Universal environment-friendly gold and silver printing ink for shrink films and preparation method for universal environment-friendly gold and silver printing ink

A general environmental protection, shrink film technology, applied in the field of ink, can solve the problems of discoloration, large friction coefficient, short storage time, etc., and achieve the effect of solving compatibility problems, small friction coefficient, strong alcohol resistance and tetrahydrofuran resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

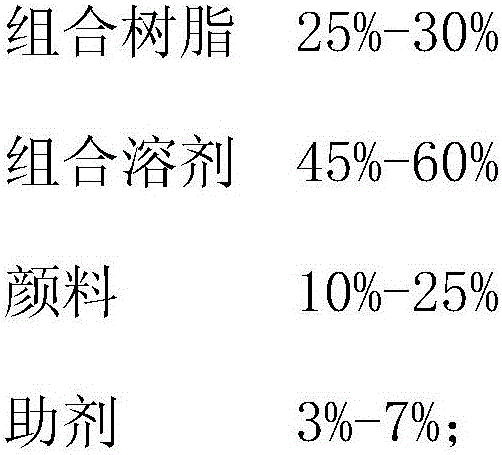

[0022] A general environment-friendly gold and silver ink for shrink film, consisting of the following raw materials in percentage by weight;

[0023] Acrylic resin 9%, nitrocellulose 7%, epoxy resin 2%, polyurethane resin 4%, chlorinated polypropylene 8%, aluminum powder pigment 15%, polyethylene wax 1.5%, kaolin 3%, antistatic agent 0.5 %, ethyl acetate 14%, isopropanol 17.5%, n-propyl acetate 10%, propylene glycol methyl ether 8.5%;

