Cloth waste treatment device for spinning

A technology for processing devices and rags, which is applied to heating devices, grain processing, cleaning methods and utensils, etc., can solve the problems of unsatisfactory processing effects of rags, and achieve the effects of improving crushing effect, convenient processing, and improving processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

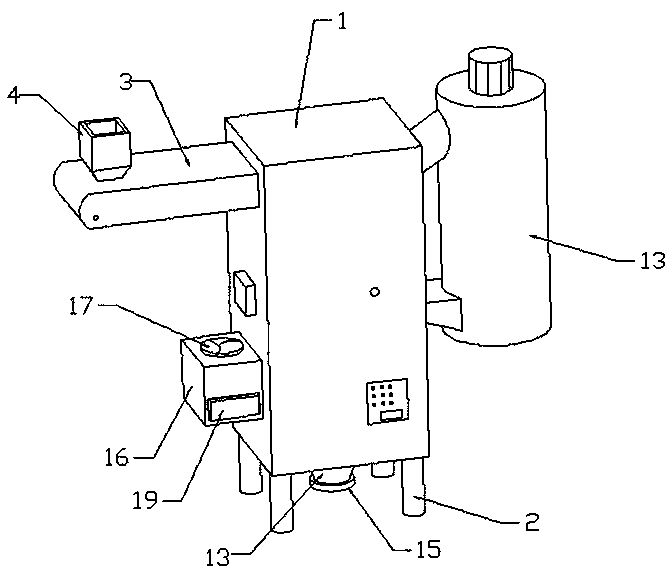

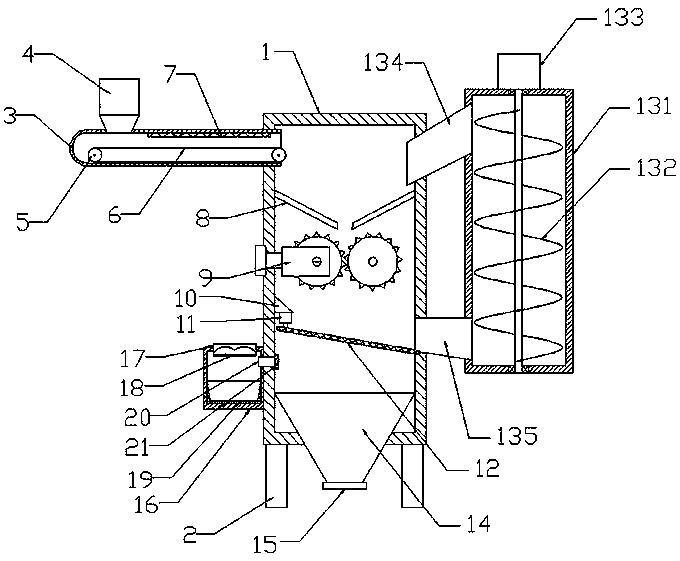

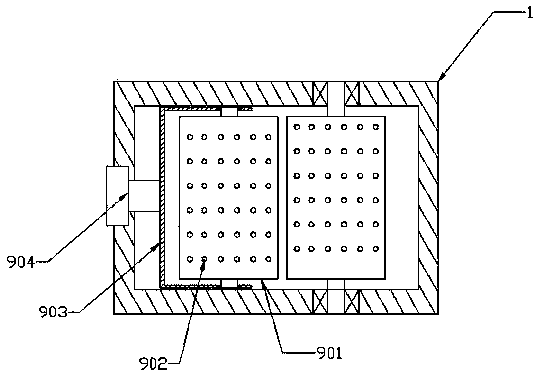

[0022] see Figure 1-3 As shown, the present embodiment is a rag processing device for weaving, comprising an outer shell 1, the four corners of the bottom of the outer shell 1 are connected with columns 2, and the upper left part of the outer shell 1 is connected with a feed channel 3, and the feed channel 3 The left side of the top of the top is connected with a hopper 4, and the left and right ends of the feed channel 3 are connected to the conveyor roller 5, and the conveyor belt 6 is set between the two sets of conveyor rollers 5, and the right end of the conveyor belt 6 extends into the inner cavity of the outer shell 1. The top of the inner cavity of the material channel 3 is connected with a heating wire 7, and the upper part of the inner cavity of the outer casing 1 is symmetrically connected with a material guide swash plate 8. The material guide slant plate 8 is located below the conveyor belt 6. The crushing mechanism 9, the left side wall of the inner cavity of th...

Embodiment 2

[0028] On the basis of Embodiment 1, the left side wall of the outer casing 1 is connected with a dust box 16, and the top of the dust box 16 is fitted with a negative pressure fan 17, and the lower end of the negative pressure fan 17 is connected with a dustproof net 18, The lower part of the dust collection box 16 is plugged with a drawer box 19, and a drainage tube 20 is connected between the dust collection box 16 and the outer shell 1. The drainage tube 20 is located under the screen 12, and the drainage tube 20 extends into the inner cavity of the outer shell 1 One end is connected with filter screen 21.

[0029] The upper surface of the mounting seat 10 is an inclined plane.

[0030] Conveyor roller 5 and scrap roller 901 all adopt motor built-in roller.

[0031] A PLC controller is connected to the outer wall of the outer casing 1 .

[0032]In this embodiment, dust is generated during the crushing process of the cloth. In order to prevent the dust from scattering and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com