Polyamide/polyketone alloy material

An alloy material, polyamide technology, applied in the field of polyamide/polyketone alloy materials, can solve the problems of reduced mechanical properties, insufficient wear resistance, irritating taste, etc.

Inactive Publication Date: 2017-06-13

温州市赢创新材料技术有限公司

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Polyamide is one of the five general-purpose engineering plastics. It has excellent mechanical properties and is widely used in electronic and electrical industries. It is often used as a component selection in electronic and electrical appliances. However, it has defects in some high-end or special applications, such as its wear resistance. Insufficient wear resistance, it is necessary to modify the wear resistance of polyamide, the literature records show that usually add wear additives, such as molybdenum disulfide, silane wear agent to improve the wear resistance of polyamide, there are also literature records, the polyamide Amides and resins with better wear resistance are made into alloys, such as PA / POM alloys, to improve the wear resistance of polyamides. Although the wear resistance can be improved by adding wear-resistant additives, the wear-resistant additives It is expensive in itself, adding too much will lead to an excessive increase in cost, and the mechanical properties of the material will be reduced by one. PA / POM alloy improves the wear resistance of the material and will not increase the cost, but the compatibility of the two The problem needs to be solved, and at the same time, POM has the disadvantage of a strong irritating taste during the molding process, so an alloy material that is easier to solve, has better compatibility, better wear resistance, and is environmentally friendly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

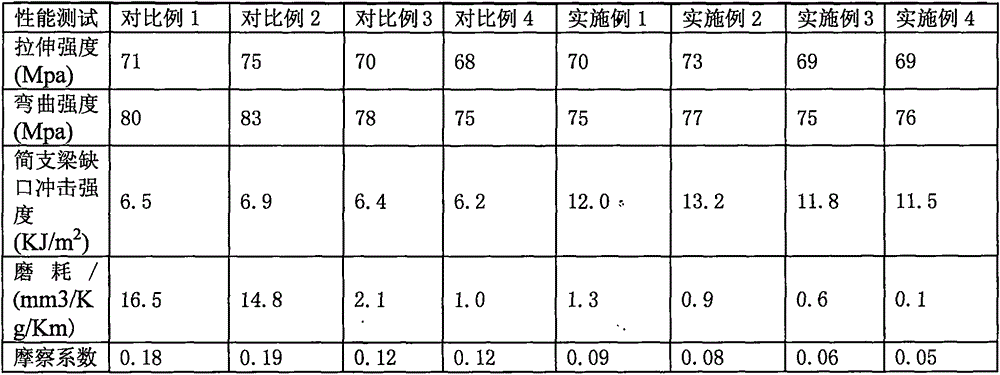

Effect test

Embodiment 1

[0024] The polyamide in embodiment 1, embodiment 3, embodiment 4 is PA6, polyamide in embodiment 2 is PA66; The compatibilizer of embodiment is styrene maleic anhydride copolymer; Embodiment 3~embodiment 4 The anti-wear agent is silicone powder; the lubricant is polyester lubricant; the compound heat stabilizer 1076 / 168 is a compound of 1:1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a polyamide / polyketone alloy material. The polyamide / polyketone alloy material comprises 55-85% of polyamide PA, 10-40% of polyketone POK, 0-10% of compatilizer, 0-3% of anti-wear agent, 0.3-1% of lubricant and 0.3-1% of compound heat stabilizer. The obtained polyamide / polyketone alloy material having excellent wear resistance is prepared through a double screw extruder; and the alloy material can be used for injection molding or extrusion molding material formed high-wear-resistance plastic components.

Description

technical field [0001] The invention relates to the field of polymer materials, in particular to a polyamide / polyketone alloy material. Background technique [0002] Polyamide is one of the five general-purpose engineering plastics. It has excellent mechanical properties and is widely used in electronic and electrical industries. It is often used as a component selection in electronic and electrical appliances. However, it has defects in some high-end or special applications, such as its wear resistance. Insufficient wear resistance, it is necessary to modify the wear resistance of polyamide, the literature records show that usually add wear additives, such as molybdenum disulfide, silane wear agent to improve the wear resistance of polyamide, there are also literature records, the polyamide Amides and resins with better wear resistance are made into alloys, such as PA / POM alloys, to improve the wear resistance of polyamides. Although the wear resistance can be improved by a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/02C08L77/06C08L73/00C08L35/06C08L83/04C08L67/00C08K5/134C08K5/526

CPCC08L77/02C08L77/06C08L2205/035C08L73/00C08L35/06C08L83/04C08L67/00C08K5/1345C08K5/526

Inventor 方万漂朱雪梅朱进平方少章王爱绿

Owner 温州市赢创新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com