the winding rods wind, the nylon threads first get in contact with guide inclined planes, then pass through the thread outlet planes and wind two adjacent hollow driving shaft connecting plates, that is, the nylon threads leave from the thread outlet planes and immediately wind the two adjacent hollow driving shaftconnecting plates; with short distance, deviation of the nylon threads is avoided, and thereby the lifting motor well ensures the height of the nylon threads by the thread outlet planes, and the uniformity of the nylon threads is further improved; the application range of the winding assembly is wider.

Owner:淮安超跃橡塑有限公司

Grass trimmer

PendingCN112021009AAvoid entanglementWinding will notCuttersAgricultural engineeringStructural engineering

The invention discloses a grass trimmer. The grass trimmer comprises a rack, a mounting base arranged on the rack, a working shell detachably connected with the mounting base through a roller shaft, acutting structure arranged in the working shell and arranged on the roller shaft in a sleeving manner, a feeding assembly communicating with an inner cavity of the working shell and a driving assembly arranged on the rack and used for driving the roller shaft to rotate. A discharging port is arranged at the bottom of the working shell. The cutting structure comprises a first cutting assembly anda second cutting assembly which are arranged in a staggered manner, and the first cutting assembly and the second cutting assembly comprise main blades arranged on the roller shaft in a sleeving manner, first connecting rods arranged on the outer edges of the main blades and stirring pieces connected with the first connecting rods. According to the grass trimmer, dry forage grass cannot be wound on the roller shaft, the grass chopping capacity is high, and the forage grass can be uniformly chopped.

Owner:新晃侗族自治县相源农业有限公司

A cable multi-angle laying construction frame

ActiveCN108711787BRealize the function of adjustable angle transmissionWon't shakeFilament handlingApparatus for laying cablesStructural engineeringElectric cables

The invention relates to a cable multi-angle laying scaffold. The cable multi-angle laying scaffold comprises a support roof, a support bottom plate, a paying-off device and a support connecting column; a square slot is arranged in the middle part of the support bottom plate, the support roof is arranged on the top of the support bottom plate through the support connecting column, and the paying-off device is connected with the bottom of the support roof; the paying-off device comprises a guiding mechanism, a clamping mechanism and a distributing mechanism; the clamping mechanism comprises a clamping telescopic column, a clamping connecting rack, a clamping claw and a clamping spring. The problems that the cable can produce friction with the sidewall of a cable well when the existing cablerack performs the cable pay-off, the cable has the hidden danger of twisting on the escalator of the cable well, the twining can occur when the cable is conveyed in two directions, and a transmissionrack can shake when the cable is conveyed in the cable well can be solved, and the function of performing angle-adjustable conveying of the cable in the cable well can be realized.

