An anti-winding conveying chain for a harvester

A conveyor chain and anti-winding technology, which is applied in the field of conveyor chains, can solve problems such as chain winding, troublesome cleaning, and affecting the driving effect of chain transmission, so as to achieve good sprocket anti-winding and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

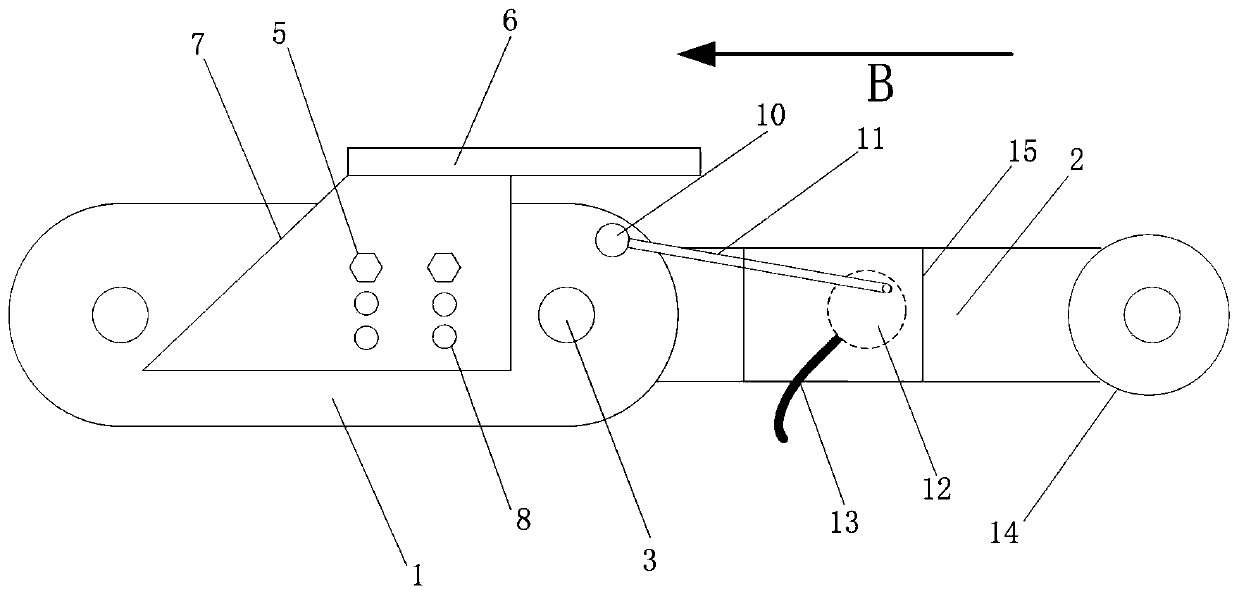

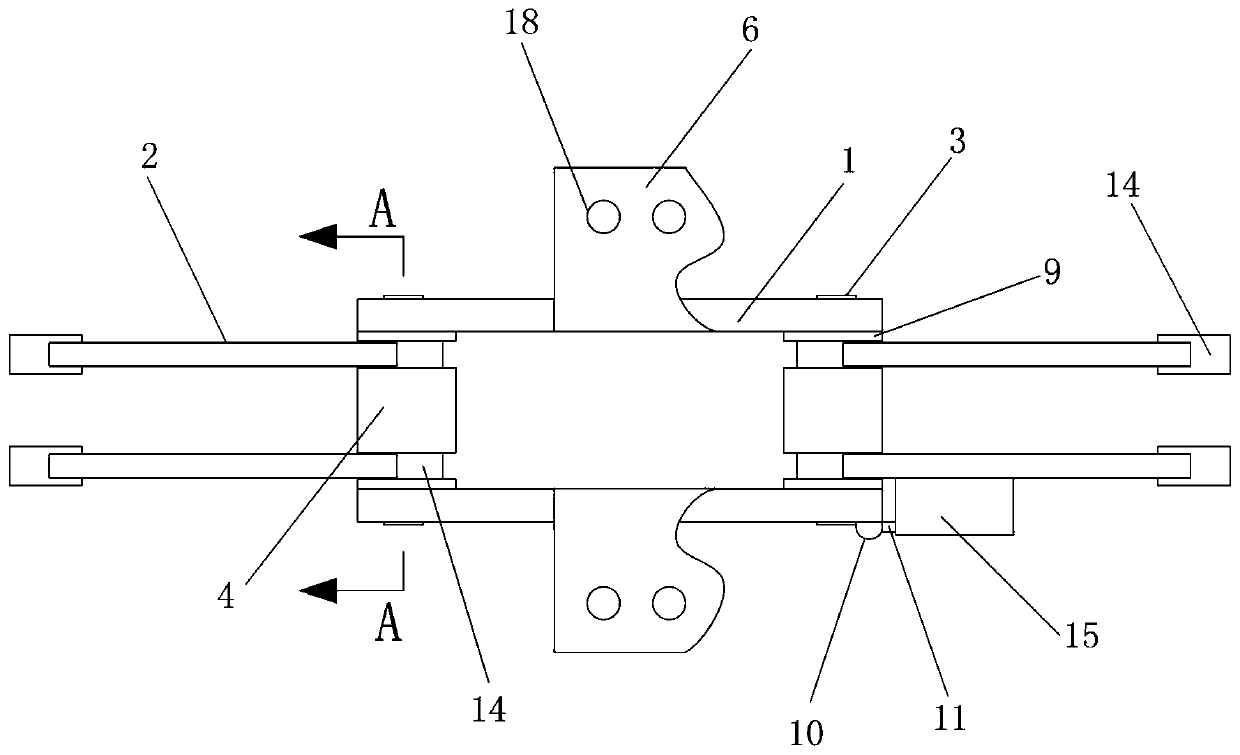

[0042] Such as Figure 1-3 As shown, the anti-winding conveying chain of the harvester disclosed by the present invention is composed of each chain link sequentially linked; each chain link includes two outer chain plates 1, two inner chain plates 2, two rollers 4, two pins Axis 3 and an anti-winding mechanism;

