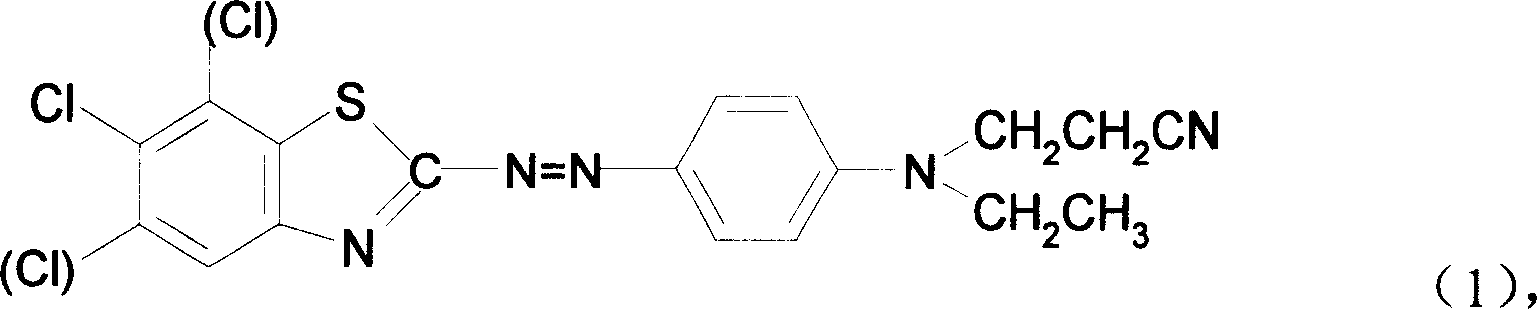

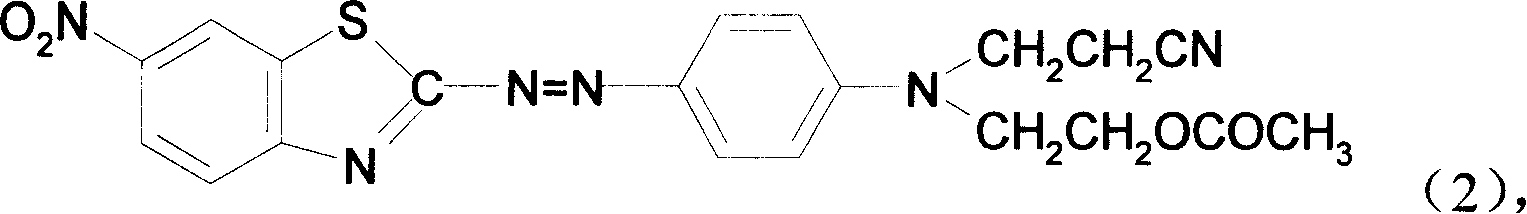

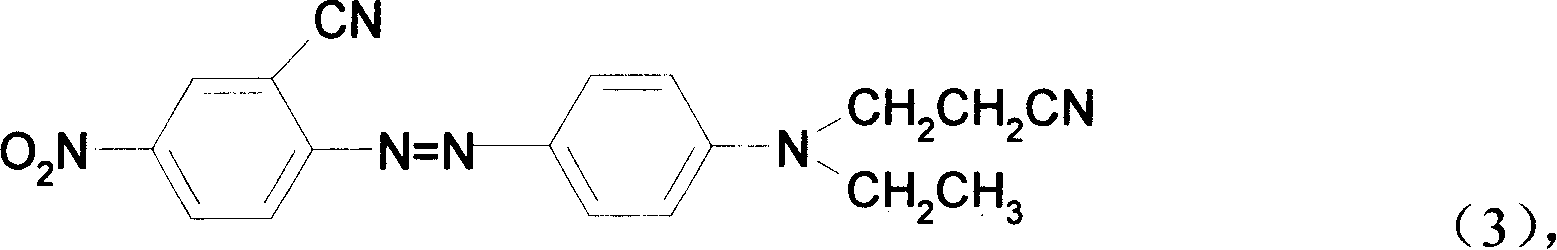

Red dispersion dyes mixture

A technology of disperse dyes and mixtures, applied in the direction of organic dyes, etc., can solve the problems of low color development rate, poor levelness, and poor sublimation fastness of dyes, and achieve good dyeing reproducibility, superior dye performance, and excellent fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] According to the ingredients list (Table 1) data as the basis, dye A, dye B, dye C, dye D and auxiliary agent (methylnaphthalenesulfonic acid formaldehyde condensate (MF), diffusing agent benzylnaphthalenesulfonic acid formaldehyde condensate ( CNF), diffused naphthalenesulfonic acid formaldehyde condensate (NNO), sodium lignosulfonate (Reax 85A), mixed in a certain ratio, added water in a ratio of 1:1, and then ground and dispersed in a sand mill, and then sprayed Dries into a commercial dye.

[0030] Example

[0031] Each take 0.5 grams of the disperse dyes prepared in Examples 1 to 9 and disperse them in 500 milliliters of water, absorb 20 milliliters and mix them with 60 milliliters of water, adjust the pH of the dyeing bath to 5 with acetic acid, heat up to 70°C and put 2 grams of poly The ester fiber is dyed, the temperature is raised from 70°C to 130°C within 30 minutes, the temperature is kept for 30 minutes, and the sampling starts when it is cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com