Patents

Literature

71results about How to "Solve compatibility issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

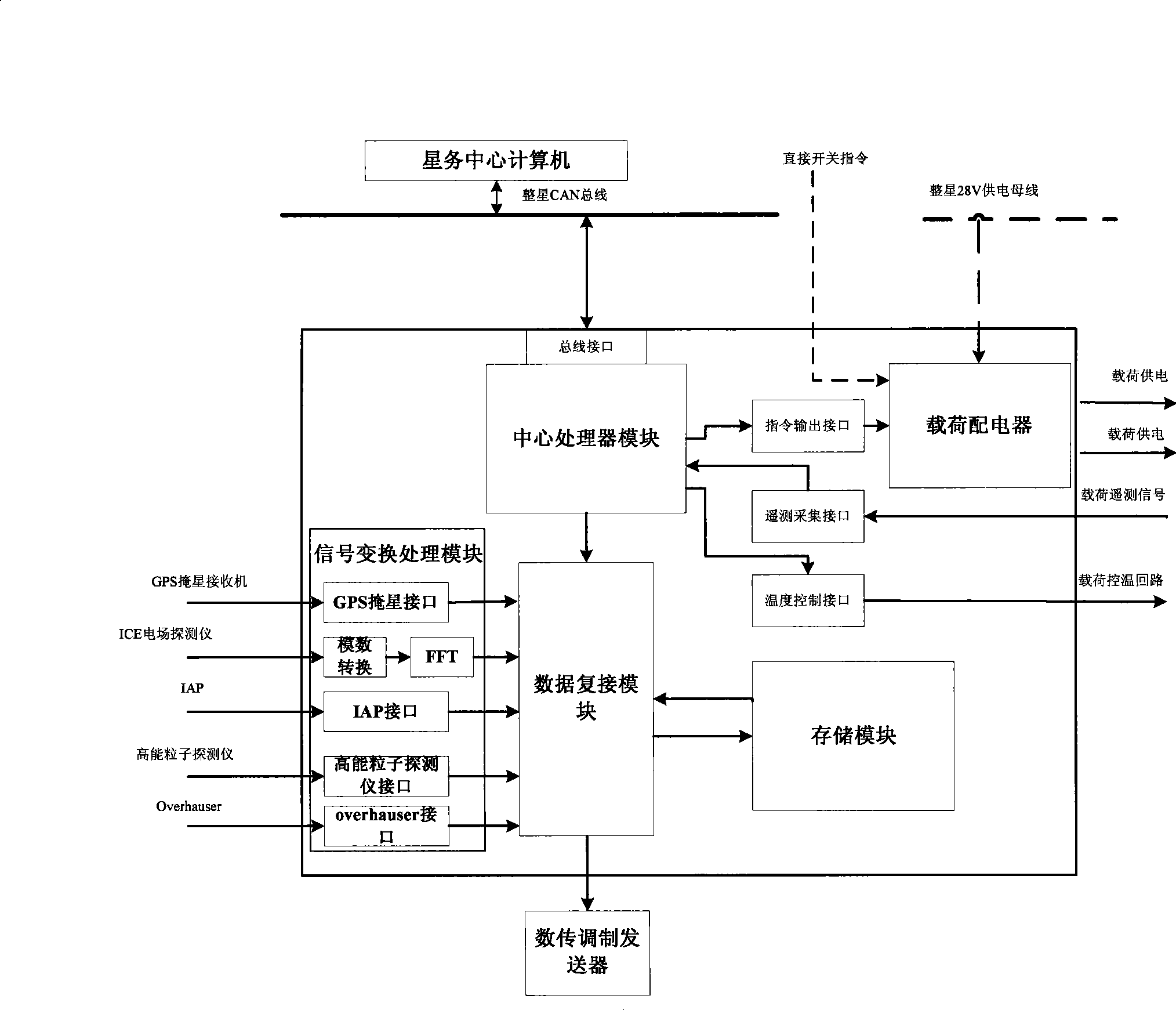

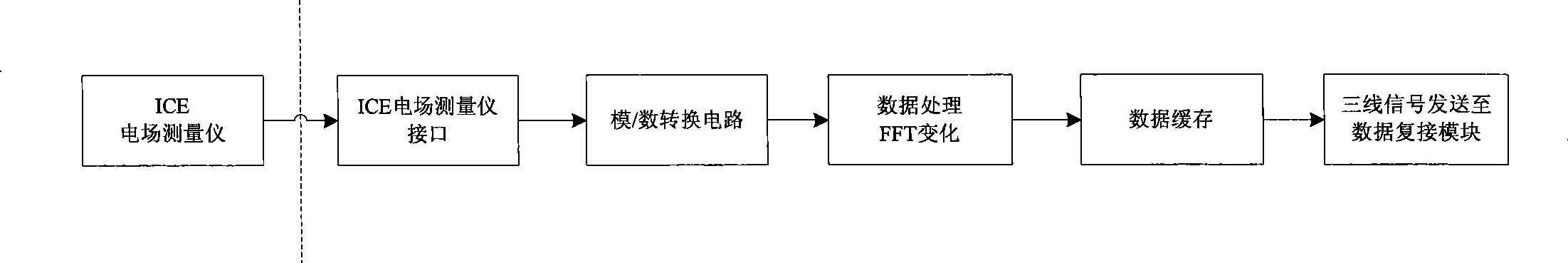

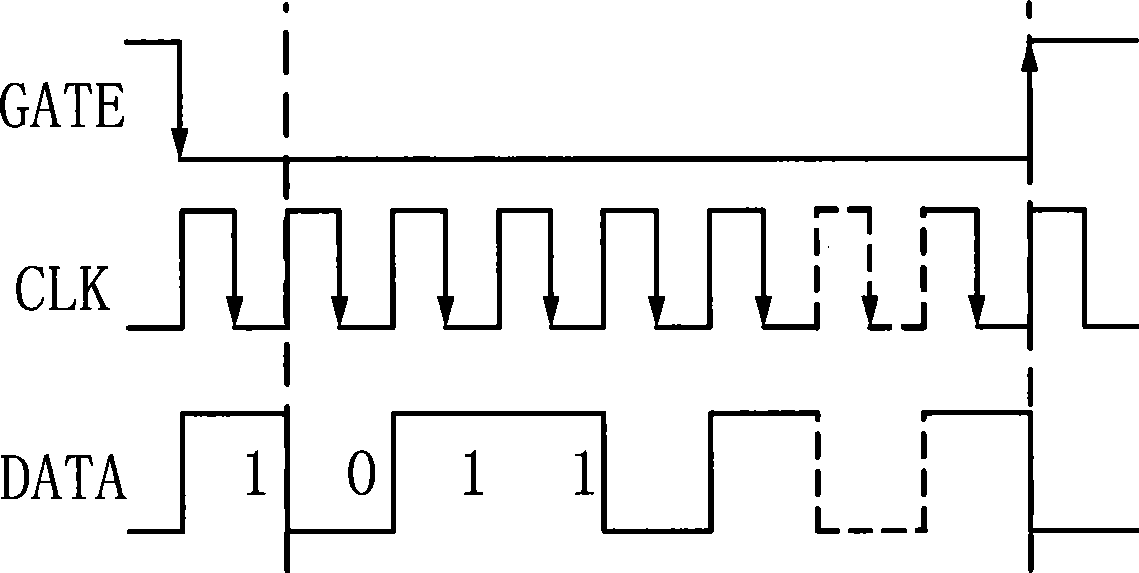

Payload management system and method for satellite

ActiveCN101488796ATo achieve the purpose of standardized designReduce complexitySpecial service provision for substationRadio transmissionSystems designDistributor

A satellite effective load management system and management method, the system comprises a load distributor, a storage module, a signal transformation processing module, a data multiple connection module and a center processor module, the modularization, integration, standardization effective load management system design conception provided by the invention integrates the data transmission, telemetering measurement remote control, power supply management to be centralized, meanwhile the standard, configurable effective load interface can be designed, so that the resource configuration and the interface configuration of the system are fixed and uniformed, the matching performance problem of effective load managing each task can be effectively solved, the good software and hardware platforms can be provided for time sequence, information and safety management of effective load management, thereby improving the effective load management design level and reducing the complicated degree, corresponding weight and power consumption and so on of the effective load management system, certain basis can be established for improving the whole star performance.

Owner:AEROSPACE DONGFANGHONG SATELLITE

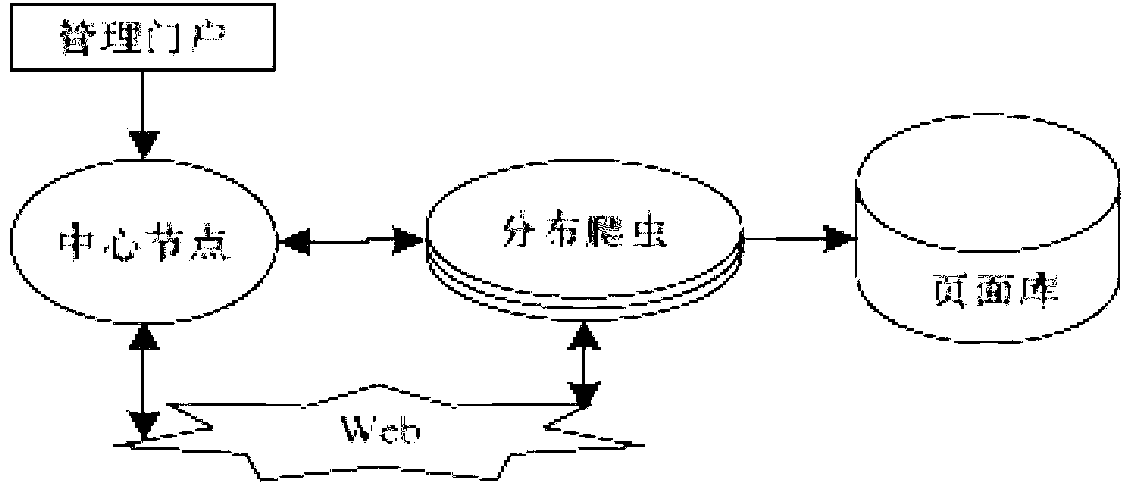

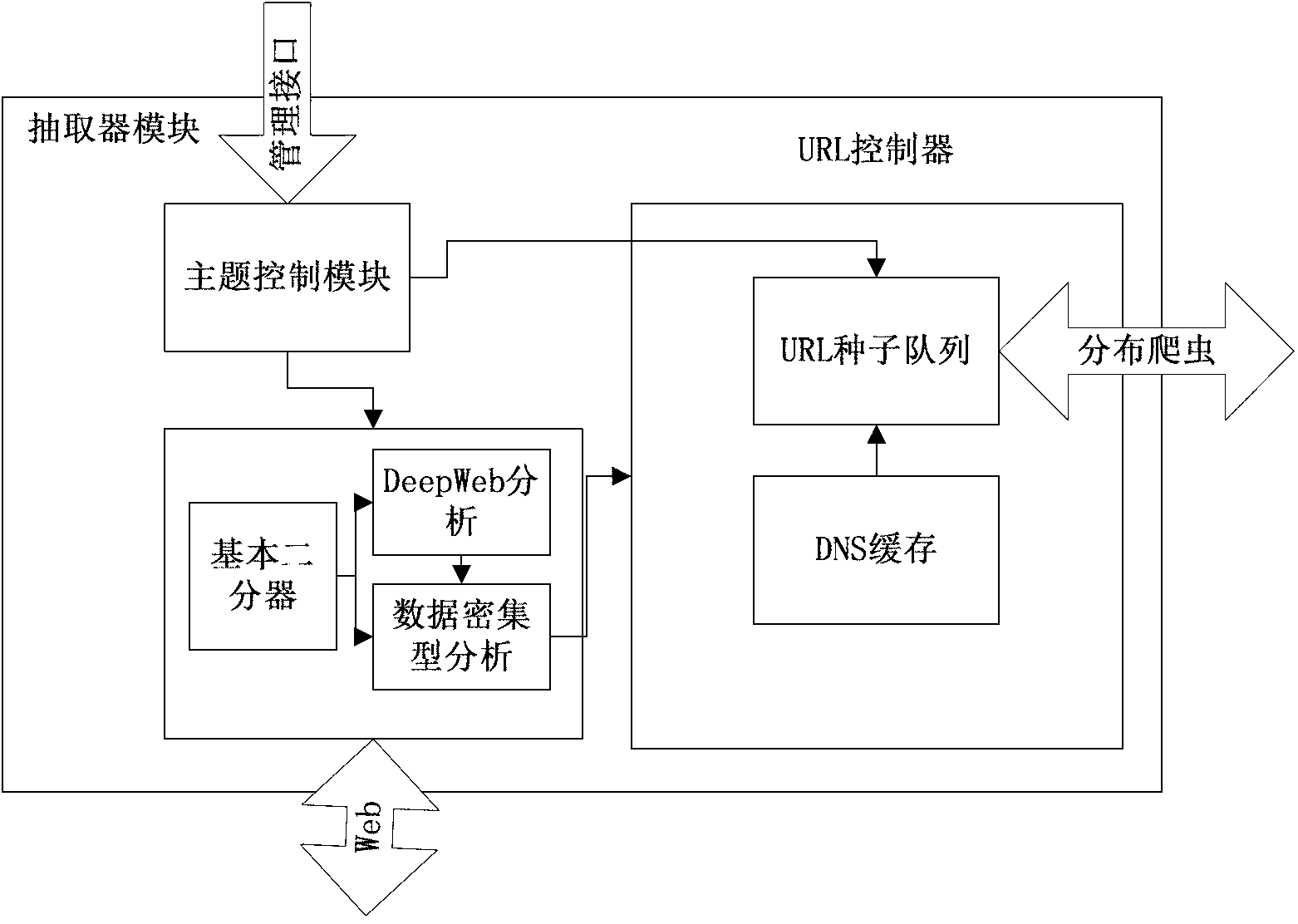

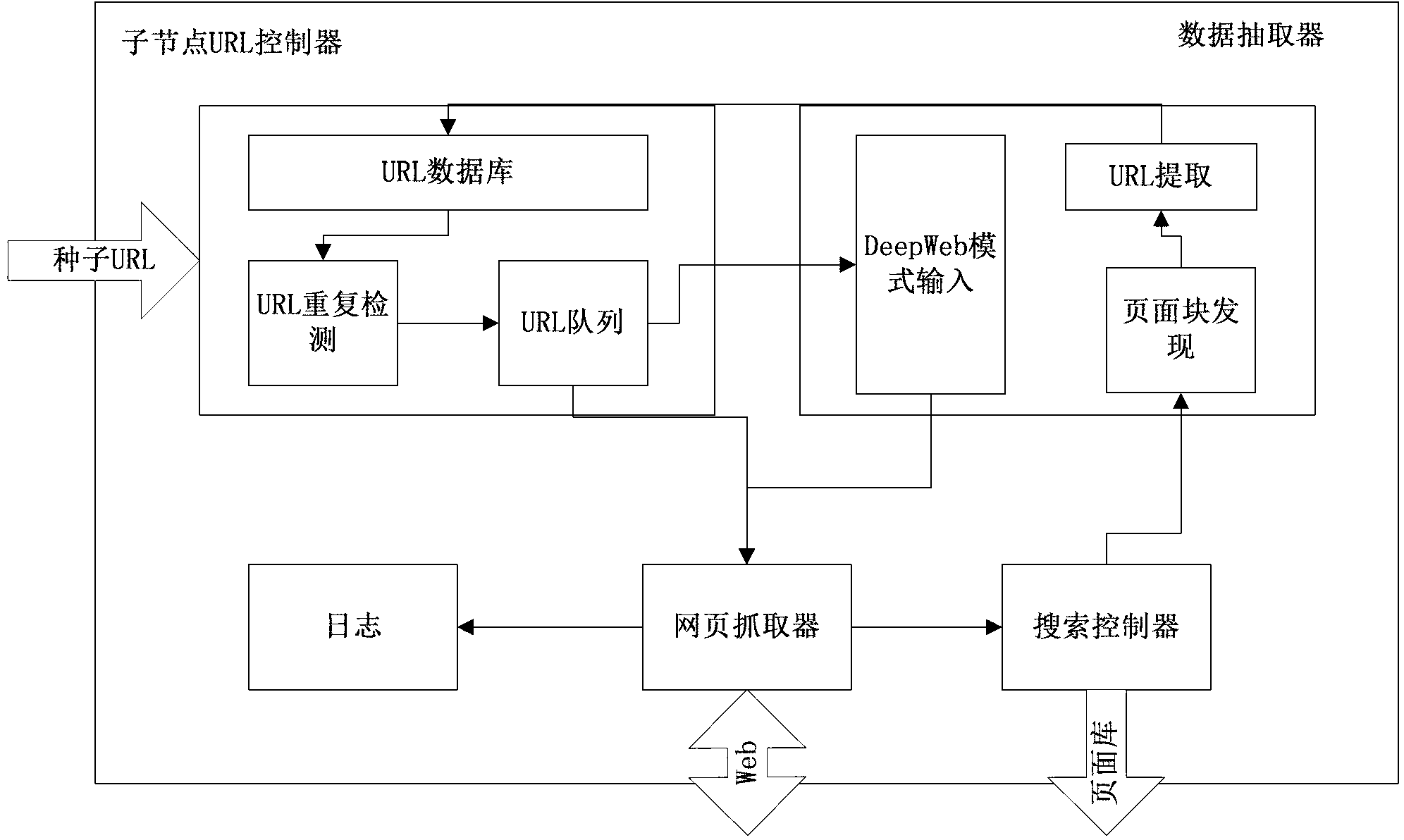

Distributed web crawler system

ActiveCN103310012ASolve Compatibility IssuesSolve the allocation problemSpecial data processing applicationsWeb crawlerUniform resource locator

A distributed web crawler system is suitable for the field of network information collection and comprises a management portal, a central node server and a distributed sub-node server, wherein the management portal is a Web interface provided for an administrator by the crawler system and can be used for viewing the logs of the central node server and the distributed sub-node server, setting and adding themes, updating a URL (uniform resource locator) seed of a theme, configuring a theme capture frequency parameter, and controlling a crawler state; the central node server and the distributed sub-node server are the main bodies of the system and can be used for operating the themes, learning a data extractor, analyzing pages and storing target pages. According to the distributed web crawler system, the capture of different themes can be accommodated by a crawler, the webpage capture speed is increased, and the quality meets the user requirement.