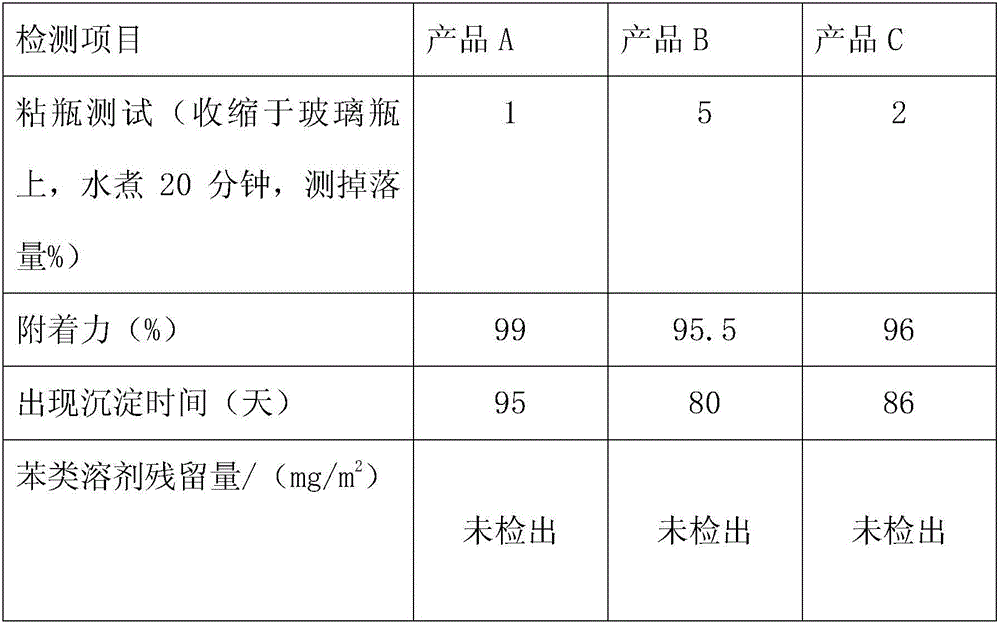

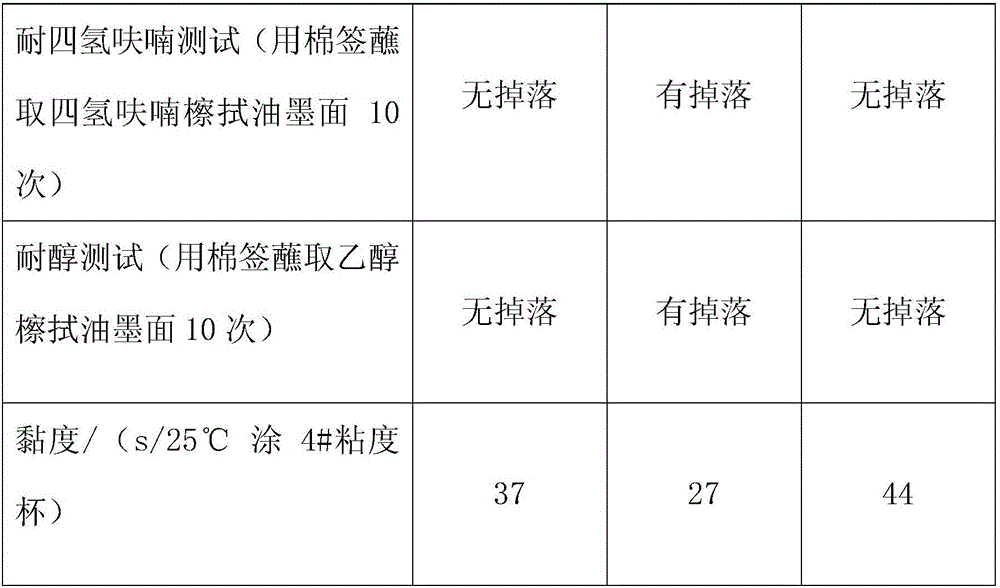

[0024] After mixing the solvent in the container according to the above ratio, add aluminum powder and soak for more than 2 hours to make it fully wet, then add other raw materials, and after fully stirring, the solvent adjusts the viscosity to reach a thin wall 3# Zahn Cup 20- The packaging can be filtered in 35 seconds to obtain "Product A".

[0025] In the preparation of the golden ink of the present invention, after the above-mentioned materials are evenly stirred, the general environment-friendly color ink for shrink film is added to adj...

Embodiment 2

[0027] A general environment-friendly gold and silver ink for shrink film, consisting of the following raw materials in percentage by weight;

[0028] Acrylic resin 9%, nitrocellulose 5%, epoxy resin 1%, polyurethane resin 5%, chlorinated polypropylene 8%, aluminum powder pigment 15%, polyethylene wax 1.5%, kaolin 2%, antistatic agent 0.5 %, ethyl acetate 17%, isopropanol 18.5%, n-propyl acetate 9%, propylene glycol methyl ether 8.5%;

[0029] After mixing the solvent in the container according to the above ratio, add aluminum powder and soak for more than 2 hours to make it fully wet, then add other raw materials, and after fully stirring, the solvent adjusts the viscosity to reach a thin wall 3# Zahn Cup 20- The package can be filtered in 35 seconds to obtain "Product B".

[0030] In the preparation of the golden ink of the present invention, after the above-mentioned materials are evenly stirred, the general environment-friendly colored ink for shrink film is added to adju...

Embodiment 3

[0032] A general environment-friendly gold and silver ink for shrink film, consisting of the following raw materials in percentage by weight;

[0033] Acrylic resin 8%, nitrocellulose 6%, epoxy resin 3%, polyurethane resin 3%, chlorinated polypropylene 6%, aluminum powder pigment 17%, polyethylene wax 1.5%, kaolin 5%, antistatic agent 0.5 %, ethyl acetate 15%, isopropanol 16.5%, n-propyl acetate 9%, propylene glycol methyl ether 9.5%;

[0034] After mixing the solvent in the container according to the above ratio, add aluminum powder and soak for more than 2 hours to make it fully wet, then add other raw materials, and after fully stirring, the solvent adjusts the viscosity to reach a thin wall 3# Zahn Cup 20- 35 seconds to filter the pack. Get "Product C".

[0035] In the preparation of the golden ink of the present invention, after the above-mentioned materials are evenly stirred, the general environment-friendly colored ink for shrink film is added to adjust the hue.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com