Patents

Literature

60results about How to "Good dyeing reproducibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

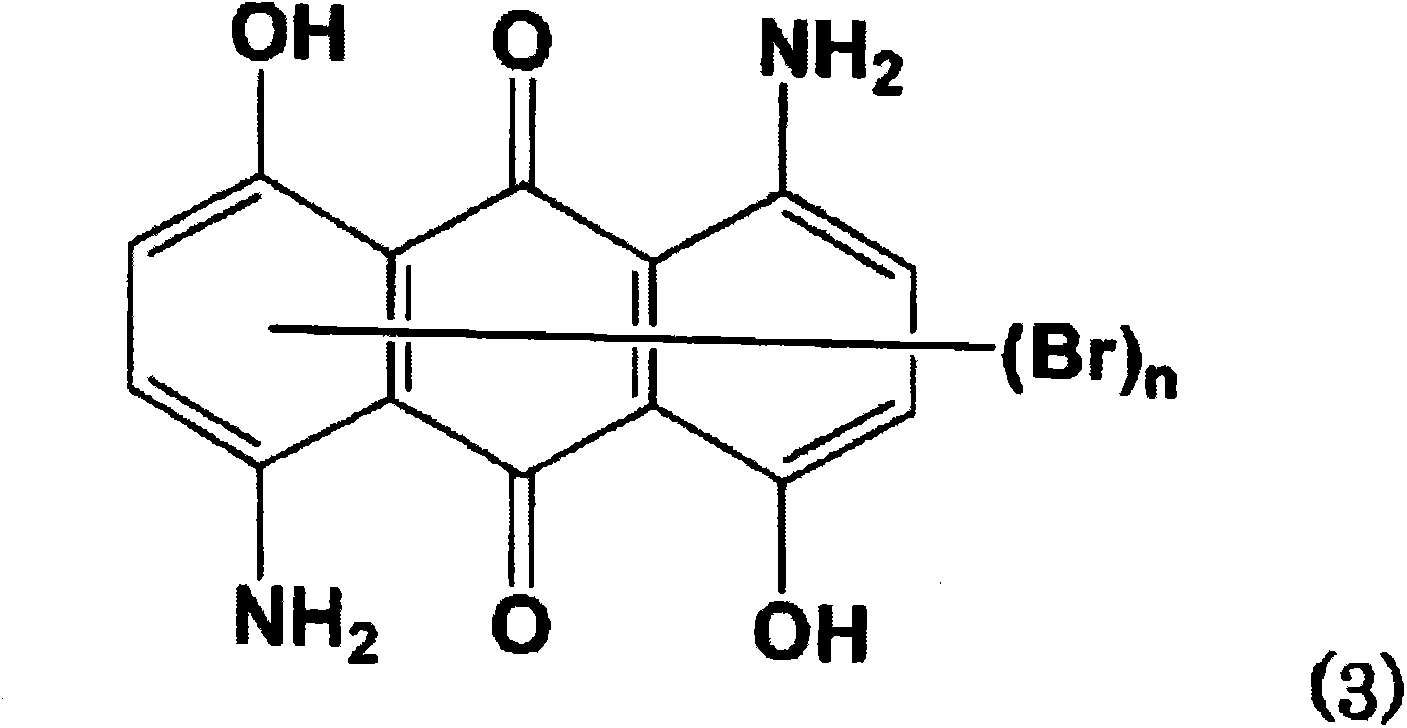

Blue disperse dye mixture

ActiveCN101705020AImprove performanceImprove dye uptakeMonoazo dyesDyeing processDisperse dyePhotochemistry

The invention discloses a blue disperse dye mixture for printing and dyeing polyester materials, which is characterized by comprising the following components in percentage by weight: 5 to 20 percent of dye A, 3 to 28 percent of dye B, 12 to 30 percent of dye C, 0 to 25 percent of dye D, and 45 to 70 percent of dispersant. The blue disperse dye mixture has the characteristics of high dye uptake, good dyeing reproducibility, good leveling property, good fastness and the like, and particularly has excellent dye uptake and wet fastness, and wide dyeing pH range.

Owner:烟台澳土复合材料有限公司

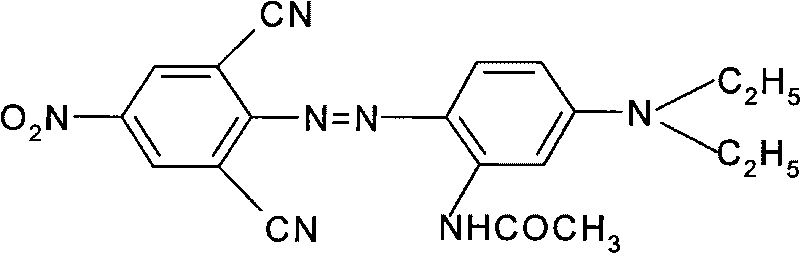

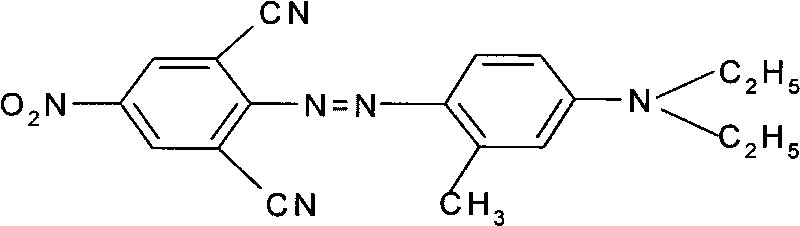

Compound dispersion red dye

InactiveCN1597790AImprove dye uptakeGood dyeing reproducibilityOrganic dyesDyeing processPolyesterPolymer chemistry

The invention relates to a compound dispersive red dye, especially relating to a polyester material printing and dyeing compound dispersive red dye, containing the following components in weight percent: monomer A 20%-45%, monomer B 5%-15% and auxiliary. It has the advantages of high dyeing ratio, good dyeing repeatability, good dyeing uniformity, excellent fastness, approach of coloured light to dispersive red S-5BL, etc.

Owner:ZHEJIANG LONGSHENG GROUP

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN1865574ASolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsAlcoholPolyvinyl acetate

The invention discloses a manufacturing method of milk protein fiber or filament or blended yarn dyeing and yarn-colored product, which is characterized by the following: changing coiling density of yarn; controlling heating temperature; adopting segmented contraction in the cylinder yarn dyeing course; adding self-producing milk protein fiber dyeing specific adjuvant; utilizing polyacrylonitile or polyvinyl acetate alcohol as carrier realize active dyeing technology of milk protein fiber; solving the difficulties of flower color, weak color and bad fastening degree problem to produce excellent washing shrinkage and stable size yarn-dyed product through weaving, shrinking and softening and final disposal.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Levelling agent used for environmentally friendly cotton and preparation method thereof

InactiveCN101974855AImprove staining reproducibilityPrevent dye aggregation and precipitationDyeing processChemistryLignosulfonates

The invention discloses a levelling agent used for environmentally friendly cotton and a preparation method thereof. The levelling agent is composed of tristyryl polyoxyethylene ether sulphate, chelating disperse agent, lignosulfonate, sodium glycol bis-(1-octyl) sulfo succinate, ammonia water, organic silicon defoaming agent and water. The invention controls dye to be uniformly absorbed and dyed; and dye can be prevented from condensation and precipitation even under the condition of low temperature high electrolyte concentration. 'Full addition method' can be adopted, thus greatly simplifying dyeing operation; the dye is ensured to be steadily and uniformly fixed, thus avoiding ununiform fixation; dyeing speck caused by insoluble calcium carbonate when in fixation by soda ash is prevented, meanwhile dyed object has pure colour and lustre, and handfeel is soft; colour yield is not influenced, batch difference can be reduced, dyeing process can be reduced, cost can be reduced, and wet fastness of dyed object can be improved.

Owner:南通斯恩特纺织科技有限公司

Red environment-friendly disperse dye mixture and application thereof

ActiveCN102952414AImprove dyeing effectGood sublimation fastnessOrganic dyesDyeing processDisperse dyeNuclear chemistry

The invention relates to the technical field of dye. Aiming at solving the problem that the textile products are required to meet the standard of ecological textile (Oeko-Tex Standard 100) in China, the invention provides a red environment-friendly disperse dye mixture which is prepared by mixing three components, i.e. mixing a dye A, a dye B and a dye C with auxiliaries, wherein the mixture comprises the following components based on parts by weight of: 15-80% of dye A, 10-69% of dye B, 0-10% of dye C and the balance of auxiliaries. After the dye mixture provided by the invention is used for dying, chlorophenasic acid and chlorophenosic acid can not be detected on the polyester fiber.

Owner:ZHEJIANG JIHUA GROUP +1

Black reactive dye composition and preparation method and application thereof

ActiveCN105802278AGood dyeing reproducibilityGood value for moneyOrganic dyesDyeing processFiberColour fastness

Provided is a black reactive dye composition and a preparation method and application thereof.The composition is composed of a component A, a component B, impurities and optional additives.The black reactive dye composition is applicable to printing and dyeing of various fibers and textile fabrics thereof, the dyeing reproducibility is good, the relative fixation rate is high, all color fastness properties are excellent, and excellent comprehensive performance is achieved.

Owner:ZHEJIANG RUIHUA CHEM

Production method for outside pasting product pretreatment and cationic dye one-bath process dyeing

The invention relates to a printing and dyeing method, and especially relates to a production method for outside pasting product pretreatment and cationic dye one-bath process dyeing. The method comprises the following steps: selecting a sample cloth, pre-setting a grey, singeing the grey, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, designing a dyeing formula, carrying out jar dyeing on the cloth sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The production method for for outside pasting product pretreatment and cationic dye one-bath process dyeing has obvious energy saving and emission reduction effects, and the handle elasticity, the color fullness and various quality indexes of fabrics obtained in the invention can meet requirements of different clients.

