Coiling device for cable production

A coil and cable technology, applied in thin material handling, transportation and packaging, transportation of filamentous materials, etc., can solve the problems that the coil can not be easily off-line from the machine body, and the difficulty of recycling the finished coil, so as to achieve convenient Effects of placement and removal, weight reduction, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

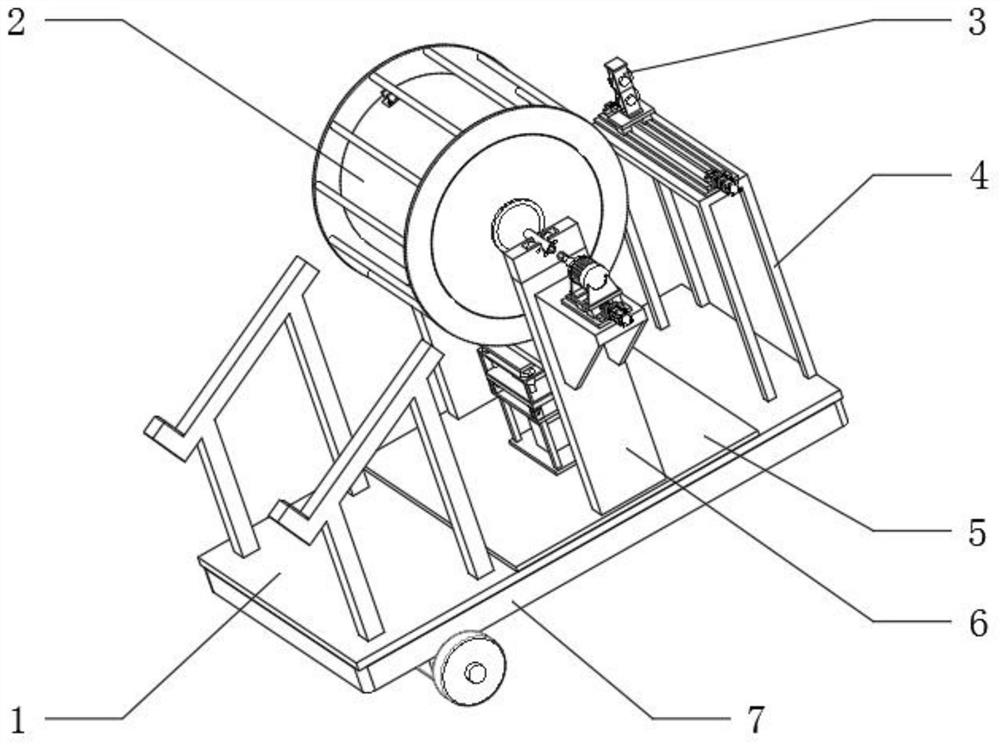

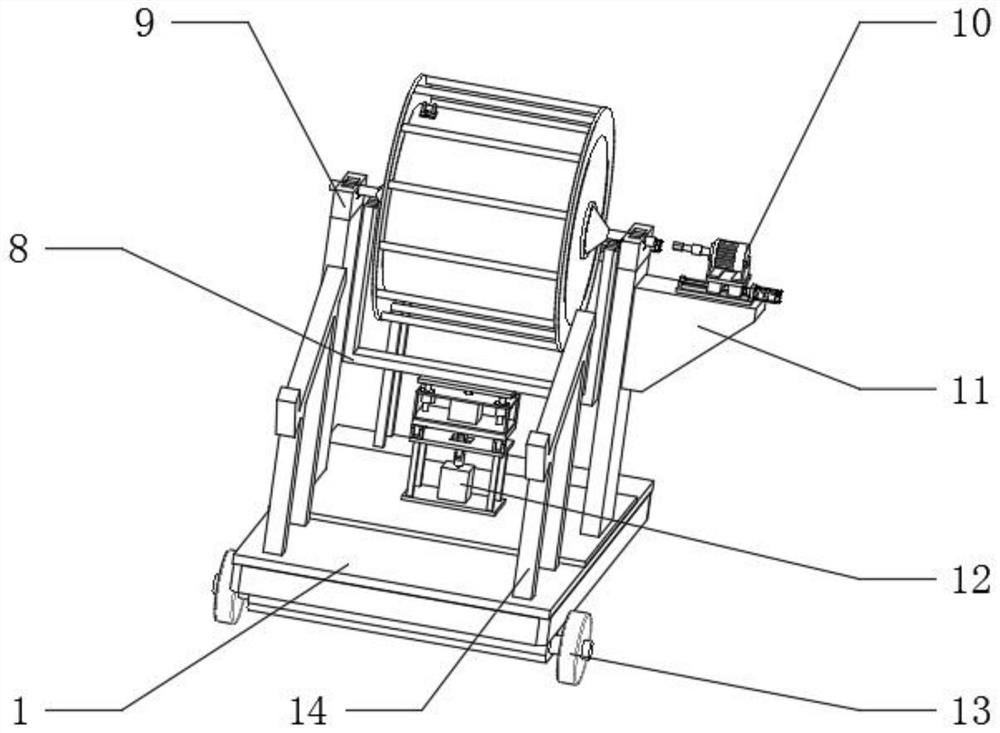

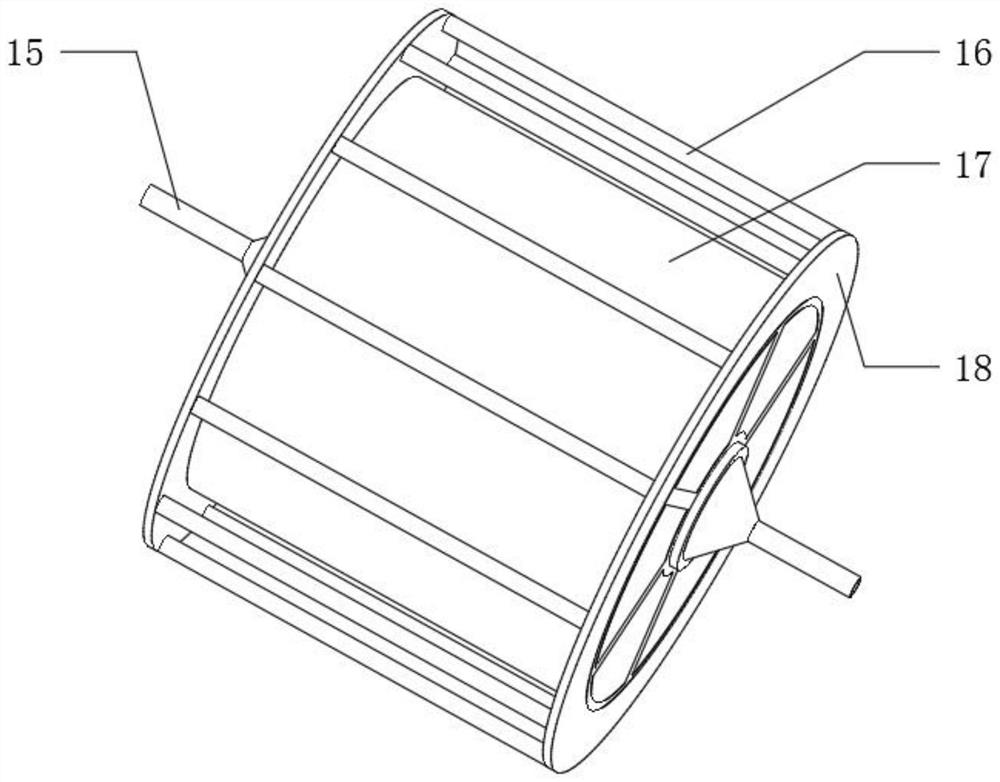

[0038] A coiling device for cable production, such as Figure 1-10 As shown, including the bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with the supporting plate 5, the top outer wall of the supporting plate 5 is fixedly connected with the arm frame 6, the top outer wall of the arm frame 6 is fixedly connected with the support assembly 9, and the top outer wall of the support assembly 9 rotates The drum assembly 2 is connected, the outer wall of one side of the arm frame 6 is fixedly connected with a horizontal frame 11, the top outer wall of the horizontal frame 11 is fixedly connected with a rotary assembly 10, the top outer wall of the bottom plate 1 is fixedly connected with a stand 4, and the top outer wall of the stand 4 is fixedly connected with a The feeding assembly 3, the top outer wall of the bottom plate 1 is fixedly connected with the connecting assembly 12; the bottom outer wall of the bottom plate 1 is fixedly connected with a fra...

Embodiment 2

[0045] A coiling device for cable production, such as figure 1 As shown, in order to solve the problem of hunger and thirst; this embodiment makes the following improvements on the basis of Embodiment 1: the feed assembly 3 includes a second plate 44 and a vertical frame 42, and the outer wall of the bottom of the second plate 44 is fixedly connected to the vertical frame 4 Top outer wall, pasting plate 2 44 Top outer wall is fixedly connected with slide rail 2, slide rail 2 cooperates with slider 2, the top outer wall of slider 2 is fixedly connected with mobile plate 2, vertical frame 42 Bottom outer wall is fixedly connected to the top of mobile plate 2 The outer wall, the top outer wall of the pasting plate 2 44 is fixedly connected with the mounting frame 2, and the outer wall of the mounting frame 2 side is fixedly connected with the feeding motor, the output shaft of the feeding motor is connected with the screw rod 2 through a coupling, and the inner wall of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com