Building construction method for wall

A building construction and wall technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low wall flatness, difficulty in ensuring wall flatness, and resource shortage, etc., so as to save investment and have a beautiful appearance , The effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

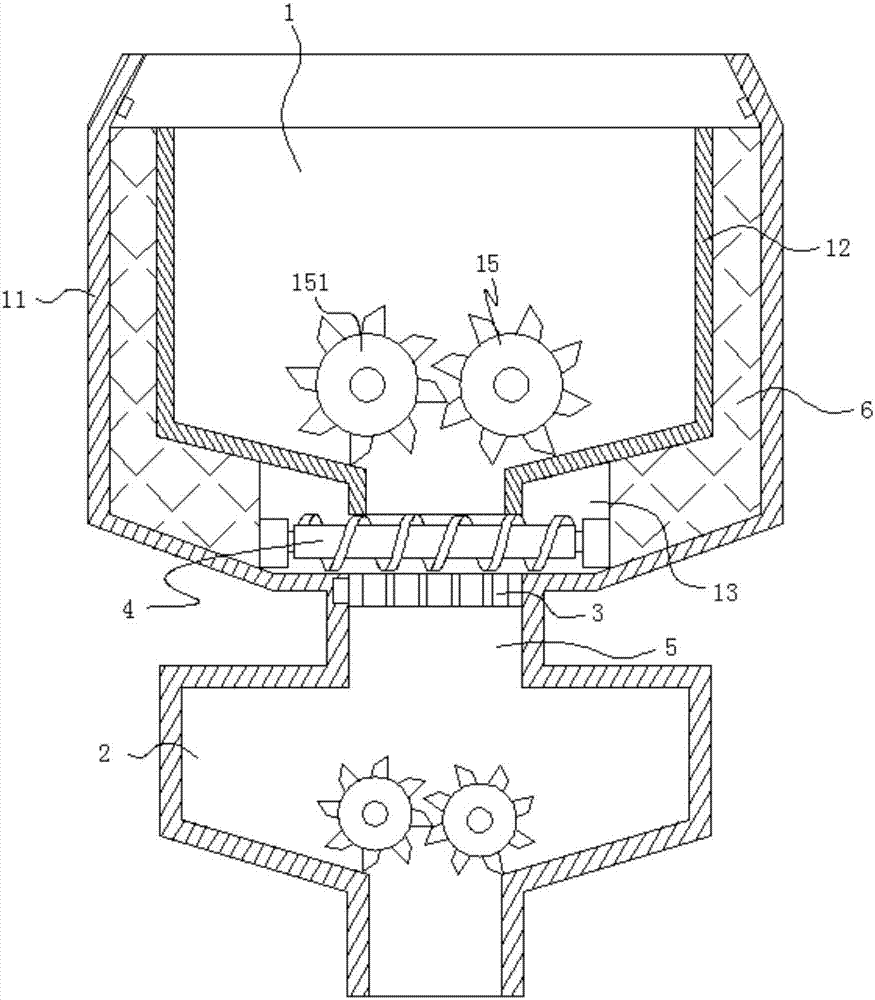

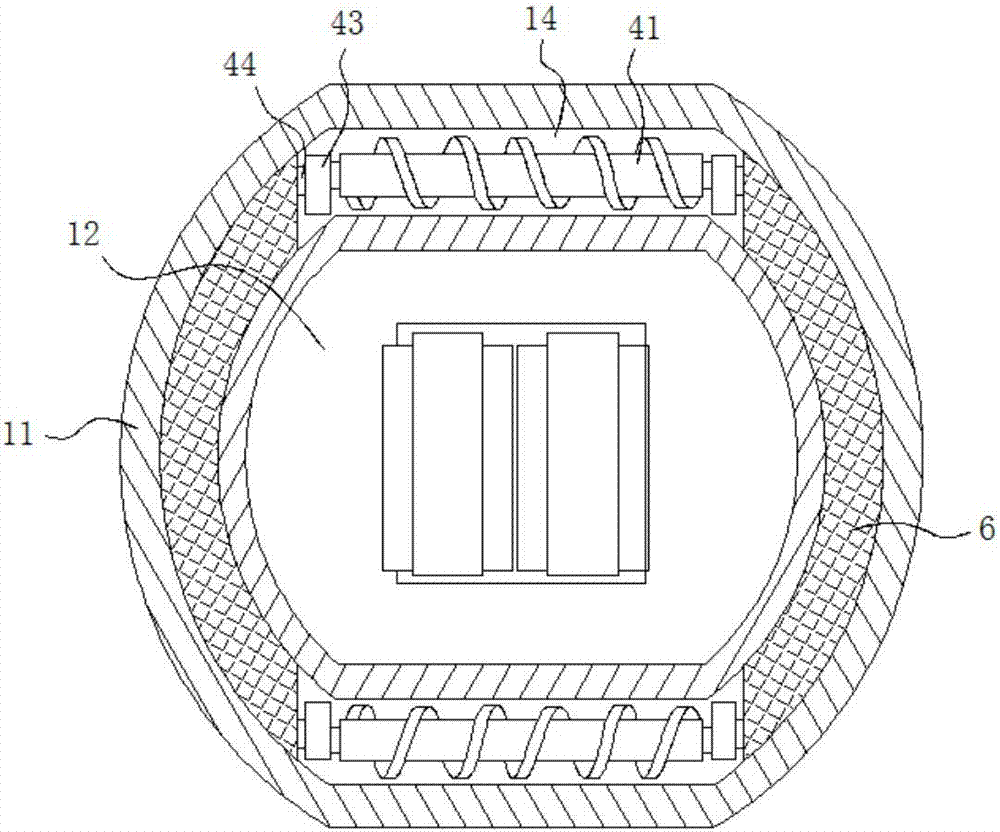

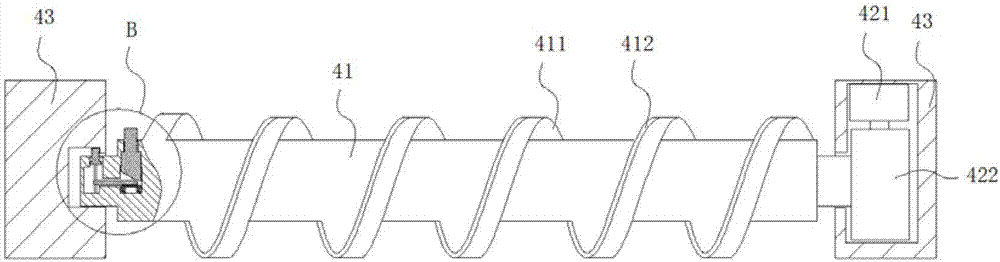

[0034]A building construction method for walls, comprising the following steps: (1) Wall building: erecting steel bars at the corresponding interior walls on the construction site, and stacking brick walls outside the steel bars; (2) Wall embryo forming: forming brick walls and Concrete is poured into the steel bar, and the wall embryo is formed after the concrete is solidified; (3) Plastering: plastering the wall with mortar. The preparation method of the mortar is as follows: use construction waste to be crushed by a crushing device , then carry out sand making to gravel by sand making machine to obtain sand, described construction waste can adopt waste concrete blocks, bric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com