Owner:ZHEJIANG HANGMIN STOCK

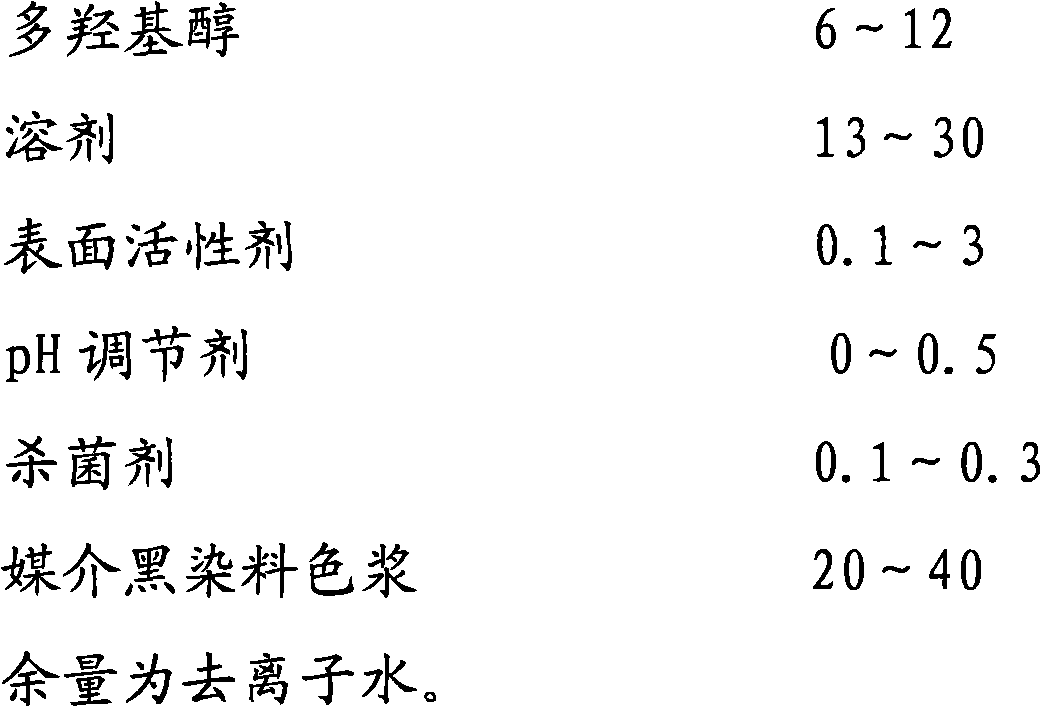

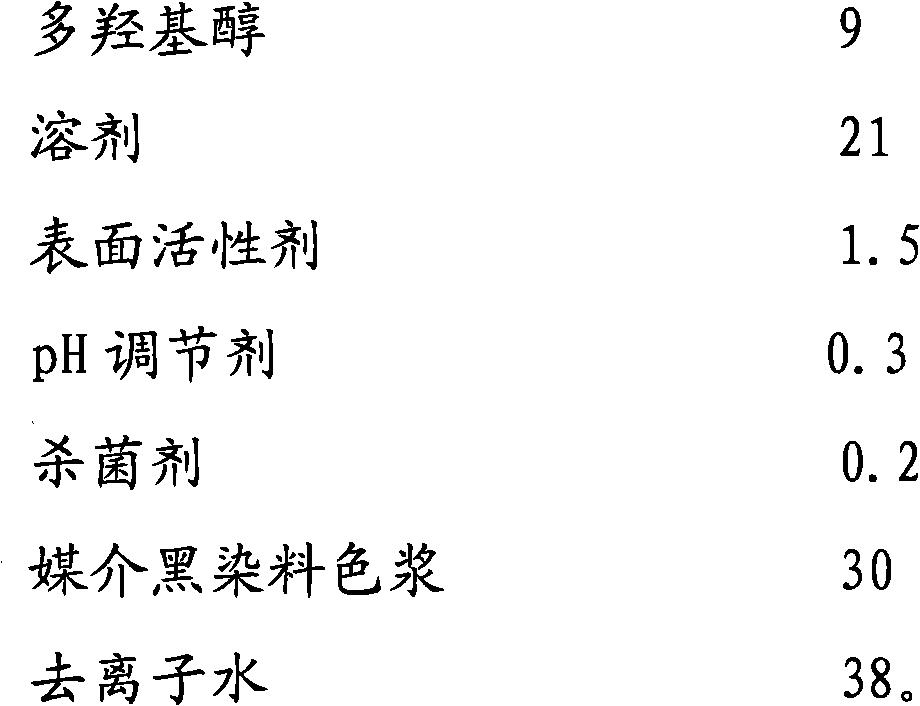

Ink composition with high-weather-resistance black dye for ink-jet printing

ActiveCN102167927ASolve the sun resistanceSolve the problem of ozone resistanceInksWater basedAlcohol

The invention discloses an ink composition with a high-weather-resistance black dye for ink-jet printing. The composition is prepared by mixing following components in percentage by weight: 6-12 percent of polyhydroxy alcohol, 13-30 percent of solvents, 0.1-3 percent of surfactants, 0-0.5 percent of pH regulators, 0.1-0.3 percent of bactericides, 20-40 percent of mordant black dye paste and the balance of deionized water. The invention also provides a method for purifying the mordant black dye paste, which comprises the following steps of: mixing mordant black dye raw powder and deionized water based on a weight ratio of 1:9, heating, filtering, and performing desalination treatment to obtain the mordant black dye paste. The ink composition with the high-weather-resistance black dye for ink-jet printing, disclosed by the invention, has extremely high light fastness and ozone resistance, the printing quality is good, the optical density is high, the quality guarantee period is long, and a nozzle is not blocked.

