One-stop electrical logging tool for composite battery busbar multifunctional testing

A multi-functional testing and compounding technology, applied in the field of machining, to avoid complicated operations and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

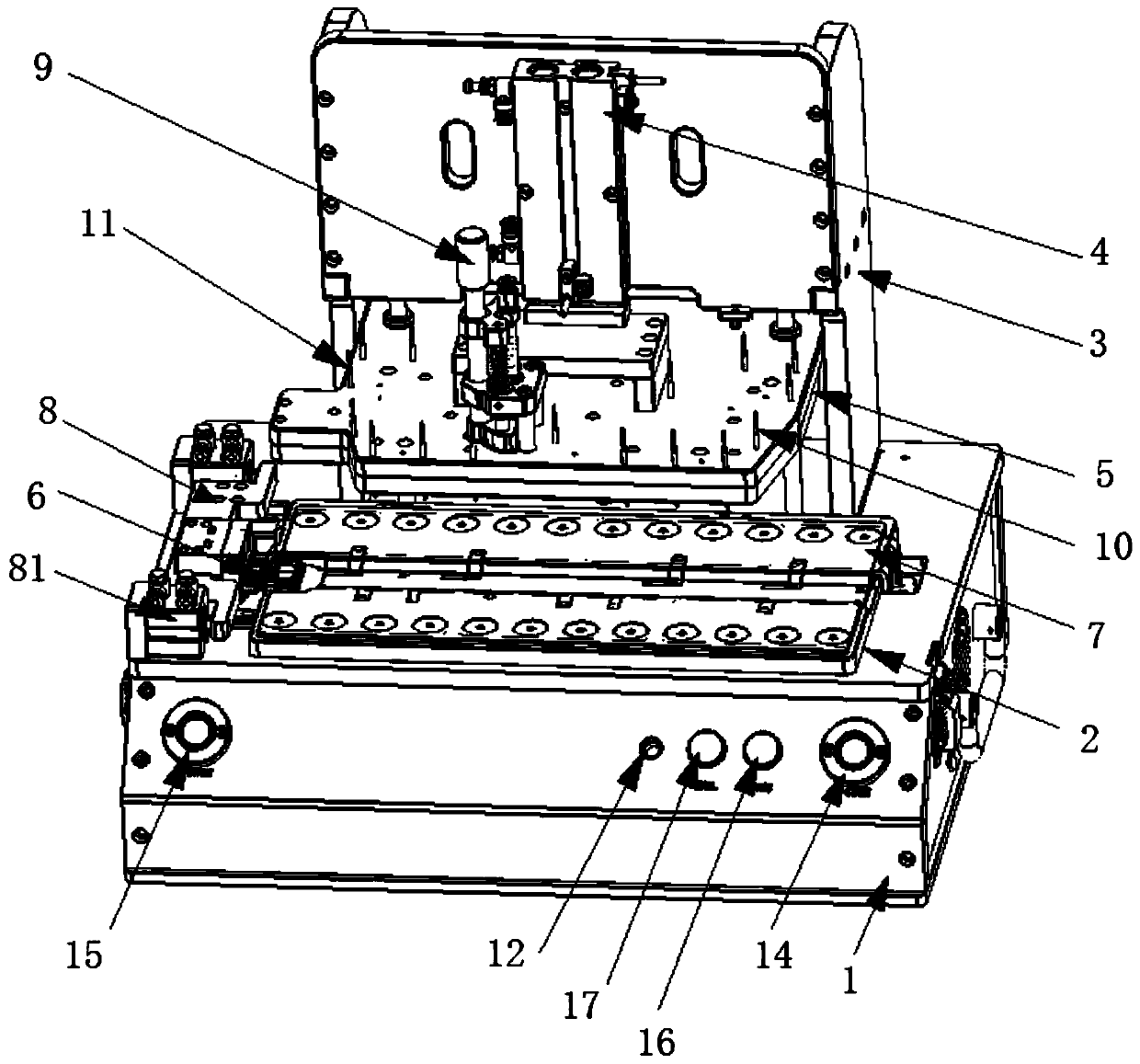

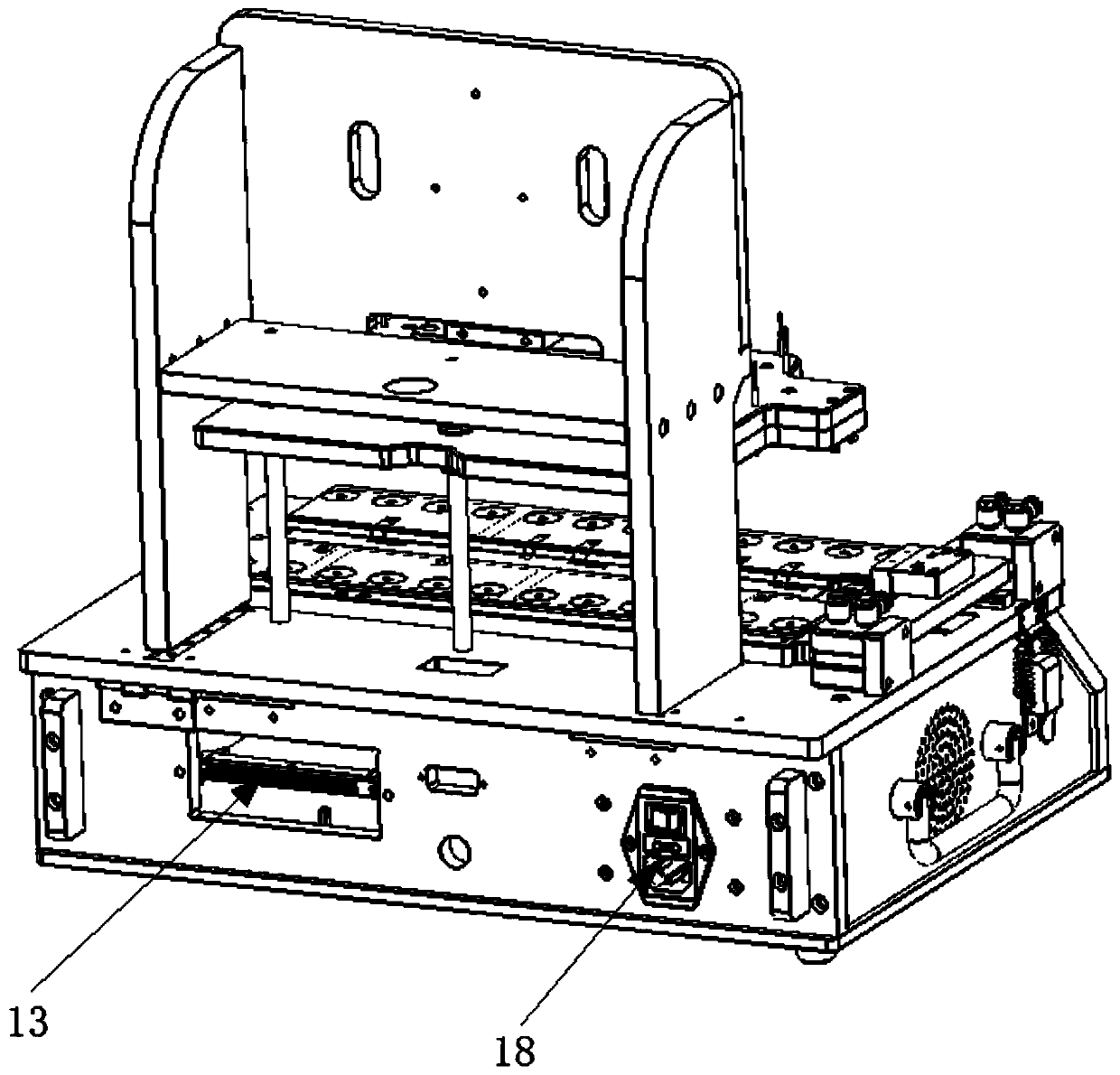

[0018] Such as figure 1 , 2 As shown, an embodiment of the present application provides a one-stop electrical testing tool for multifunctional testing of composite battery busbars, and the one-stop electrical testing tool for multifunctional testing composite battery busbars includes: base 1 , Positioning frame 2, bracket 3, driving rod 4, leveling mechanism 5, connector 6; the positioning frame 2 and the bracket 3 are respectively arranged on the base 1, and the driving rod 4 is arranged on the bracket 3, and the bottom is connected to the leveling mechanism 5. The drive rod 4 drives the leveling mechanism 5 to reciprocate up and down; the positioning frame 2 is fixed on the base 1 and is located on the leveling mechanism Below the mechanism 5, the connector 6 is arranged on the base 1 and located between the two positioning frames 2.

[0019] The test product 7 is leveled on the positioning frame 2 by setting the leveling mechanism 5, and the driving rod 4 is used to move the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com