Owner:慧科教育科技集团有限公司

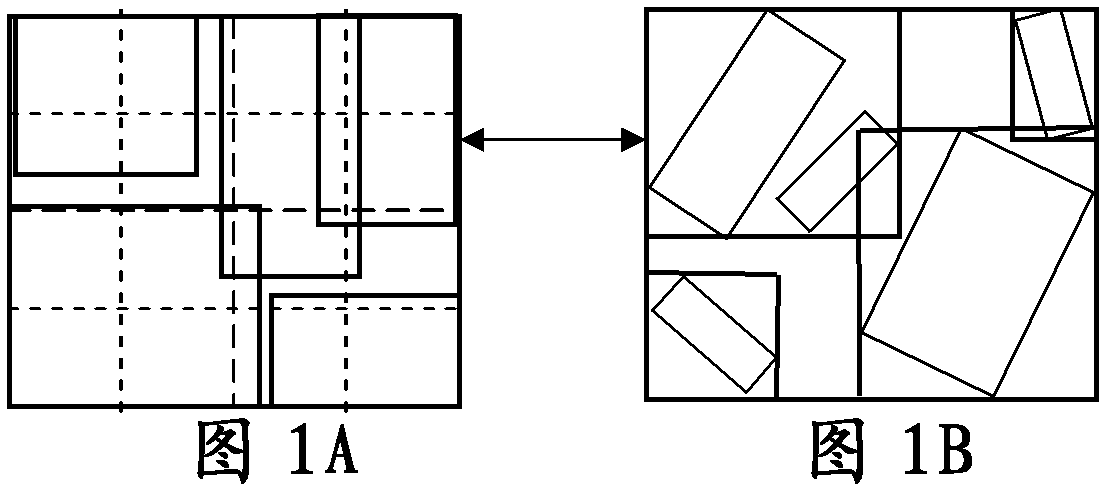

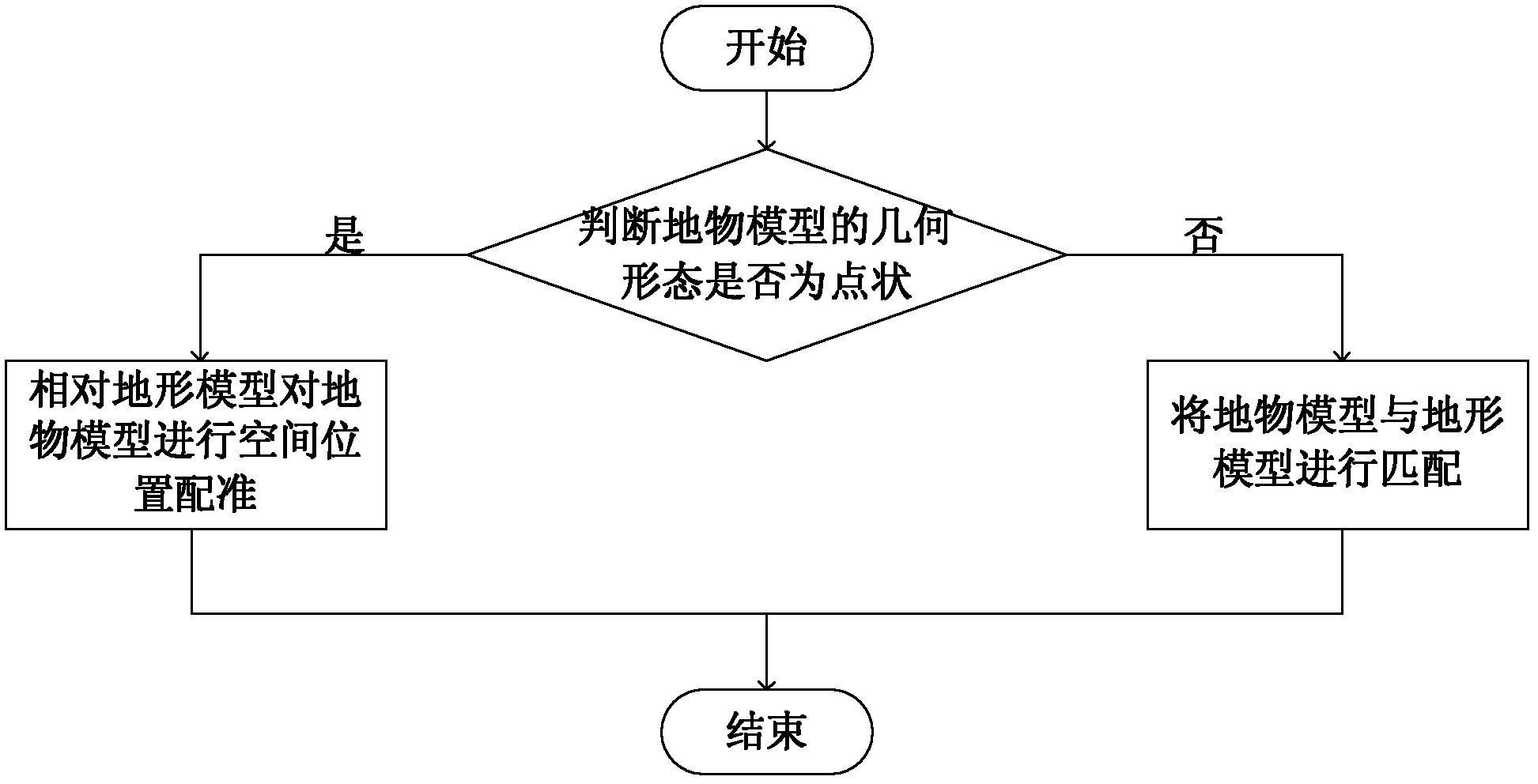

3D (three-dimensional) model matching method

InactiveCN102254350AAchieving Fusion MatchingAvoid crossing3D modellingTerrainThree dimensional model

The invention provides a 3D (three-dimensional) model matching method, comprising the following steps of: judging the geometric shape of a ground object model; if the geometric shape of the ground object model is punctiform, registering the spatial location of the ground object model relative to a terrain model; and if the geometric shape of the ground object model is planar or banded, matching the ground object model with the terrain model, so that hierarchic fusion matching between data of the ground object model and data of the terrain model is realized, thereby solving such distortion problems that the ground object model floats in the air or goes underground under the condition of a visual scale.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

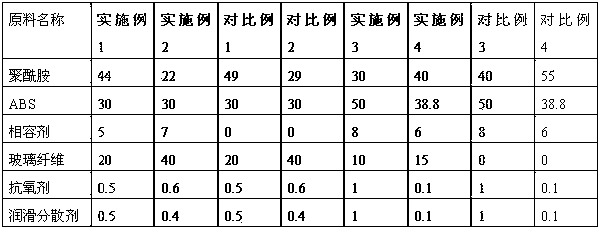

Polyamide/polyketone alloy material

The invention provides a polyamide / polyketone alloy material. The polyamide / polyketone alloy material comprises 55-85% of polyamide PA, 10-40% of polyketone POK, 0-10% of compatilizer, 0-3% of anti-wear agent, 0.3-1% of lubricant and 0.3-1% of compound heat stabilizer. The obtained polyamide / polyketone alloy material having excellent wear resistance is prepared through a double screw extruder; and the alloy material can be used for injection molding or extrusion molding material formed high-wear-resistance plastic components.

Owner:温州市赢创新材料技术有限公司

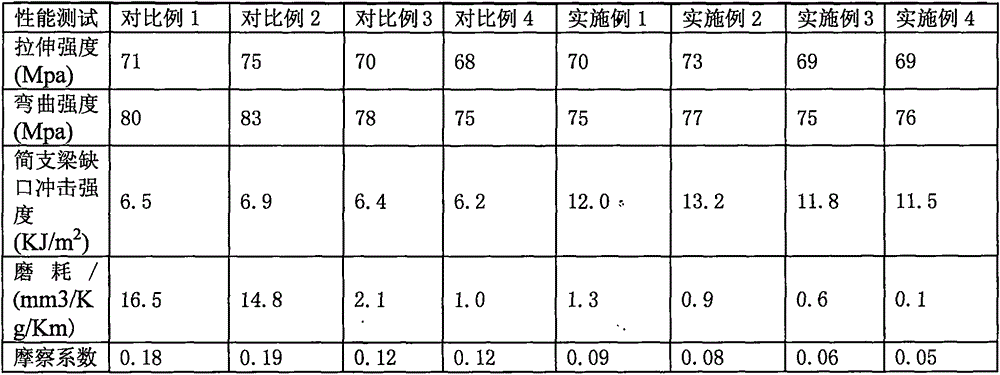

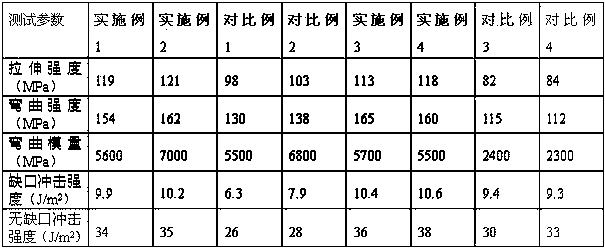

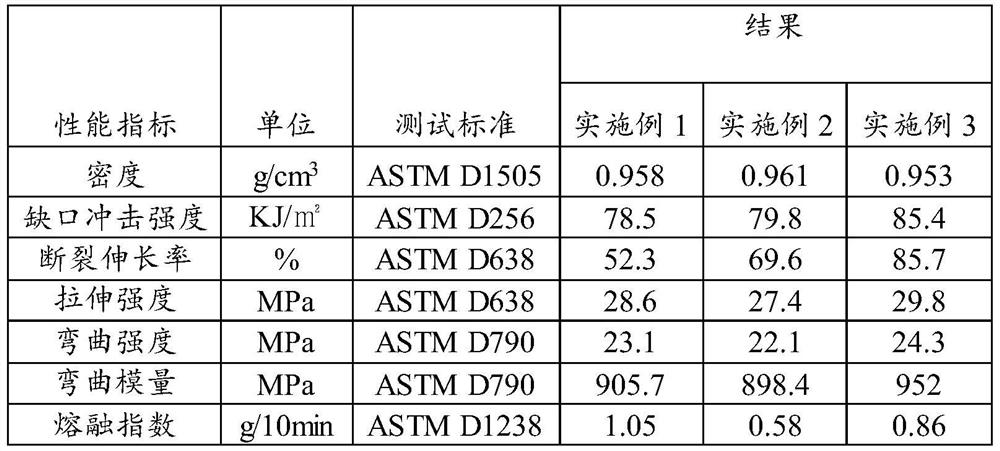

High-strength high-toughness glass-fiber-reinforced PA/ABS (polyamide/acrylonitrile-butadiene-styrene) composite material and preparation method thereof

The invention discloses a high-strength high-toughness glass-fiber-reinforced PA / ABS (polyamide / acrylonitrile-butadiene-styrene) composite material which is prepared from the following raw materials in percentage by weight: 10-65% of polyamide, 10-50% of ABS, 5-15% of compatilizer, 10-40% of glass fiber, 0.1-1% of antioxidant and 0.1-1% of lubricating and dispersing agent. The invention also discloses a preparation method of the high-strength high-toughness glass-fiber-reinforced PA / ABS composite material. The glass-fiber-reinforced PA / ABS composite material disclosed by the invention has the advantages of high strength, high toughness, stable quality and excellent comprehensive mechanical properties, and can be widely used in products in the fields of automobile interior and exterior components, electronic and electric appliances and the like.

Owner:SHANGHAI SUNNY

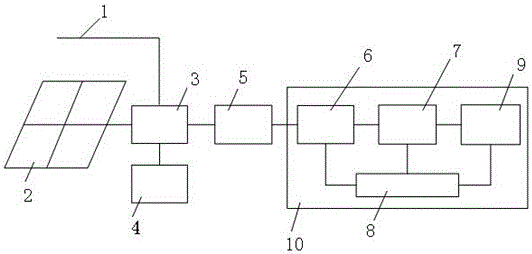

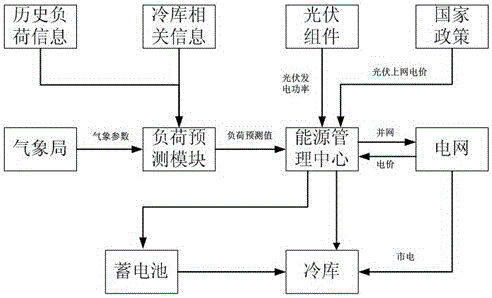

Photovoltaic refrigerator system controlled based on load prediction and demand response of neural network

ActiveCN105928292AEffective combinationSolve Compatibility IssuesBatteries circuit arrangementsLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a photovoltaic refrigerator system controlled based on the load prediction and demand response of a neural network. A city power grid is connected with a control circuit, a photovoltaic cell panel is connected with an inverter circuit through the control circuit, and the inverter circuit is connected with a refrigerator. A load prediction module is used for building a refrigerator load prediction model according to the meteorological data of Meteorological Bureau, historical load information, refrigerator storing capacity, the types of stored goods and refrigerating temperature and predicting the future load of the refrigerator. An energy management center module is used for making an operation strategy and carrying out control through photovoltaic generation power, the predicted load of the refrigerator and the comparison and analysis of photovoltaic generation on-grid power price and city power price. The photovoltaic refrigerator system can realize the effective combination of photovoltaic generation and the refrigerator, solves the matching problem of photovoltaic generation and the refrigerator through load prediction, reduces fluctuation caused by photovoltaic generation to the power grid, and can not only meet the requirements of users but also realize energy saving and emission reduction.

Owner:山东三九制冷设备有限公司

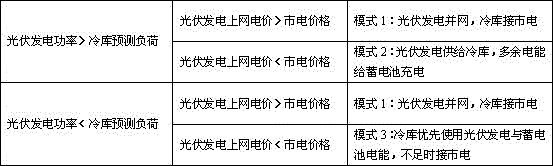

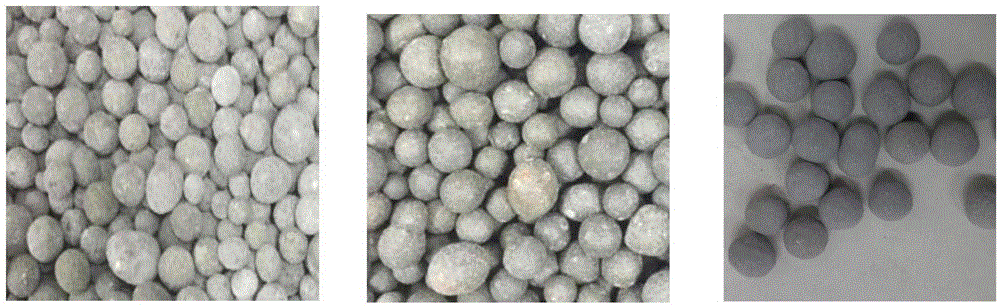

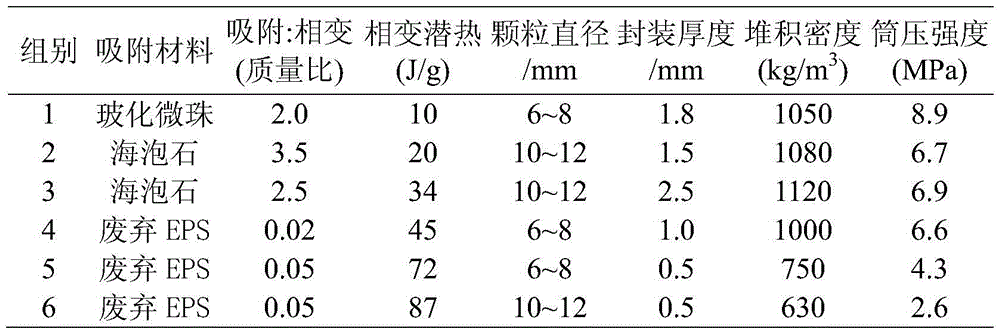

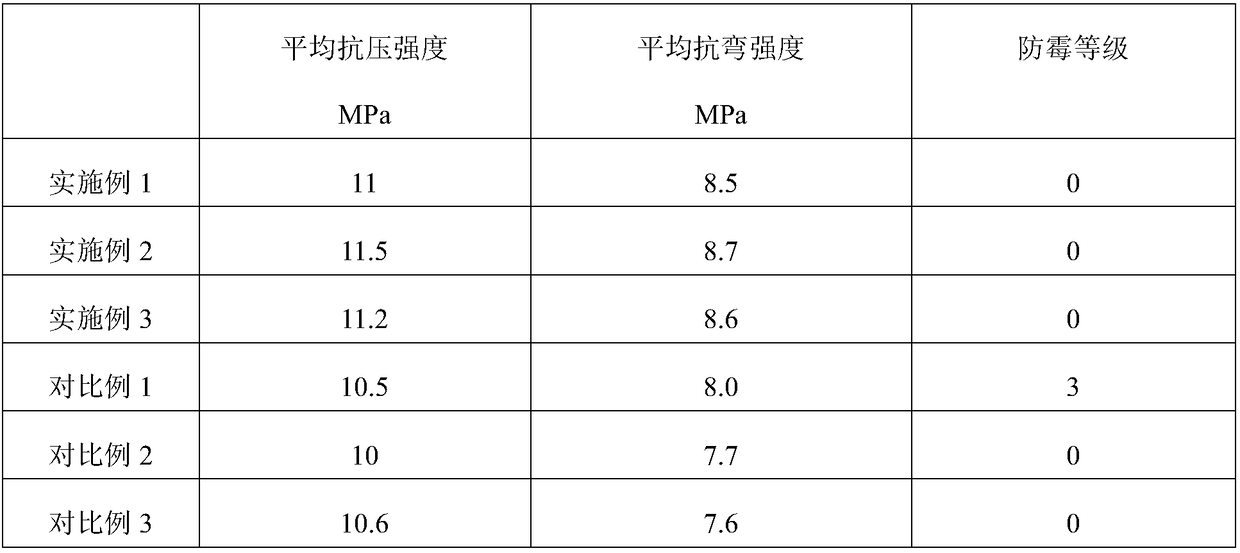

Building phase-change heat storage composite material used as light aggregate

InactiveCN105621918AHigh strengthSolve compatibility issuesHeat-exchange elementsHeat storage materialCompressive strength

The invention discloses a building phase-change heat storage material used as light aggregate, which solves the problems of difficulty in storage, high leakage tendency in use, and difficulty in actual construction in the phase-change material which is used in building materials at present. The phase-change heat storage material serving as an aggregate has adjustable phase-change temperature points. The particle diameter is 1.6-20mm, the phase-change latent heat is 10-100 J / g, the cylindrical compressive strength is 2.5-10.0 MPa, and the 80-DEG C cold / heat circulation loss rate is almost zero. The heat storage material is applicable to mortar, concrete or masonry structures with requirements for the heat storage function. The building phase-change heat storage composite material is composed of an adsorbing material, a phase-change material and a packaging material. The adsorbing material adsorbs a certain proportion of the phase-change material with the phase-change temperature of 15-32 DEG C, and then is packaged by the packaging material. The building phase-change heat storage composite material has the advantages of favorable sealability, controllable phase-change temperature and higher strength, and can solve the problems of difficulty in storage, low stability, poor formability and the like in the existing phase-change material.