Owner:深圳市墨库图文技术有限公司

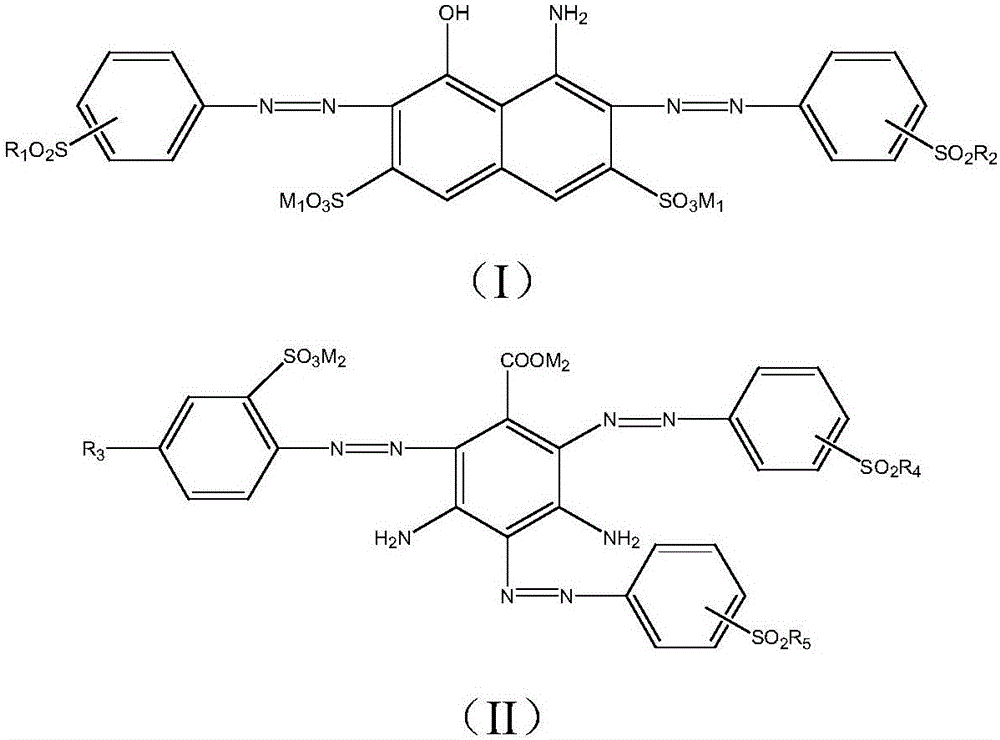

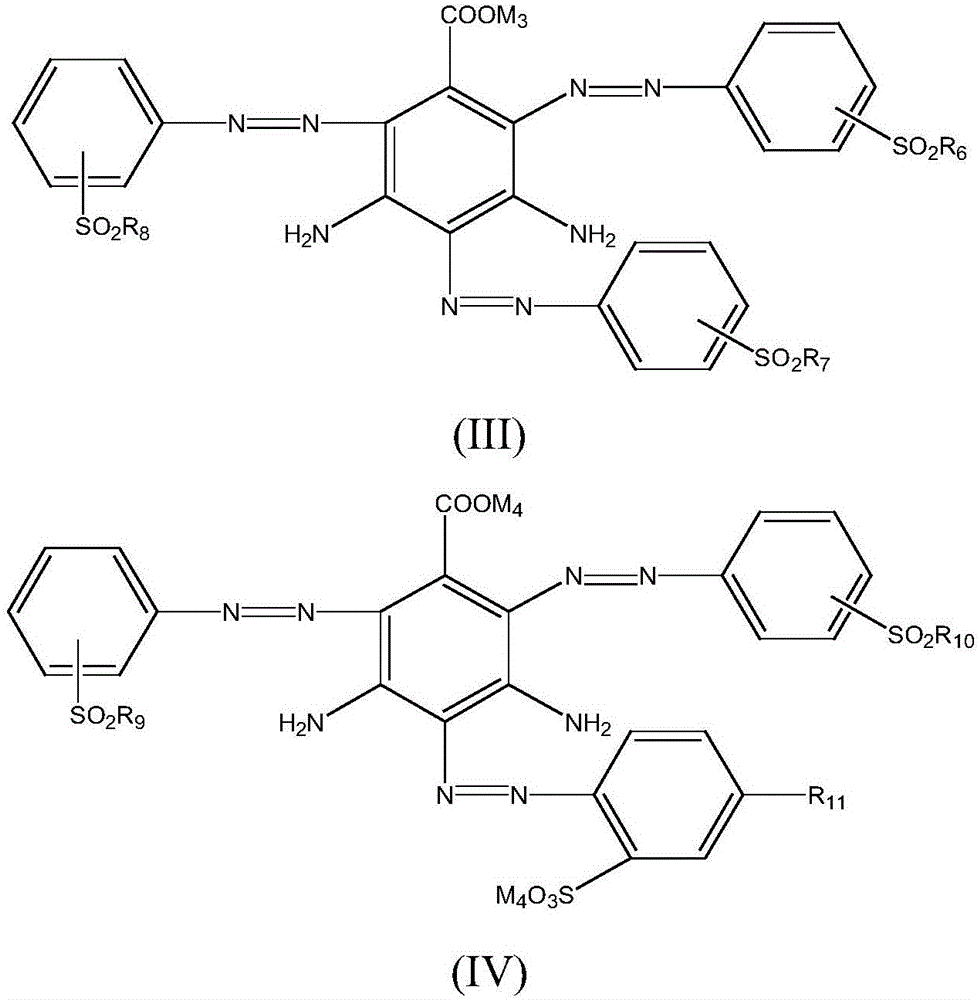

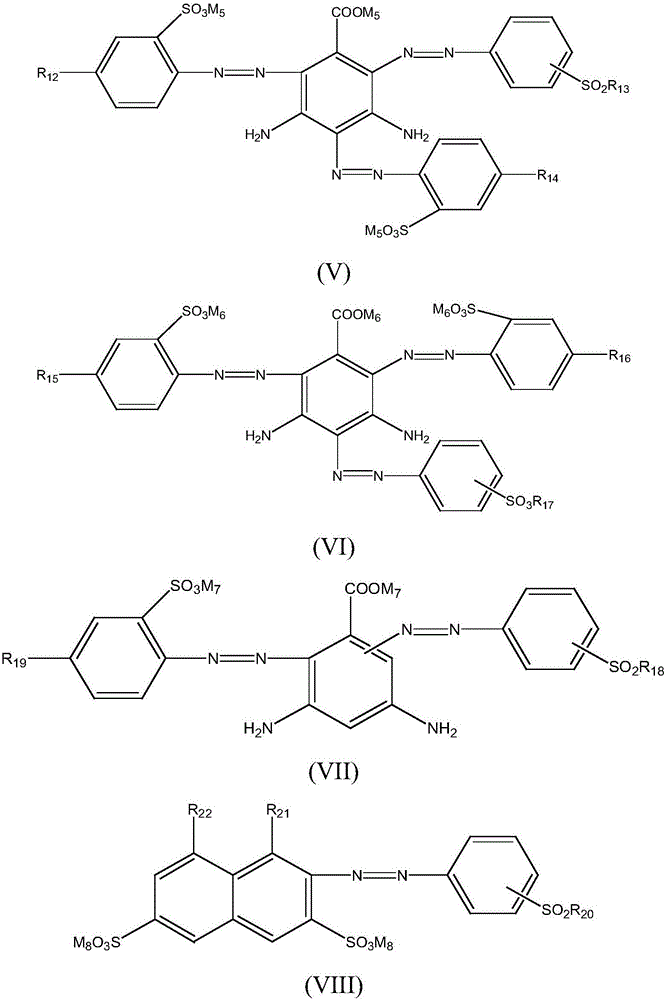

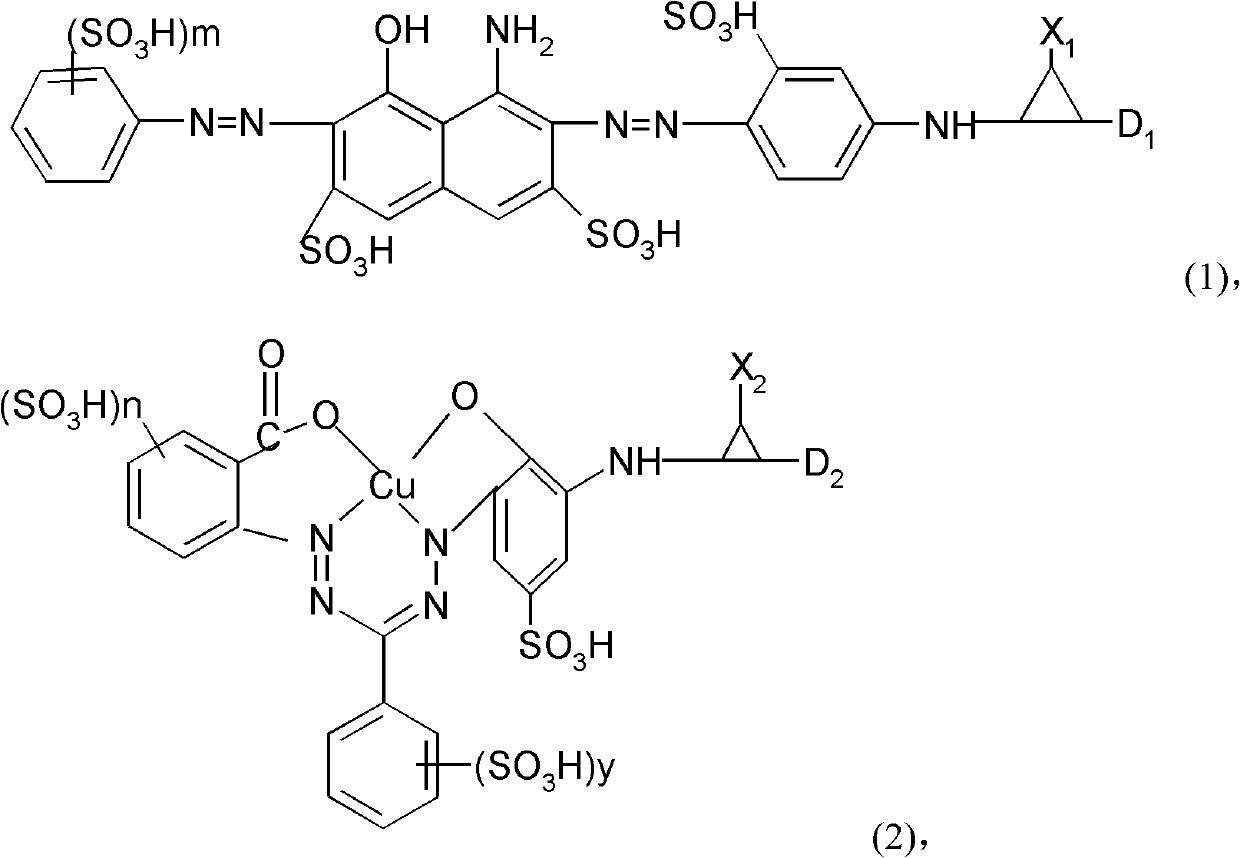

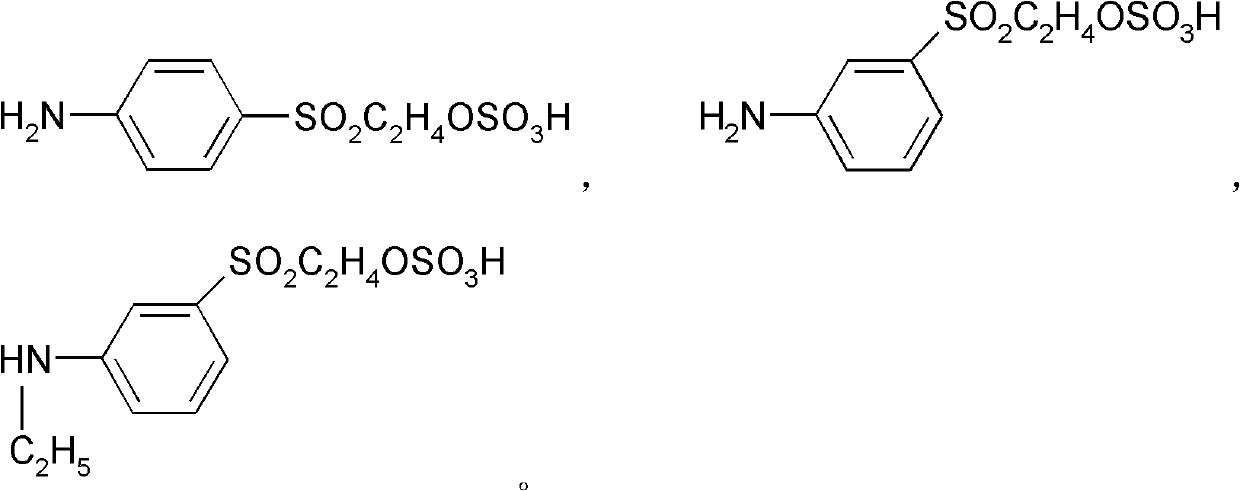

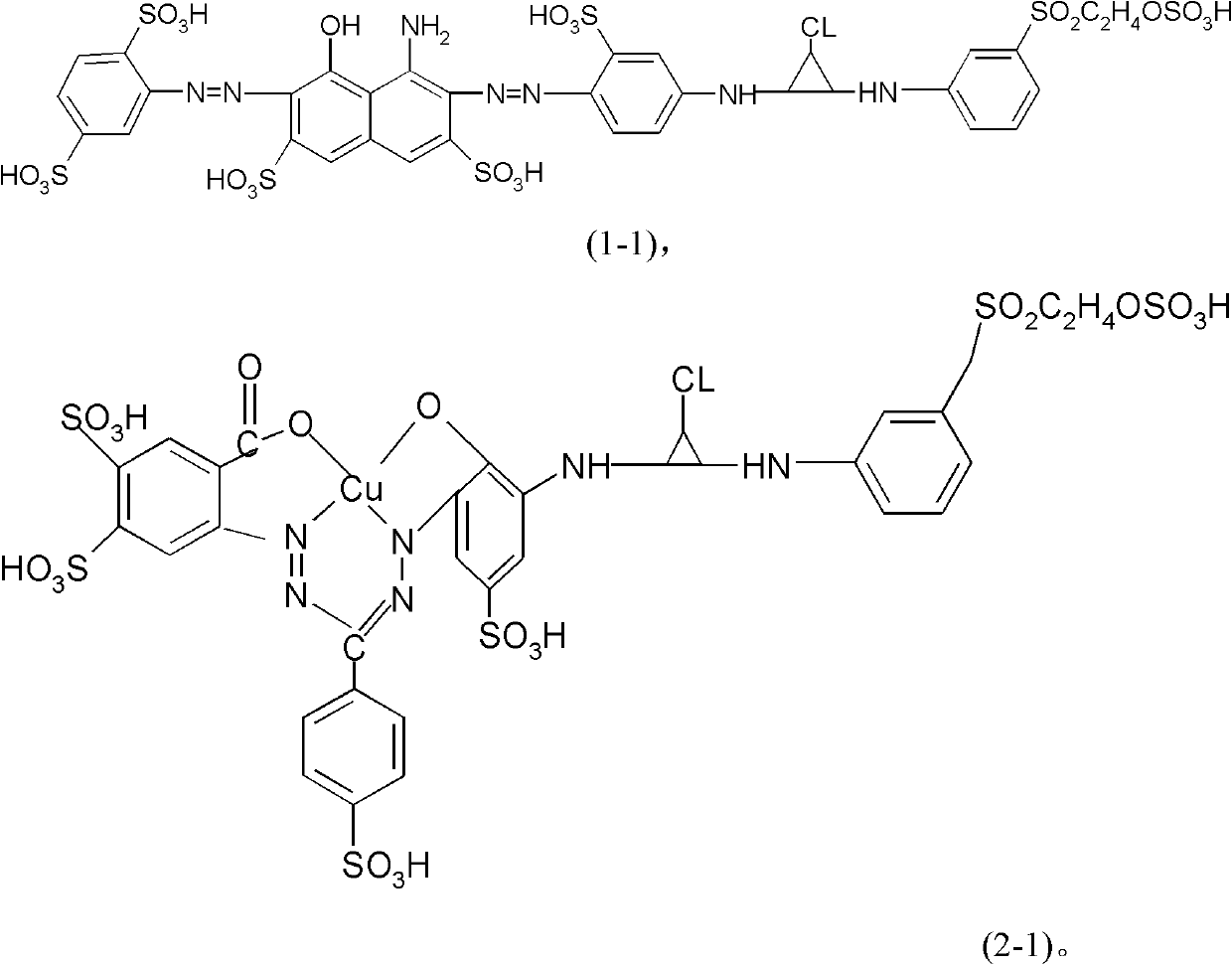

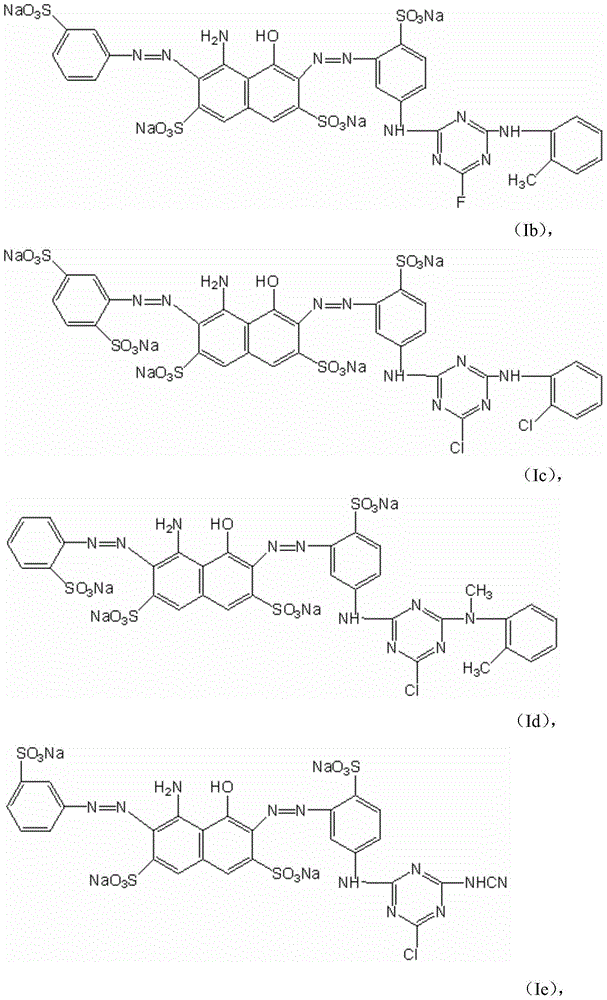