Owner:湘潭潭州电力建设有限公司

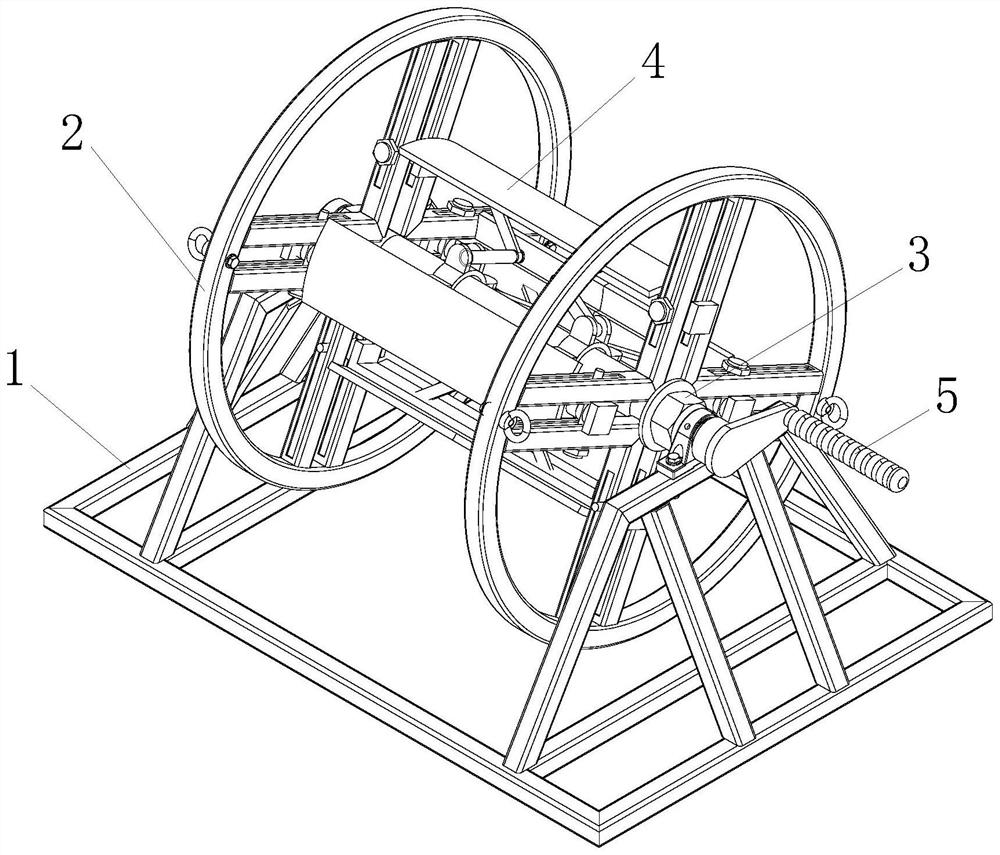

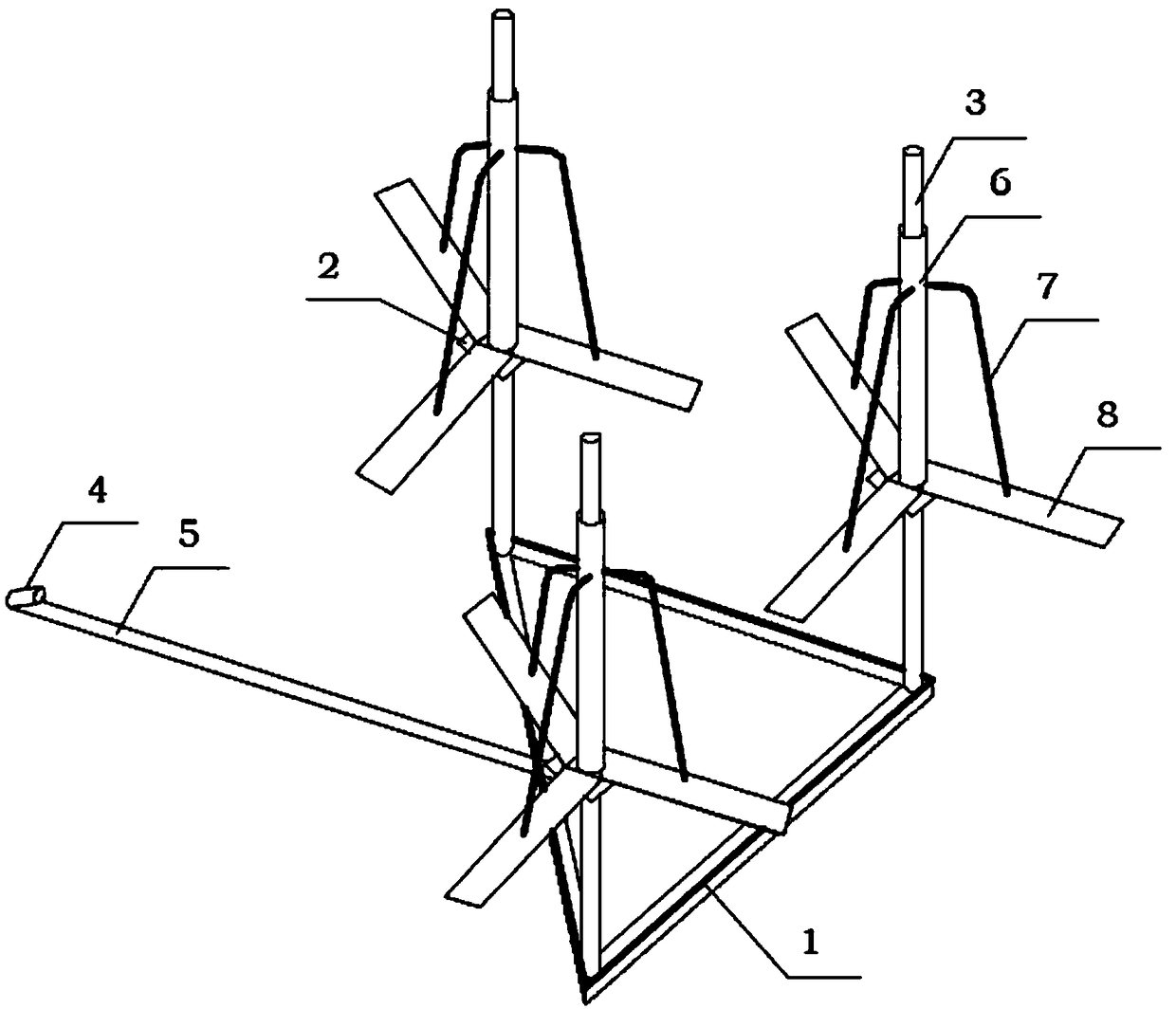

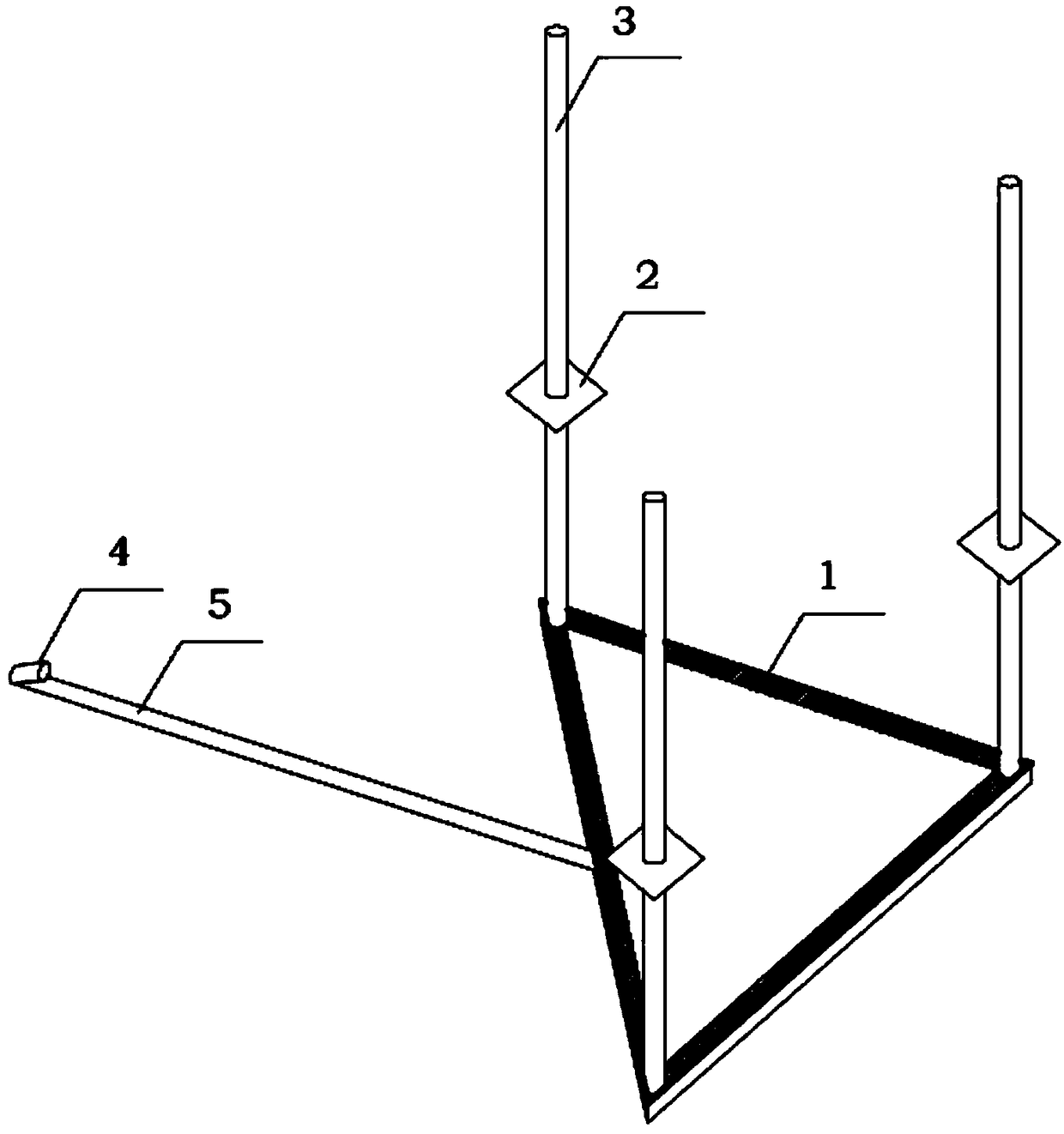

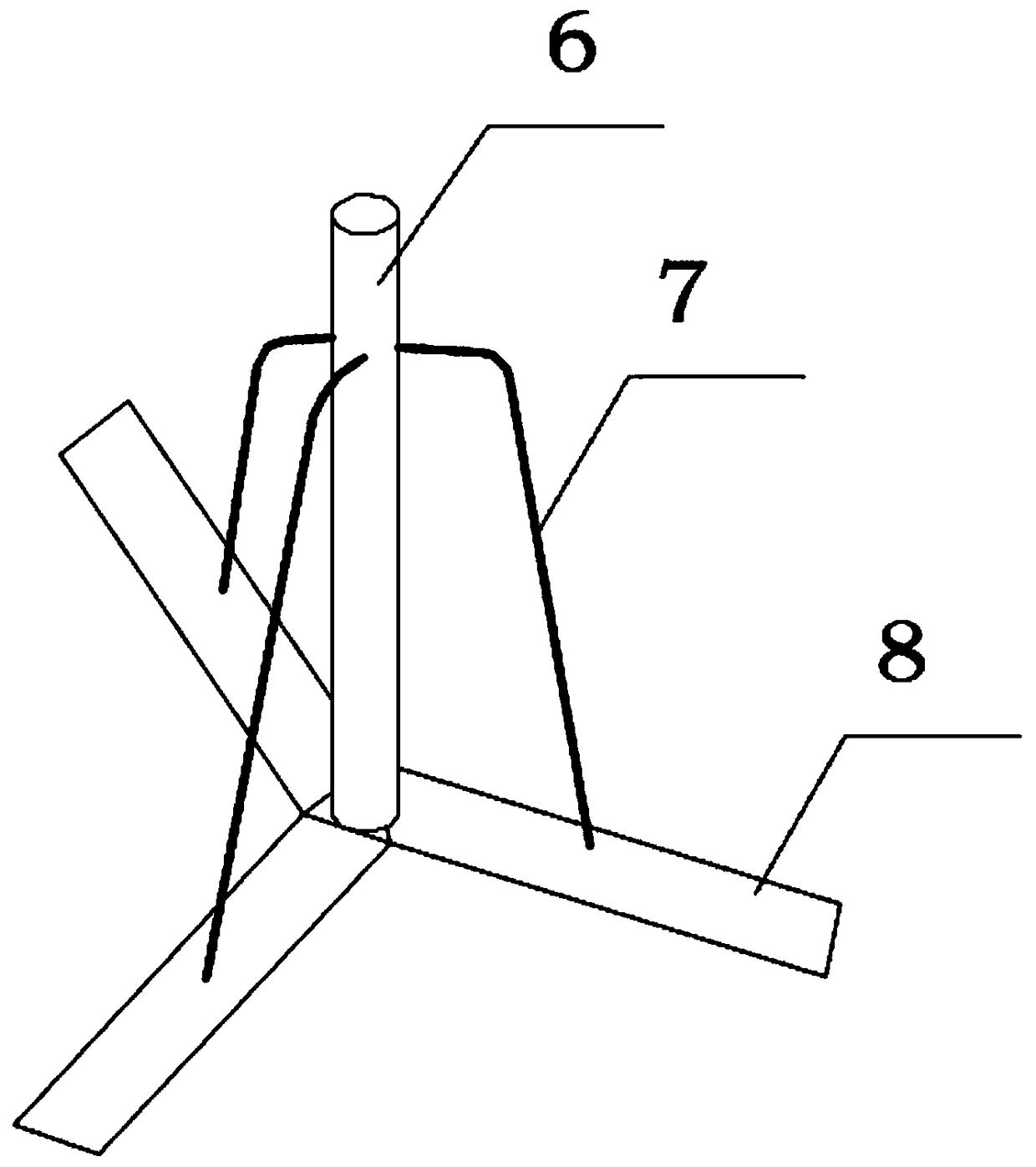

Multi-cable synchronous unwinding device

The invention provides a multi-cable synchronous unwinding device. The multi-cable synchronous unwinding device comprises an unwinding rack and unwinding cable reels, wherein the unwinding rack comprises a base, first connecting rods and a supporting rod, the base is of an equilateral triangle structure, the first connecting rods are fixedly connected above three end points of the base, supportingseats are further fixed on the first connecting rods, each supporting seat is rectangular, one side edge of the base is fixedly connected to one end of the supporting