Concrete placing equipment

A material distribution device and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of hidden safety hazards, large rotational resistance, easy blockage, etc., and achieve the effects of improving flexibility, convenient operation, and improving lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

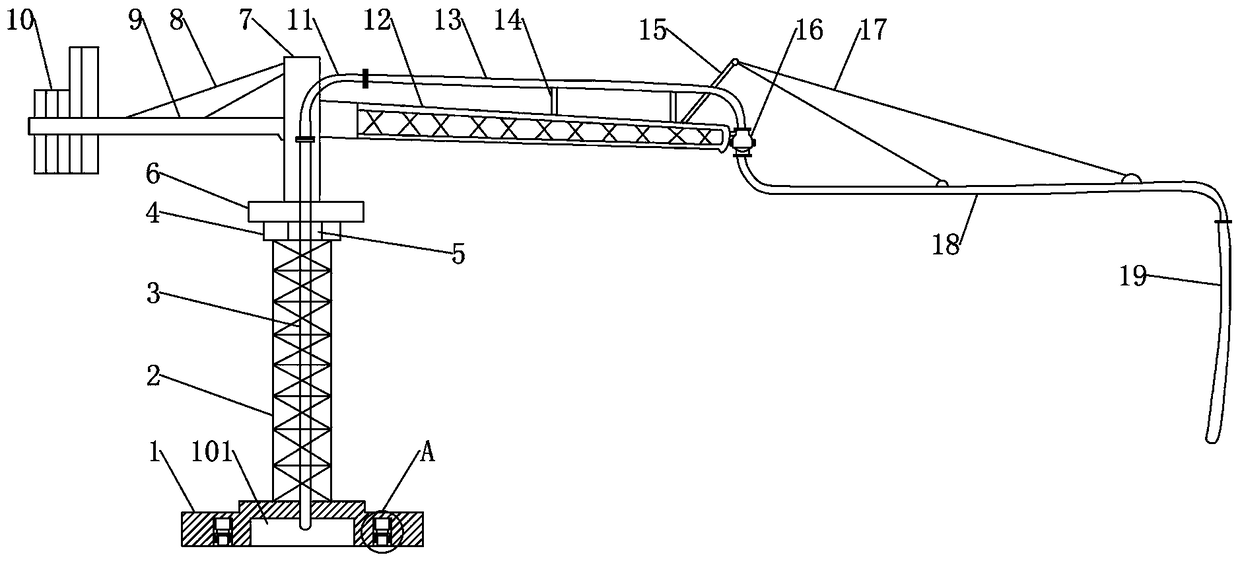

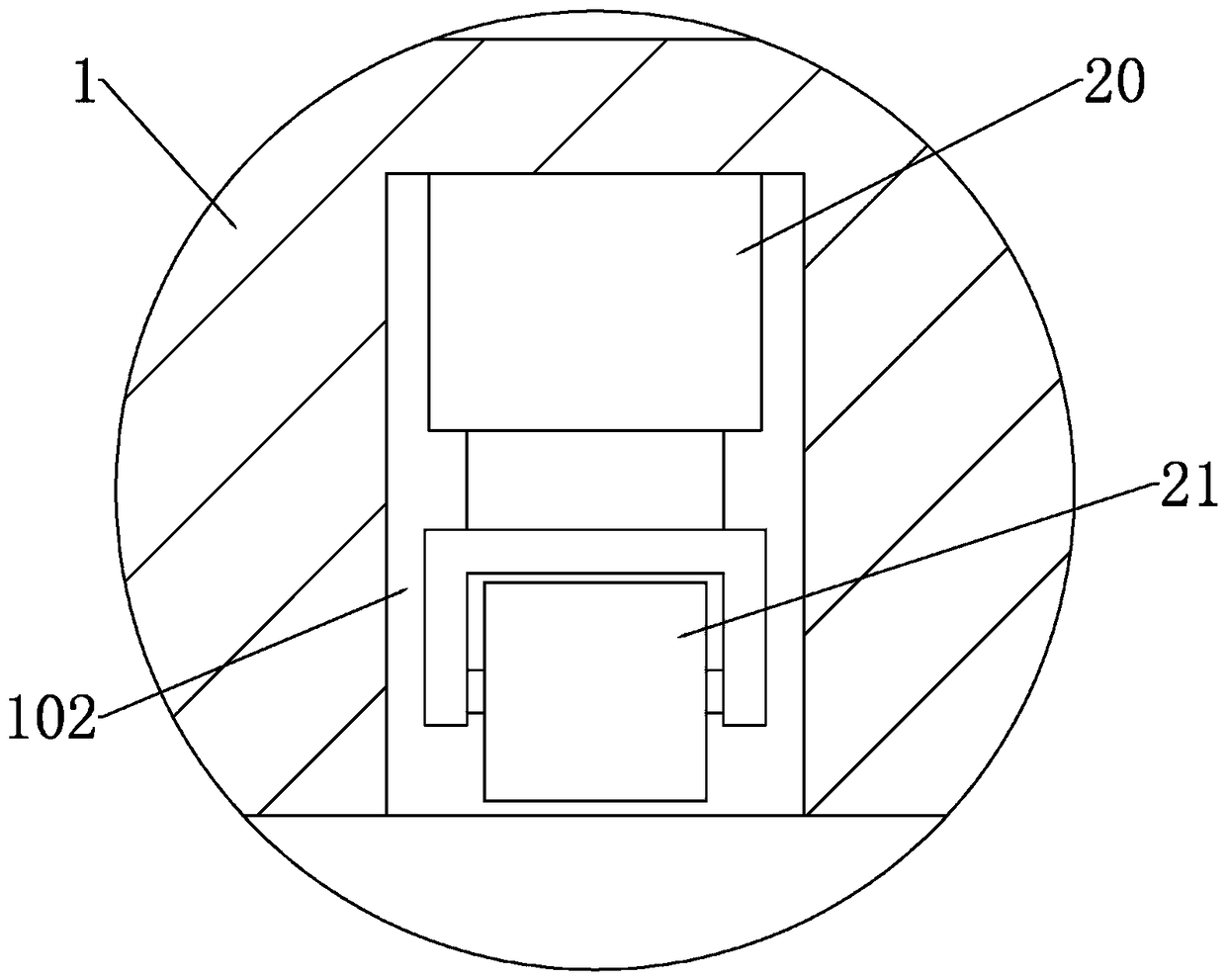

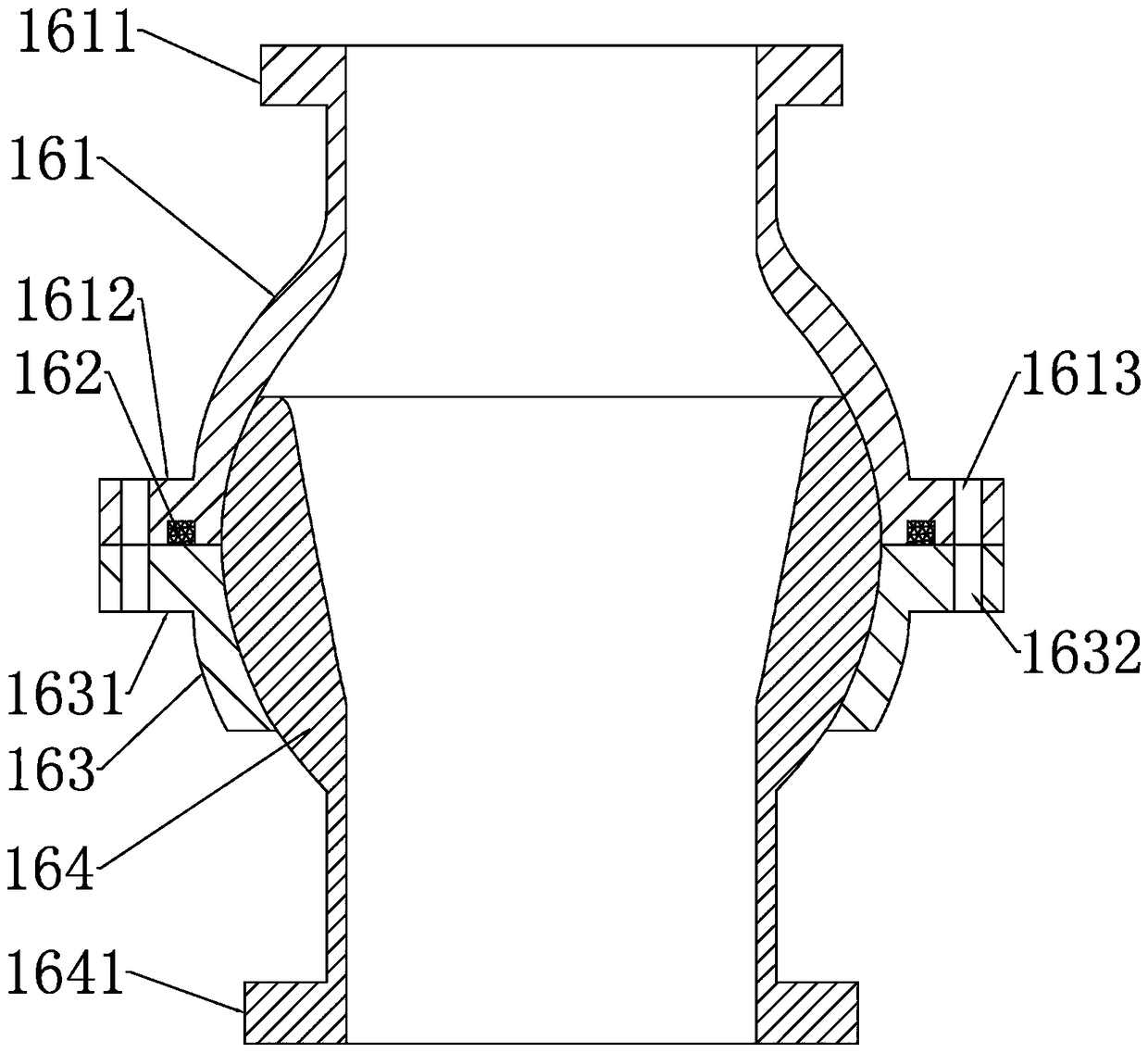

[0019] Embodiment one: if Figure 1-3 As shown, the concrete distributing device includes a base 1, a stand 2, an upper mounting seat 6, a balance arm 9, a main beam 12 and a feeding pipe. Bearing seat 4, a slewing bearing 5 is set in the bearing seat 4, the lower end of the upper mounting seat 6 is set in the slewing bearing 5, the balance arm 9 and the main beam 12 are