[0043] The two outer chain plates 1 are arranged in parallel and facing each other;

[0044] Both ends of the pin shaft 3 are vertically and rotatably installed on the two outer chain plates 1;

[0045] The two pin shafts 3 are parallel to each other and are respectively located at the two ends of the outer chain plate 1;

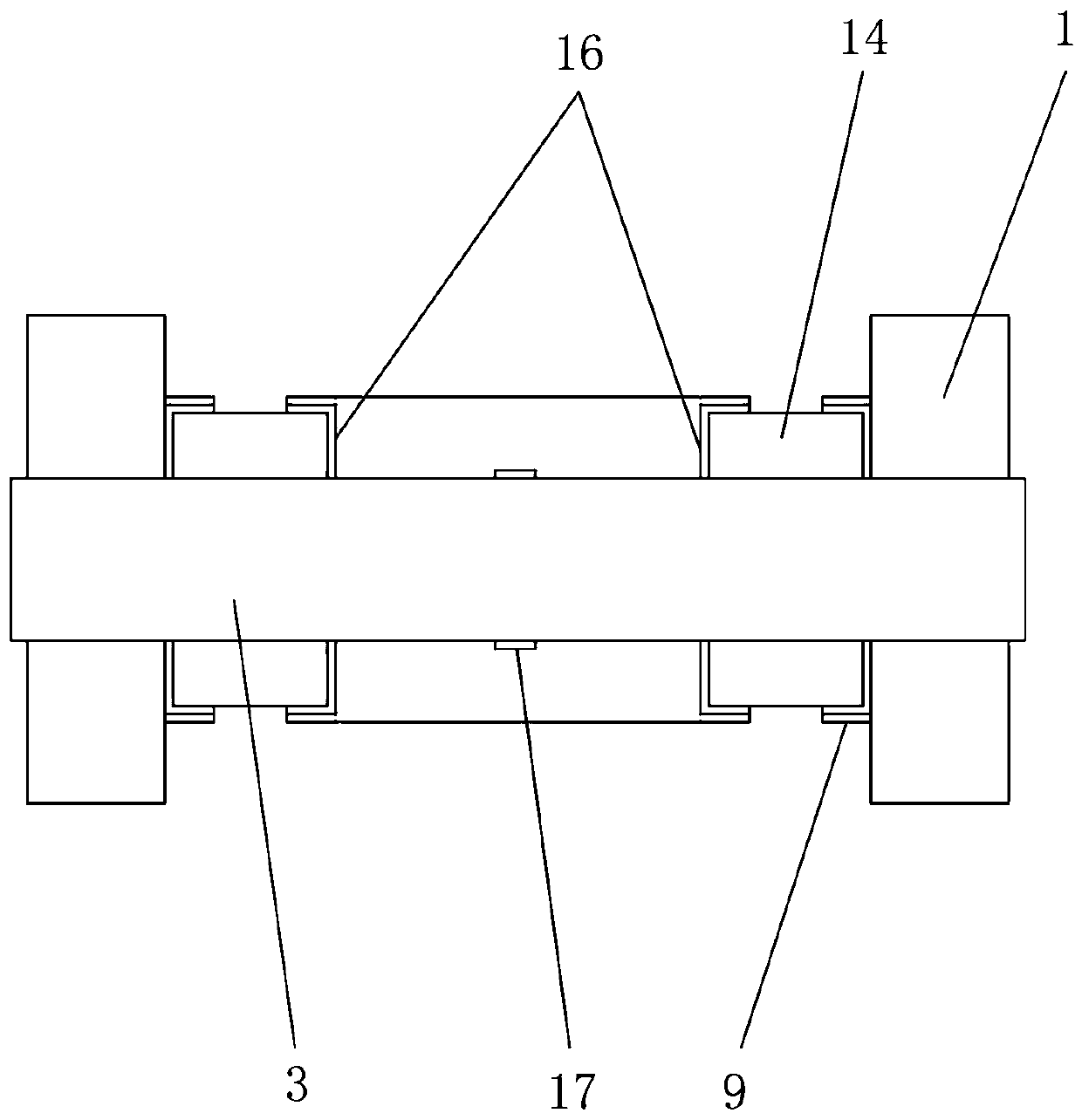

[0046] Both ends of the inner chain plate 2 are provided with a shaft sleeve 14, and the thickness of the shaft sleeve 14 is greater than the thickness of the inner chain plate 2, so that it is convenient to set the two ends of the shaft sleeve 14 and effectively prevent the outer chain plate from 1 and inner chain plate 2 chain joints and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com