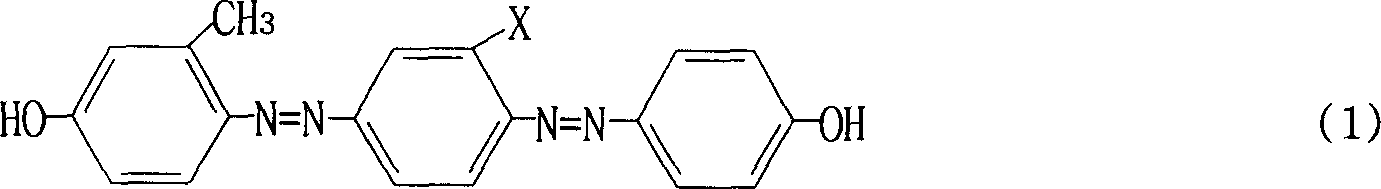

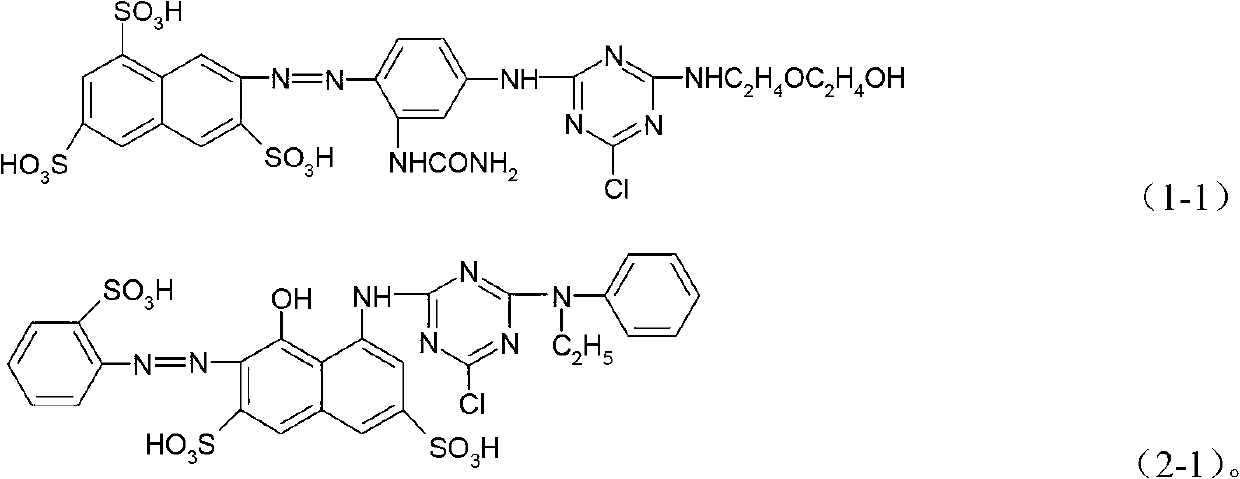

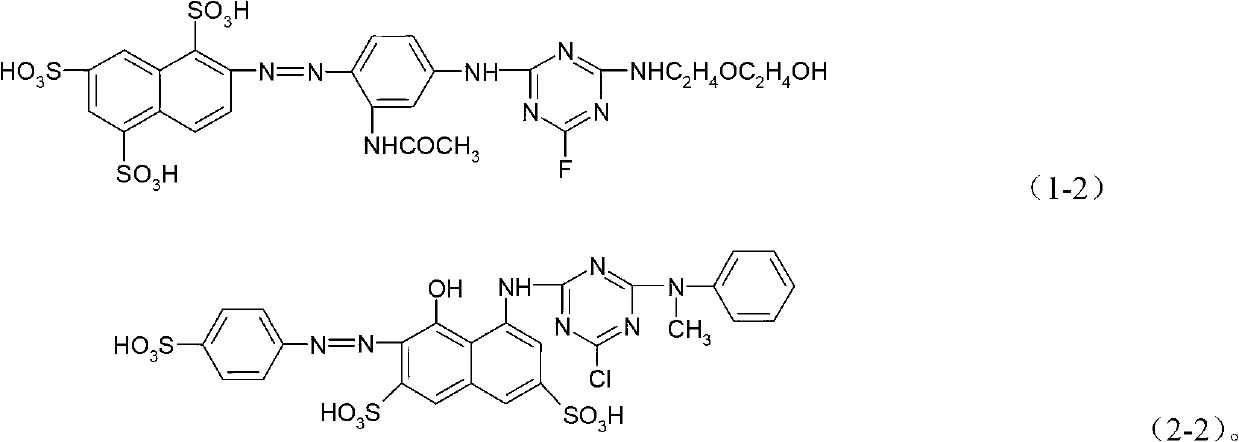

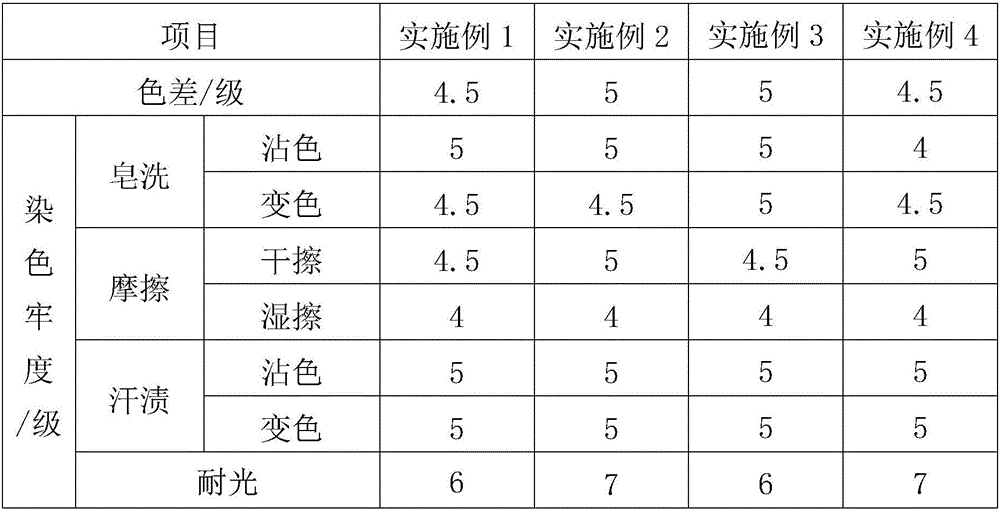

Blue reactive dye mixture and preparation and application thereof

ActiveCN102212276AGood Light Color Lifting PowerHigh color fixing rateOrganic dyesDyeing processCellulosePerspiration

