Pressure testing device of tappet body

A technology of pressure testing and rod body, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, measuring force, etc., can solve the problems of low test efficiency, increase production cost, complex structure, etc., and achieve improved test Efficiency, high power transmission efficiency, smooth motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

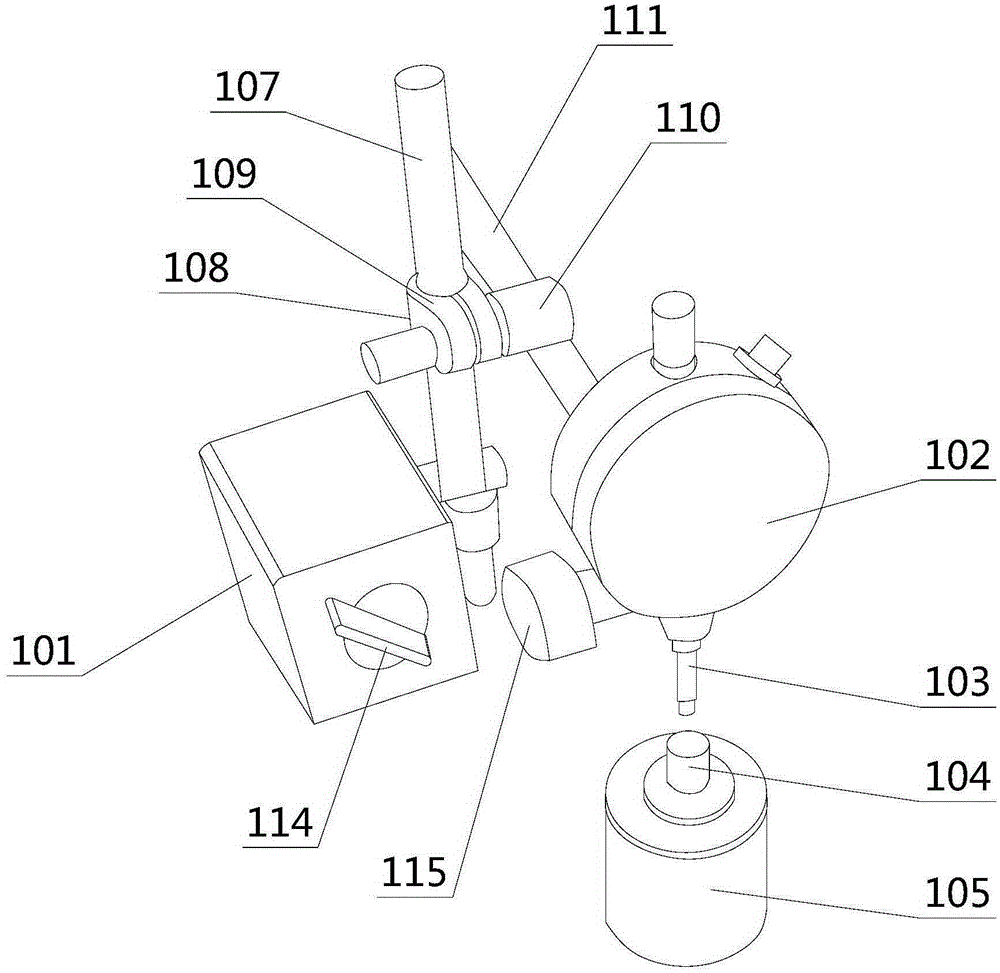

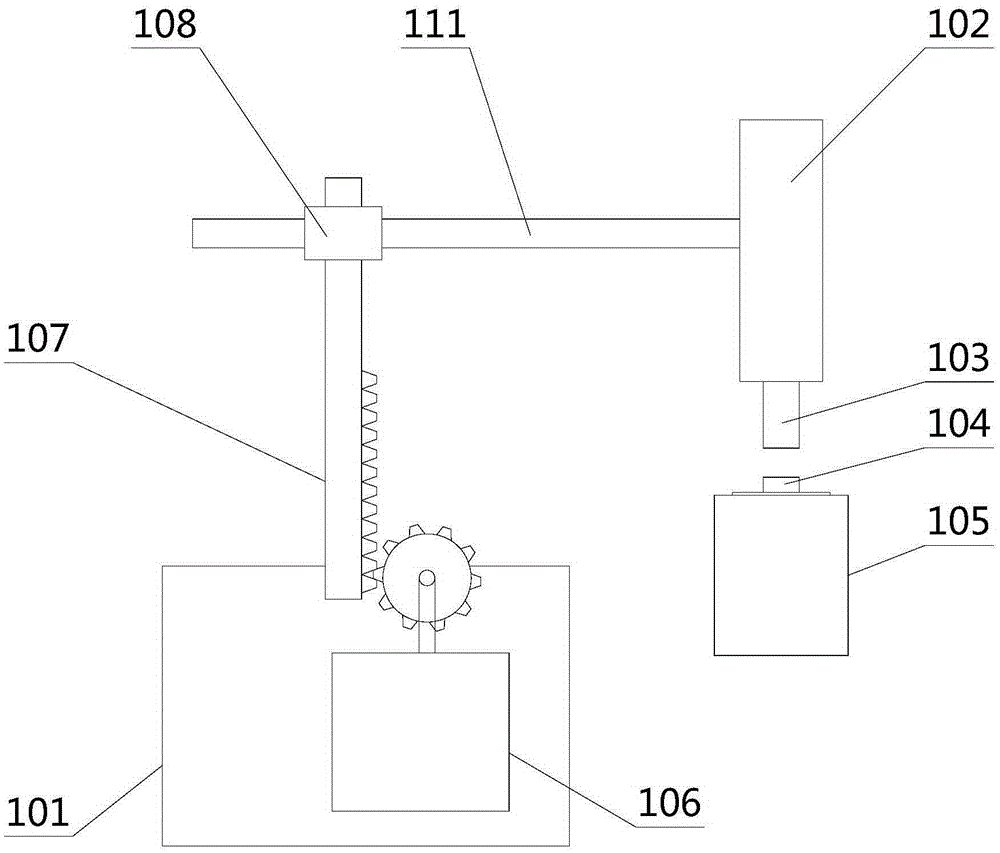

[0036] see figure 1 with figure 2 , the present embodiment provides a tappet body pressure testing device, the tappet body pressure testing device includes a base 101 and a dynamometer 102, the base 101 is provided with a lifting device, the lifting device is fixedly connected to the dynamometer 102, and the dynamometer 102 is provided with a test head 103 . The tappet body pressure testing device also includes a fixed sleeve 105 that can cooperate with the tappet body 104. The fixed sleeve 105 is arranged under the test head 103. When the lifting device drives the dynamometer 102 to move downward, the test head 103 presses the tappet body 104. .

