Spatial three-dimensional multifunctional steel truss bridge anti-electricity maintenance vehicle

A steel truss bridge, multi-functional technology, applied to bridges, bridge parts, bridge construction, etc., can solve the problems of increased steel consumption and cost, large amount of lower maintenance vehicles, and insufficient bridge maintenance, so as to achieve safe maintenance operations Reliable, reduced maintenance workload, easy to transport and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

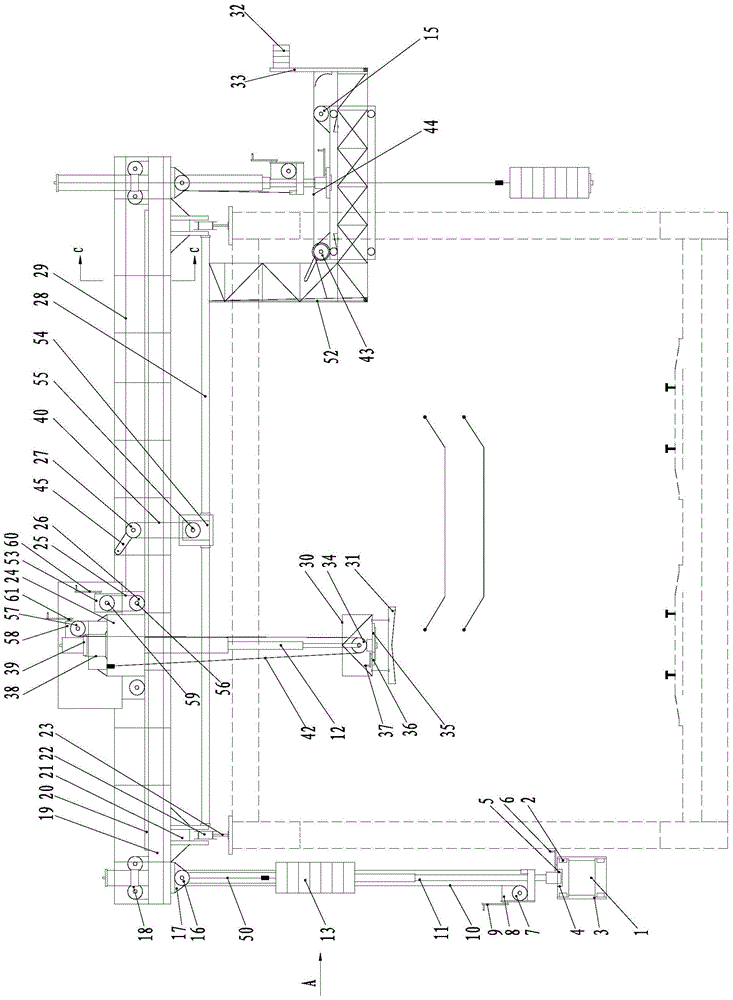

[0024] Attached below Figure 1-6 An embodiment of the present invention is described.

