A special trolley for rotating coke tank maintenance

A technology of coke pots and trolleys, applied in the field of dry quenching, can solve the problems of waste, high safety risks, high maintenance operation costs, etc., and achieve the effect of saving maintenance costs, reducing labor intensity, and safe maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

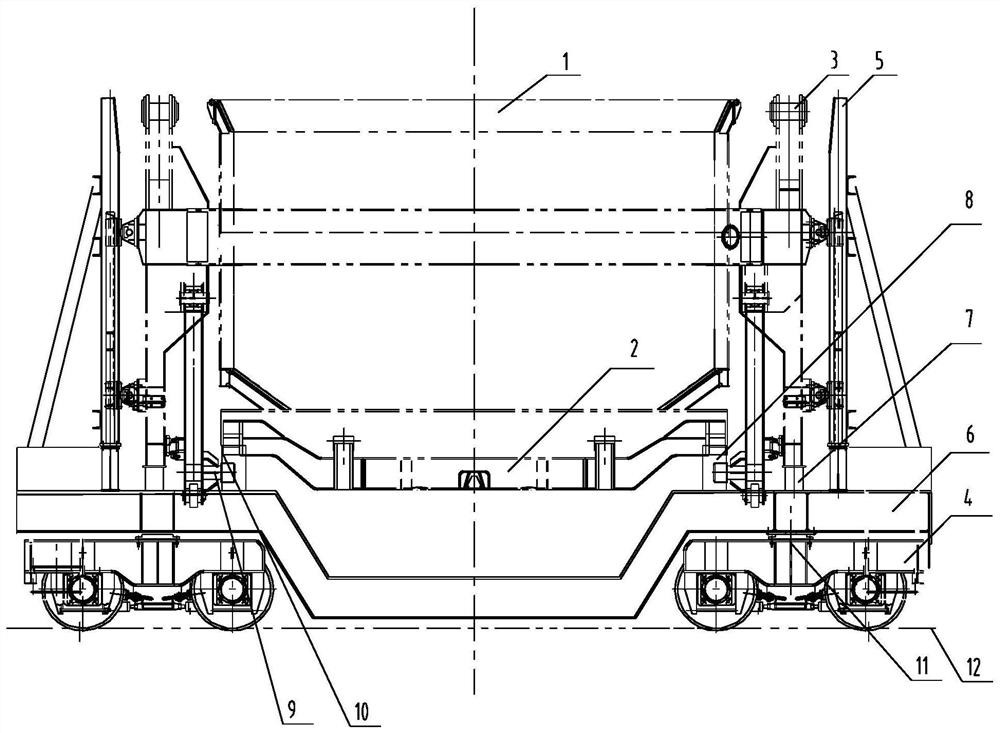

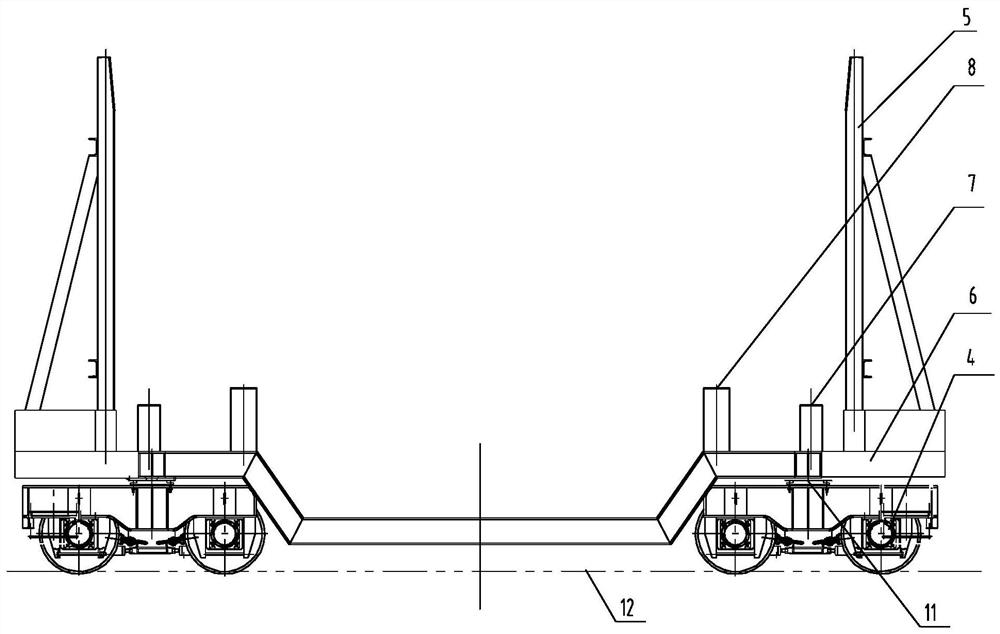

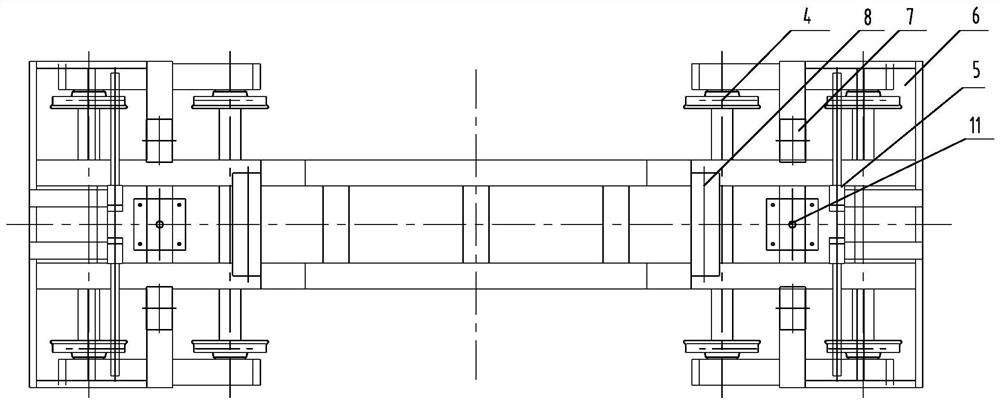

[0032] Such as Figure 1-10 As shown, a special trolley for rotating coke tank maintenance includes a trolley wheel set 4 , a trolley frame 6 , a guiding and fixing frame 5 , a coke tank base 8 , and a coke tank spreader base 7 .

[0033] The platform frame 6 is an ingot type steel beam structure, the middle part is concave, and the two ends are platform structures. Two groups of platform wheel sets 4 are hinged on the lower part of the platform at both ends of the platform frame 6 through the turntable 11 .

[0034] The guiding and fixing frame 5 is a steel beam structure, and the guiding and fixing frame 5 is welded by the base 13, the guide rail 14 and the triangular support frame 15. The coke pot spreader base 7 and the coke pot base 8 are elongated bases welded by section steel. Two guide fixing frames 5 , four coke tank spreader bases 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com