Yarn winding device

A winding device and yarn technology, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of yarn unwinding and looping, yarn breakage, and package winding stop. , to achieve the effect of preventing looping, preventing yarn breakage, and preventing poor lead-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

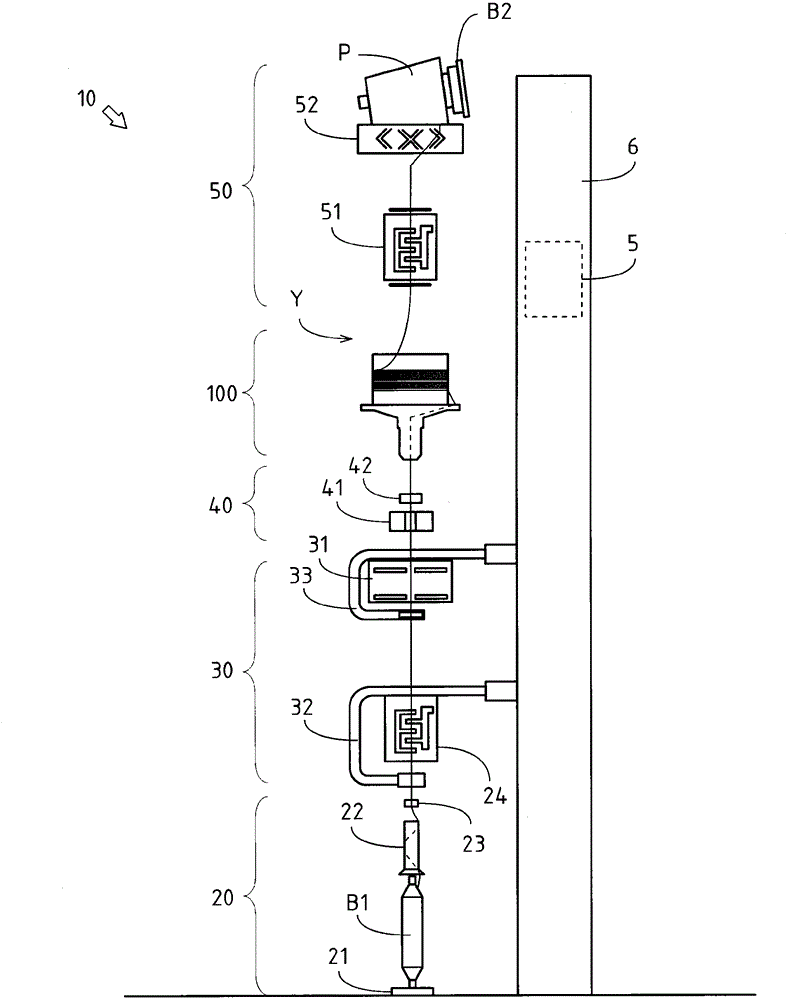

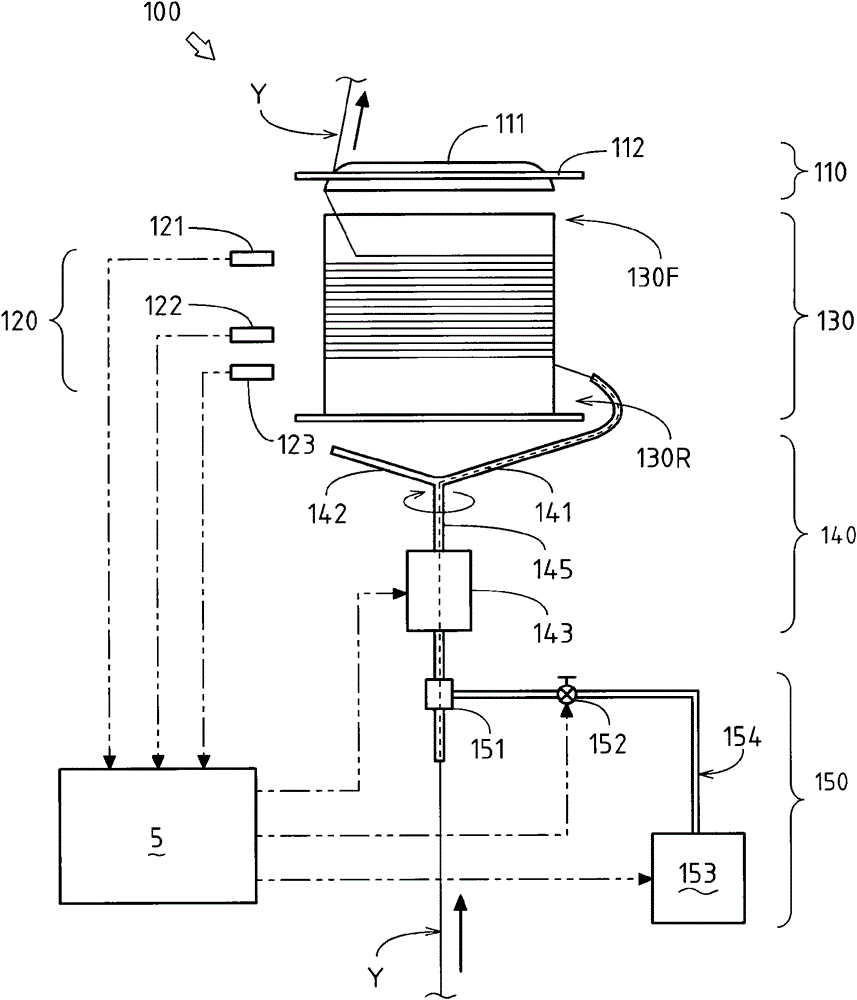

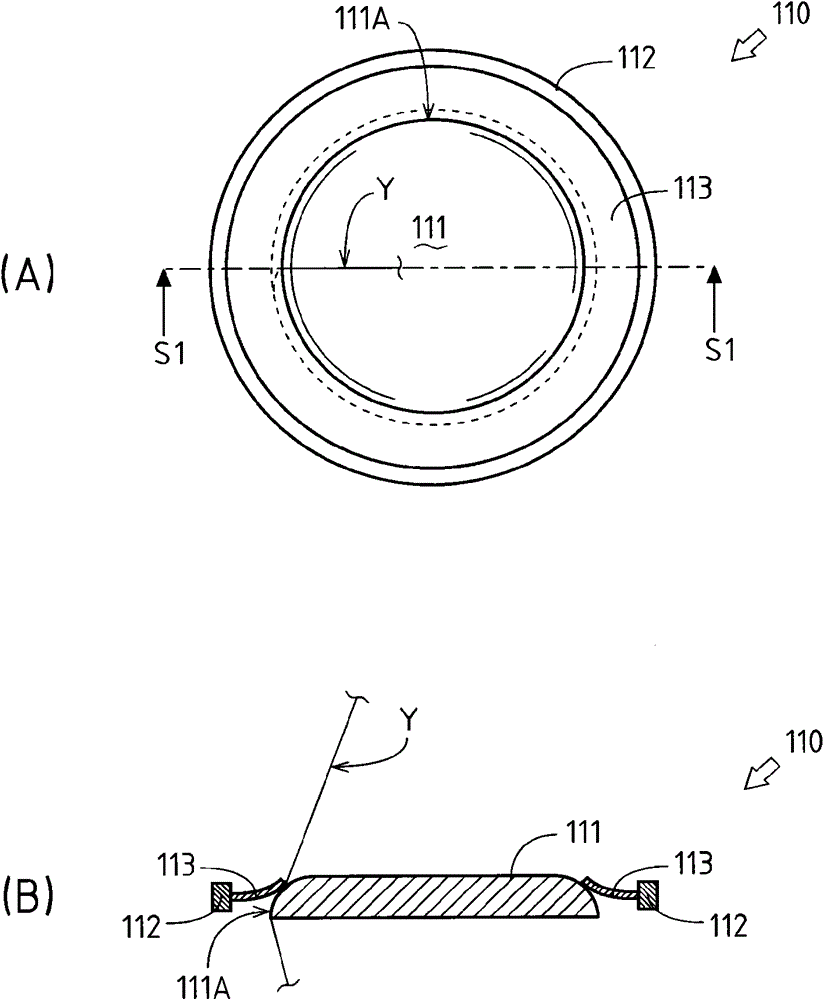

[0034] use figure 1 , the winding unit 10 of the first embodiment of the automatic winding device of the present invention will be described.

[0035] The winding unit 10 is a device that removes yarn defects on the yarn supplying bobbin B1 around which the yarn Y spun by the spinning machine is wound, and forms a package P for winding. The winding units 10 are arranged side by side along the longitudinal direction of the machine bed of the automatic winder.

[0036] The structure of the winding unit 10 will be described.

[0037] The winding unit 10 includes a controller 5 , a frame 6 , a yarn supplying unit 20 , a yarn joining unit 30 , a yarn defect detecting unit 40 , a yarn accumulating device (accumulator) 100 , and a winding unit 50 .

[0038] The frame 6 is a device that supports each device constituting the winding unit 10 . The frame 6 supports the yarn supplying unit 20, the yarn joining unit 30, the yarn defect detecting unit 40, the yarn accumulating device 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com