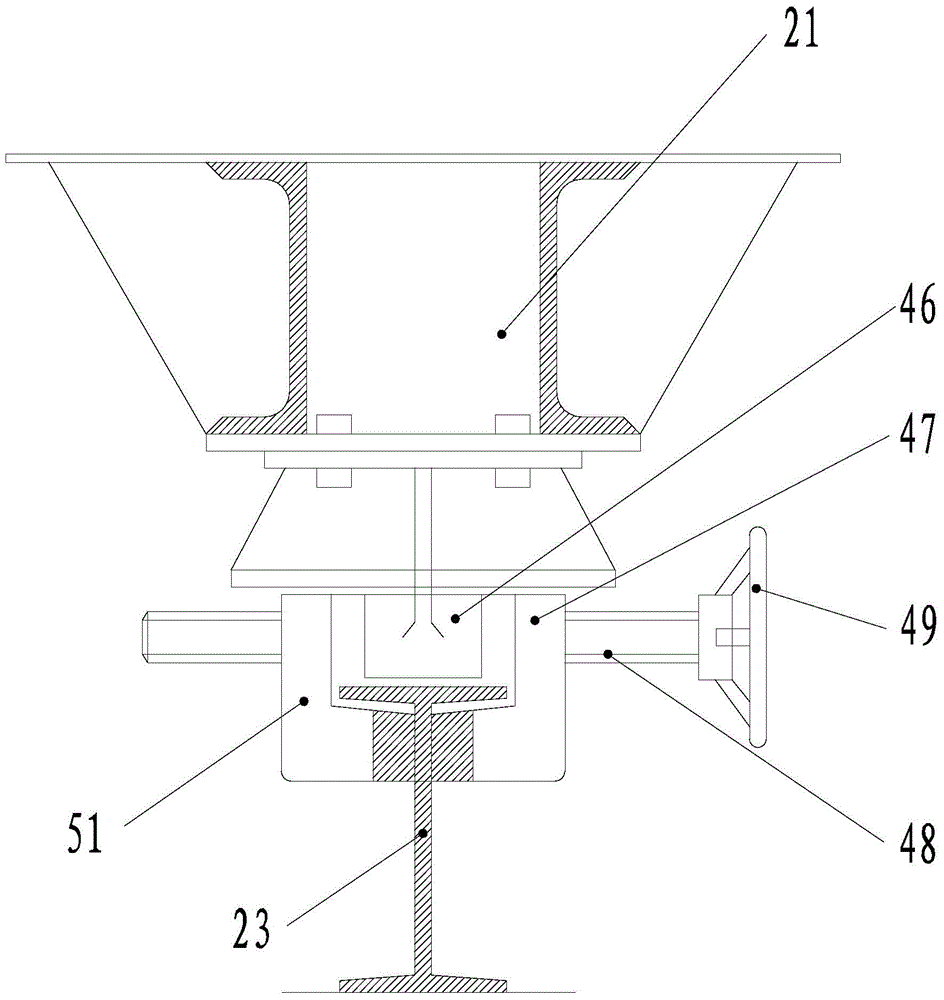

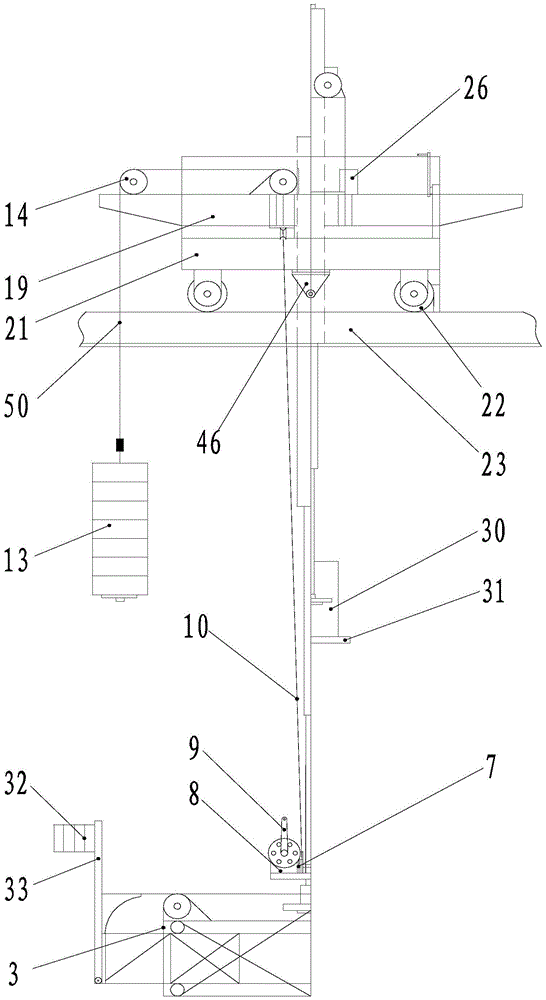

[0025] The space three-dimensional multifunctional steel truss bridge electrical protection work inspection vehicle has a large frame 29. The bottom of the large frame 29 is provided with two horizontally parallel simply supported beams 19 and the two simply supported beams 19 pass through a horizontal connection 41 The fixed connection is integrated. The lower end of the large frame 29 is provided with a longitudinal running system adapted to the longitudinal running rail 23 provided on the upper end of the steel beam. The longitudinal running system includes a running frame 21, a running wheel 22, and a transmission The axle 28, the cart travel reducer 54, the cart sprocket I 27 and the cart sprocket II 55. Specifically, a running frame 21 is provided on both sides of the lower end surface of the large frame 29, and both ends of the running frame 21 are There is a running wheel 22, a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com