High-frequency transformer common-mode noise and conduction radiation testing method

A high-frequency transformer, common mode noise technology, applied in the field of transformer quality inspection, can solve the problem of inability to timely and effectively monitor, inability to effectively reflect the impact of common mode noise and conduction radiation of the coil winding potential distribution shielding layer, company and customer losses, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

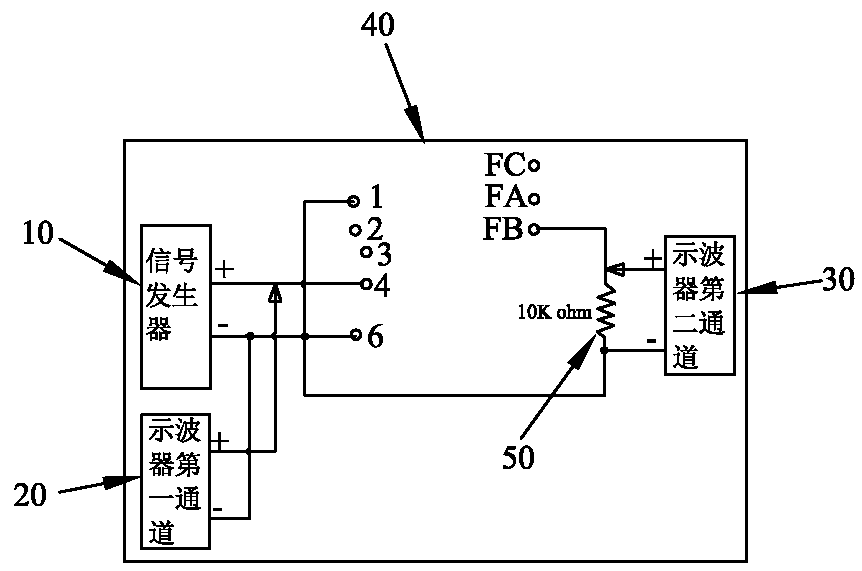

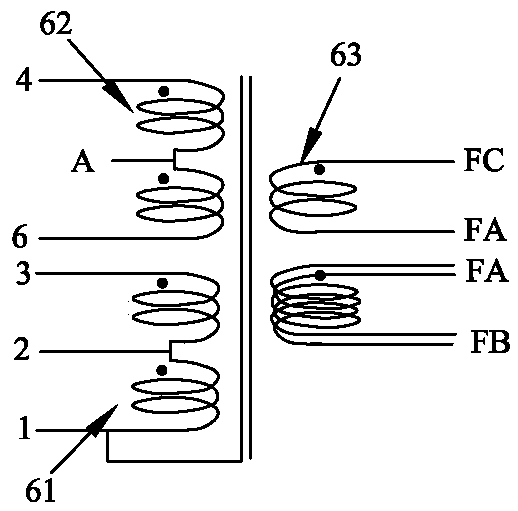

[0040] Please refer to figure 1 with figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention. It is a high-frequency transformer common-mode noise and conducted radiation test method, which is used for the common-mode noise CMN and conducted radiation EMC test of high-frequency transformers. When only testing the pins of the transformer itself, you can know the size of the common mode noise and conducted radiation generated by the transformer itself corresponding to the power supply. composition. Test the common mode noise and conduction radiation data of the whole machine as the reference standard for the coupling voltage test, or use self-made transformer internal shielding winding open-circuit defective products and good product samples, refer to good products and defective products to formulate the upper and lower limit test ranges corresponding to VPP, and pass the above equipment Connection test to determine the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com