Owner:SOUTHEAST UNIV

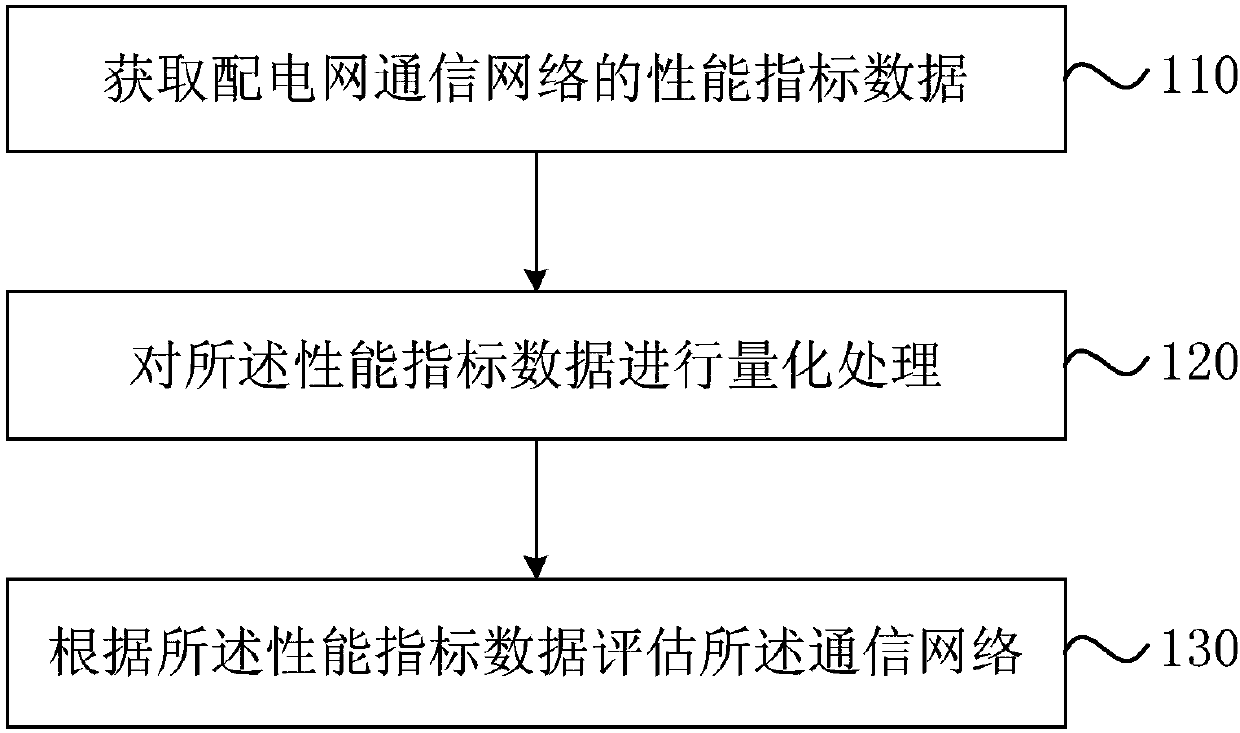

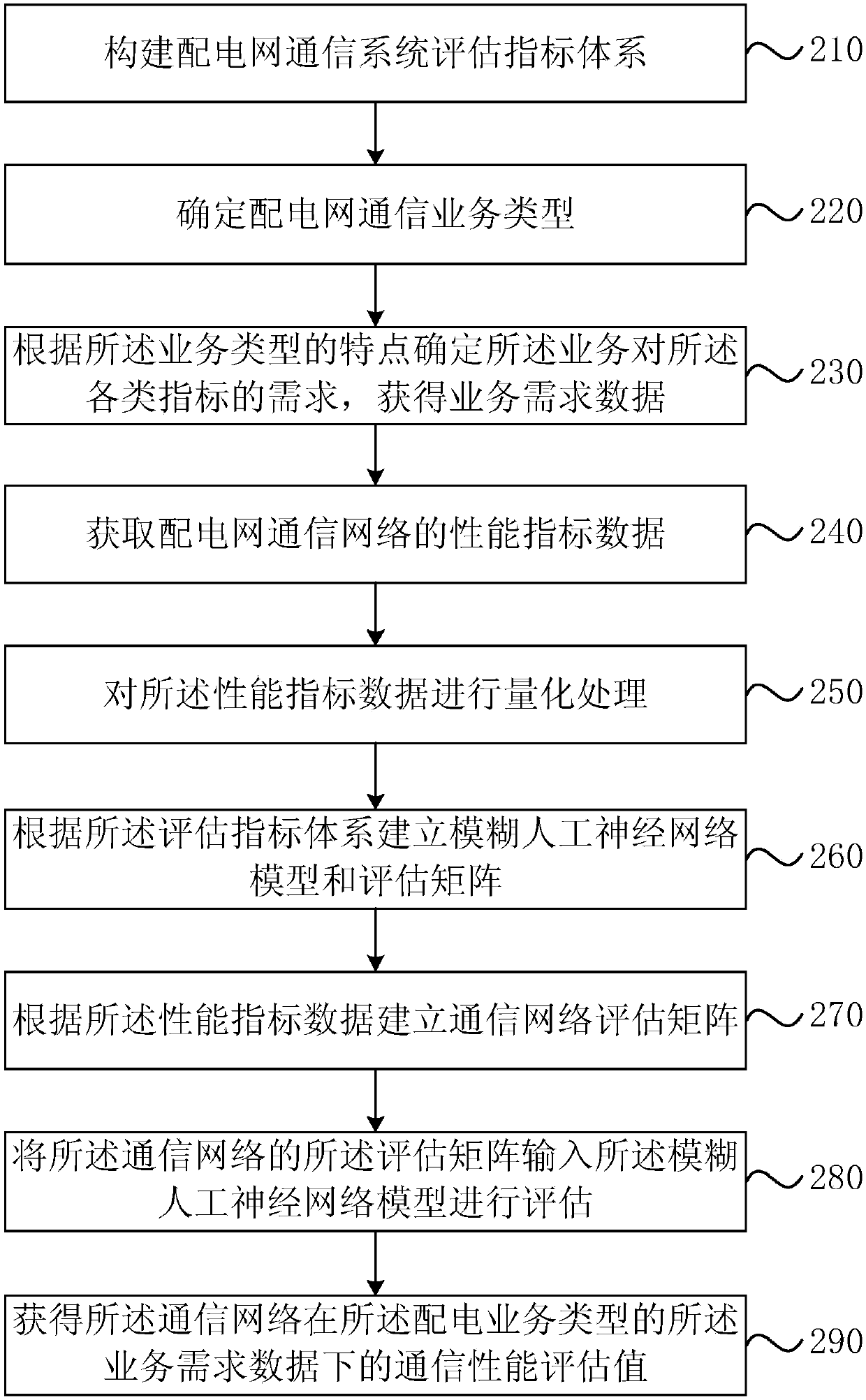

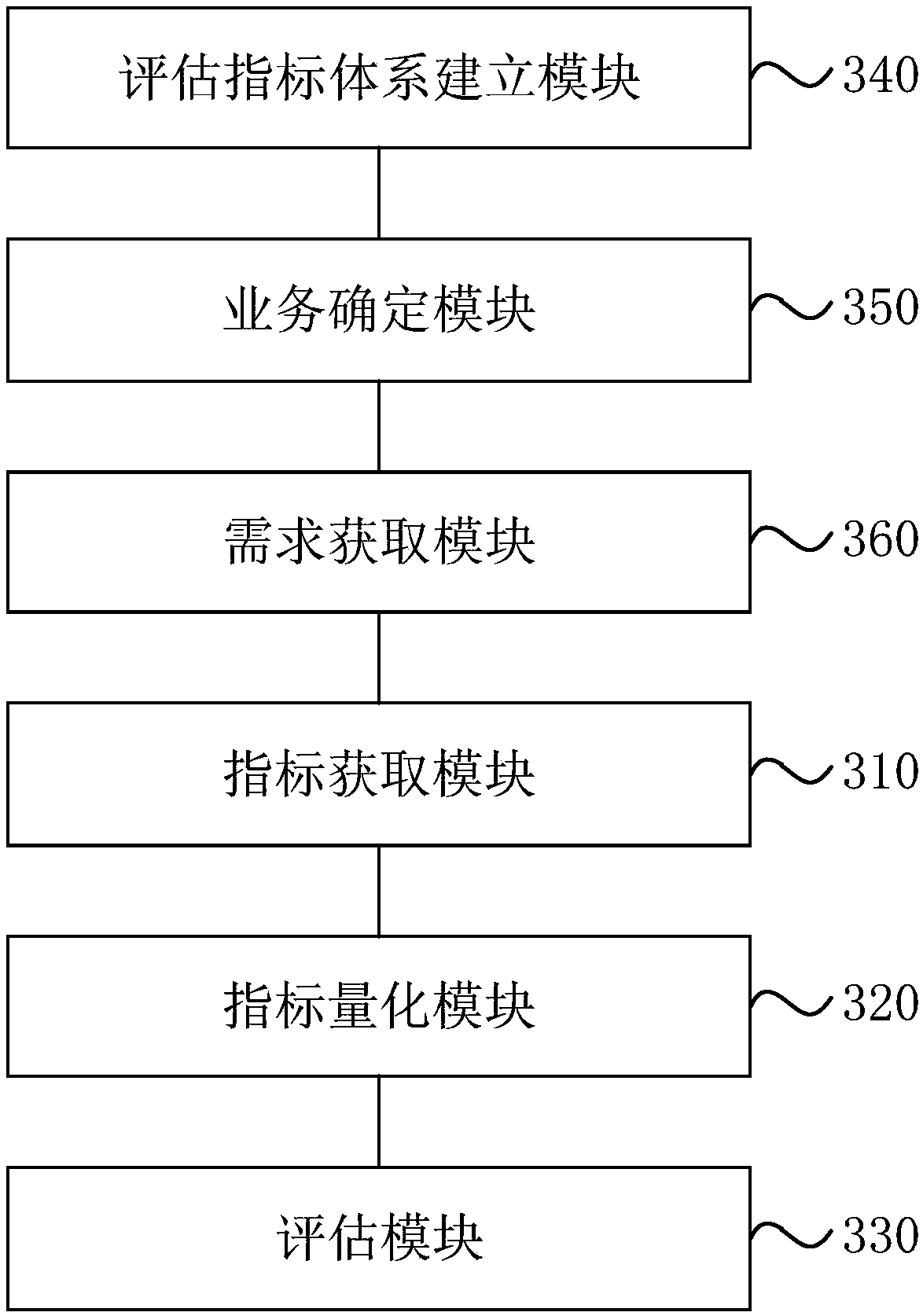

Power distribution network communication system performance evaluation method and device

InactiveCN107634866ASolve Compatibility IssuesImplement Performance EvaluationData switching networksAssessment methodsIndex system

The invention discloses a power distribution network communication system performance evaluation method and device. The method comprises the steps of obtaining performance index data of a power distribution network communication system; carrying out quantization processing on the performance index data; and evaluating the communication network according to the performance index data. According tothe method and the device, a communication performance evaluation index system adaptive to power distribution network communication business transmission is defined, various pieces of performance index data are obtained, fussy normalization processing is carried out on the performance index data, and the communication network is evaluated according to the performance index data. The matching between a communication technology and power distribution business is solved, and the guidance for the model selection of the communication technology in a power distribution communication network construction and transformation process is provided. The performance evaluation of the communication system under different power distribution network business type demands is realized.

Owner:朱秋华

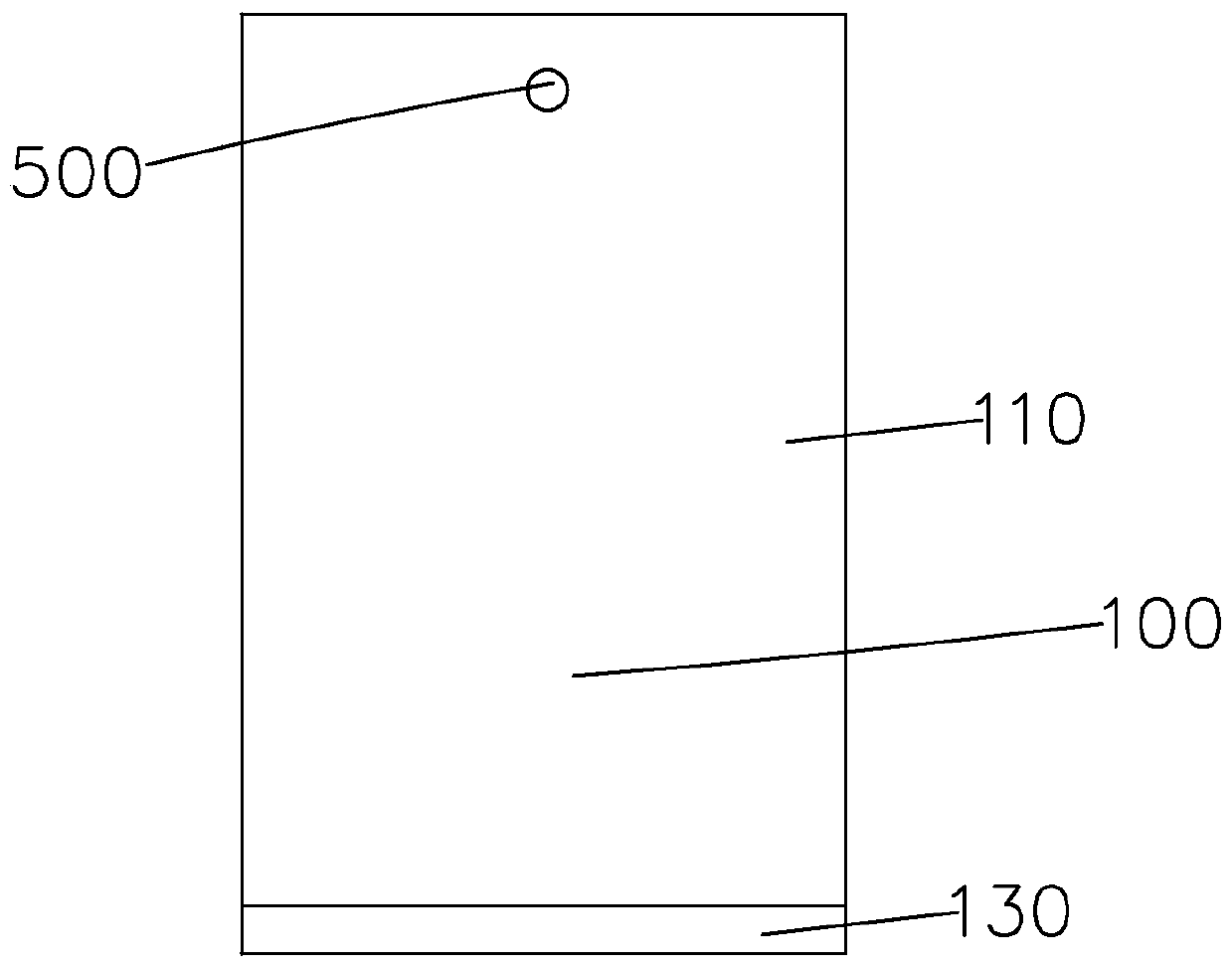

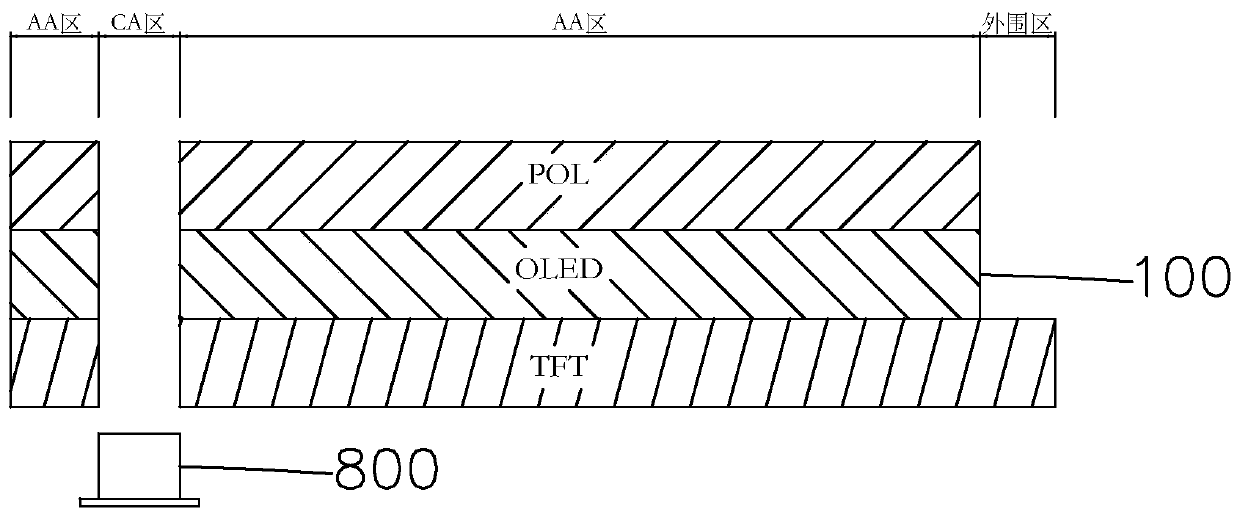

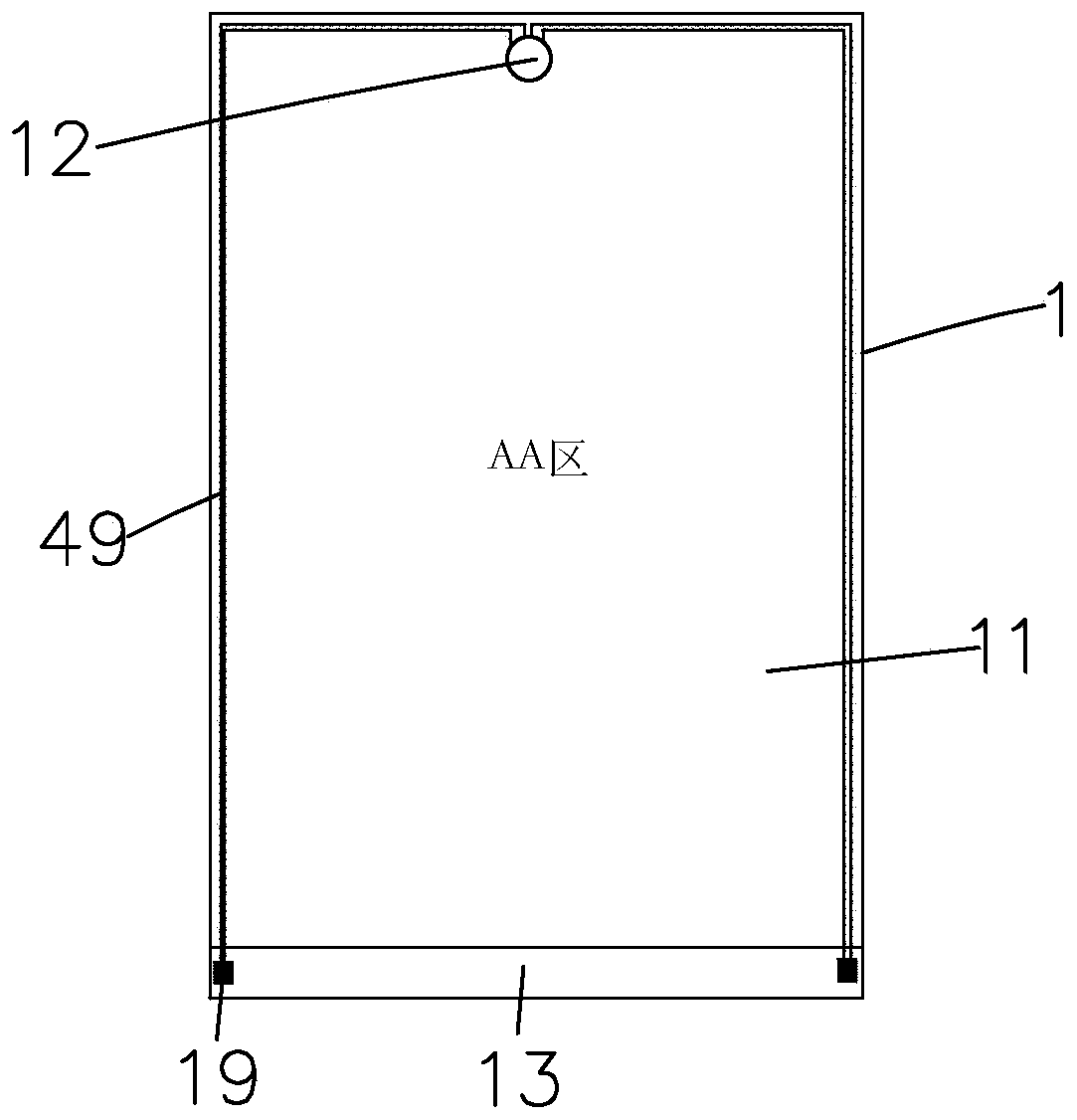

OLED display device

ActiveCN110071150AIncrease the screen ratioImprove AssemblabilitySolid-state devicesSemiconductor devicesDisplay deviceTransmission line

The invention provides an OLED display device comprising a display panel and a camera component, wherein the display panel comprises a base substrate and a display film layer, the camera component comprises a sensor, a signal module and a lens, the sensor is disposed on a recess of the base substrate, the height of the sensor is greater than the depth of the recess, the upper end of the sensor andthe signal module extend into the TFT layer of the display film layer, the TFT layer is internally provided with a camera signal transmission line electrically connected to the signal module, and thelens is disposed in the opening of the display film layer correspondingly located to the upper part of the sensor. The OLED display device provided by the invention respectively builds the sensor andlens of the camera component into the display panel structure relatively independently such that the assembly of the camera component is during the manufacturing process of the display panel, therebyimproving the degree of integration of the display panel and the camera component, realizing the high-integration assembly of the OLED display device with the design of the under-screen camera, and effectively improving the screen ratio and the assemblability of the display device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