The invention discloses a blue reactive dye mixture. The blue reactive dye mixture is characterized by comprising a dye shown in a general formula (1) and a dye shown in a general formula (2 in the weight ratio of (68.6-60):(26.3-32). The dye mixture has excellent light color boosting capacity and high color fixing rate when dyeing or printing cellulose, has higher dyeing reproducibility than ordinary commercial dyes, and can effectively solve the problems of dyeing defects and staining; and the formula is low in cost. Moreover, the blue reactive dye mixture has excellent color fastness to sunlight and perspiration-light, and is applicable to various application processes.

Owner:HUBEI COLOR ROOT TECH CO LTD

Dye liquor and black dye composition used for anodized aluminium dyeing and dyeing method

ActiveCN110016705ALow priceGood dyeing reproducibilitySurface reaction electrolytic coatingYELLOW DYEPhotochemistry

The invention belongs to the field of fine chemical engineering, and discloses a black dye composition used for anodized aluminium dyeing. The black dye composition is composed, by weight percent, 30to 50% of black dye A, 30 to 50% of black dye B, 5 to 15% of yellow dye and 1 to 10% of red dye. The invention further provides dye liquor prepared through the black dye composition. The invention further provides a method for using the dye liquor for carrying out anodized aluminium dyeing. Through the method, an aluminum part can obtain the state-stable and durable black.

