Large material plate replacing device

A material tray and tray technology, which is applied in the field of large material tray changing devices, can solve the problems such as the loading and unloading structure that has not yet occurred, and achieve the effects of simple and practical structure, reduced manpower, and smooth and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

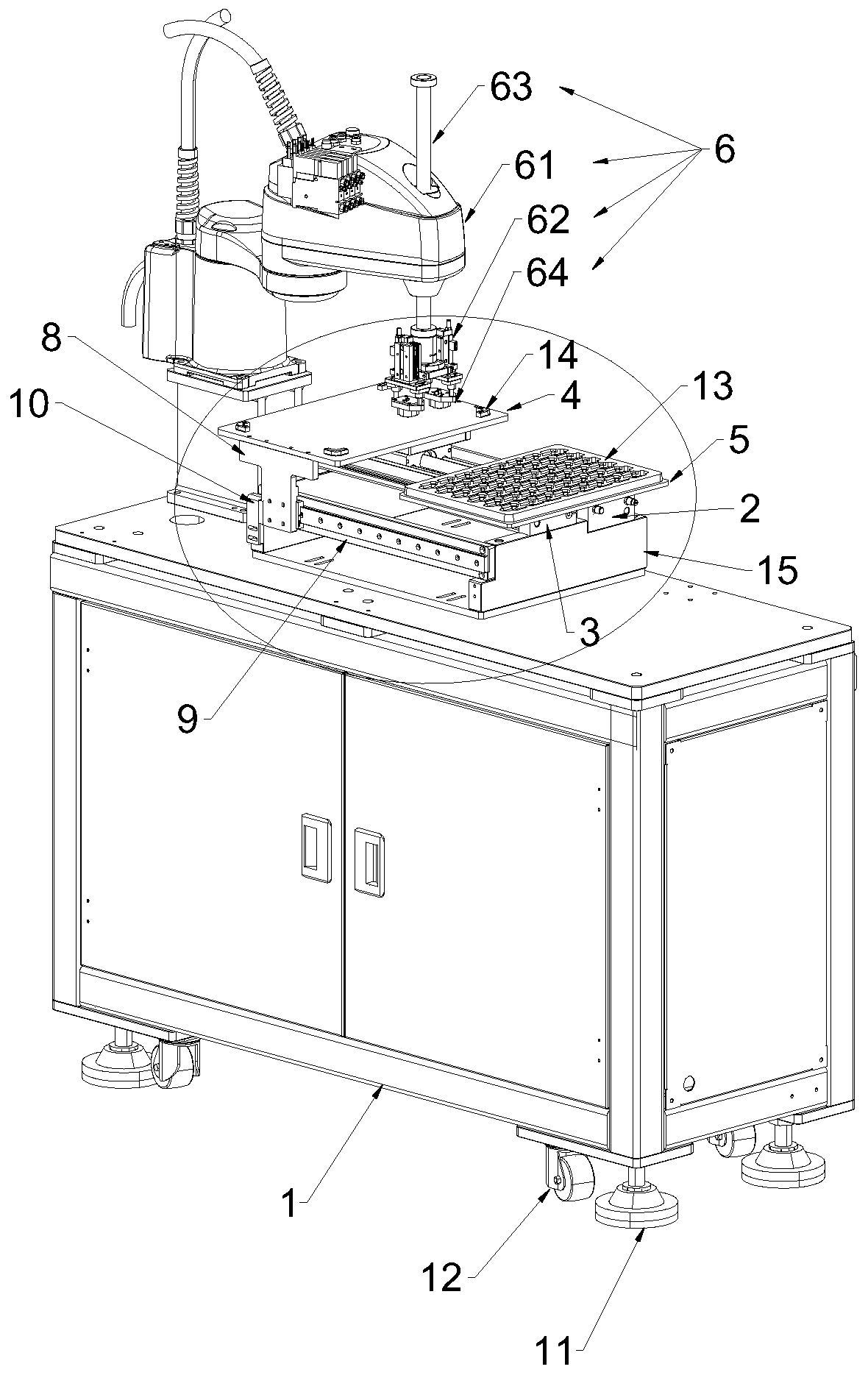

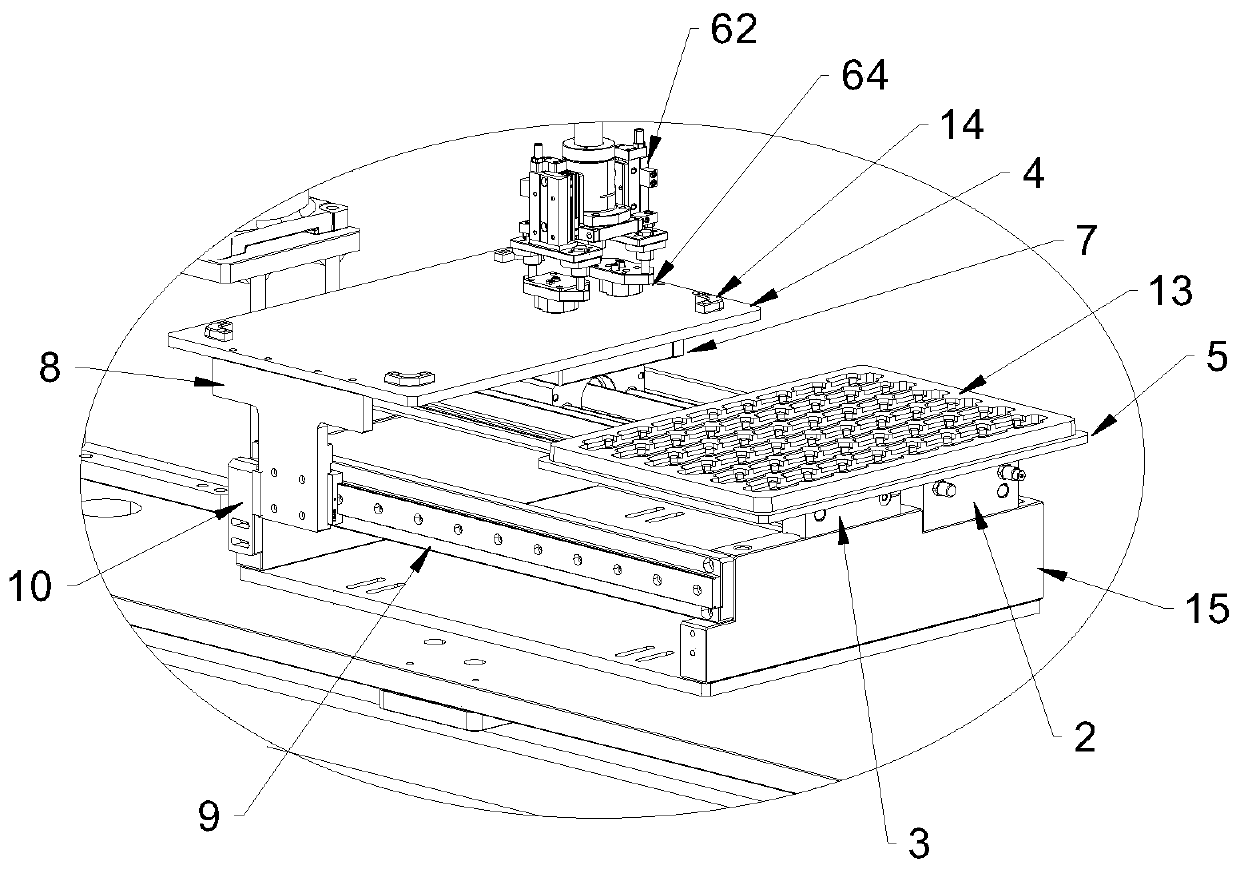

