Method for preparing wood-plastic composite material from cherry wood chips

A wood-plastic composite material and wood chip technology, which is applied in the field of preparing wood-plastic composite materials by using cherry wood chips, can solve the problems of large shrinkage, affect the performance of wood-plastic composite materials, poor mechanical properties, etc., and achieves improved interface compatibility, The effect of improving interfacial compatibility and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

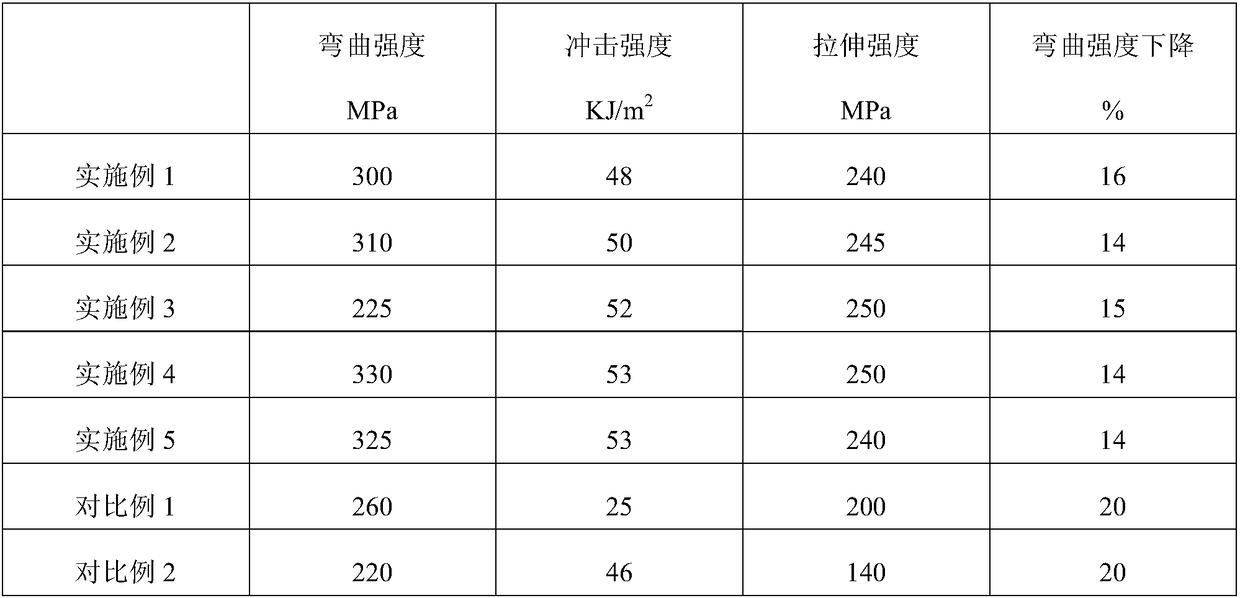

Examples

Embodiment 1

[0028] A kind of method that utilizes cherry wood sawdust to prepare wood-plastic composite material, comprises the following steps:

[0029] S1. Sawdust treatment

[0030] Add 60 parts of cherry wood chips, 6 parts of calcium stearate and 4 parts of nano-alumina into the ball mill, and stir for 20 minutes to obtain modified wood chips.

[0031] S2. Mixing

[0032] Add 5 parts of modified basalt fiber, 6 parts of glass fiber, 30 parts of waste plastics, 3 parts of nano-zinc oxide and 3 parts of magnesium salt whisker into the modified wood chips, and mix uniformly to obtain a mixture.

[0033] The modified basalt fiber is obtained by immersing or coating the basalt fiber with a modifier, and the modifier includes: 40% film-forming agent, 10% coupling agent, 3% lubricant, 8% Modified nano-SiO 2 particles and the rest is water.

[0034] S3. Granulation

[0035] Add 0.5 part of heat stabilizer, 0.5 part of lubricant and 0.5 part of solubilizer to the mixture, continue stirri...

Embodiment 2

[0040] A method for preparing wood-plastic composite materials using cherry wood chips, wherein step S2. In mixing materials, 10 parts of modified basalt fibers, 6 parts of glass fibers, 30 parts of waste plastics, and nanometer zinc oxide are added to the modified wood chips. 3 parts and 3 parts of magnesium salt whiskers, mix evenly to obtain a mixture. Other steps are with embodiment 1.

Embodiment 3

[0042] A method for preparing a wood-plastic composite material using cherry wood chips, wherein step S2. In mixing materials, 15 parts of modified basalt fibers, 6 parts of glass fibers, 30 parts of waste plastics, and nanometer zinc oxide are added to the modified wood chips. 3 parts and 3 parts of magnesium salt whiskers, mix evenly to obtain a mixture. Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com