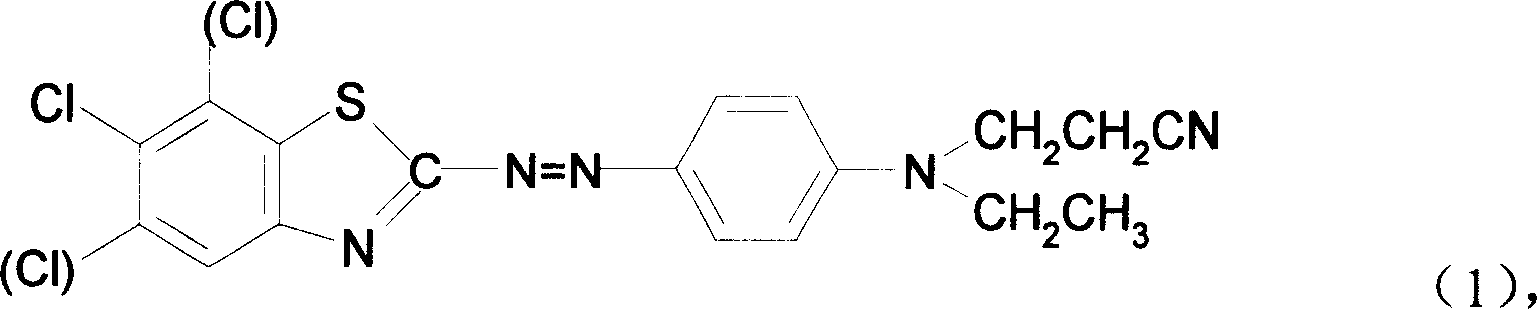

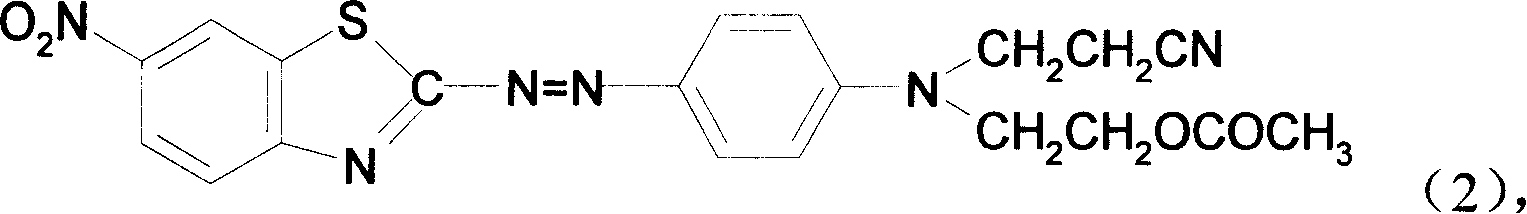

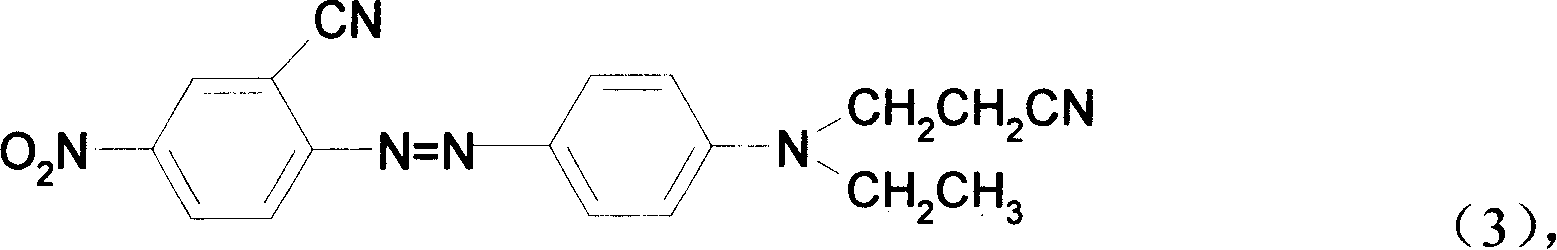

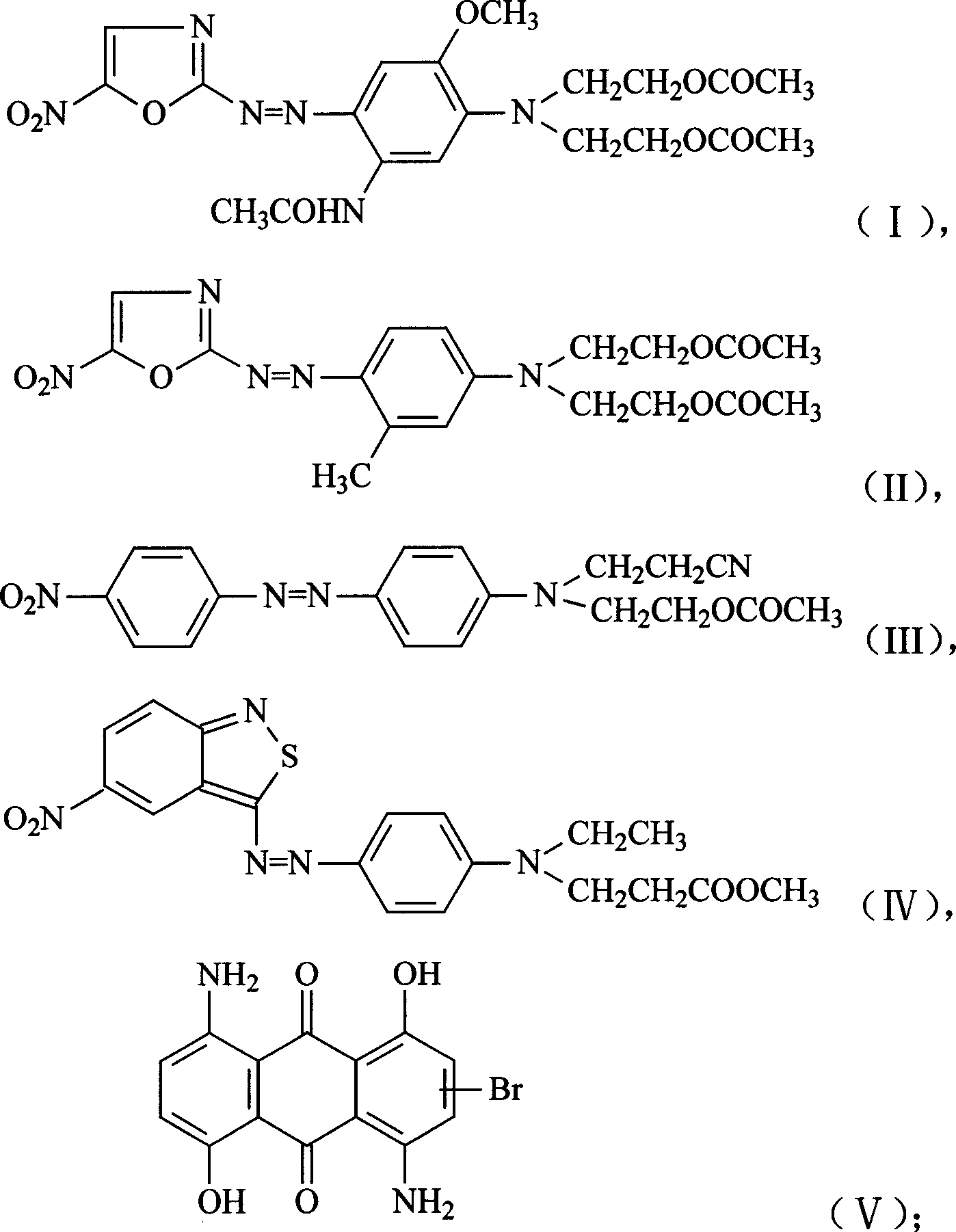

Red dispersion dyes mixture

The present invention relates to one kind of red dispersive dye mixture for printing and dyeing polyester material, and provides one new kind of red dispersive dye mixture with high level dyeing property, good dyeing reproductivity, high build-up and excellent fastness. The red dispersive dye mixture is prepared with dye A 12-27 wt%, dye B 21-42 wt%, dye C 1-10 wt%, dye D 1-10 wt%, and assistant for the rest, and through a conventional preparation process. The assistant is one or several of naphthalene sulfonic acid-formaldehyde condensate, methyl naphthalene sulfonic acid-formaldehyde condensate, benzyl naphthalene sulfonic acid-formaldehyde condensate and lignosulfonate.

Owner:ZHEJIANG JIHUA GROUP +1

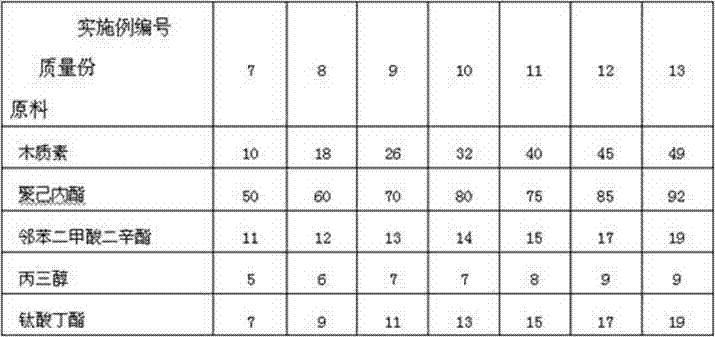

Lignin/polycaprolactone environment-friendly degradable film and preparation method thereof

InactiveCN102924893AImprove the interface binding forceImprove mechanical propertiesSolventChemistry

The invention discloses a lignin / polycaprolactone environment-friendly degradable film and a preparation method thereof. The preparation method is characterized by comprising the following steps: 5-50 parts by mass of lignin, 50-95 parts by mass of polycaprolactone, 10-20 parts by mass of dioctyl phthalate, 5-10 parts of by mass glycerol and 5-20 parts of by mass of solubilizer, and evenly mixing to obtain a blend compound; adding the blend compound into a double-screw extruder, carrying out melt blending at 60-140 DEG C under the pressure of 0.5-1.0 MPa for 10-15 minutes, extruding to form, cooling, and granulating to obtain the cylindrical granular blend material; and extruding the cylindrical granular blend material with an inflation film manufacturing machine, and carrying out blow molding and film formation to obtain the lignin / polycaprolactone environment-friendly degradable film. The lignin / polycaprolactone environment-friendly degradable film has the advantages of excellent degradability, excellent stretching resistance, excellent mechanical properties, wide raw material sources, simple technique and strong practicality, and can easily implement industrial production.

Owner:SOUTHWEAT UNIV OF SCI & TECH

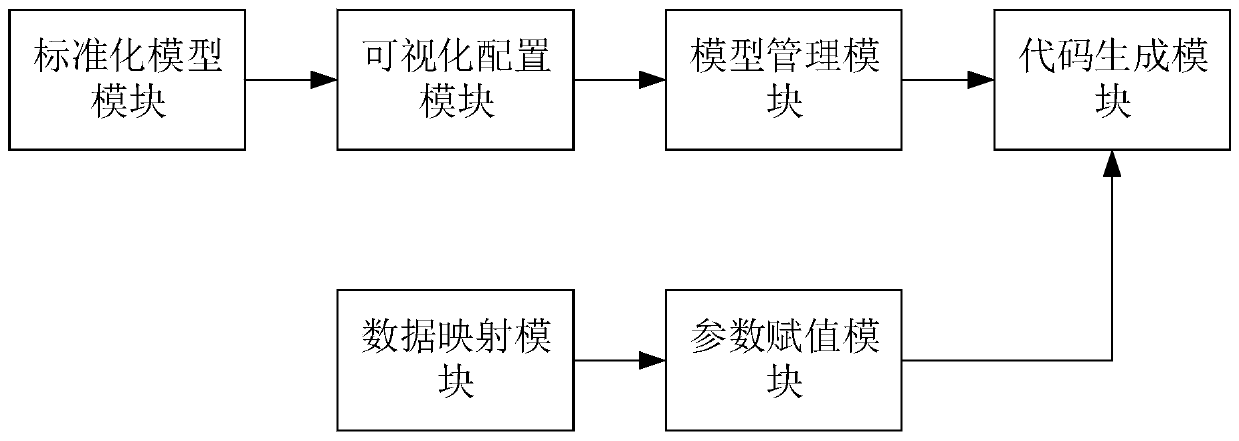

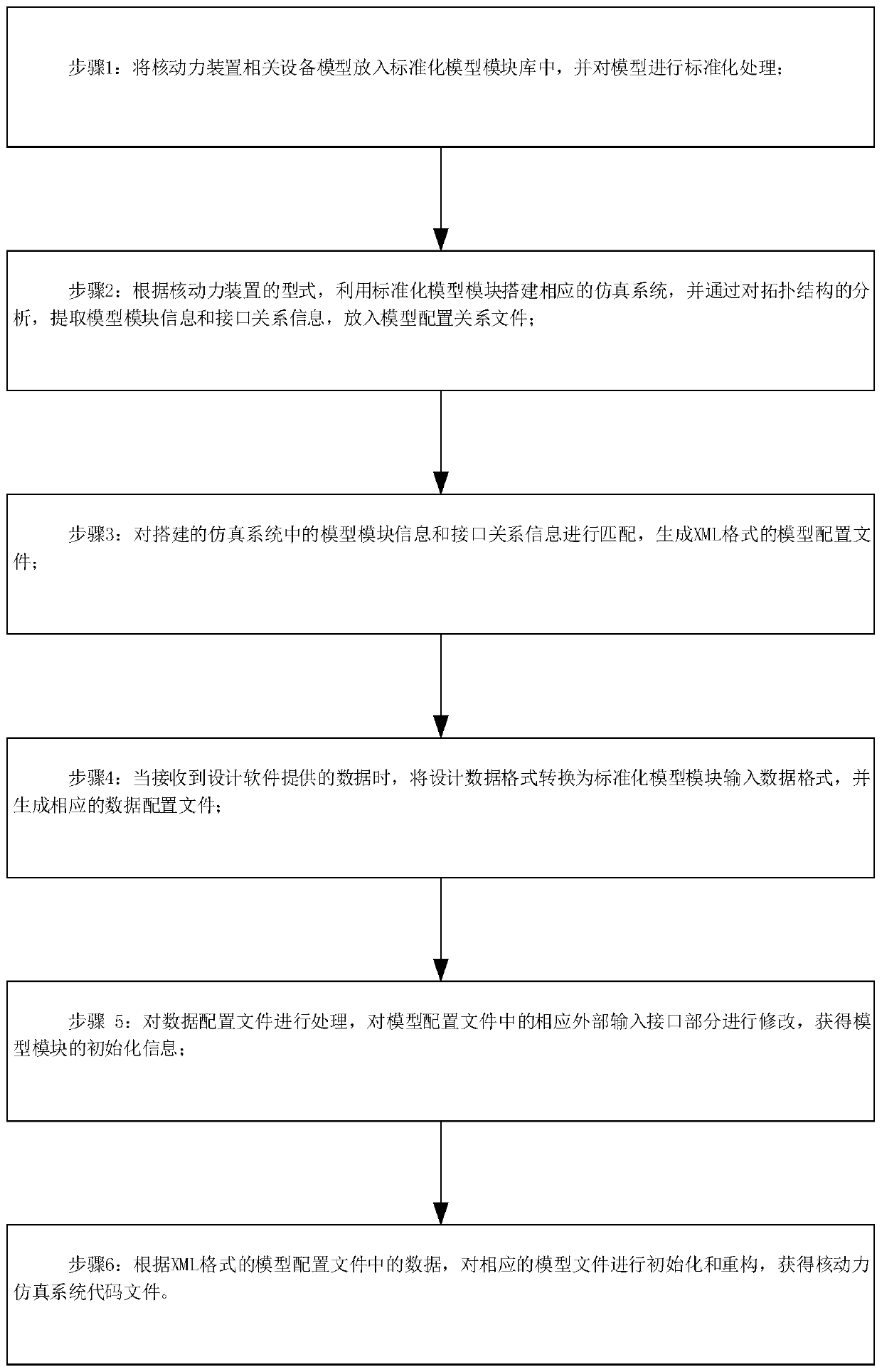

Simulation model development system of nuclear power device and analysis method

PendingCN110705078AReduce complex system designImprove device development efficiencyAnalogue computers for nuclear physicsDesign optimisation/simulationCode generationData class

The invention discloses a simulation model development system for a nuclear power device, and the system comprises a standardized model module which is used for simulating related equipment forming the nuclear power device; a visual configuration module used for establishing an association relationship between the standardized model modules; a model management module used for storing the corresponding standardized model module information and interface relationship information into a model configuration file in an XML format; a data mapping module used for realizing format conversion of data types between the design software and the analysis software; a parameter assignment module used for obtaining initialization parameter information of the model; and a code generation module used for initializing and reconstructing the corresponding model to obtain a simulation model code. The system has the advantages that the matching problem of each independently designed nuclear power subsystemis solved, and a technical means is provided for discovering design defects and optimizing system operation.

Owner:HARBIN ENG UNIV

Water-soluble color sand self-leveling polyurethane mortar

InactiveCN106927725AImprove mechanical propertiesWide range of temperature adaptationVegetable oilWear resistant

The invention provides a water-based colored sand self-leveling polyurethane mortar, which can be used as an industrial floor and has excellent properties, such as heavy impact resistance, mechanical heavy load resistance, chemical resistance, etc., and can be used in high temperature and humid environments. The polyurethane mortar of the invention uses colored quartz sand to match the color paste, and the overall coating has sufficient compatibility, which can realize the long-term artistic decoration of the floor. The polyurethane mortar of the present invention adopts modified vegetable oil polyether polyol water dispersion, and diisocyanate, such as diphenylmethane diisocyanate (MDI), and high-performance concrete is cured at the same time, and the colored quartz sand in the system can strengthen The hardness of the coating, the obtained coating is durable and wear-resistant, and has various decorative effects. The polyurethane mortar system of the present invention can also be used for repairing and renovating building entities, or realizing decoration purposes on various substrates, etc.

Owner:广州固耐特新材料有限公司

Anti-corrosion process for steel structure

InactiveCN109622332ASimple anti-corrosion processSimple processAnti-corrosive paintsSpecial surfacesEpoxyHydrogen

The invention discloses an anti-corrosion process for a steel structure. The anti-corrosion process comprises the following steps of S1, surface pretreatment of the steel structure, S2, surface descaling of the steel surface, S3, preparation of waterborne rust anticorrosive coating for the steel structure, S4, preparation of a primer, S5, steel structure coating, and S6, paint coating quality inspection and acceptance. The anti-corrosion process combines the characteristics of an epoxy emulsion and an acrylic emulsion to improve the comprehensive performance of the coating, a polyaniline emulsion is directly added into the coating to solve the compatibility problem between polyaniline and other polymer emulsions and the stability problem of the prepared anticorrosive coating, the anti-corrosion performance of the coating is improved, acid and active hydrogen in conversion liquid and polyaniline can promote the curing of the epoxy resin to be used as a curing agent for an epoxy emulsion, the process is simple, and the cost is low. The anti-corrosion process of the steel structure is simple, has good anti-corrosion performance and simple construction, can greatly reduce the labor intensity of coating, has high weather resistance, and can realize long-term protection for the steel structure.

