Ion-exchange process technique of hexavalent chrome-containing waste water

An ion exchange method and treatment process technology, applied in the field of wastewater treatment technology, can solve the problems of low degree of automation, complex resin regeneration and maintenance operations, resin pollution, etc., and achieve high degree of automation, good wastewater treatment effect, and good treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

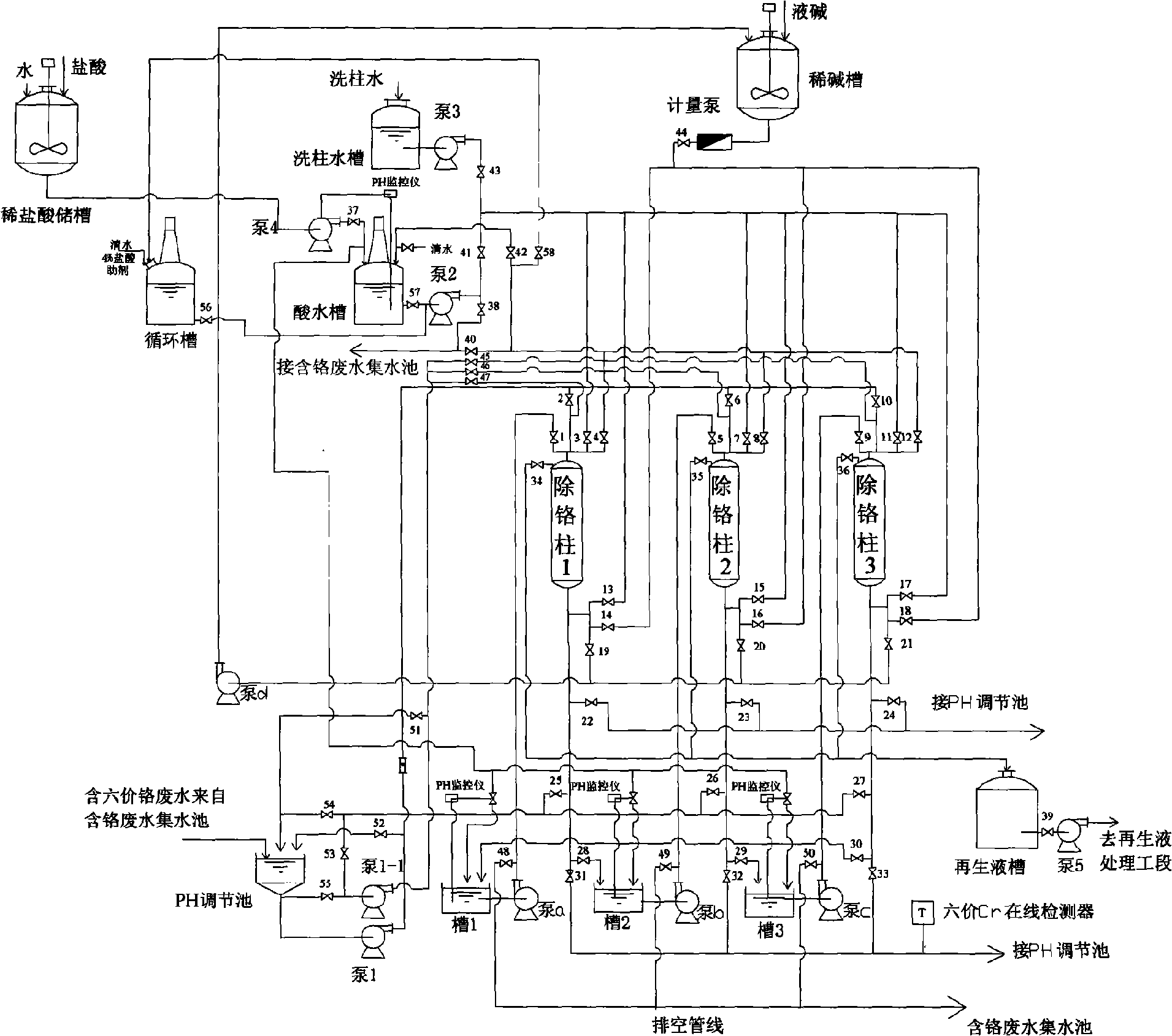

Image

Examples

Embodiment 1

[0030] The water quality of chromium-containing wastewater in an electroplating plant is shown in Table 1:

[0031] Table 1 The maximum concentration of pollutants in chromium-containing wastewater mg / L

[0032] Wastewater type

Water volume (m 3 / d)

pH

Cr 6+

Cr 3+

Cu 2+

Ni 2+

Zn 2+

CN -

Chromium-containing wastewater

100

0.5-0.7

150

30

10

8

6

5

[0033] The effluent after the process of the present invention is required to reach Cr 6+ Concentration <0.5mg / L, the specific equipment and operation are as follows:

[0034] 1. Equipment:

[0035] Chromium removal column: according to the design of three columns, the resin volume of a single column is 2m 3 , the resin is D301 / D301T, the material of the exchange column is glass fiber reinforced plastic, and the height of the resin accounts for 2 / 3 of the height of the whole column. A cyanide online monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com