electric maintenance ladder

An electric power maintenance and cable technology, applied in the field of electric power maintenance ladders, can solve problems such as inconvenience in use, and achieve the effects of increasing service life, increasing adsorption force, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

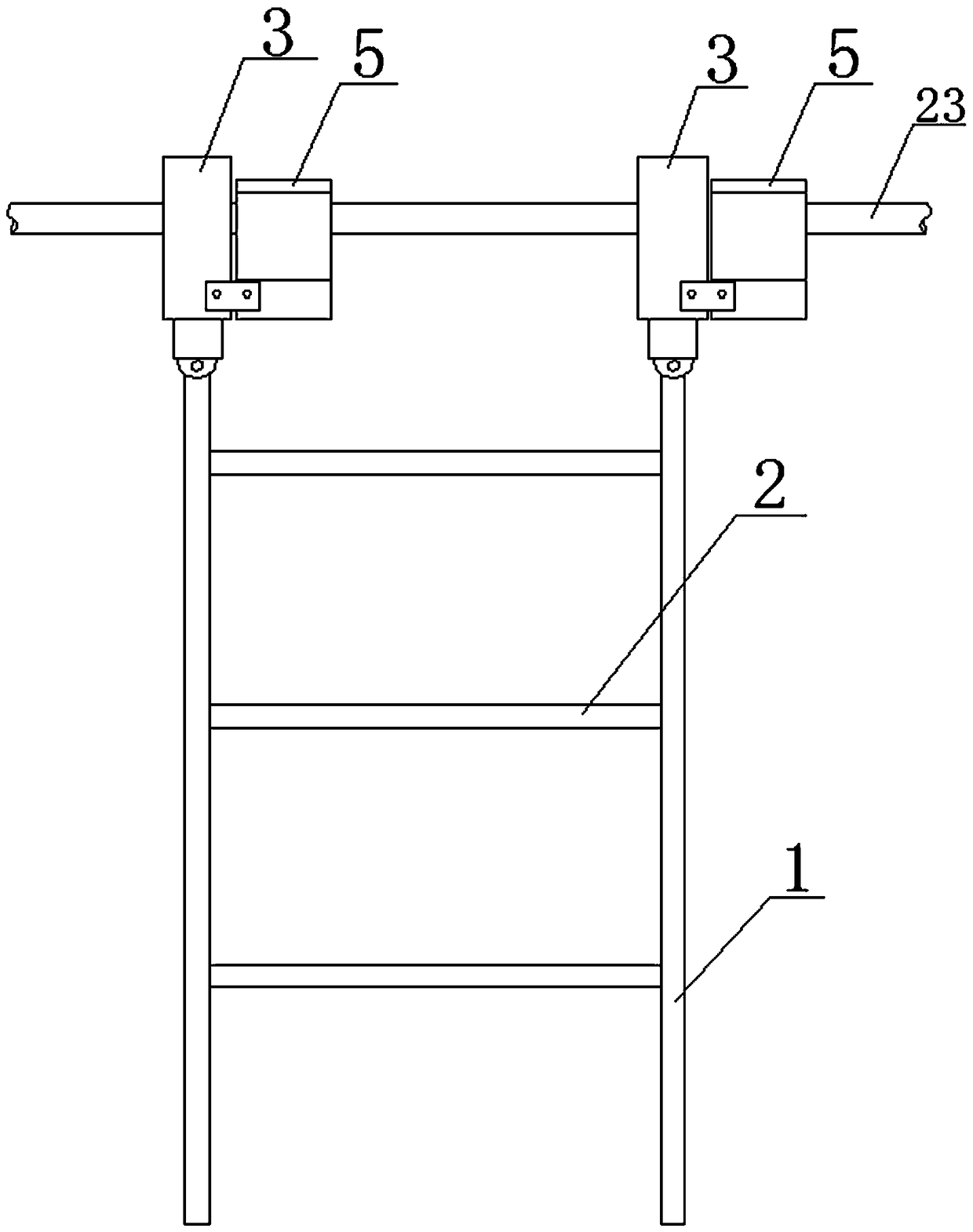

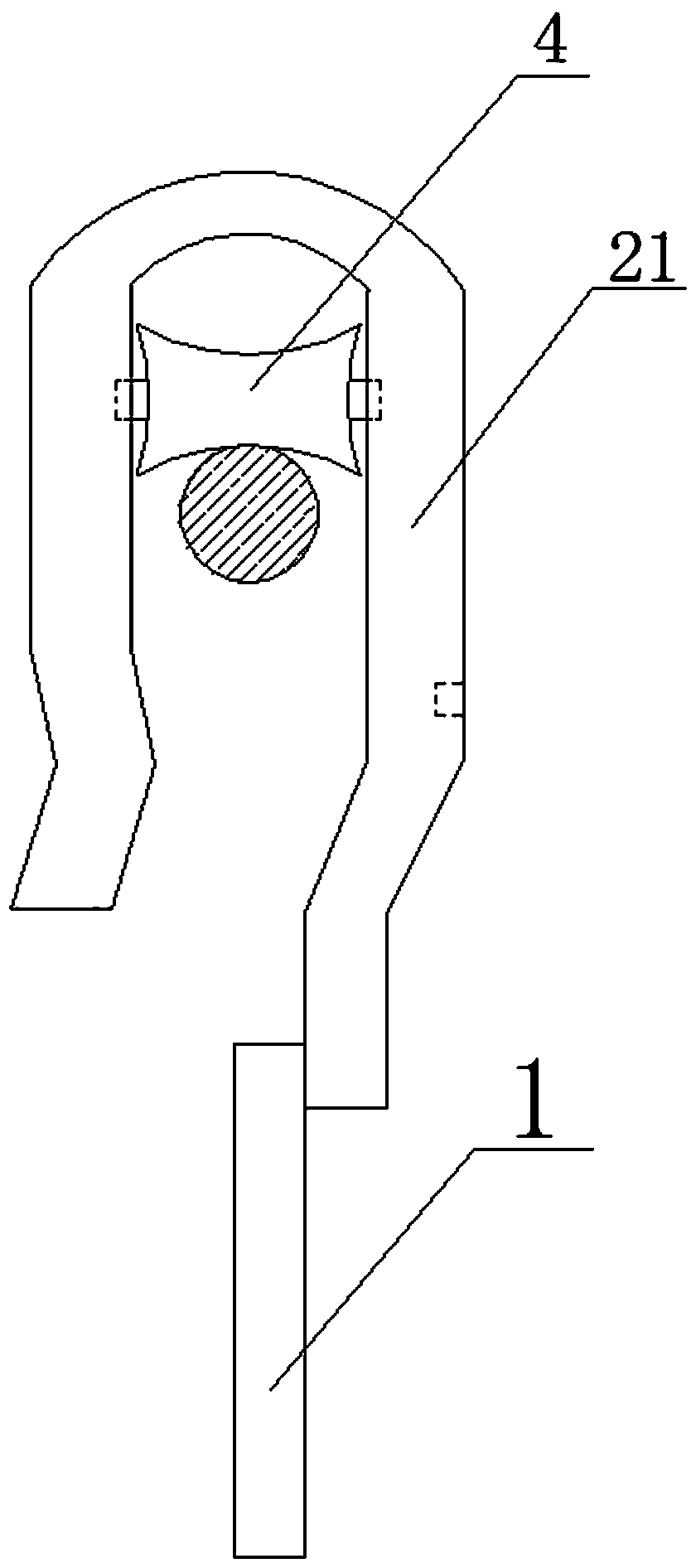

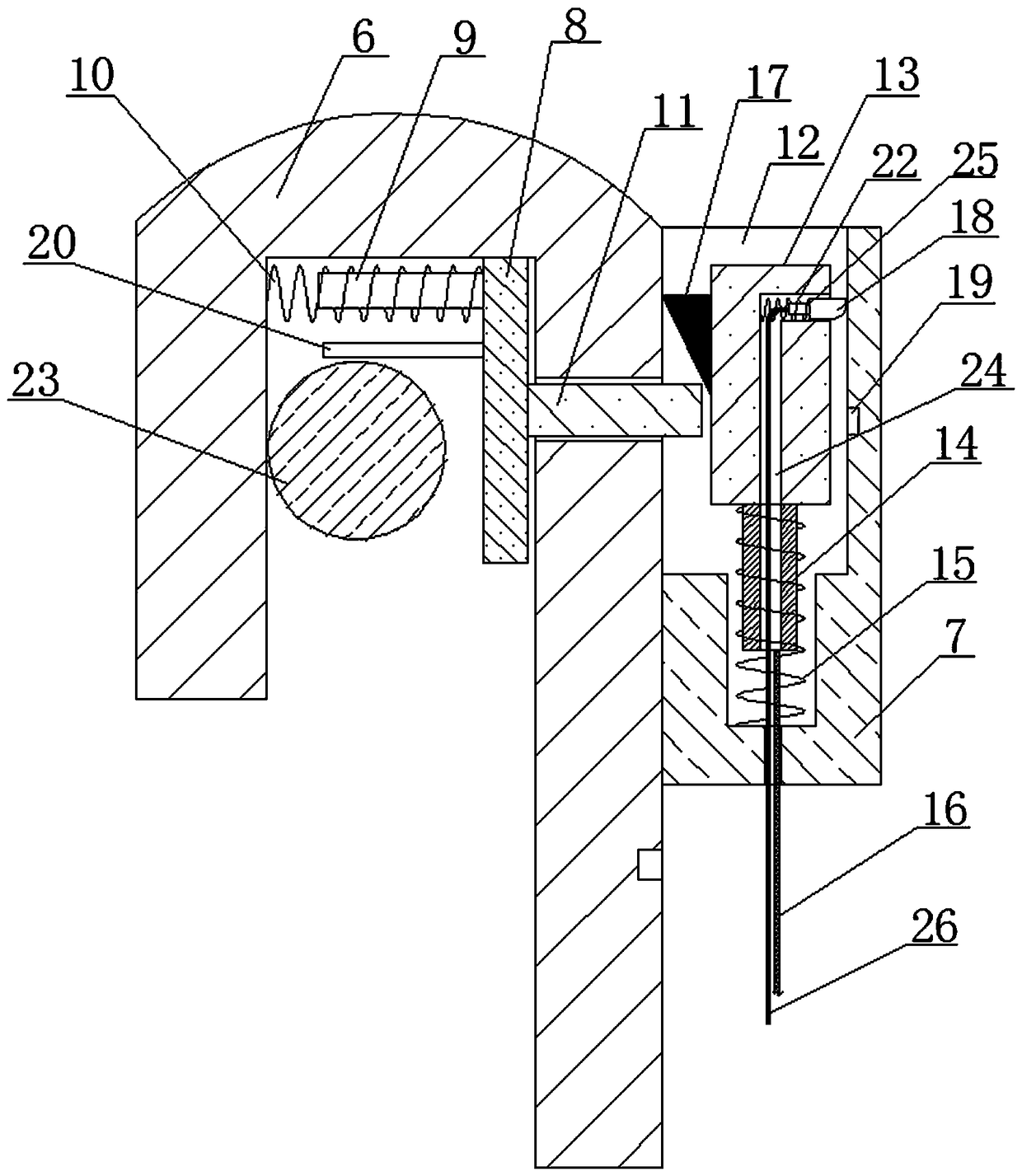

[0033] Such as Figure 1-3 shown, where in order to be compatible with figure 1 Corresponding, Figure 2-3 The left side is defined as the front end, and the right side is defined as the rear end. An electric maintenance ladder includes two cables 1 and a plurality of pedals 2 fixed between the cables 1 . Wherein two cables 1 tops fix two hanging heads 3 respectively, and hanging head 3 comprises inverted U-shaped hook 21 and is fixed in the pulley 4 in inverted U-shaped hook 21, and wherein hanging head 3 sides fix braking device 5, wherein Hanging head 3 and braking device 5 bottoms are all provided with threaded holes, and the fixing plate of bolt is set and hanging head 3 and braking device 5 are fixed together, and pulley 4 can slide on cable 23.