Owner:绍兴市上虞嘉利盛助剂工业有限公司

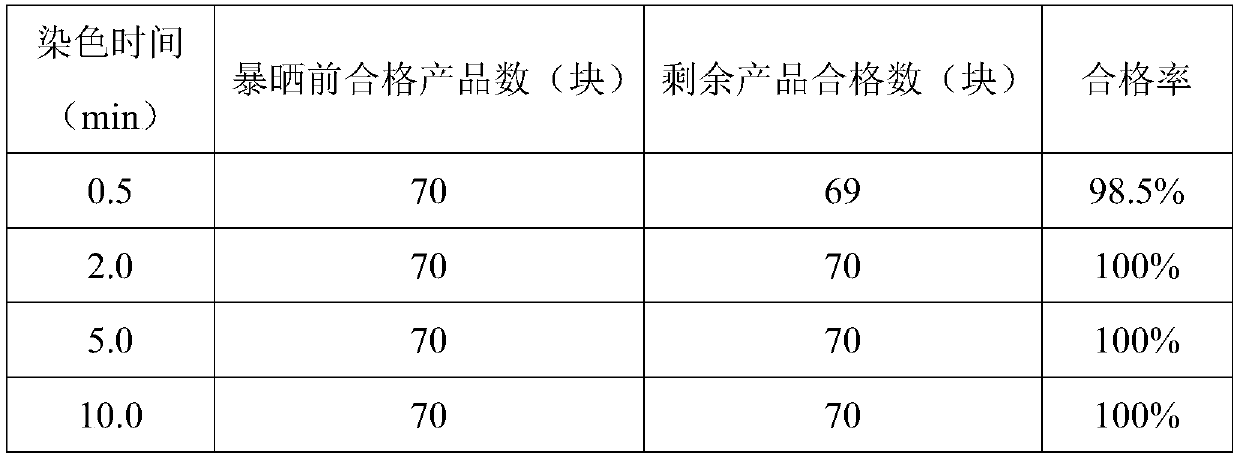

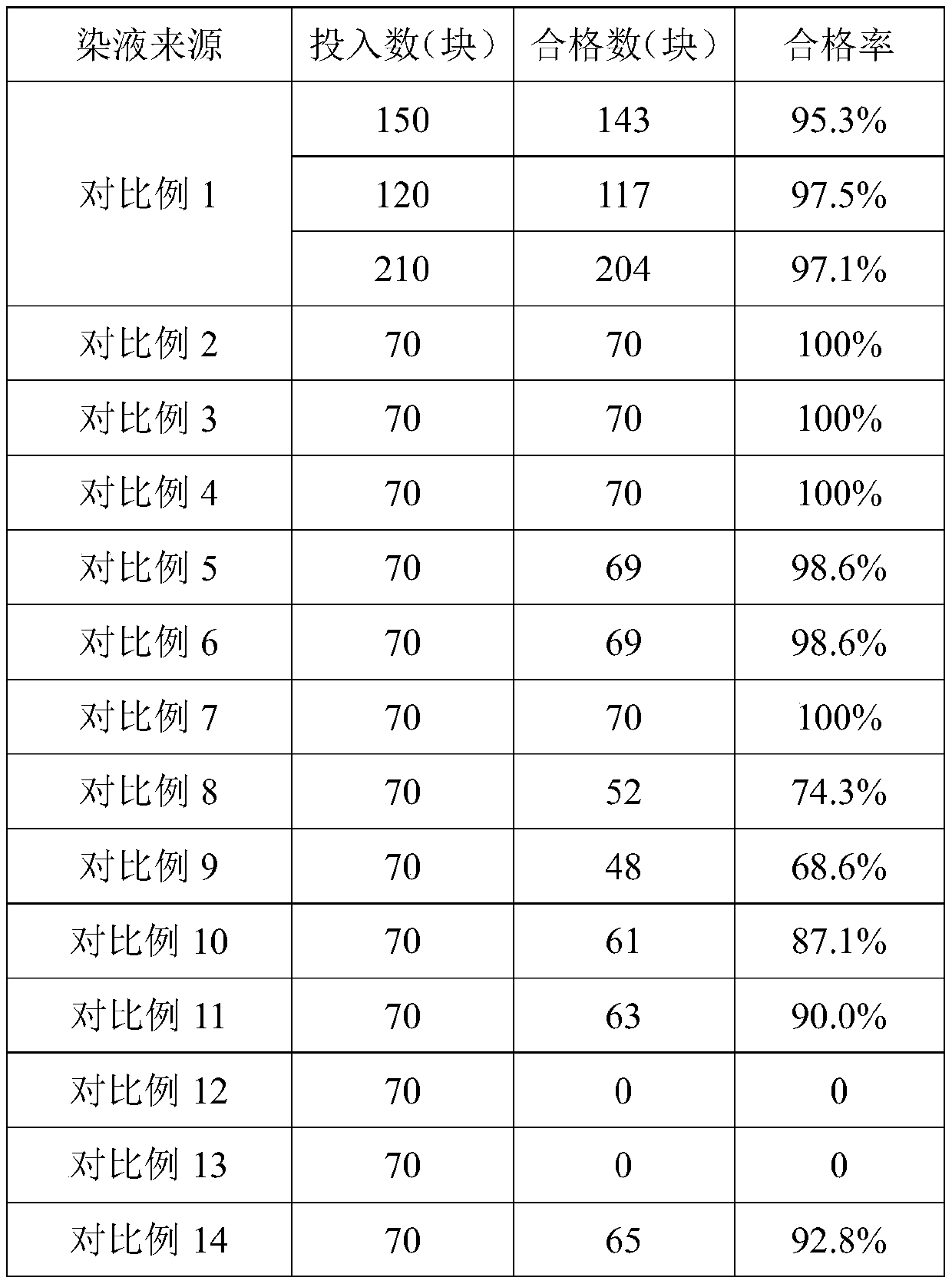

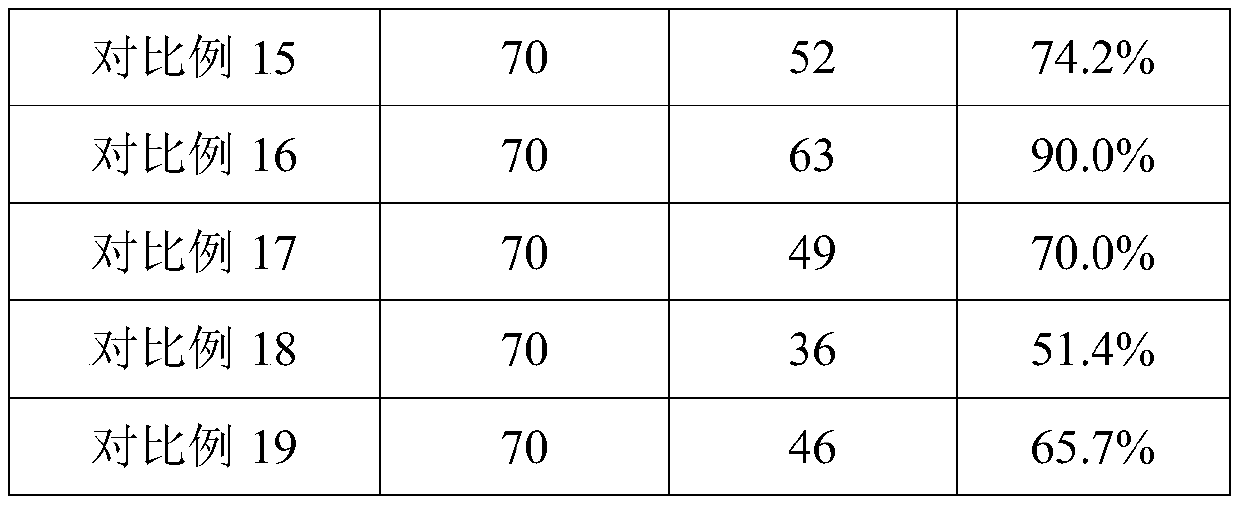

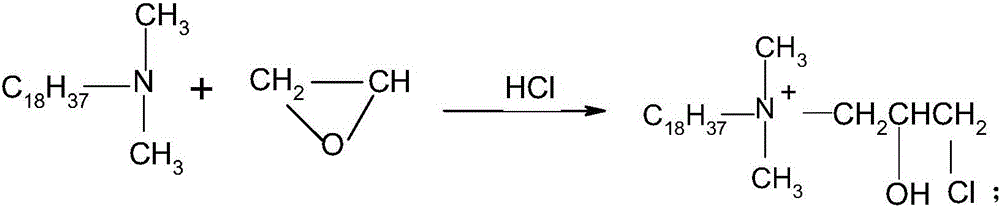

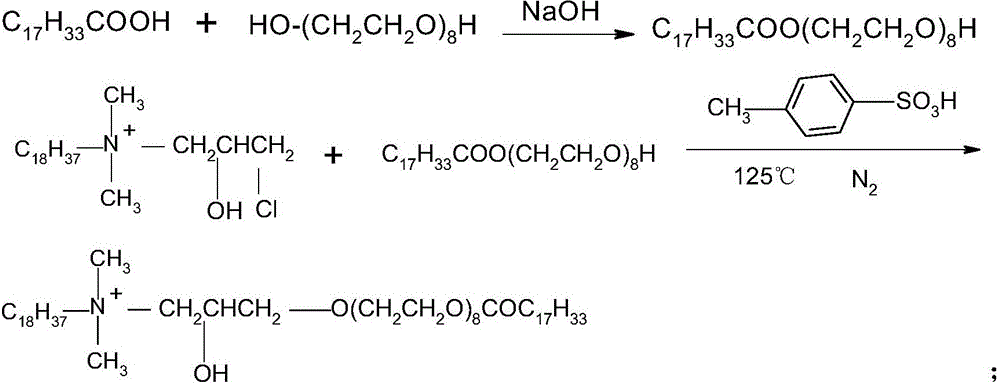

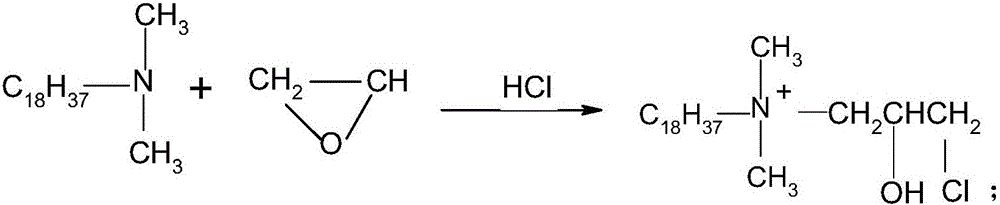

Preparation method of leveling agent for one-bath dyeing of polyester-cotton fabric

ActiveCN106436376AReduce foamingGood dyeing reproducibilityOrganic compound preparationDyeing processReactive dyePrecipitation

The invention discloses a preparation method of a leveling agent for one-bath dyeing of a polyester-cotton fabric. The method comprises the first step of synthesis of polyoxyethylene ether oleate hydroxypropyl dimethyl octadecyl ammonium chloride (N-EO8) and the second step of mixing according to a formula. According to the prepared leveling agent for one-bath dyeing of the polyester-cotton fabric, a polyoxyethylene ether structure with 8 EOs is adopted, so that cotton dyed on reactive dyes and polyester dyed on disperse dyes both have a good level dyeing effect; the leveling agent has excellent dispersing performance, moderate retarding performance, extremely low foamability, dye bath conditioning performance such as scale inhibition and high stability to acid, alkali, electrolytes (anhydrous sodium sulphate), hard water and temperature, can prevent the situation that temperature change causes dye agglomeration and precipitation, can guarantee that the same hue is dyed gradually during color matching, and has extremely good dyeing reproducibility.

