Conveyor chain for harvester

A technology for conveying chains and harvesters. It is applied in the direction of harvesters, belts/chains/gears, chain rings, etc. It can solve the problems of chain winding, troublesome cleaning, slipping teeth, etc., and achieve good sprocket anti-winding and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

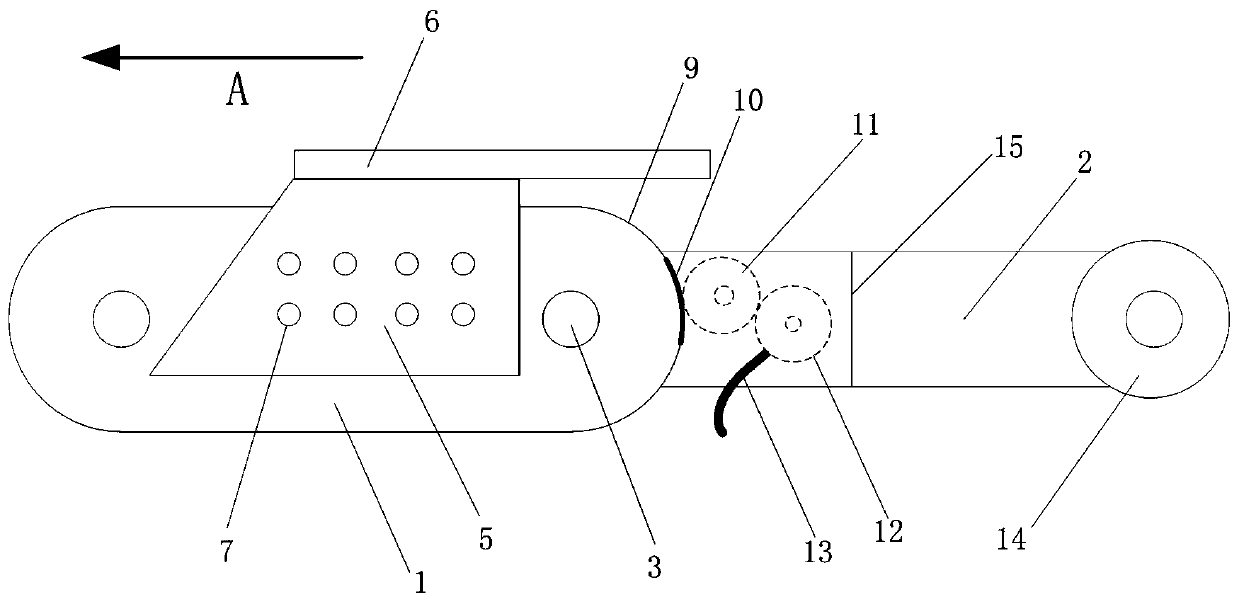

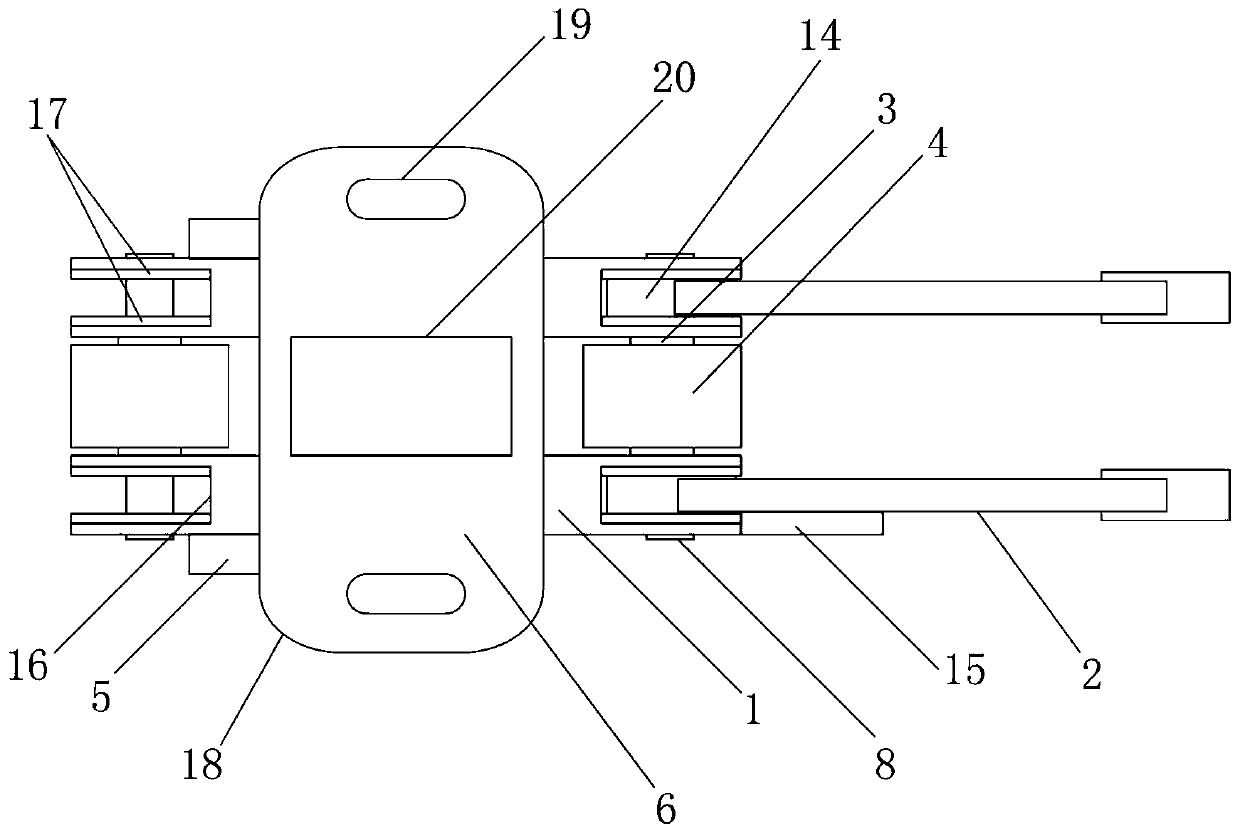

[0043] Such as figure 1 and 2 As shown, a conveyor chain for a harvester provided by the present invention is formed by linking each chain link in sequence; each chain link includes two main chain plates 1, two secondary chain plates 2, two sleeves 3, two rollers Sub 4, two pin shafts 8 and an anti-winding mechanism;

[0044] The two main chain plates 1 are arranged in parallel and facing each other;

[0045] The two sleeves 3 are arranged in parallel between the two main chain plates 1, and a ring of limiting collar is provided on the outer circumference of the sleeve 3;

[0046] The two rollers 4 are sleeved on the two sleeves 3 respectively, and a limit groove is provided on the inner circumference of the rollers 4;

[0047] The said limiting protruding ring is embedded in the limiting groove, and can be rotated relatively, and the position of the roller 4 is relatively fixed by using the cooperation of the limiting protruding ring and the limiting groove, which will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com