respectively arranged on both sides of the upper mounting seat 6, and the end of the balance arm 9 A counterweight box 10 is provided. The feeding pipe comprises a standpipe 3, a transverse pipe 13, a rotating pipe 18 and a discharge hose 19, the standpipe 3 is fixedly mounted in the stand 2, the transverse pipe 13 is fixedly installed on the upper end of the balance arm 9, and the standpipe 3 The upper end and the rear end of the transverse pipe 13 are connected through the connecting elbow 11, the front end of the transverse pipe 13 and the rear end of the rotating pipe 18 are rotationally connected through...

Embodiment 2

[0022] Embodiment two: see Figure 4 , on the basis of Embodiment 1, in order to further improve the flexibility of the distribution device, the upper end surface of the upper mounting base 6 is provided with an upper mounting base hinged seat 61, and the lower end surface of the main beam 12 is provided with a main beam hinged seat 121. A swing arm hydraulic cylinder 22 is arranged between the hinged seat 61 of the mounting seat and the hinged seat 121 of the main beam. In the beam hinge seat 121; the side wall of the upper support 7 is provided with an upper support hinge seat 71, and the rear end of the main beam 12 is hinged in the upper support hinge seat 71; the connecting elbow 11 is a soft connecting pipe, which can be used Cloth tube. The main beam 12 can swing up and down through the drive of the swing arm hydraulic cylinder 22, which improves the lift of the pipeline, further improves the flexibility of the material distribution device, and is more convenient to us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com