Damping oil suction hose and manufacturing process thereof

An oil-absorbing hose and process technology, which is applied to siphons, hoses, pipes, etc., can solve the problems of poor flattening resistance, poor flexibility of the connecting parts at both ends, and small radial bearing capacity of the oil-absorbing hose, and achieves good strength and rigidity. , Good anti-suction performance, good anti-radial force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

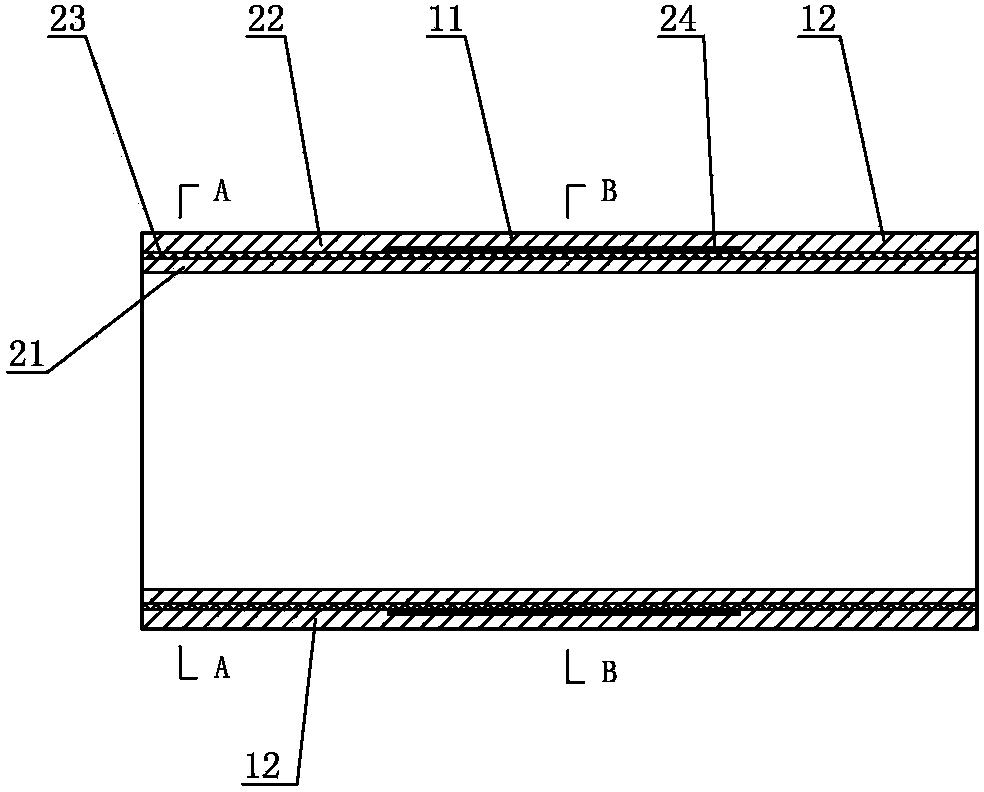

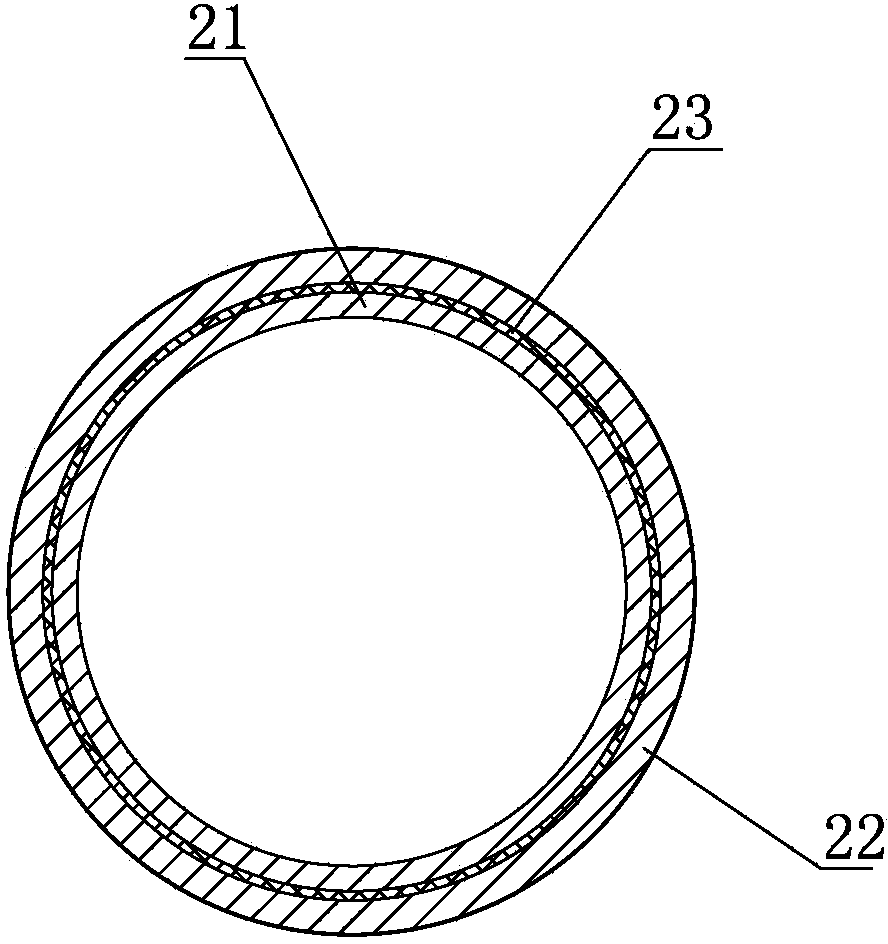

[0040] Such as figure 1 As shown, the shock-absorbing oil-absorbing rubber hose is a straight pipe. In the axial direction, there is a middle section 11 of the shock-absorbing oil-absorbing hose and connectors 12 connected to both ends of the middle section. Such as figure 1 with image 3 As shown, in the radial direction, the shock-absorbing oil-absorbing rubber hose includes an inner rubber layer 21, an outer rubber layer 22, and a fiber layer 23. The fiber layer is preferably a fiber mesh layer, and the fiber mesh layer has good bending performance and good tensile performance. In addition, the fiber mesh cloth layer has a net-like structure, and the fibers interact with each other. Therefore, not only the strength of the shock-absorbing oil-absorbing hose is better, but also its flexibility is good. Such as figure 1 with Figure 4 As shown, a steel wire 24 is wound between the fiber layer and the cover layer in the middle section.