Owner:淮北市菲美得环保科技有限公司

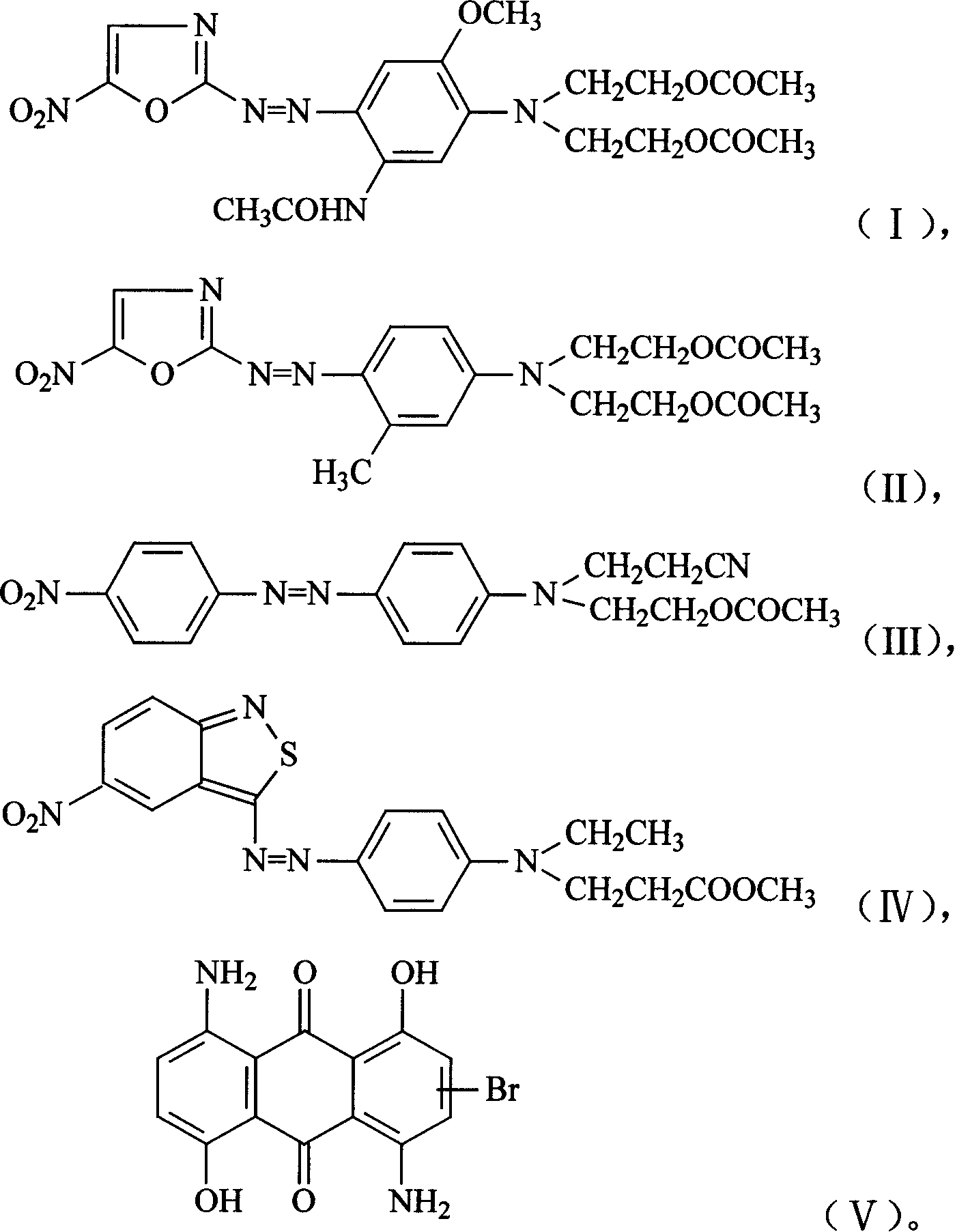

Disperse dye mixture and its product

ActiveCN1931927AGood compatibilityGood same colorOrganic dyesDyeing processDisperse dyePhotochemistry

The present invention relates to disperse dye mixture and its product. The disperse dye mixture and its product have excellent level dyeing property, good compatibility, high build-up and good dyeing homochromatism at different temperature. The disperse dye mixture consists of following fiver dye components: dye A 10-80 wt%, dye B 1-70 wt%, dye C 10-80 wt%, dye D 1-50 wt%, and dye E 1-35 wt%, with all the dye components being shown in the expresses. The disperse dye mixture product features its composition of the disperse dye mixture and assistant in weight ratio of 1 to 0.6-8.

Owner:ZHEJIANG JIHUA GROUP +1

Method for preparing wood-plastic composite material from cherry wood chips

The present invention provides a method of preparing a wood-plastic composite material from cherry wood chips, and the method comprises the steps of wood chip treatment, mixing, granulation, and forming. According to the method, the wood chips are firstly modified with calcium stearate and nano-alumina, and then mixed with modified basalt fiber, glass fiber, waste plastic, nano zinc oxide and magnesium salt whisker for granulation and forming. The prepared wood-plastic composite material uses the cherry wood chips and the waste plastic as main materials, is beneficial to the reuse of waste andscrap, can save energy and relieve environmental pressure, and has better mechanical properties.

Owner:贵港市万升木业有限公司

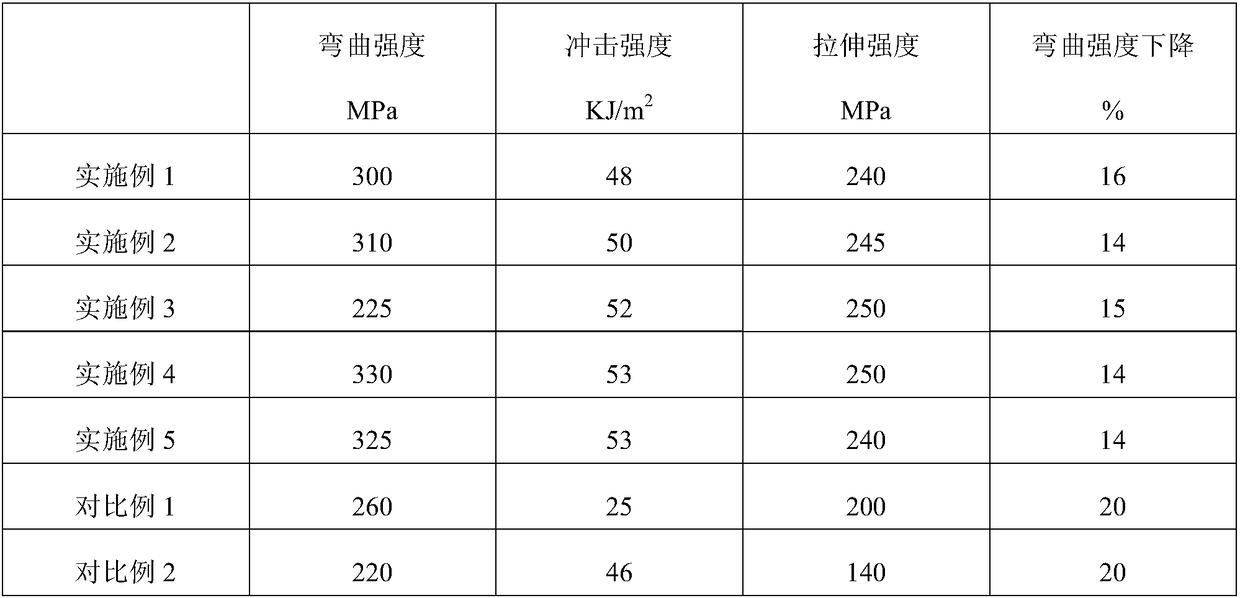

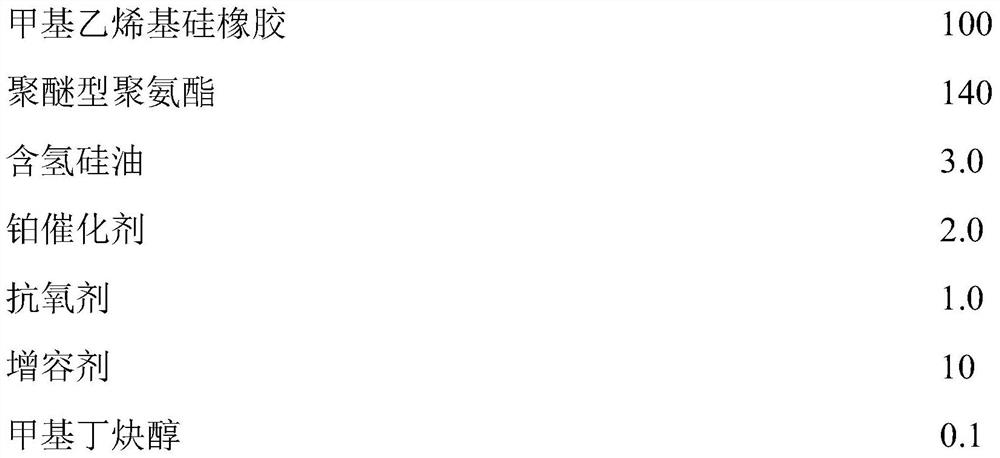

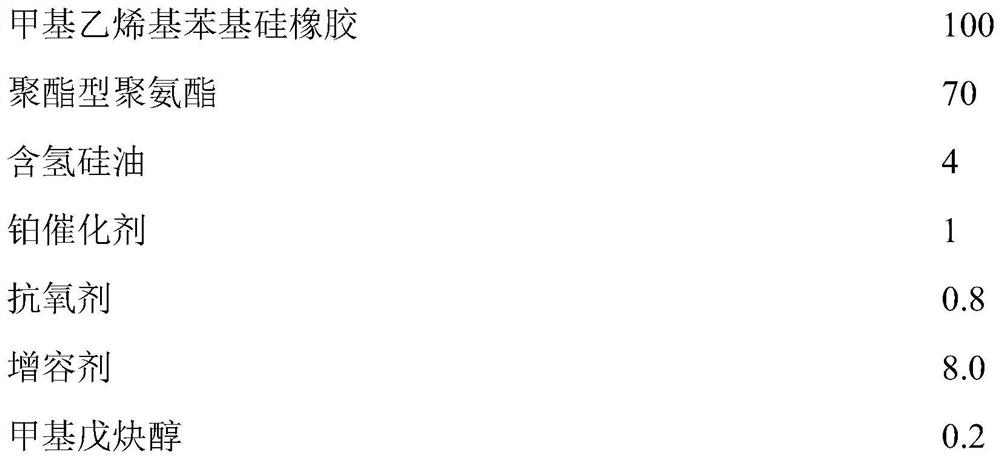

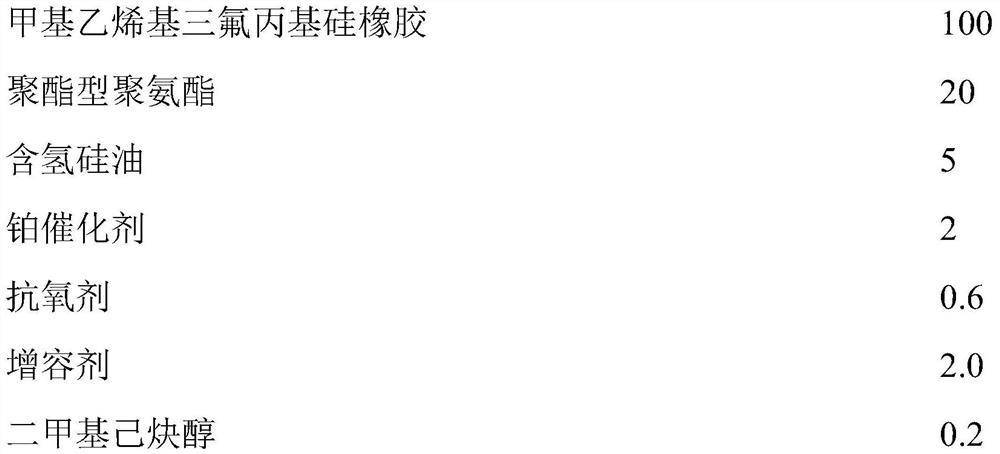

Silicone rubber/polyurethane thermoplastic vulcanized rubber as well as preparation method and application thereof

ActiveCN112143231ASolve compatibility issuesCross-linking speed is easy to controlThermoplasticOrganosilicon

The invention provides silicone rubber / polyurethane thermoplastic vulcanized rubber and a preparation method thereof. According to the invention, a block copolymer of organosiloxane is used as a compatibilizer to improve the compatibility of silicone rubber and polyurethane; and meanwhile, through a new dynamic vulcanization process design, the polyurethane is partially isolated from a platinum catalyst, so that the influence of the polyurethane on the platinum catalyst is reduced, and the material performance is improved. The silicone rubber / polyurethane thermoplastic vulcanized rubber provided by the invention has excellent mechanical properties and elasticity, and the extrusion surface is smooth.

Owner:BEIJING UNIV OF CHEM TECH

Special adhesive for foam glass insulation system as well as preparation method and use method of adhesive

ActiveCN107337409AExcellent water resistance tensile bond strengthImprove the economic efficiency of the enterpriseClimate change adaptationHeat proofingEtherWater resistant

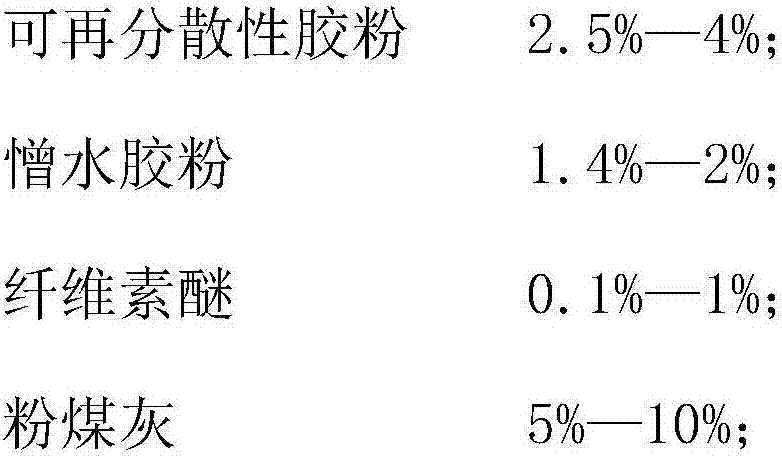

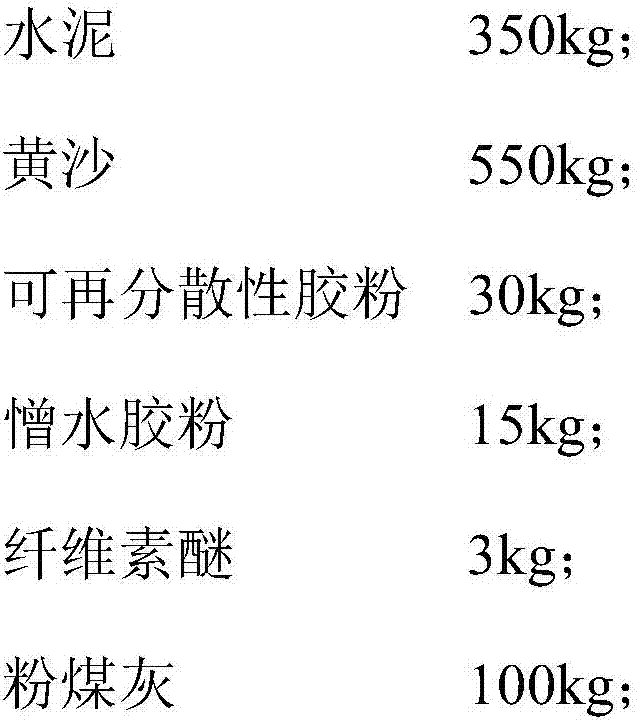

The invention relates to the technical field of adhesives for building materials, in particular to a special adhesive for a foam glass insulation system as well as a preparation method and a use method of the adhesive. The adhesive is characterized by being prepared from raw materials in percentage by mass as follows: 20%-40% of cement, 51%-63% of yellow sand, 2.5%-4% of redispersible rubber powder, 1.4%-2% of hydrophobic rubber powder, 0.1%-1% of cellulose ether and 5%-10% of fly ash, wherein the cement is level-42.5 cement; the yellow sand is dry middle sand which is 40-70 meshes. Compared with the prior art, the adhesive has enough tensile bond strength and shear strength, particularly has excellent water resistant strength and tensile bond strength and has flexibility; the problem about bonding matching of a base material with foam glass in an external wall insulation system is solved, and a foam glass insulation system product with excellent combination property is provided for building insulation market.

Owner:上海永丽节能材料有限公司

High-modulus and low-dielectric-constant basalt fiber enhanced PC (polycarbonate) material and preparation method thereof

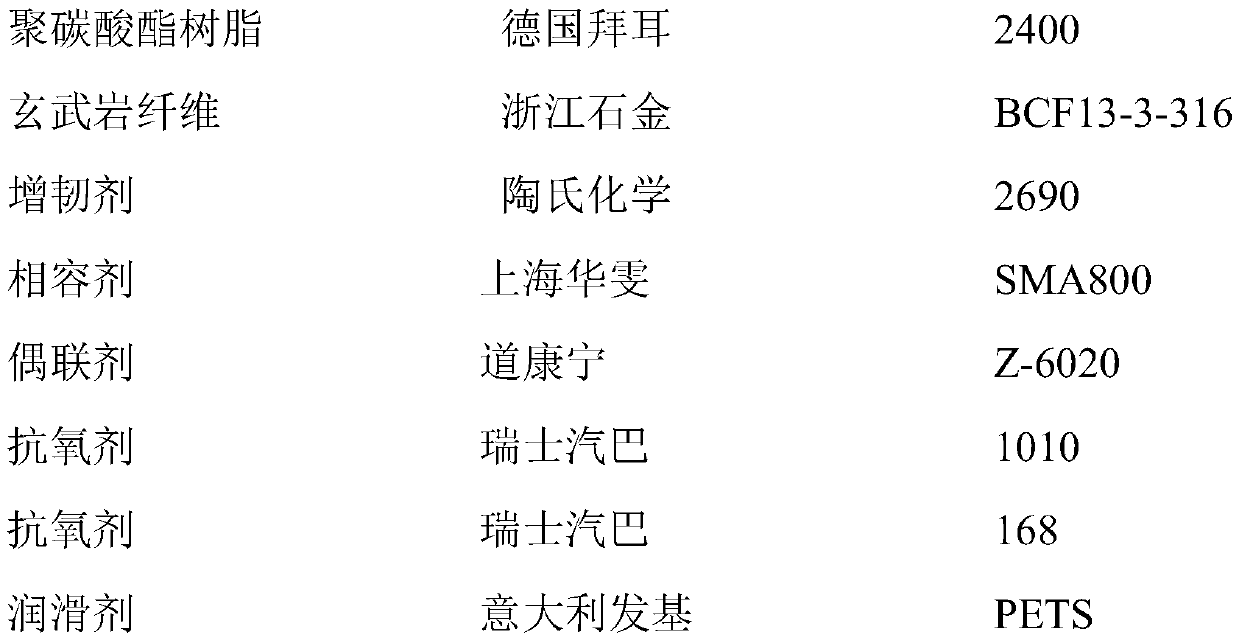

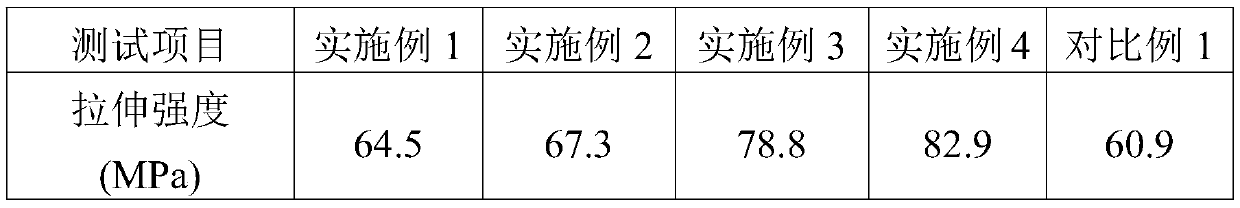

The invention relates to the technical field of high polymer materials and particularly discloses a high-modulus and low-dielectric-constant basalt fiber enhanced PC (polycarbonate) material and a preparation method thereof. The high-modulus and low-dielectric-constant basalt fiber enhanced PC material comprises 800-900 parts by weight of PC, 50-100 parts by weight of basalt fiber, 5-10 parts by weight of a compatilizer, 40-45 parts by weight of a toughener, 1-2 parts by weight of a coupling agent, 2-4 parts of an antioxidant and 5-10 parts of a lubricant. The mechanical property of the product is kept with the adoption of the toughener and the compatilizer, the binding force of PC and the basalt fiber is increased by use of the coupling agent, the compatible problem of PC and the basalt fiber is solved, a blended system keeps good comprehensive performance, and the low-dielectric-constant index is realized by adjusting the content of the basalt fiber.

