Support assembly and construction method of cast-in-place box girder

A technology of supporting components and construction methods, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high construction risks, many risk factors, and unstable supports, so as to reduce engineering costs, ensure construction safety, and ensure The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0020] The invention provides a supporting component of a cast-in-place box girder.

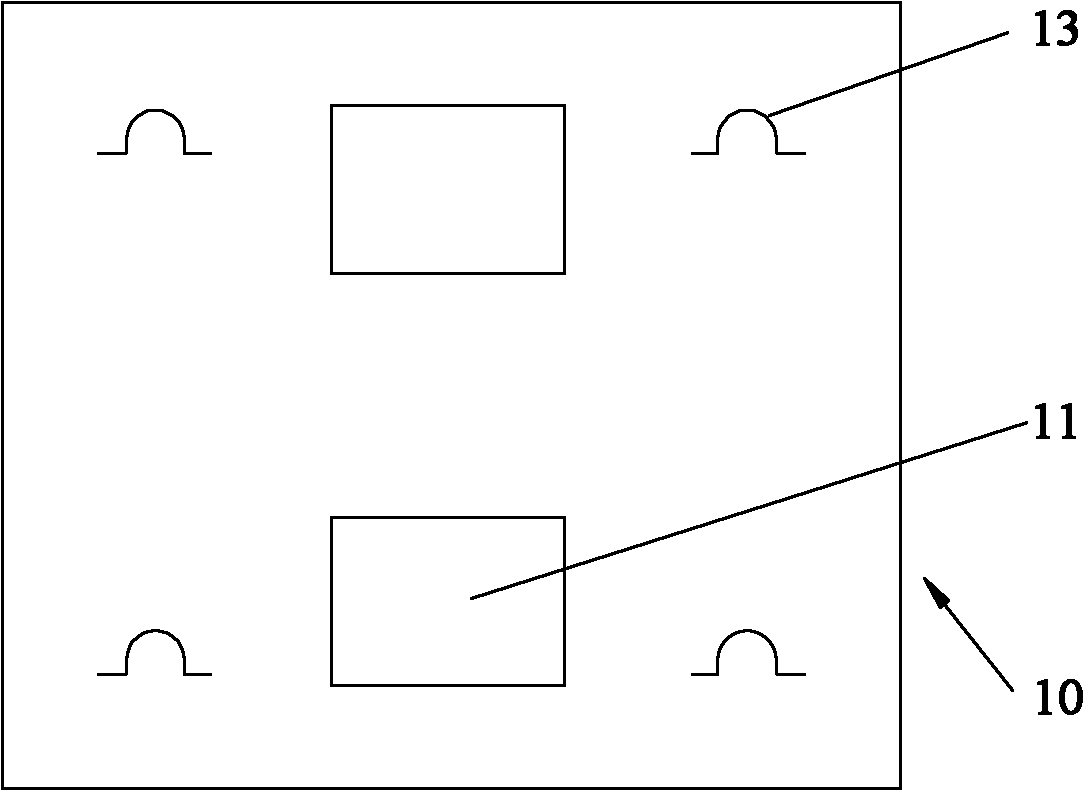

[0021] The support assembly of the cast-in-place box girder according to the present invention includes: a prefabricated base 10 for a temporary pier, which is a reinforced concrete prefabricated part;

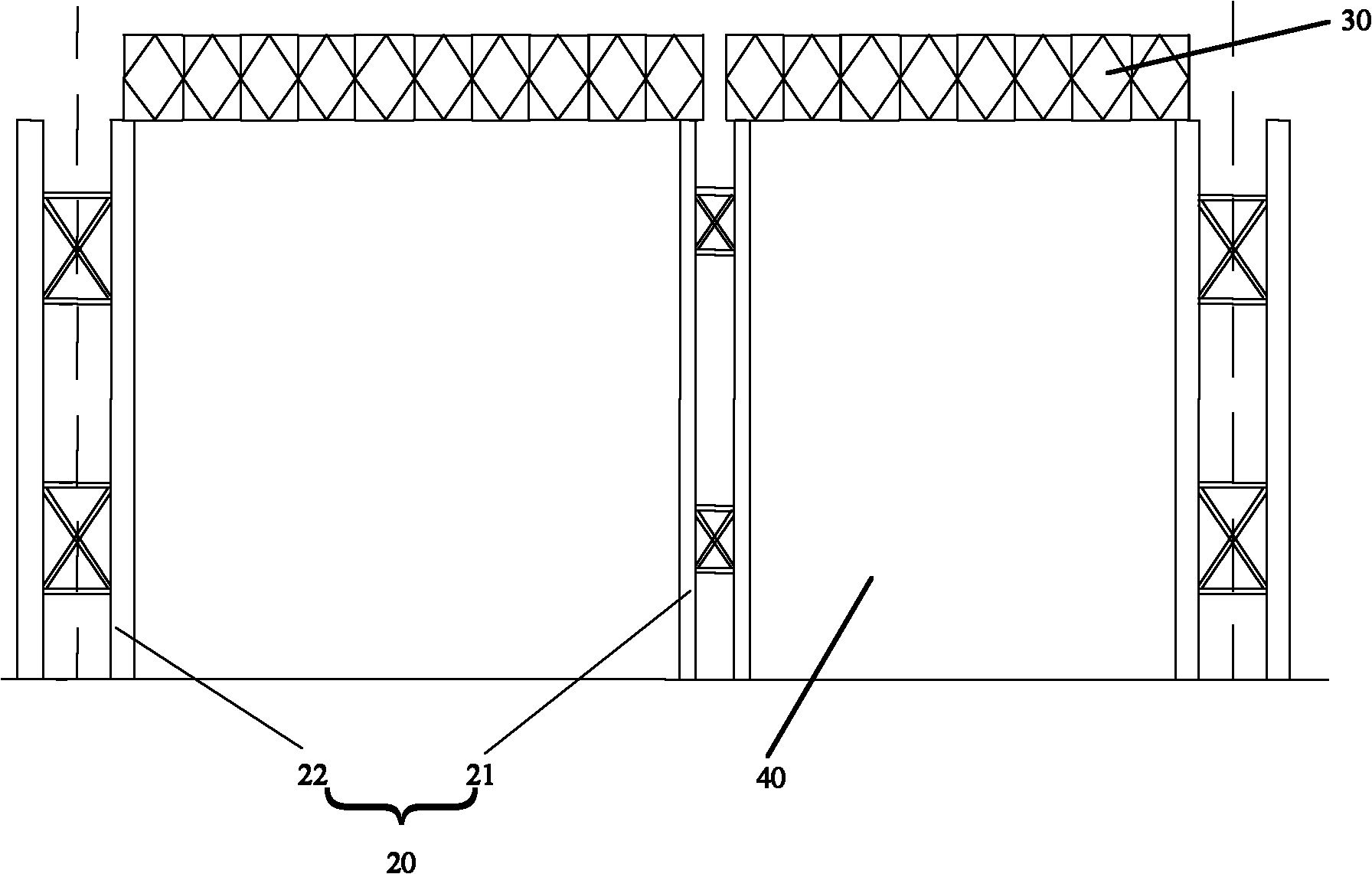

[0022] Such as figure 1 Shown, the present invention is provided with in the mid-span of cast-in-situ box girder and around the permanent buttress of bridge body temporary buttress 20 is set, is used for supporting and strengthening beam body and the permanent buttress of reinforced concrete structure that has built, and , during construction, the cast-in-place box girder construction is carried out with the support system composed of the temporary pier 20 and the beam body 30 . The temporary buttress 20 is fixed vertically on the prefabricated ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com