[0041] The shock-absorbing oil-abso...

no. 2 approach

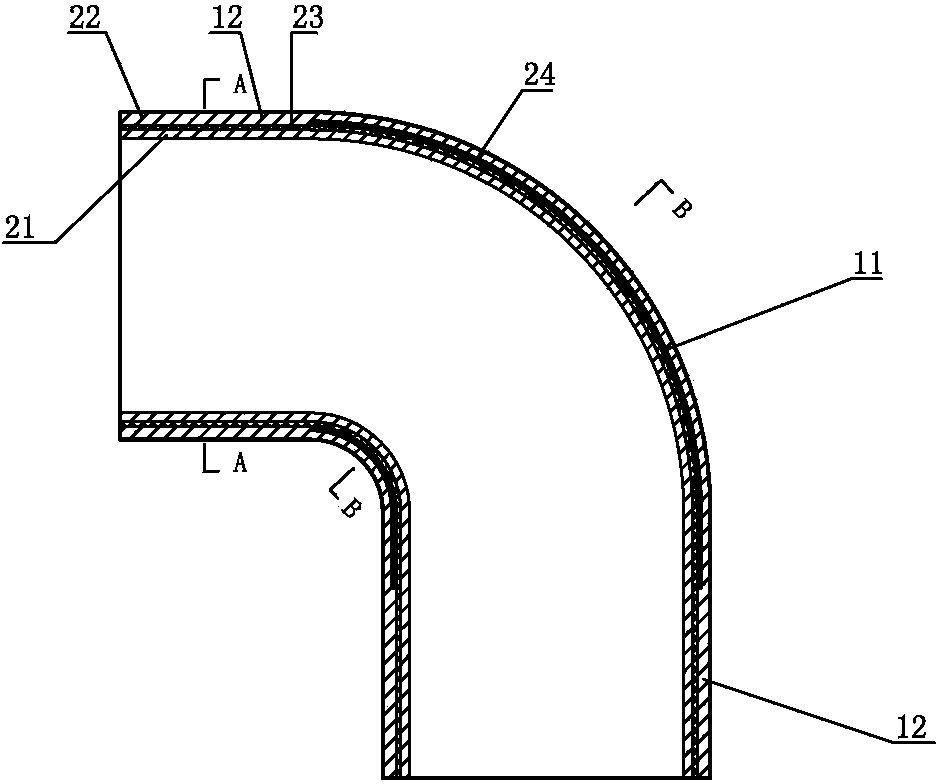

[0053] Such as figure 2 As shown, the shock-absorbing oil-absorbing hose is an elbow. In the axial direction, the middle section 11 of the shock-absorbing oil-absorbing hose and the connectors 12 connected to both ends of the middle section, wherein the curved part is the middle section. Such as figure 2 with image 3 As shown, in the radial direction, the shock-absorbing oil-absorbing rubber hose includes an inner rubber layer 21, an outer rubber layer 22, and a fiber layer 23. The fiber layer is preferably a fiber mesh layer, and the fiber mesh layer has good bending performance and good tensile performance. In addition, the fiber mesh cloth layer has a net-like structure, and the fibers interact with each other. Therefore, not only the strength of the shock-absorbing oil-absorbing hose is better, but also its flexibility is good. Such as figure 2 with Figure 4 As shown, a steel wire 24 is wound between the fiber layer and the cover layer in the middle section.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com