Owner:横店集团得邦工程塑料有限公司

Corrosion resistance technology of steel structure

InactiveCN109848012ASimple anti-corrosion processSimple processPretreated surfacesAnti-corrosive paintsEpoxyWeather resistance

The invention discloses a corrosion resistance technology of a steel structure. The corrosion resistance technology of the steel structure comprises the following steps of S1, carrying out surface pretreatment on the steel structure; S2, derusting the surface of a steel material; S3, preparing a waterborne over-rust corrosion protective coating of the steel structure; S4, coating the steel structure; and S5, inspecting and accepting the oil paint coating quality. According to the corrosion resistance technology of the steel structure provided by the invention, the characteristics of an epoxy emulsion and an acrylic emulsion are combined, so that the combination property of a coating is improved; a polyaniline emulsion is directly added into the coating, so that the compatible problem of polyaniline and other macromolecule emulsions and the stability problem of the prepared corrosion-resistance coating are solved, and the corrosion resistance of the coating is improved; and acid and reactive hydrogen in the polyaniline can promote the curing of the epoxy resin, and the polyaniline is used as a curing agent of the epoxy emulsion, so that the process is simple and low in cost. The corrosion resistance technology of the steel structure is simple, not only has favorable corrosion resistance, but also is simple and convenient to construct, is capable of greatly relieving the labor intensity of coating, has high weather resistance at the same time, and can realize long-time protection on the steel structure.

Owner:淮北市菲美得环保科技有限公司

Method for transplanting consubstantial cell nucleus

The present invention belongs to the field of bioengineering technology, and is especially biological consubstantial cell nucleus grafting and cloning technology. By means of biological cloning technology, the present invention takes consubstantial nucleus donor cell and denucleated egg mother cell with clear genetic background for consubstantial cell nucleus grafting to prepare cloned animal. The present invention has relatively high matching between the donor nucleus DNA and acceptor cytoplasm and the electronic compatibility inside nuclear substance, and can improve the development of cloned embryo and raise cloning efficiency. The said technology may be used in cloning animal to obtain high quality livestock.

Owner:SHANGHAI INST OF MEDICAL GENETICS SHANGHAI CHILDRENS HOSPITAL

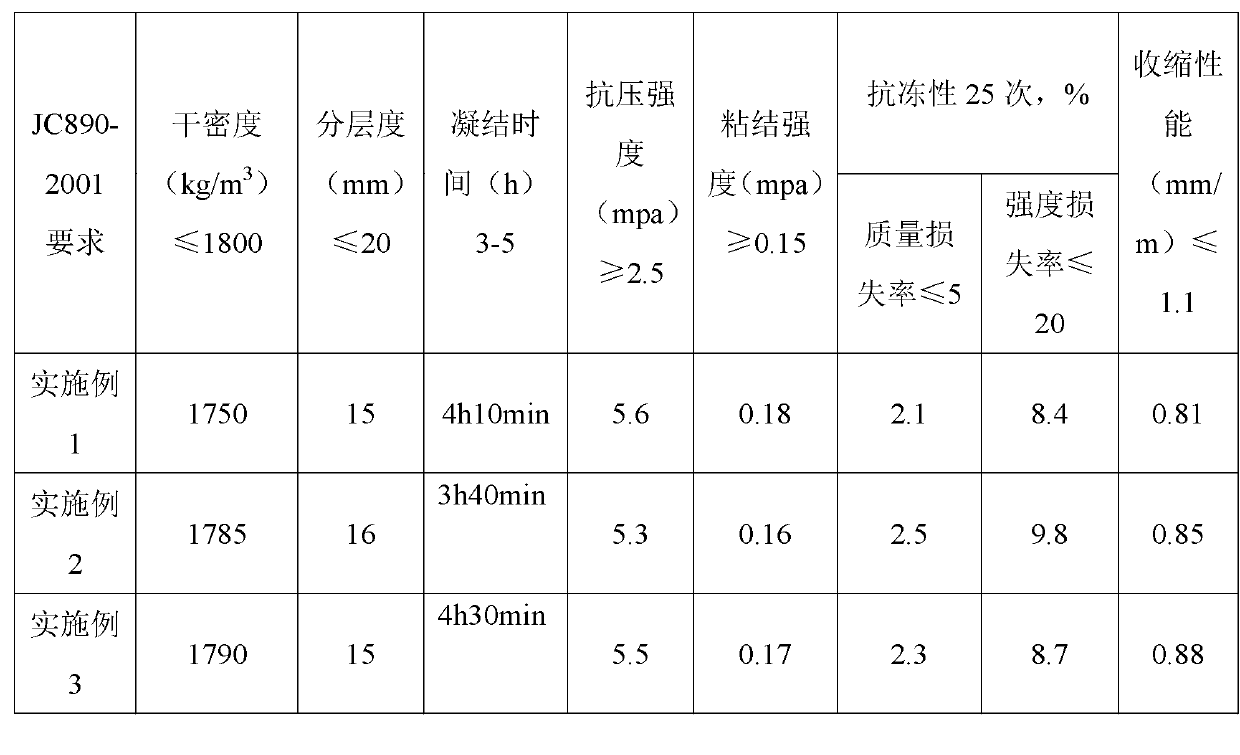

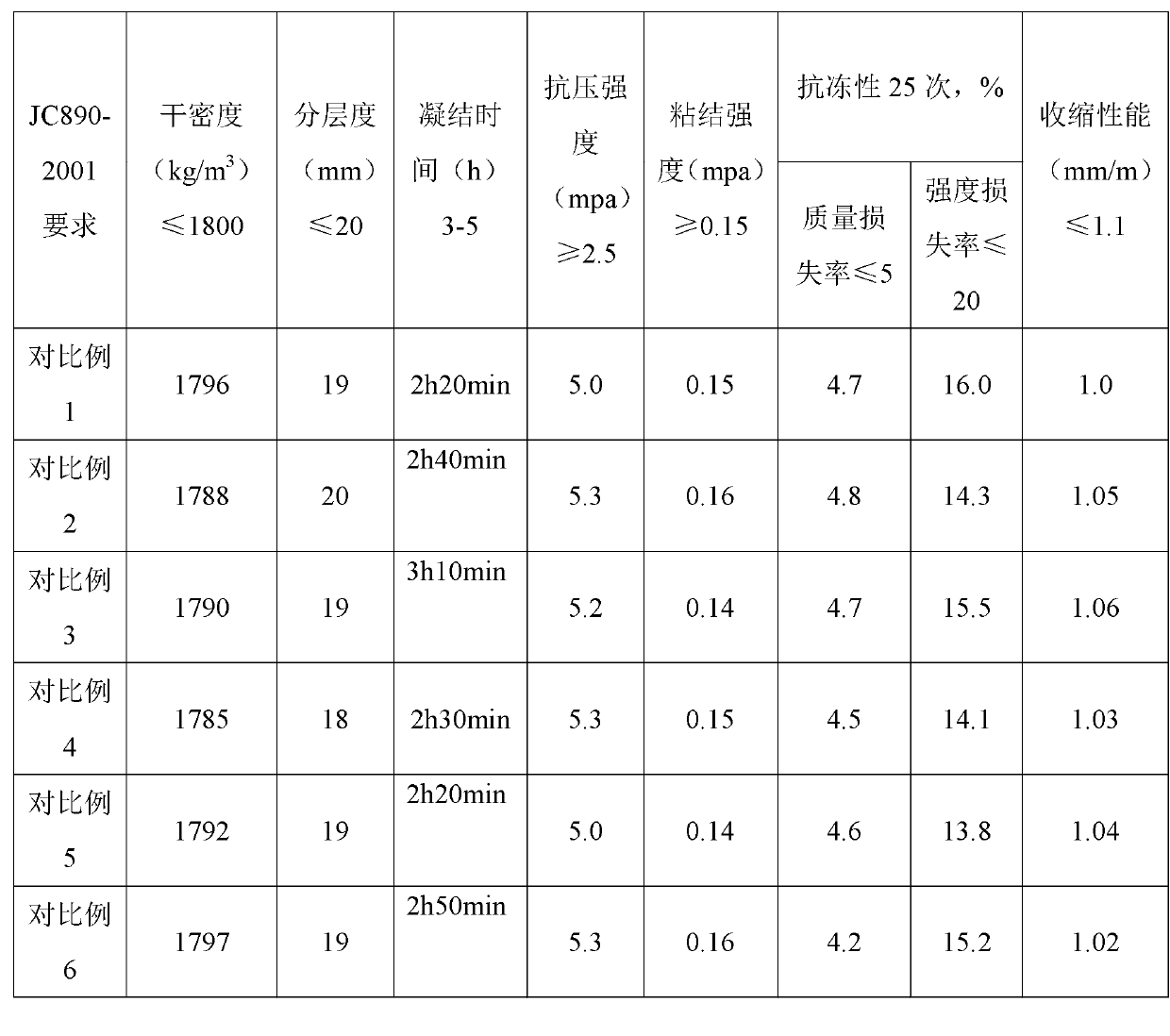

Masonry plastering anticracking agent

ActiveCN103342503AExcellent performance indexSimple preparation processSuperplasticizerPyrophosphate

The invention relates to a mortar admixture, particularly a masonry plastering anticracking agent. The masonry plastering anticracking agent is composed of the following components in percentage by weight: 2.2-2.8% of reactive silica, 4.5-5.5% of redispersible latex powder, 7.0-8.0% of inorganic gel, 19-21% of sodium bentonite, 4.5-5.5% of urea-formaldehyde resin, 2.2-2.8% of sodium dodecyl benzene sulfonate, 17.0-18.0% of naphthalene high efficiency water reducing agent, 2.2-2.8% of sodium lauryl sulfate, 14.5-15.5% of methyl cellulose, 1.7-2.3% of sodium pyrophosphate, 19-21% of silica fume and 0.4-0.6% of polypropylene fiber with the length of 5-6 mm. After adding the masonry plastering anticracking agent, the mortar has excellent compression strength, freezing resistance and shrinkage resistance.

Owner:俞锡贤

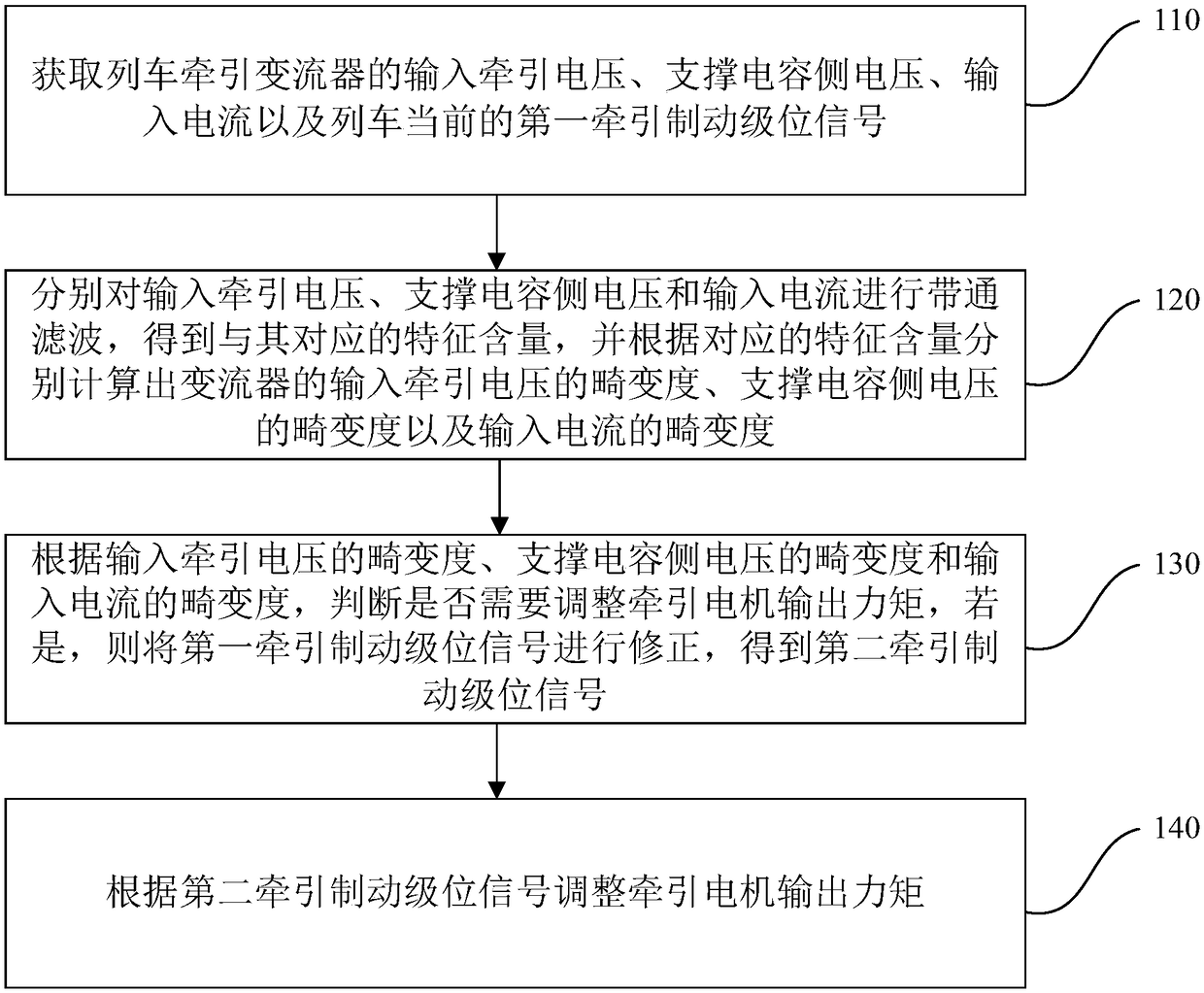

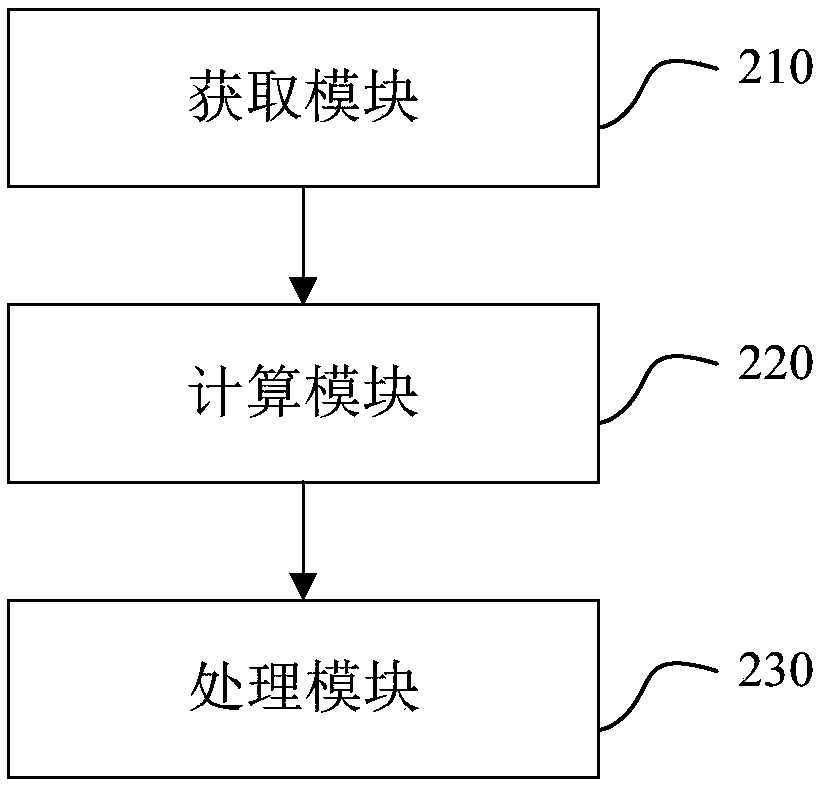

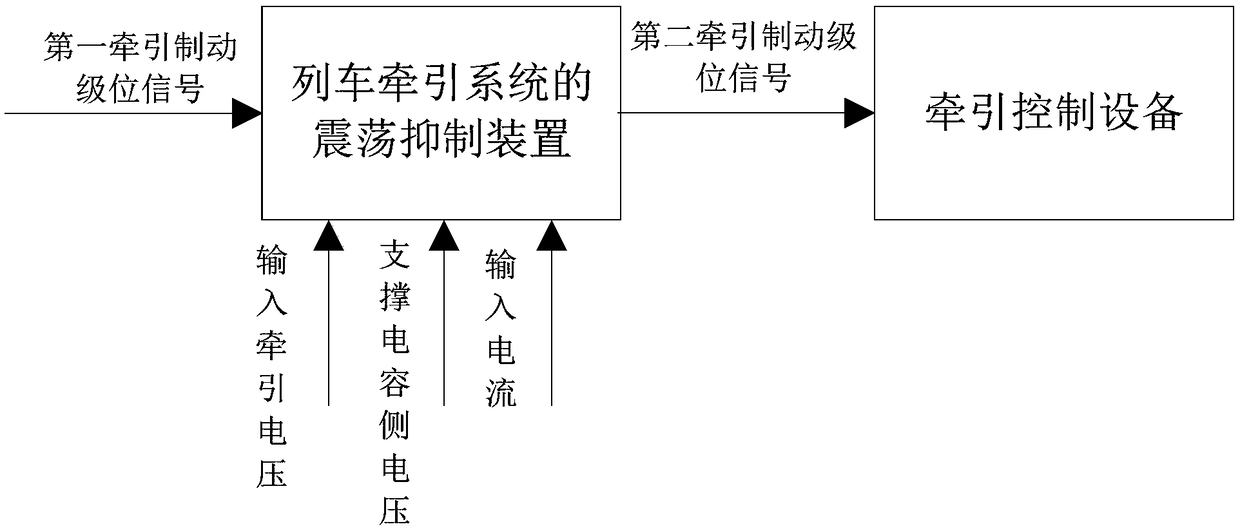

Oscillation restraining method and device for train traction system

ActiveCN108656963ASuppress shockSolve Compatibility IssuesSpeed controllerPropulsion using dc motorsCapacitanceTraction system

The invention provides an oscillation restraining method and device for a train traction system. The oscillation restraining method comprises the steps that the distortion degree of the input tractionvoltage, the distortion degree of the supporting capacitor side voltage and the distortion degree of the input current of a current transformer are calculated; according to the distortion degree of the input traction voltage, the distortion degree of the supporting capacitor side voltage and the distortion degree of the input current, a first traction brake level signal is corrected, and thus a second traction brake level signal is obtained; and according to the second traction brake level signal, the output torque of a traction motor is adjusted. According to the oscillation restraining method and device for the train traction system, characteristic contents corresponding to the input traction net voltage, the supporting capacitor side voltage and the input direct current of the tractioncurrent transformer in the train traction system are monitored, the distortion degrees of the corresponding net voltage, the corresponding voltage and the corresponding current are calculated according to the corresponding characteristic contents, the backward stage output torque of the traction current transformer is finely adjusted according to the distortion degrees, and accordingly oscillation on the direct current side of the traction system is restrained.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