Owner:FOSHAN SANSHUI DACHANG PRINTING & DYEING WEAVING CO LTD

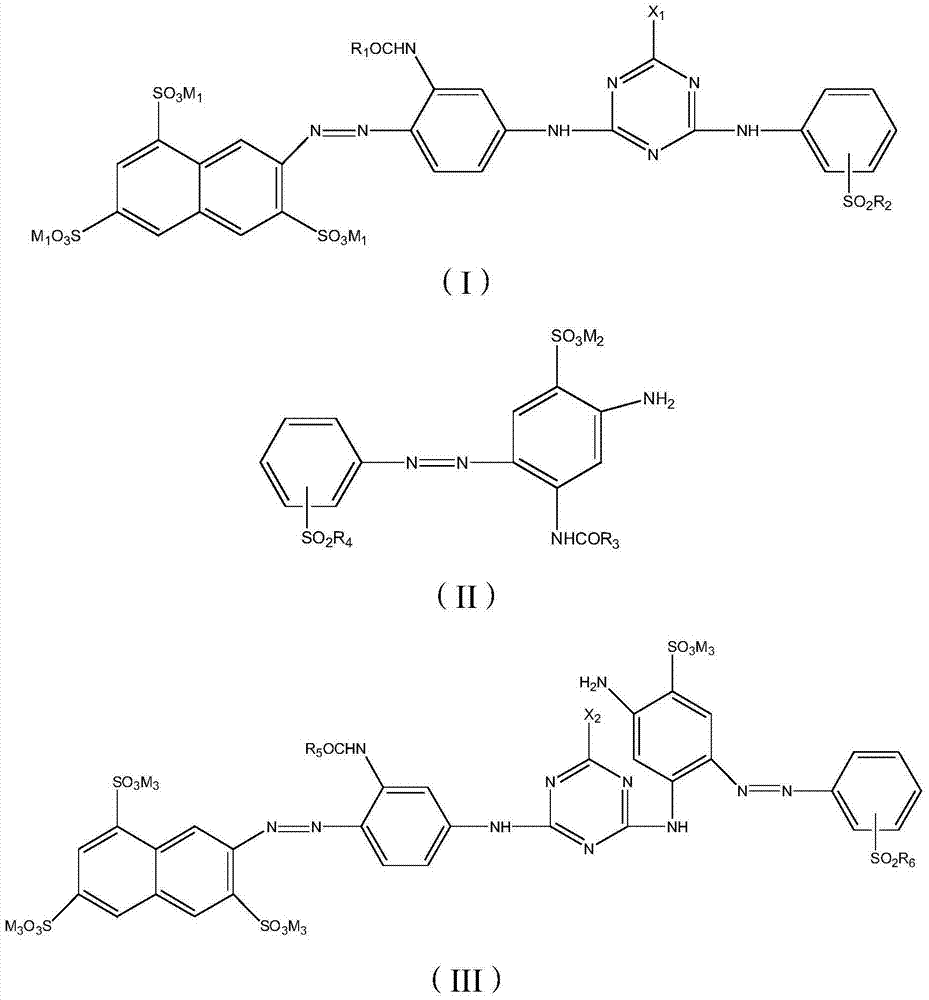

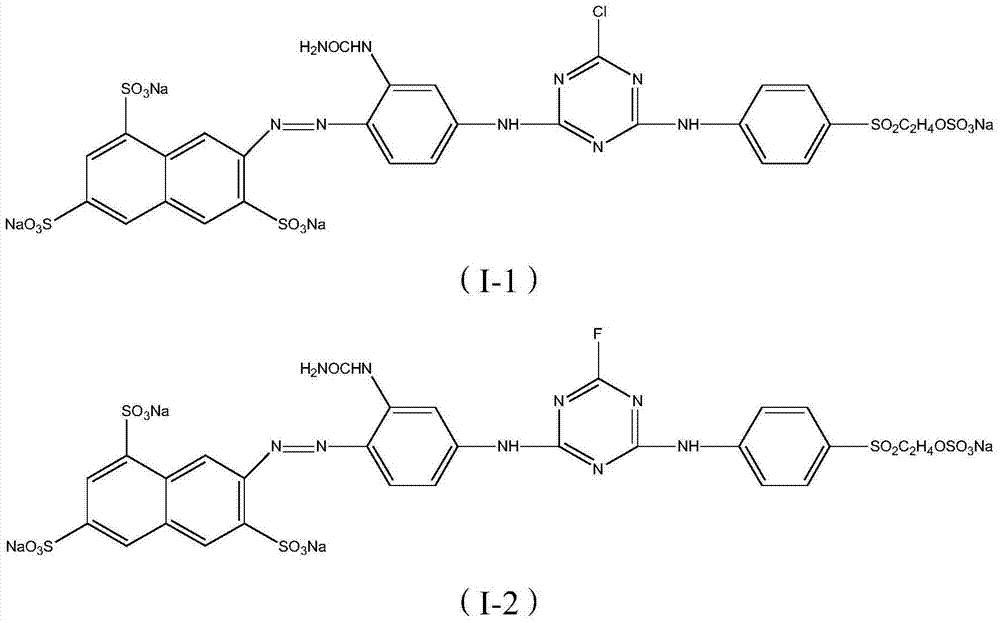

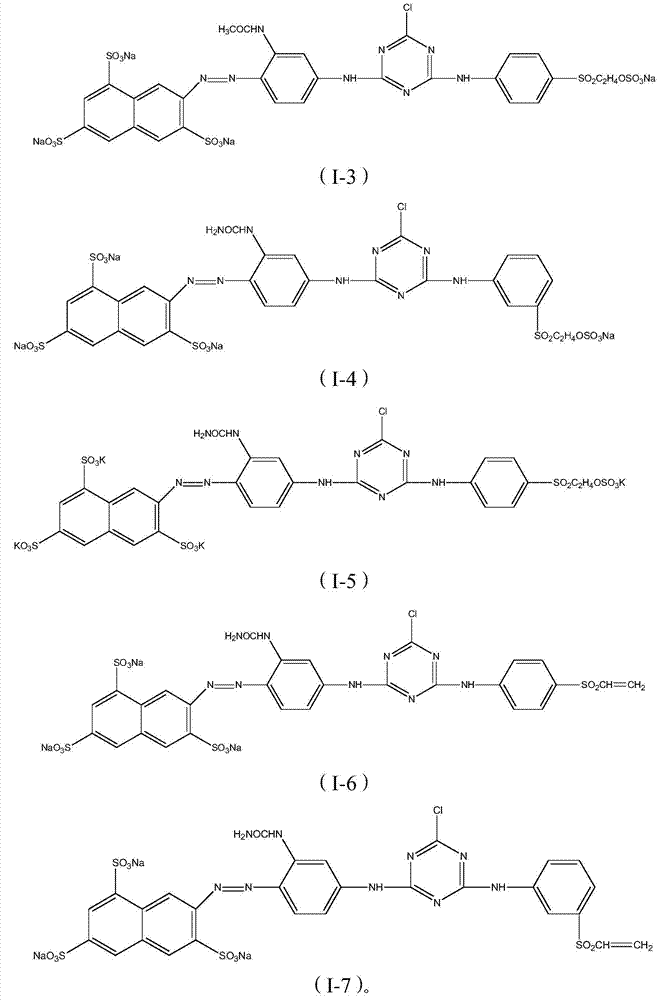

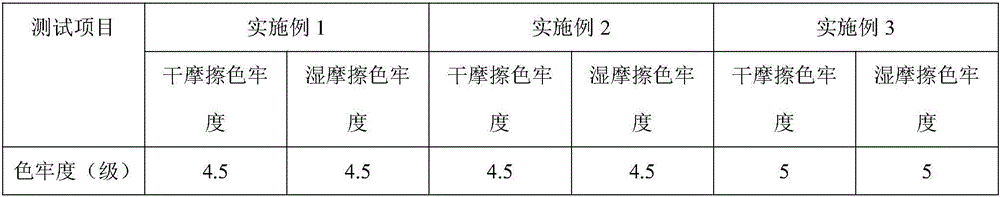

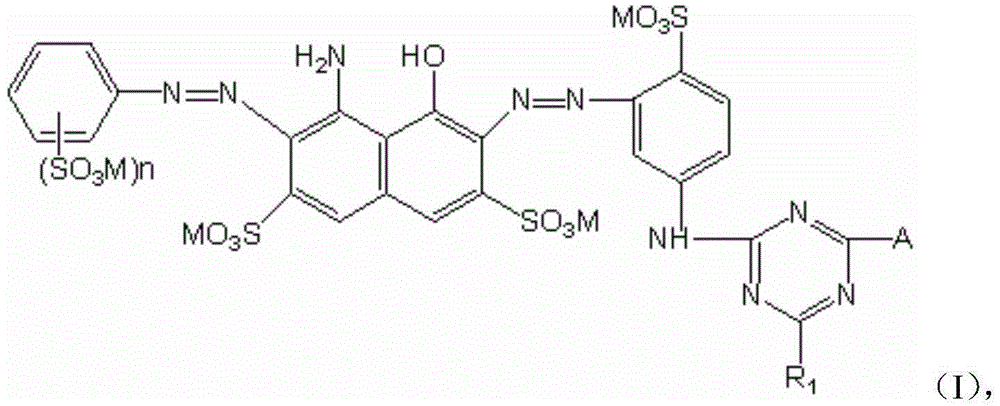

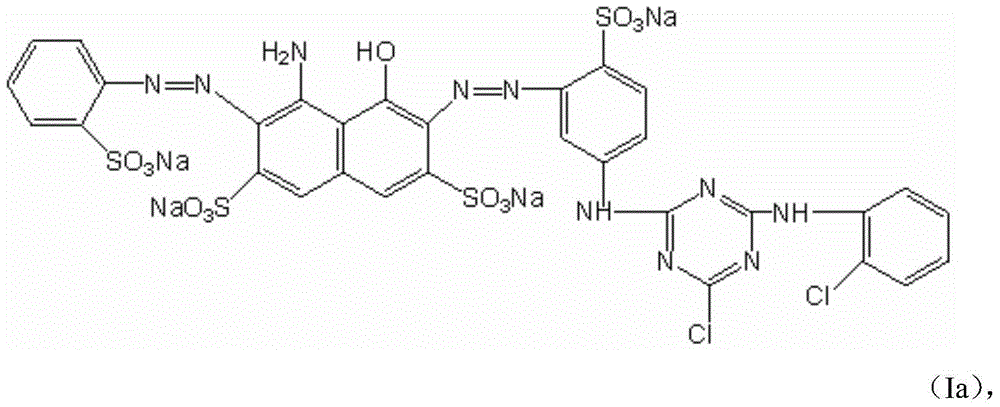

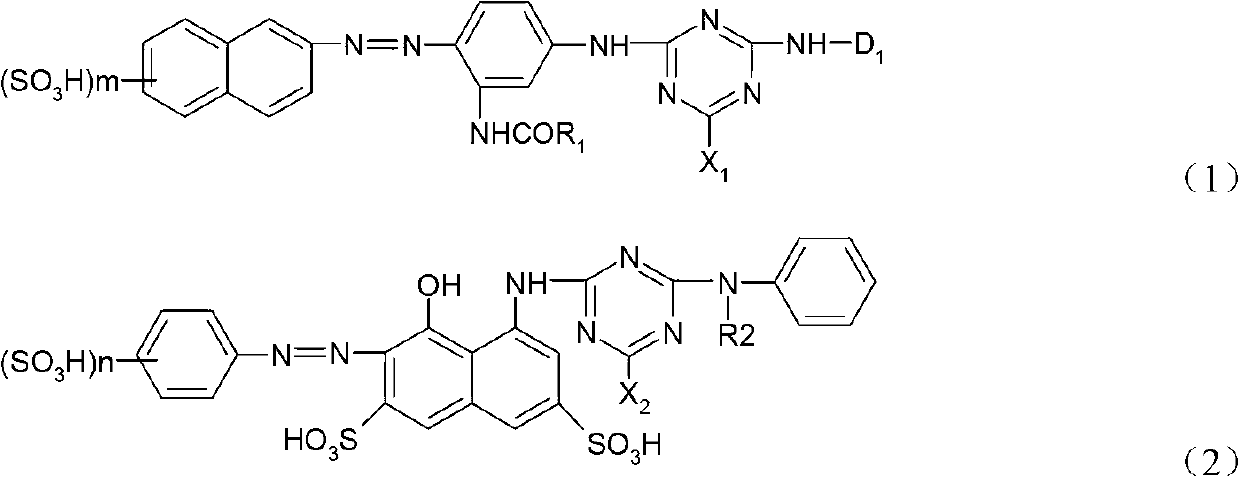

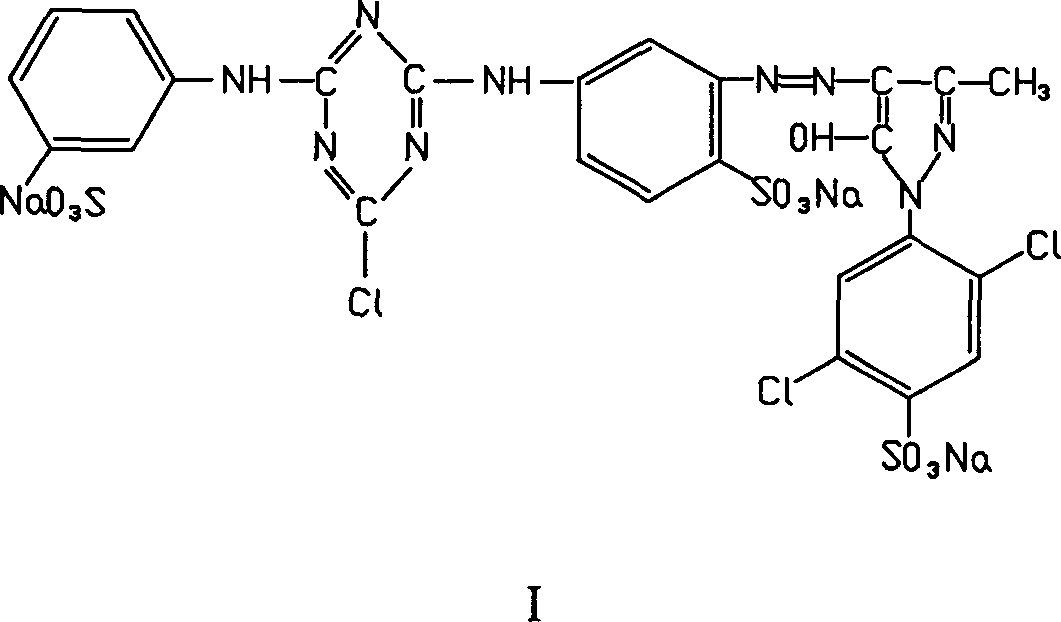

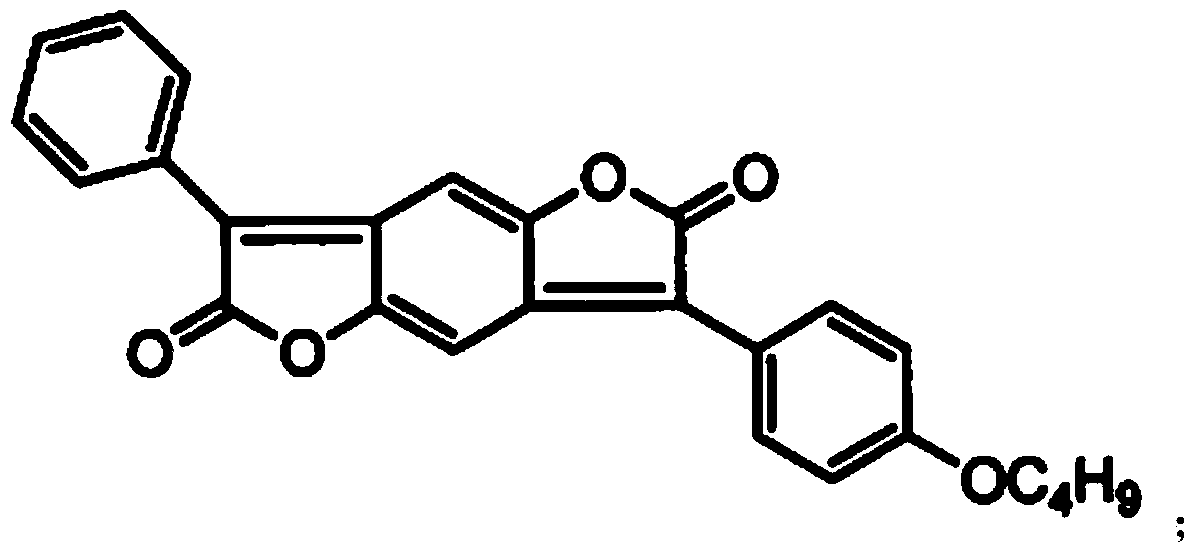

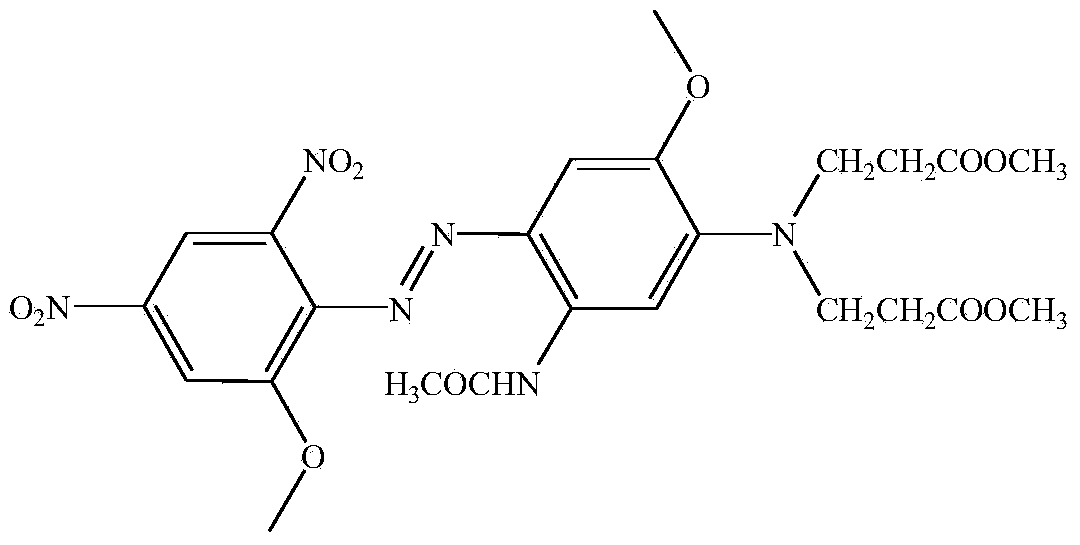

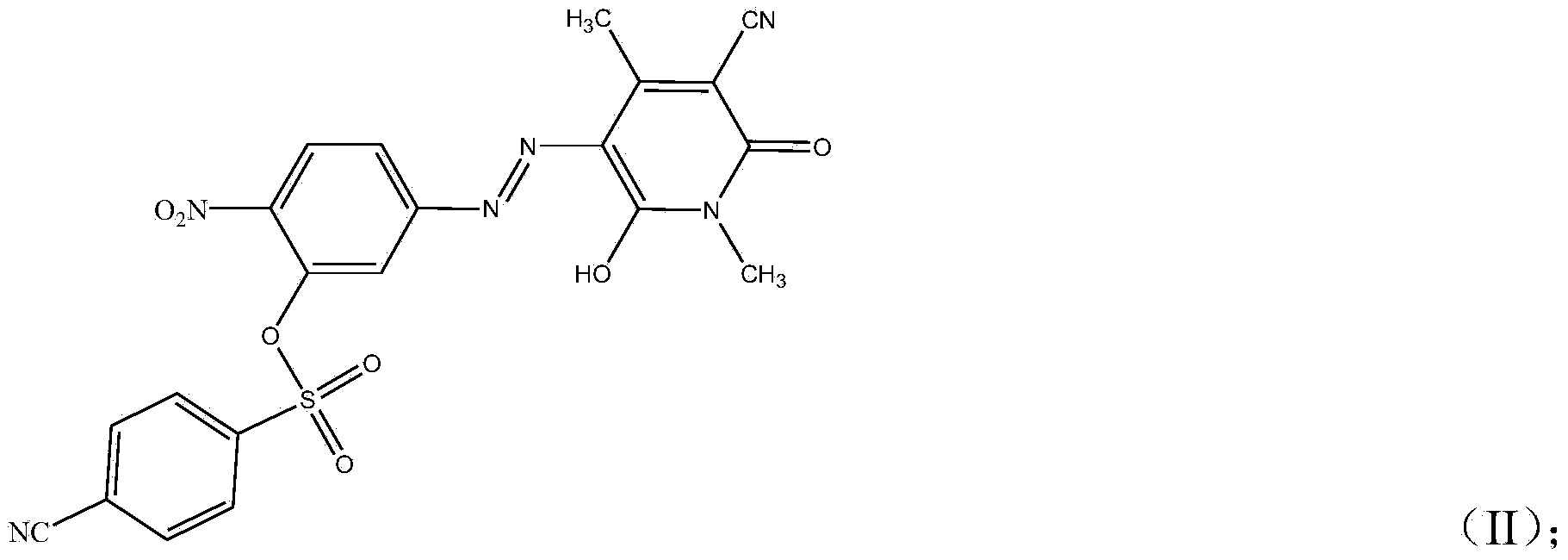

Preparation method and application of yellow reactive dye combination and fibers or fiber fabrics dyed with yellow reactive dye combination

The invention provides a preparation method and application of a yellow reactive dye combination, and fiber or fiber fabrics dyed with the yellow reactive dye combination, and belongs to the field of reactive dye. The dye combination is composed of, by weight parts, 30-60 parts of a component A shown in a formula (I), 30-60 parts of a component B shown in a formula (II), 1-10 parts of a component C shown in a formula (III), and 0-60 parts of auxiliaries. The yellow reactive dye combination is applicable to dyeing various fibers and fiber fabrics and can obtain excellent color fastness performance.

Owner:ZHEJIANG RUIHUA CHEM

Dyeing technology of wool/polyester blended fabric

InactiveCN106149407AThe dyeing process is simpleHigh color fastnessDyeing processAnimal fibresPolyesterAcetic acid

The invention discloses a dyeing technology of wool / polyester blended fabric. The dyeing technology comprises the steps of (1) preparing a pretreatment solution: adding an acetic acid-sodium acetate buffer solution and fatty acid methyl ester ethoxylate into mixed liquid of ethanol and water, and evenly stirring to prepare the pretreatment solution; (2) pretreating a textile of the wool / polyester blended fabric; (3) preparing dye liquor: adding a reactive dye for wool into the mixed liquid of the ethanol and the water, adding a leveling agent while stirring, evenly stirring and then preparing the dye liquor; (4) dyeing: putting the wool / polyester blended fabric treated in the step (2) into the dye liquor prepared in the step (3), wherein the initial temperature of the dye liquor is 10-20 DEG C; after that, heating the dye liquor up to 40-50 DEG C at the heating rate of 5-6 DEG C / min, and then heating the dye liquor up to 60-90 DEG C at the heating rate of 2-3 DEG C / min; dyeing the wool / polyester blended fabric, then washing, soaping, washing and drying to obtain a finished product.

