Lignin/polycaprolactone environment-friendly degradable film and preparation method thereof

A technology of polycaprolactone and degradable film, which is applied in the field of lignin/polycaprolactone environmentally friendly degradable film and its preparation, can solve the problems of poor enterprise condition and secondary pollution of the environment, and achieves improvement of mixing uniformity and improved mixing efficiency. The effect of improving the interfacial bonding force and the degree of phase separation between the two-phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

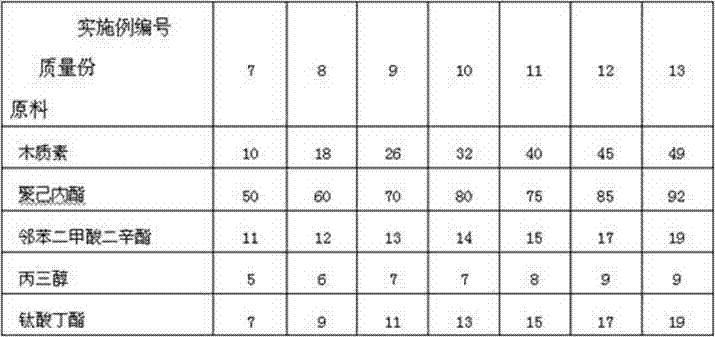

Examples

Embodiment 1

[0028] A specific preparation method of a lignin / polycaprolactone environmentally friendly degradable film is as follows: mix 30g lignin with 270g polycaprolactone, add 5ml butyl titanate, 10mlDOP, 5ml glycerol, and mix well, Slowly add to a two-stage twin-screw extruder for extrusion, use circulating water to cool, then cut into pellets, and extrude and blow to form a film under the action of the screw extruder.

Embodiment 2

[0030] A specific preparation method of a lignin / polycaprolactone environmentally friendly degradable film is as follows: mix 60g lignin with 240g polycaprolactone, add 10ml butyl titanate, 15mlDOP, 8ml glycerol, mix and stir evenly, Slowly add to a two-stage twin-screw extruder for extrusion, use circulating water to cool, then cut into pellets, and extrude and blow to form a film under the action of the screw extruder.

Embodiment 3

[0032] A specific preparation method of a lignin / polycaprolactone environmentally friendly degradable film is as follows: mix 90g lignin with 210g polycaprolactone, add 15ml butyl titanate, 15mlDOP, 10ml glycerol, and mix well, Slowly add to a two-stage twin-screw extruder for extrusion, use circulating water to cool, then cut into pellets, and extrude and blow to form a film under the action of the screw extruder.

[0033] The mechanical property test results of the film blown according to this example (lignin / polycaprolactone blend film) are shown in Table 1 below:

[0034] Table 1:

[0035]

[0036] Note: The test conditions for mechanical properties in Table 1 are: test method (ASTMD 882-02), humidity 45%, temperature 30°C;

[0037] The average thickness of the lignin / polycaprolactone blend film is 0.412mm, the tensile strength is 8.28MPa, and the elongation is 716.73%. The mechanical properties of the blend film are good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com