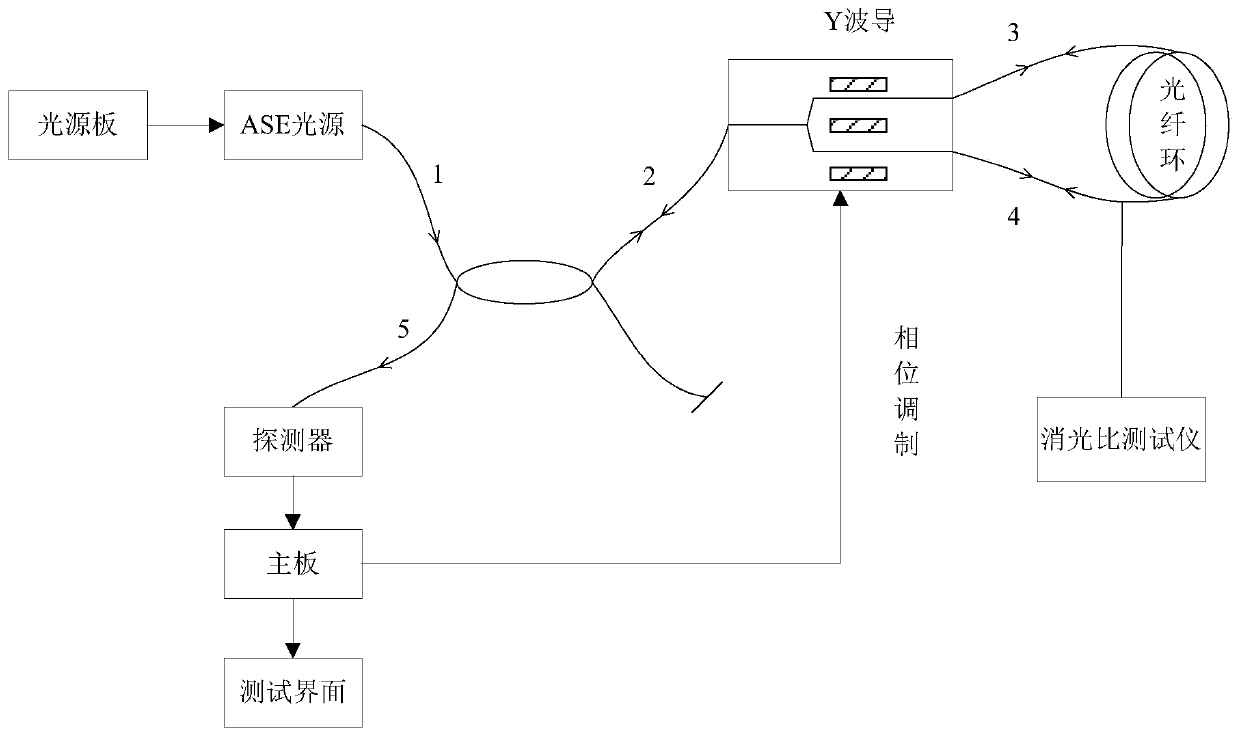

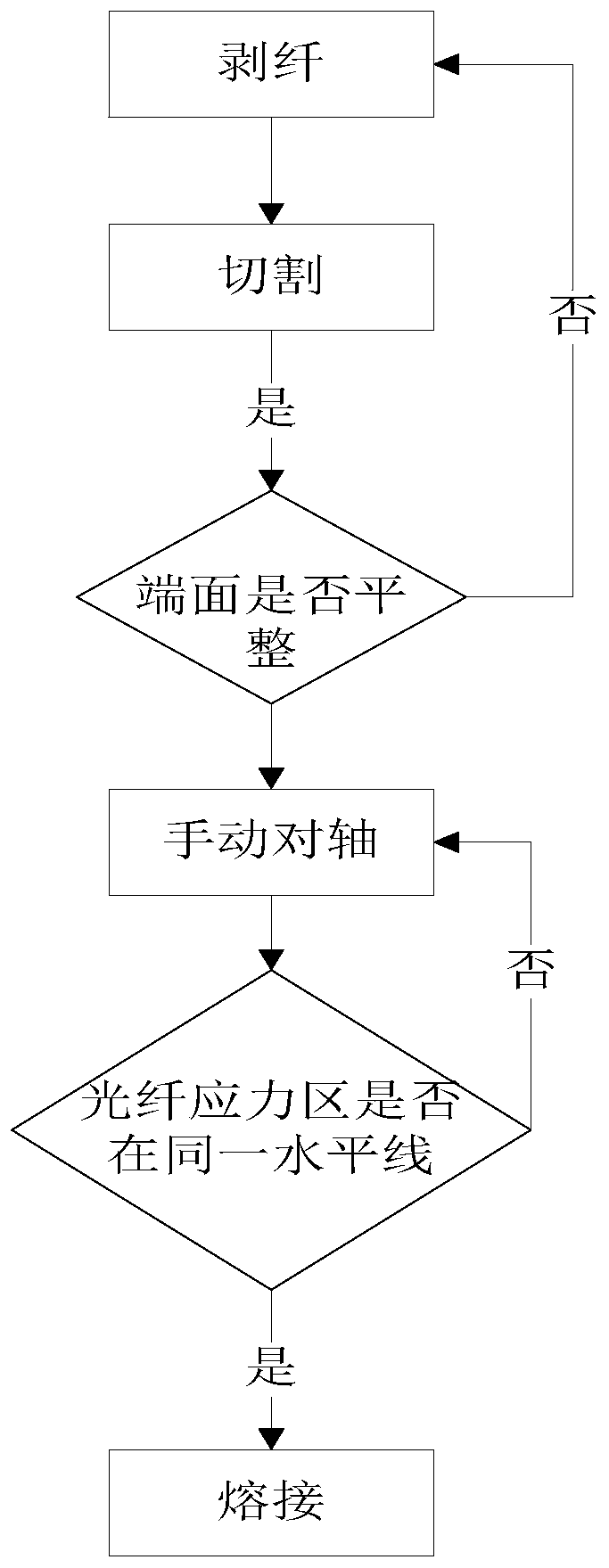

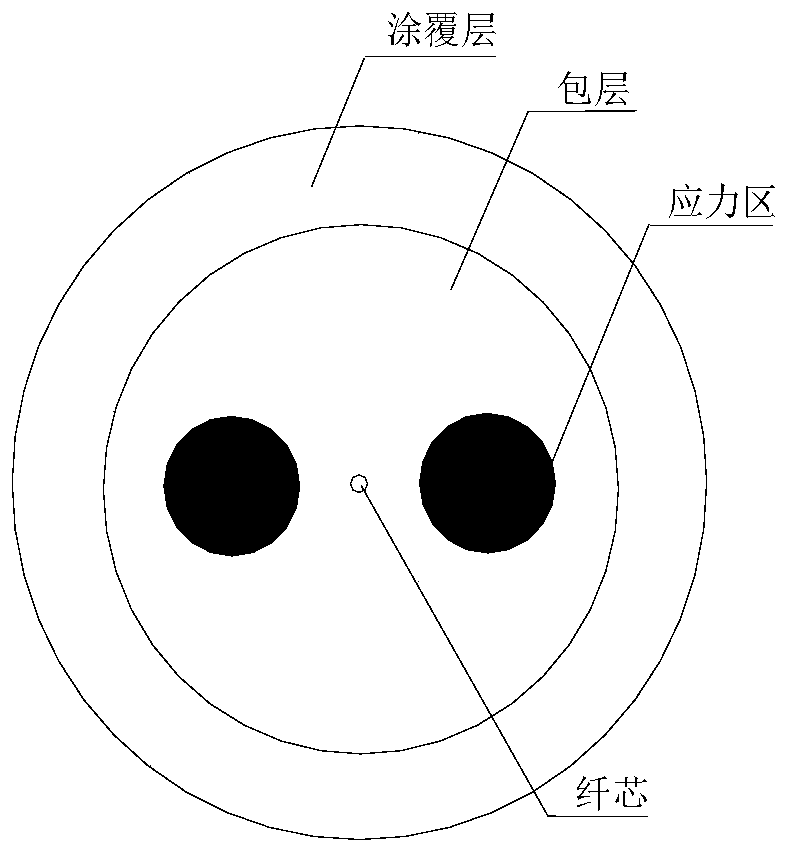

Fiber-optic gyroscope system based on 60-micron optical fiber and optical fiber welding method

ActiveCN111076715AHigh precisionExpand the miniaturization marketSagnac effect gyrometersCoupling light guidesLight sourceMaterials science

The invention discloses a fiber-optic gyroscope system based on a 60-micron optical fiber and an optical fiber welding method. According to the invention, a sensitive optical fiber ring formed by winding 60 optical fibers is used and a set of high-precision fiber-optic gyroscope is built, wherein the size of the fiber-optic ring is phi 96.5 * phi 109.5 * 16.5 (the inner diameter * the outer diameter * the thickness), the length of the fiber-optic ring is about 3400 m, and the theoretical precision of the fiber-optic ring can reach 0.0005 degree / h compared with an 80 fiber-optic ring (2500 m) with the same volume. A light source with a tail fiber of 80 or 125, a Y waveguide, a coupler and a detector are continuously used, and the solution to a problem of welding matching of a 60 optical fiber ring and the 80 waveguide is the key. An FSM-100P polarization-maintaining welding machine from the Fujikura and an ERM-102 extinction ratio tester of a GP company are used for manually aligning and welding 60 optical fibers and 80 waveguide fibers, the extinction ratio of the 60 optical fibers and the 80 waveguide fibers is tested, and the extinction ratio is compared with an extinction ratioof 80 optical fiber rings and 80 waveguide fibers. Connection of the whole fiber-optic gyroscope system is completed, and the zero-bias stability of the fiber-optic gyroscope system is tested. According to the invention, the matching problem of 60 optical fiber and 80 optical fiber devices is solved, and the selection of devices for manufacturing gyroscopes is more flexible.

Owner:HEBEI HANGUANG HEAVY IND

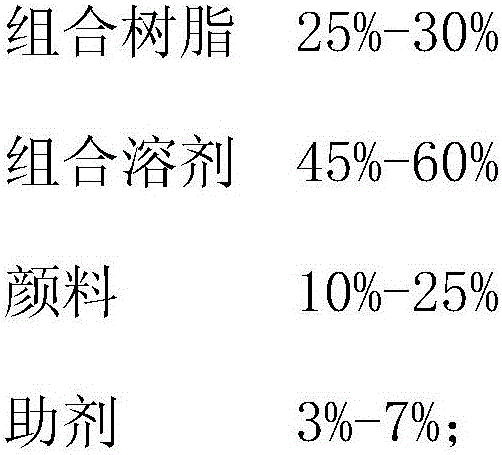

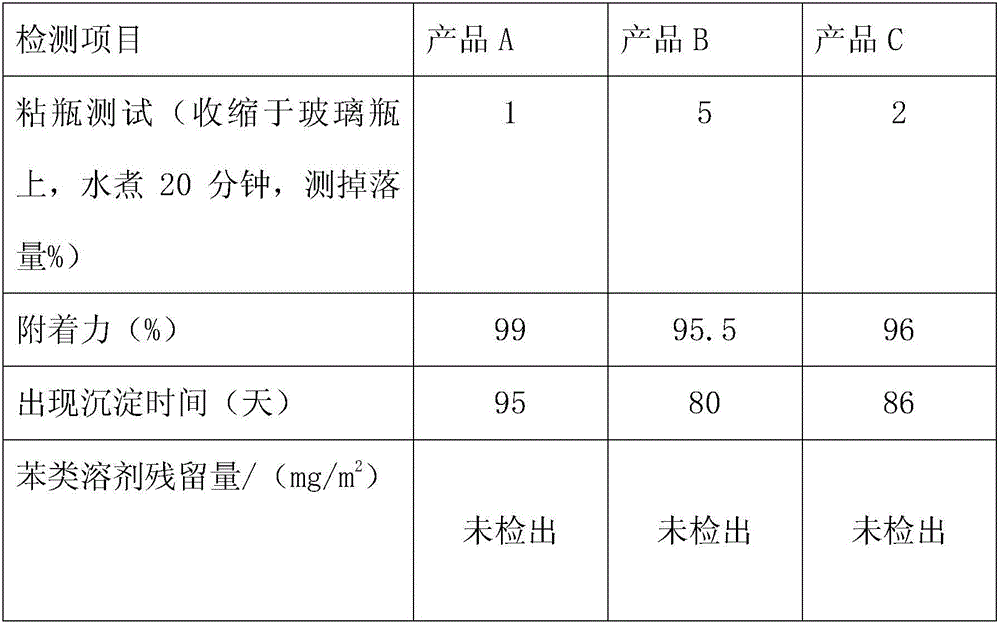

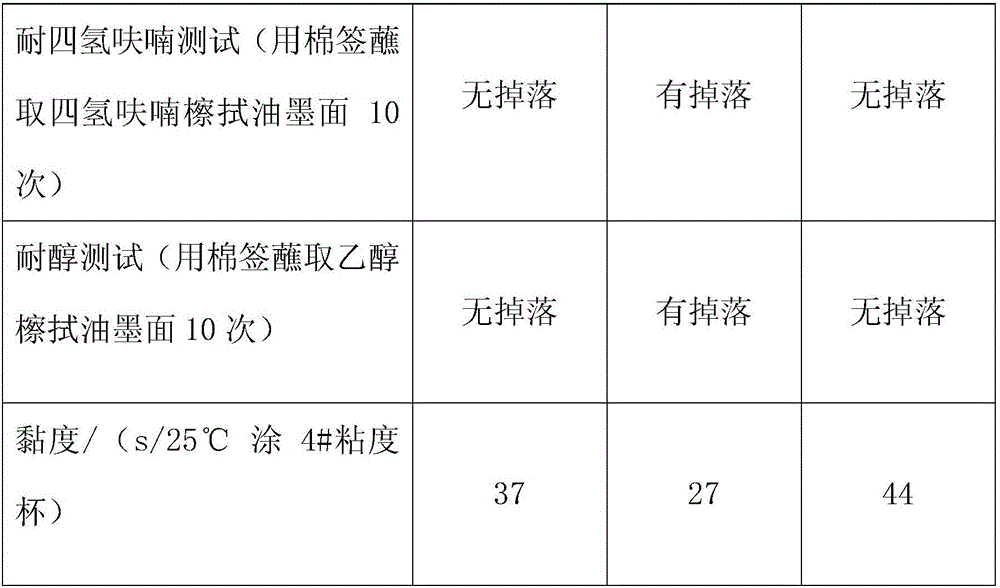

Universal environment-friendly gold and silver printing ink for shrink films and preparation method for universal environment-friendly gold and silver printing ink

InactiveCN106590161AReduce coefficient of frictionSolve compatibility issuesInksHigh resistanceEpoxy

The invention discloses a universal environment-friendly gold and silver printing ink for shrink films and belongs to the technical field of printing ink. The universal environment-friendly gold and silver printing ink is prepared from the following raw materials in percentage by mass: 25% to 30% of resin combination, 45% to 60% of solvent combination, 10% to 25% of pigment and 3% to 7% of auxiliaries, wherein the resin combination is prepared from acrylic resin, dinitrocellulose, epoxy resin, polyurethane resin and chlorinated polypropylene, and the solvent combination is a mixture of ethyl acetate, isopropanol, n-propyl acetate and propylene glycol methylether. The printing ink disclosed by the invention is benzene-free and ketone-free and can be universally applied to PVC, PET and OPS thermal-shrink films; the printing ink can be stored for 3 months without discoloring and precipitating and is small in coefficient of friction; and after the printing ink is printed in a manner of being matched with the thermal-shrink films, the shrink films are free of curling and tinting, the print products are in line with environment-friendly requirements and are safe and non-toxic and recoverable, and the printed shrink films have very high resistance to alcohols and tetrahydrofuran, so that the problem in compatibility with glue when the films are subjected to skin-packaging closing is excellently solved.

Owner:CHENGDU PRESSTER NEW MATERIALS

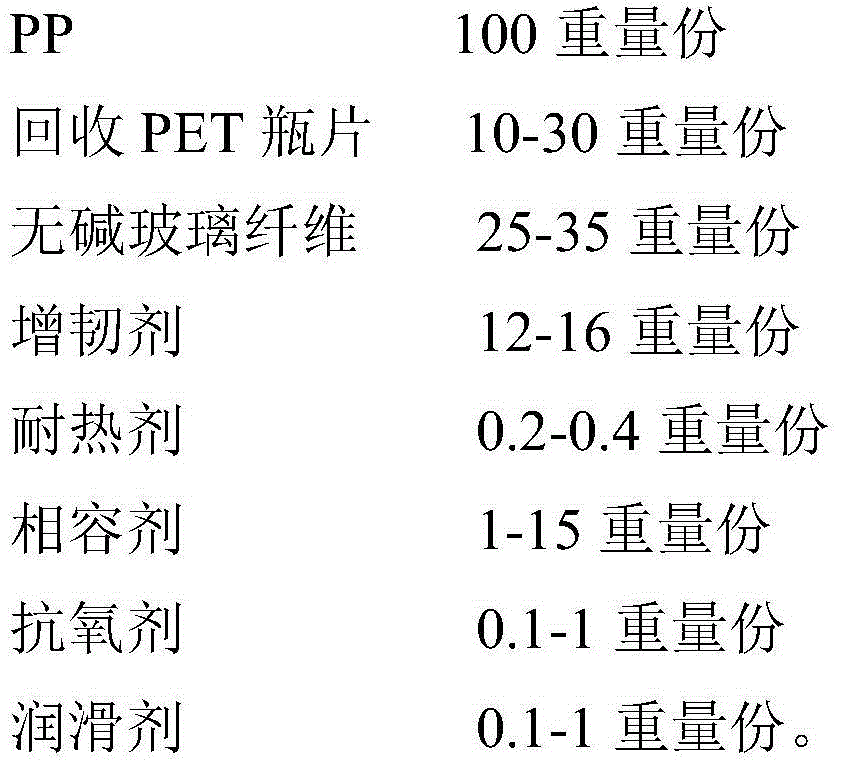

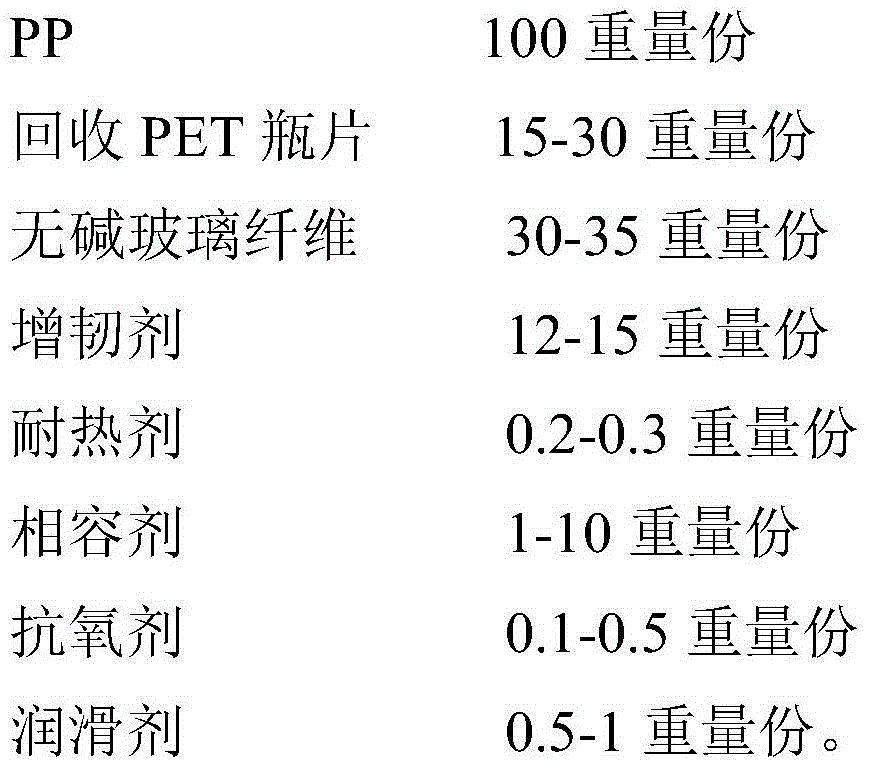

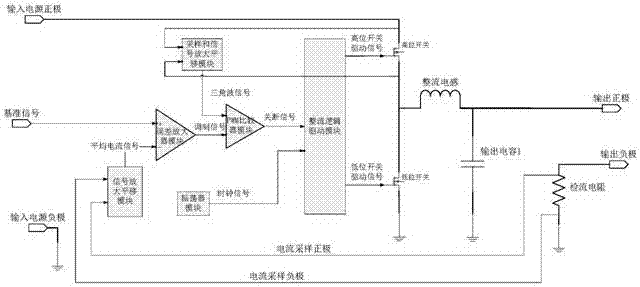

Reinforced PP/recycled PET bottle flake alloy for vehicle fan wind wheels, and preparation method thereof

The present invention relates to the technical field of polymer materials, particularly to an alloy composite material and a preparation method thereof. The reinforced PP / recycled PET bottle flake alloy comprises the following raw materials by weight: 100 parts of PP, 10-30 parts of recycled PET bottle flakes, 25-35 parts of alkali-free glass fibers, 12-16 parts of a toughening agent, 0.2-0.4 part of a heat-resistant agent, 1-15 parts of a compatibilizing agent, 0.1-1 part of an antioxidant, and 0.1-1 part of a lubricant. According to the present invention, the raw materials are used to prepare the alloy composite material according to a certain ratio, such that the compatibility problem of PP and recycled PET is solved, the interfacial tension between the two materials in the PP and recycled PET system is reduced, the interfacial width is increased, the system forms the thermodynamically stable phase state structure having the uniform macroscopic phase and microscopic phase separation system characteristics, and the composite material maintains good mechanical properties.