[0037] When the tappet body pressure testing device provided in this embodiment is in use, the tappet body 104 is installed on the fixed sleeve 105, the lifting device is activated, and the lifting device drives the dynamometer 102 to move downward, so that the test head 103 presses the tappet body 104, And continue to apply for...

no. 2 example

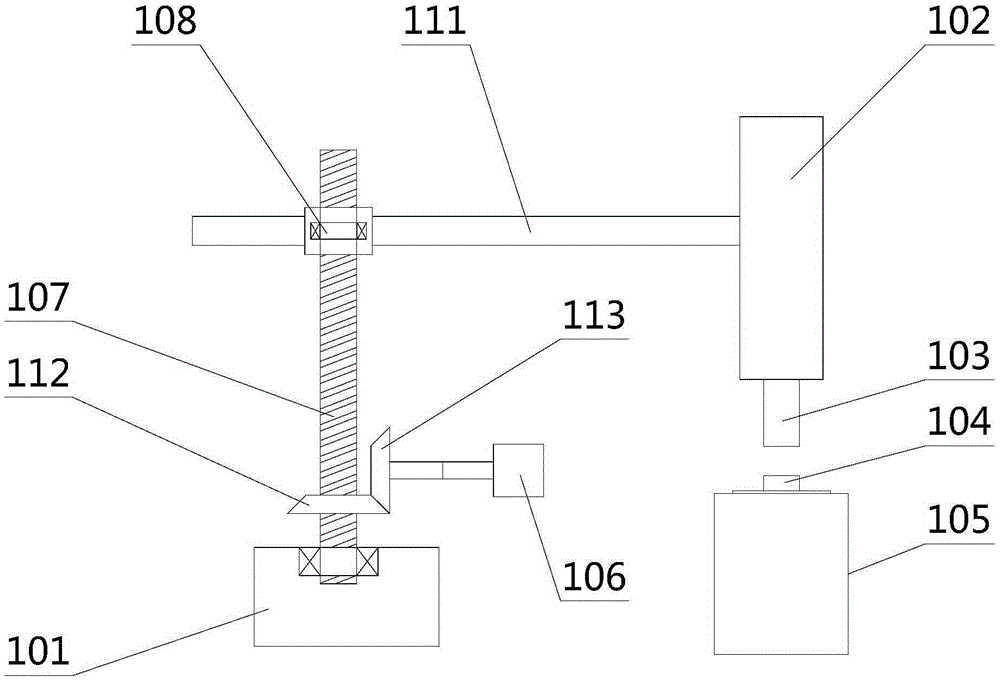

[0053] The difference between the tappet body pressure testing device provided in this embodiment and the tappet body pressure testing device provided in the first embodiment lies in that the structure of the lifting mechanism is different.

[0054] Specifically, see image 3 , in the present embodiment, vertical rod 107 is screw rod, and the lower end of screw rod is fixed on the base 101 by bearing, and the lower end of screw rod is provided with first bevel gear 112, and motor 106 is connected with second bevel gear 113, and first bevel gear 112 and The second bevel gear 113 cooperates, the fixing part 108 is connected with the nut through the bearing, and the nut cooperates with the screw rod.

[0055] The motor 106 drives the first bevel gear 112 through the second bevel gear 113, and the rotation of the first bevel gear 112 drives the screw to rotate, and the screw is fixed to the base 101 through a bearing. Then, when the screw rotates, the nut moves linearly on the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com