Maintenance apparatus and maintenance process method for high-temperature gas cooled reactor control rod drive mechanism

A technology for a high-temperature gas-cooled reactor and a driving mechanism, which is applied in the field of reactor maintenance, can solve the problems of prolonging the period of helium purification and dehumidification, and destroying the helium atmosphere, and achieves the effect of ensuring safety and preventing diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

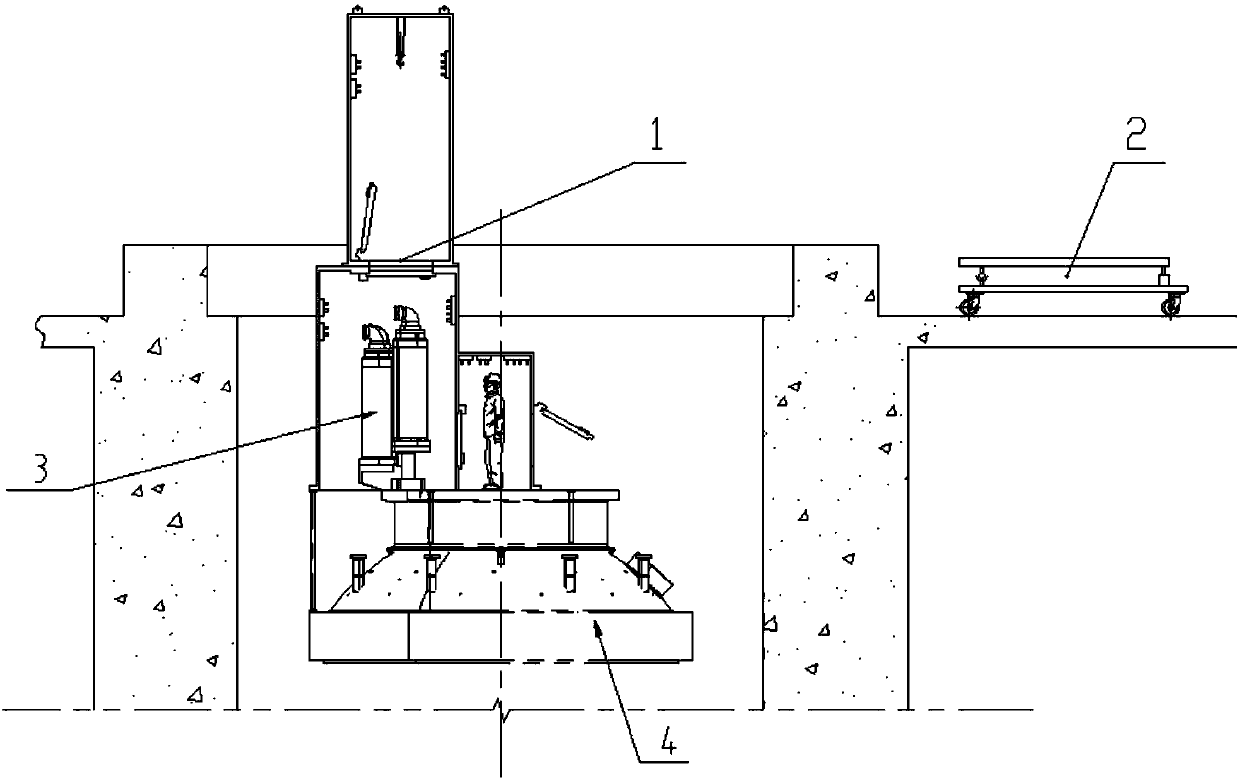

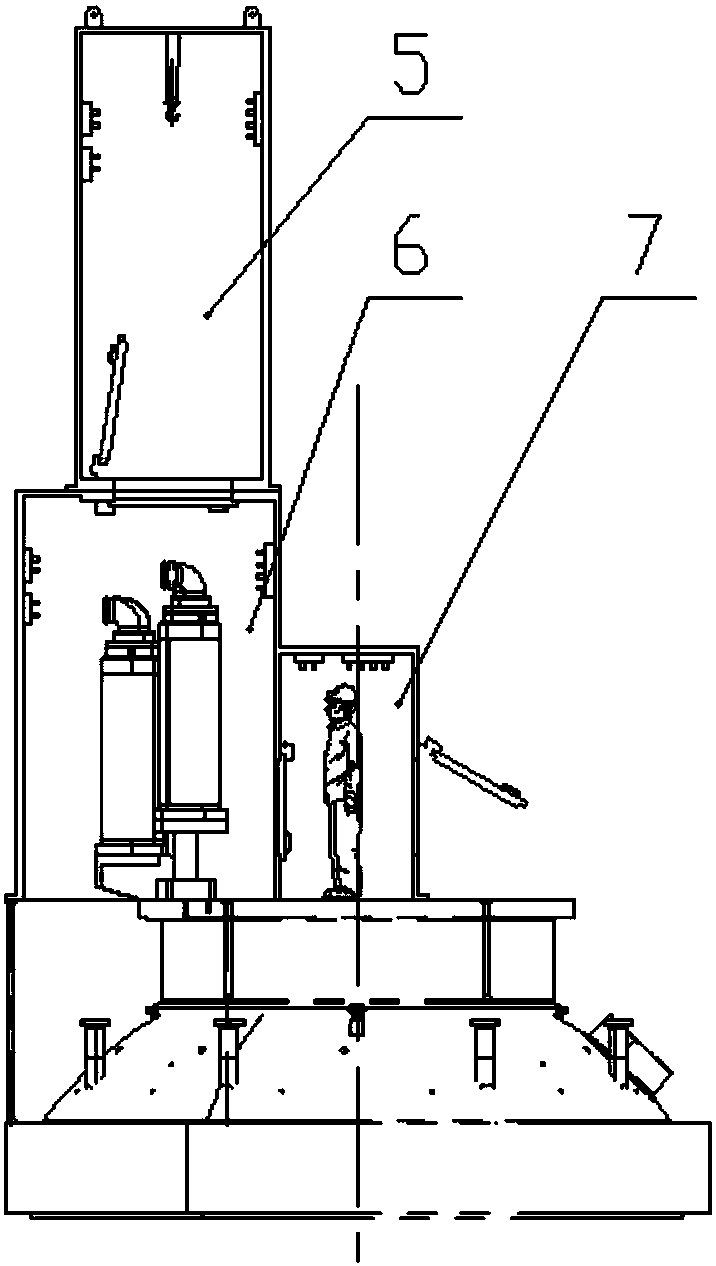

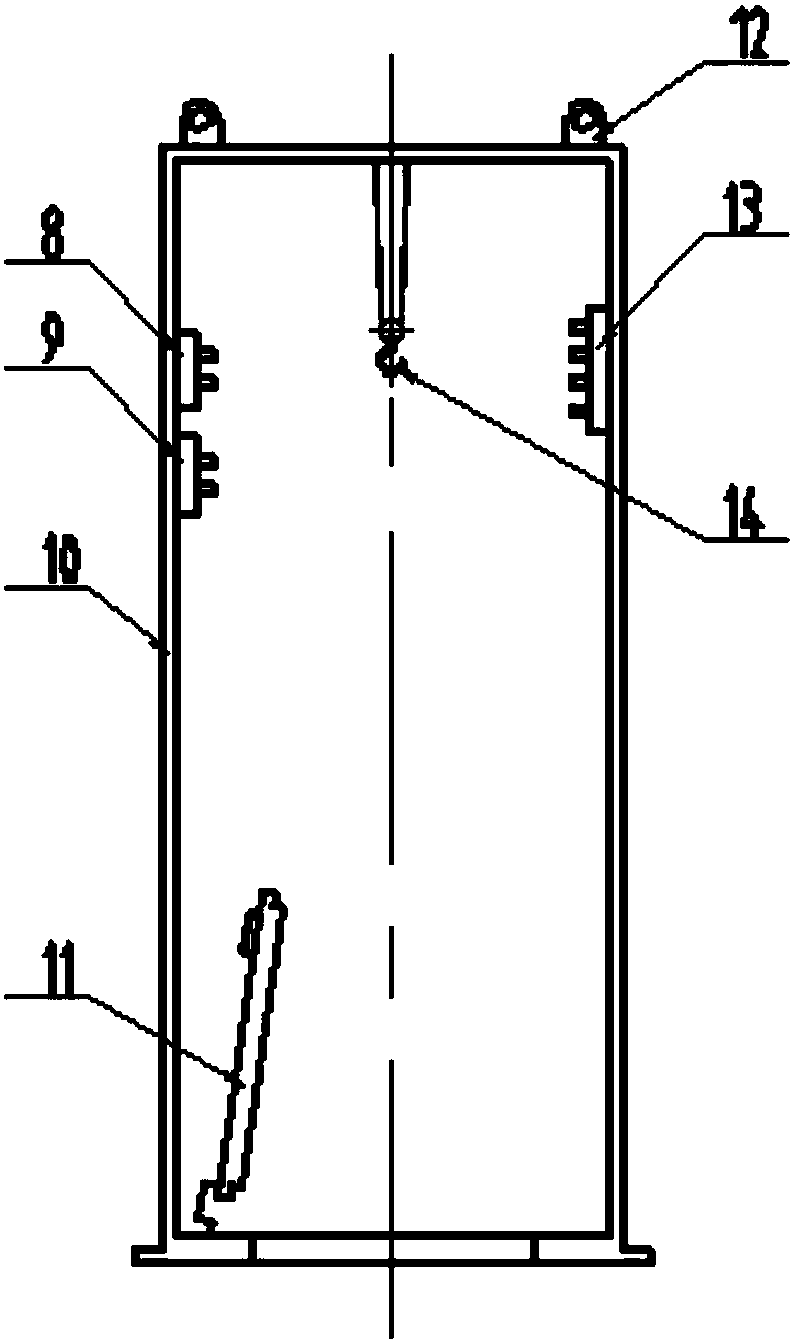

[0019] Such as figure 1 As shown in -4, the high temperature gas-cooled reactor control rod drive mechanism maintenance device of the present invention includes an atmosphere isolation device 1 and an inspection platform 2; the atmosphere isolation device 1 includes a transfer cabin 5, a main cabin 6 and a transition cabin 7; the transfer cabin 5 includes Temperature sensor I8, pressure sensor I9, transfer cabin body 10, transfer cabin door 11, transfer cabin lifting lug 12, helium concentration detector I 13 and hook 14; main cabin 6 and transition cabin 7 are integrated structures, including temperature Sensor II15, pressure sensor II16, main compartment body 17, main compartment door I18, main compartment lug 19, helium concentration detector II20, main compartment hatch II21, temperature sensor III22, pressure sensor III23, helium concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com