Owner:上海奇彩塑胶原料有限公司

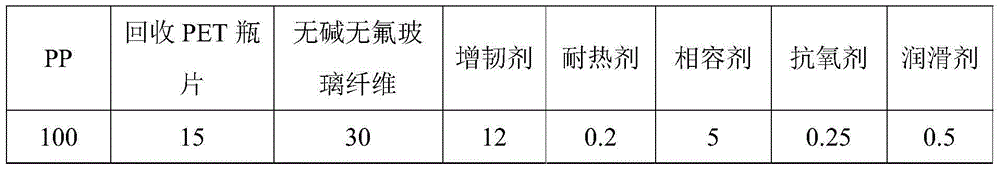

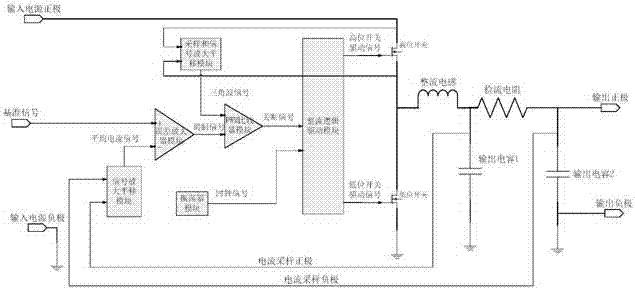

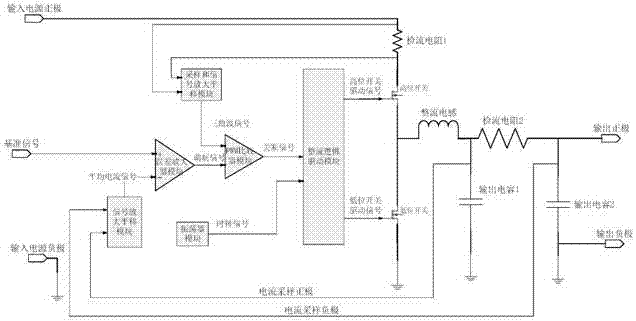

Novel constant-output-current BUCK circuit

ActiveCN106961216ASolve Compatibility IssuesGuaranteed accuracyDc-dc conversionElectric variable regulationCapacitanceAverage current

The invention discloses a novel constant-output-current BUCK circuit which comprises the components of a current sensing resistor, wherein one end of the current sensing resistor is connected with a rectifying switch node, and the other end is connected with an output anode; an output capacitor of which one end is connected with the output anode and the other end is connected with an output cathode; a high-level switch which is connected with an input power supply anode and a rectifying switch node; a low-level switch which is connected with an input power supply cathode and the rectifying switch node; a first signal amplifying and translating module which generates a triangular wave signal; a second signal amplifying and translating module which generates a real-time current signal; and an average value calculating module which acquires an average current signal that represents an inductor average current value according to the real-time current signal. Compared with prior art, the novel constant-output-current BUCK circuit has advantages of settling a high-level switch matching problem, preventing cost increase and switching efficiency reduction by means of one current sensing resistor, ensuring high precision of output current, and preventing a problem of actual use performance reduction caused by factors of uncertain frequency, etc.

Owner:江苏芯潭微电子有限公司

HDPE reclaimed material, preparation method thereof and HDPE pipe

PendingCN112390999AIncrease the length of the molecular chain segmentGood flexibilityPolymer scienceCross linker

The invention provides an HDPE reclaimed material and a preparation method thereof, and the preparation method comprises the following steps: A) crushing an extrusion grade HDPE reclaimed material toobtain a crushed material; and B) mixing the crushed material, a cross-linking agent and an inorganic filler, and carrying out extrusion granulation to obtain the HDPE reclaimed material, wherein thecross-linking agent is an aromatic cross-linking agent and / or an aliphatic cross-linking agent. Compared with the prior art, the preparation method provided by the invention has the advantages that the recycled waste polyethylene small hollow material containing 10% of other plastic impurities is used as a main raw material, the molecular weight and the flowability of polyethylene are regulated and controlled by adopting a chemical repairing means, the molecular chain segment length of the material is increased through a chain extension reaction, and the material is endowed with high flexibility, and mechanical properties of impact strength is improved; meanwhile, the problem of compatibility of impurities in the crushed material raw materials and main body plastic is solved, and the special pipe material with excellent ring flexibility is prepared. The invention further provides a HDPE pipe.

Owner:CHINA GEZHOUBA GRP LVYUAN TECH CO LTD

Antiseptic wood-plastic material and preparation method thereof

The invention provides an antiseptic wood-plastic material and a preparation method thereof. The antiseptic wood-plastic material is prepared by the following steps and prepared from the following rawmaterials in parts by weight: 30 to 60 parts of sawdust powder, 20 to 50 parts of resin, 5 to 15 parts of modified basalt fiber, 0.1 to 1 part of a heat stabilizer, 0.1 to 1 part of a lubricant, 0.1to 1 part of a solubilizer, 1 to 5 parts of nano zinc oxide and 1 to 2 parts of a mildew preventive, wherein the mildew preventive is prepared from the following raw materials in parts by weight: 5 to15 parts of nano zinc oxide, 5 to 10 parts of nano silicon dioxide, 5 to 10 parts of gallotannic acid, 1 to 3 parts of triethanolamine, 1 to 5 parts of an aluminate coupling agent, 1 to 5 parts of white mineral oil, 1 to 3 parts of olive oil, 1 to 3 parts of litsea cubeba oil, 0.5 to 1.5 parts of palmitic acid and 2 to 5 parts of glycerin monostearate. According to the antiseptic wood-plastic material disclosed by the invention, the sawdust powder and the resin are utilized as the main materials; by means of adding the modified basalt fiber, nano calcium carbonate and the mildew preventive, apreservative effect of the wood-plastic material is improved.

Owner:德保县广鑫贸易有限公司

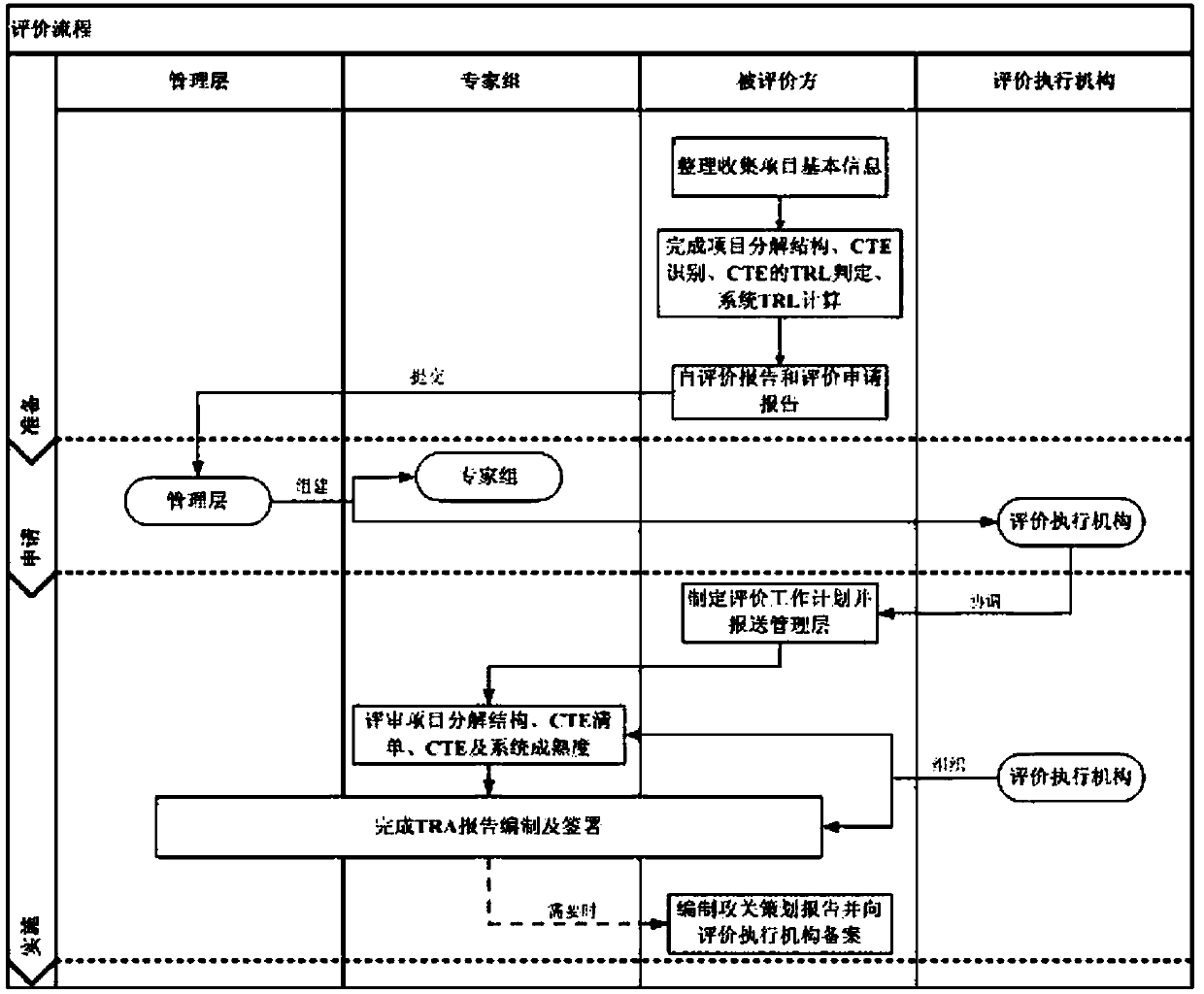

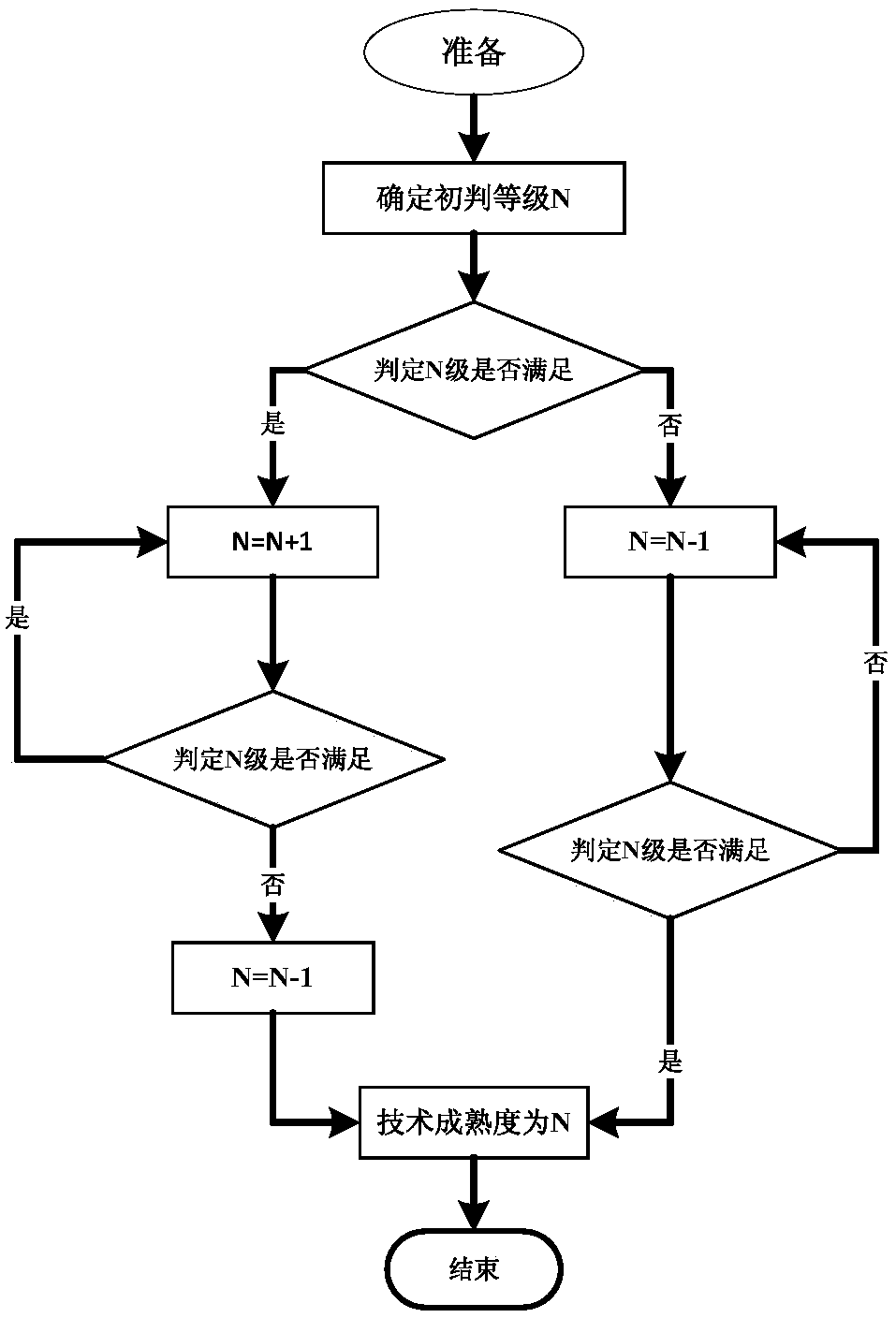

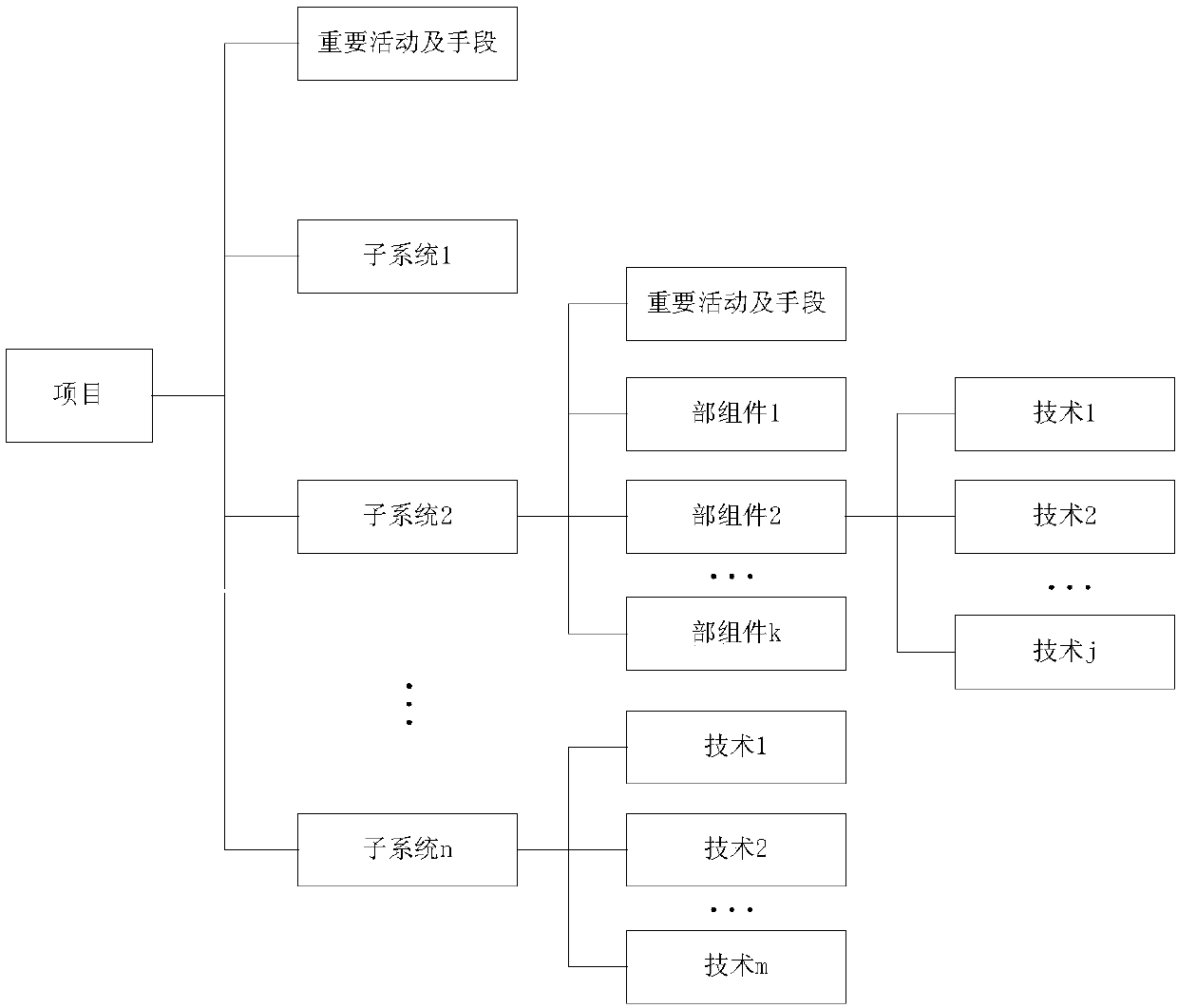

CTE technology maturity evaluation method and project technology maturity evaluation method

PendingCN107705016AResponsibilities are clearThe evaluation method is scientific and efficientResourcesProcess specificationComputer science

The invention discloses a CTE technology maturity evaluation method. The method comprises the steps of (1) establishing a technology maturity evaluation framework; (2) according to the technology maturity evaluation framework, establishing a technology maturity evaluation general rule; (3) conducting the iteration judgment according to the technology maturity evaluation general rule, and obtaininga final evaluation result. According to the evaluation method, a scientific evaluation criterion, a standard evaluation process and an explicit evaluation organization are established, so that the evaluation method is scientific and efficient, clear in organization duties, standard in process and easy in operation. The evaluation process is convenient for achieving unified management and traceability.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com