[0034]The brake device 5 comprises an inverted U-shaped hook two 6 and a fixed block 7 fixed on the inverted U-shaped hook two 6 rear ends, wherein the U-shaped hook two 6 and the fixed block 7 are fixed by welding, and the i...

Embodiment 2

[0045] The structure of embodiment 2 is the same as that of embodiment 1, the difference is:

[0046] In the present invention, the surfaces of the hanger 3 and the braking device 5 are all sprayed with insulating and wear-resistant coatings, and the surfaces of the hanging head 3 and the braking device 5 are all sprayed with insulating and wear-resistant coatings. The insulating and wear-resistant coating is made of the following raw materials in parts by weight: 35 parts of acrylic emulsion, 32 parts of epoxy resin, 9 parts of silica sol, 11 parts of oxalic acid polyester, 6 parts of silicon nitride, and 5 parts of nano silicon dioxide , 13 parts of nitrile rubber powder, 4 parts of polyethylene glycol octyl phenyl ether, 4 parts of sodium lignosulfonate, 18 parts of solvent and 8 parts of water.

[0047] The solvent is a mixture of ethanol and toluene at a volume ratio of 1:1.5.

[0048] The insulating wear-resistant coating is prepared by the following steps:

[0049] (1...

Embodiment 3

[0053] The structure of embodiment 3 is the same as that of embodiment 1, the difference is:

[0054] In the present invention, the surfaces of the hanger 3 and the braking device 5 are all sprayed with insulating and wear-resistant coatings, and the surfaces of the hanging head 3 and the braking device 5 are all sprayed with insulating and wear-resistant coatings. The insulating wear-resistant coating is made of the following raw materials in parts by weight: 36 parts of acrylic emulsion, 30 parts of epoxy resin, 10 parts of silica sol, 10 parts of oxalic acid polyester, 7 parts of silicon nitride, and 4 parts of nano silicon dioxide , 14 parts of nitrile rubber powder, 3 parts of polyethylene glycol octyl phenyl ether, 5 parts of sodium lignosulfonate, 16 parts of solvent and 9 parts of water.

[0055] The solvent is a mixture of ethanol and toluene at a volume ratio of 1:2.

[0056] The insulating wear-resistant coating is prepared by the following steps:

[0057] (1) Mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com