rod, the supporting rod is upwards inclined to the base 1, and the other end of the supporting rod is fixedly connected with a threading pipe; and the unwinding cable reels comprise second connecting rods and coil bottom frames, thesecond connecting rods are connected to the upper portions of the first connecting rods in a sleeving mode, and are located at the upper ends of the supporting seats, each coil bottom frame is rectangular, the coil bottom frames are fixedly connected to the lower ends of the second connecting rods, and coil supports are connected between the second connecting rods and the coil bottom frames. Themulti-cable synchronous unwinding device aims to solve the problems that an unwinding tool adopted during traditional construction site electrical installation is large in mass, is large in occupied area and can only assist a single cable in unwinding.

Owner:CHINA MCC17 GRP

A steel pipe automatic rotary spraying system and steel pipe rotary spraying process

The invention relates to a steel pipe automatic rotating and spraying system and a steel pipe rotating and spraying process. The steel pipe automatic rotating and spraying system comprises a supporting plate and a spraying device; mounting holes are uniformly formed in the supporting plate; through the mounting holes of the supporting plates, the steel pipe automatic rotating and spraying system is mounted on external mobile equipment; the spraying device is mounted at the top of the left end of the supporting plate; and the spraying device comprises an electric arc spraying machine, a fixingframe, a rotating frame, a rotating motor, a rotating connecting plate, a rotating mechanism, a rotating shaft, a clamping mechanism, a guiding mechanism, a rotating telescopic column, a follow-up connecting plate, an angle adjusting rod and a buffering spring. According to the steel pipe automatic rotating and spraying system, difficult problems that a user needs to hold spraying gun to perform spraying operation on an existing blow-off pipe during performing electric arc spraying on the existing blow-off pipe, potential safety hazards are available in manual operation, a spraying gun power supply wire is easy to wind during electric arc spraying, breakage can be caused during spraying a welding wire and so on can be solved.

Owner:龙元明筑科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com