Printing mechanism of ceramic decorating machine

A printing mechanism and printing machine technology, applied in printing machines, rotary printing machines, printing and other directions, can solve the problems of noise, scraper offset, affecting printing accuracy, etc., and achieve the effect of reducing noise, reducing vibration, and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

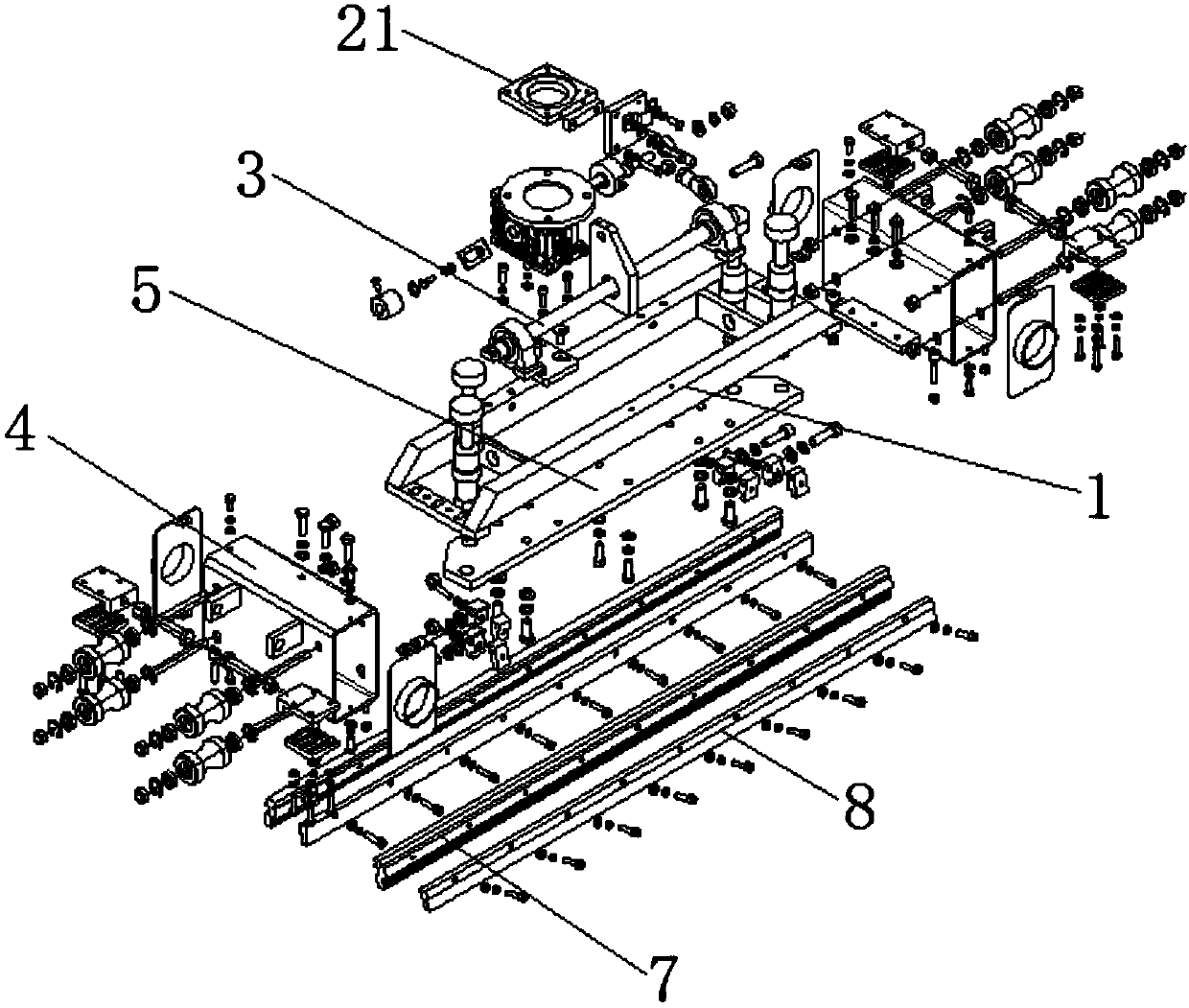

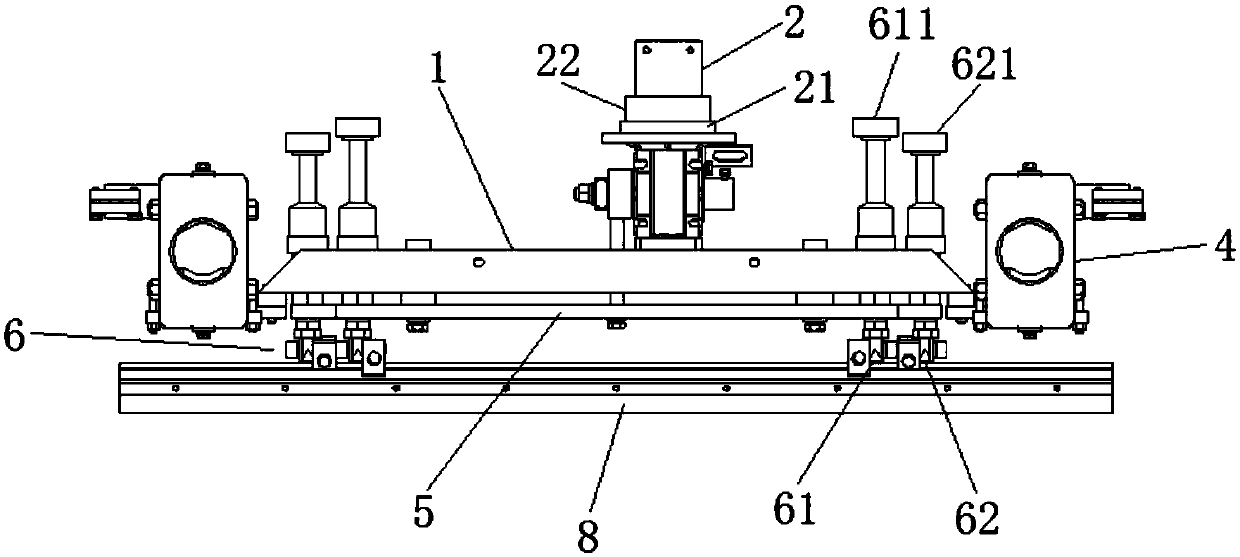

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

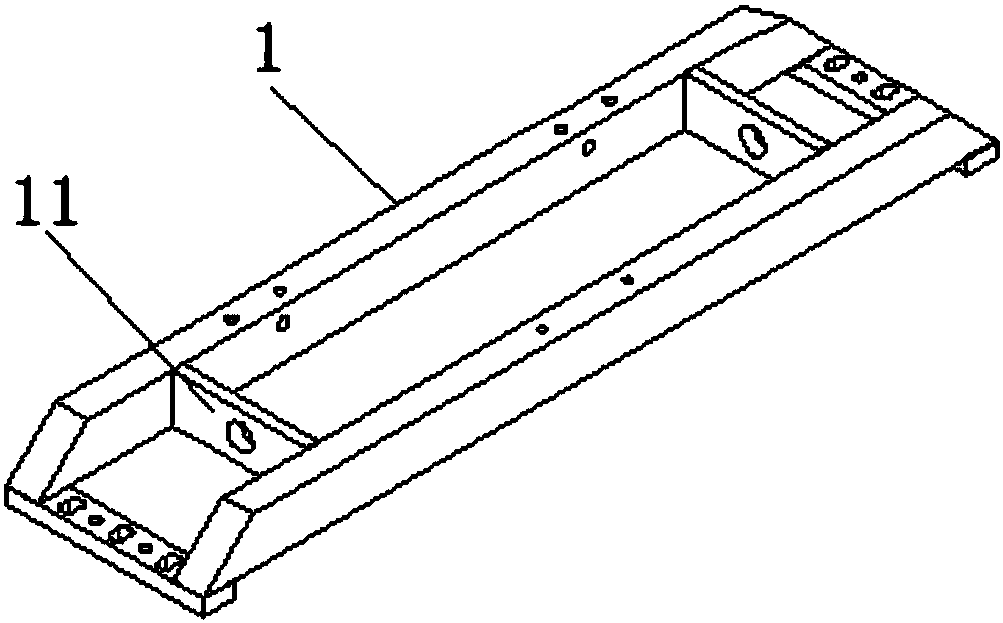

[0020] Such as Figure 1-Figure 5 As shown, the printing mechanism of the ceramic printing machine of the present invention includes a beam frame 1, a stepping motor 2, a rotating shaft 3, a roller box 4, a scraper mounting plate 5, a scraper 6, a knife hanging plate 7 and a knife clamping plate 8, wherein:

[0021] The crossbeam frame 1 is arranged in a rectangular frame structure, and the left and right parts of the crossbeam frame 1 are provided with reinforcing plates 11. By providing the reinforcing plates 11, the structural strength of the crossbeam frame 1 is improved, and its use stability is improved.

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com