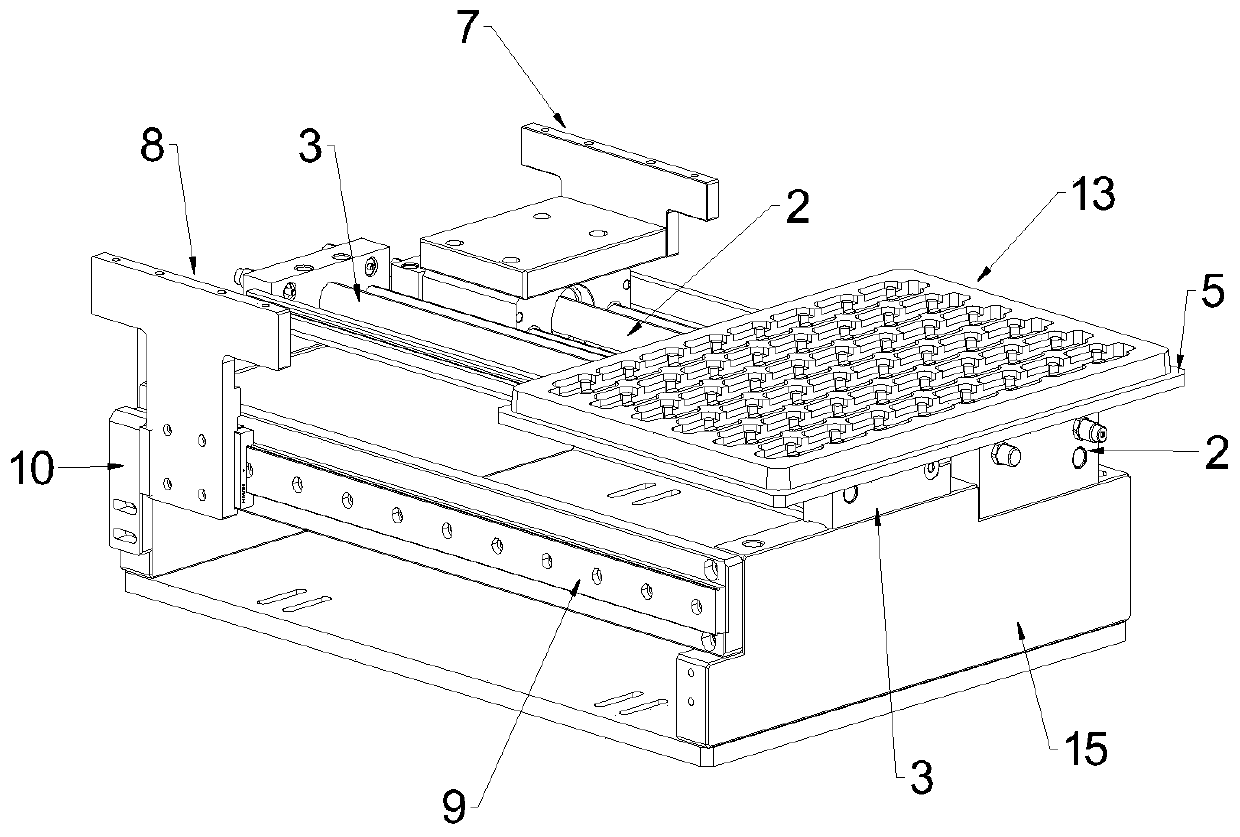

[0018] Figure 1-Figure 3 A large tray changing device according to an embodiment of the present invention is schematically shown. In the large environment where the equipment is used, there are many detection stations, and an automatic loading and unloading mechanism is added. However, due to the large size of the machine, it is not suitable to add a large-scale automatic loading and unloading mechanism, and the detection time is also long. The material tray 13 is large, and the action of changing the tray is infrequent. So adopted the large charging tray 13 changing device among the present application. It not only saves space, but also reduces the cost of the whole machine, and is easy to operate, reduces the workload, and realizes automatic loading, automatic unloading and plate placement.

[0019] As shown in the figure, the device for changing large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com