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Reactive dye mixture

Relating to the technical field of dyes, the invention provides a reactive dye mixture to solve the problems of easy staining, low solubility and undesirable color fastness of printing navy blue and black dyes during washing. The reactive dye mixture is made of, by weight, 1-80% of a dye A, 20-99% of a dye B, and 0-50% of a dye C. The dye has excellent dissolution performance, is easy to wash off and difficult to stain each other, and has excellent perspiration fastness, washing fastness and rubbing fastness, as well as good color paste storage stability, thus being very suitable for printing of cellulose fiber, and the steaming or baking curing process.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

High-temperature environmentally-friendly chemical fiber dyeing technology

InactiveCN107164976AGuaranteed functionAvoid damageBiochemical treatment with enzymes/microorganismsDyeing processFiberCellulose

The invention relates to a high-temperature environmentally-friendly chemical dyeing technology. The technology comprises preprocessing, pre-setting, dyeing, water washing, soaping, dye fixation, softening, drying, setting and winding. A stepped heating dyeing method is adopted, and the heating and cooling rates and the dyeing time are strictly controlled, so dyeing of a fiber fabric has high fastness, the dyeing is uniform, and the dyeing has good stability; an anti-dyeing salt S is added in the dyeing process, so the destroy of potential aldehyde groups in cellulose molecules in chemical fiber filaments to a dye is greatly improved, thereby a dyed product has pure color light, the color difference of dyeing is avoided, and the reappearance and the stability of the dyeing are good. Chemical fiber filaments finally produced in the invention have the advantages of uniform dyeing, stability, strong recurrence, elasticity, softness and high dyeing fastness.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

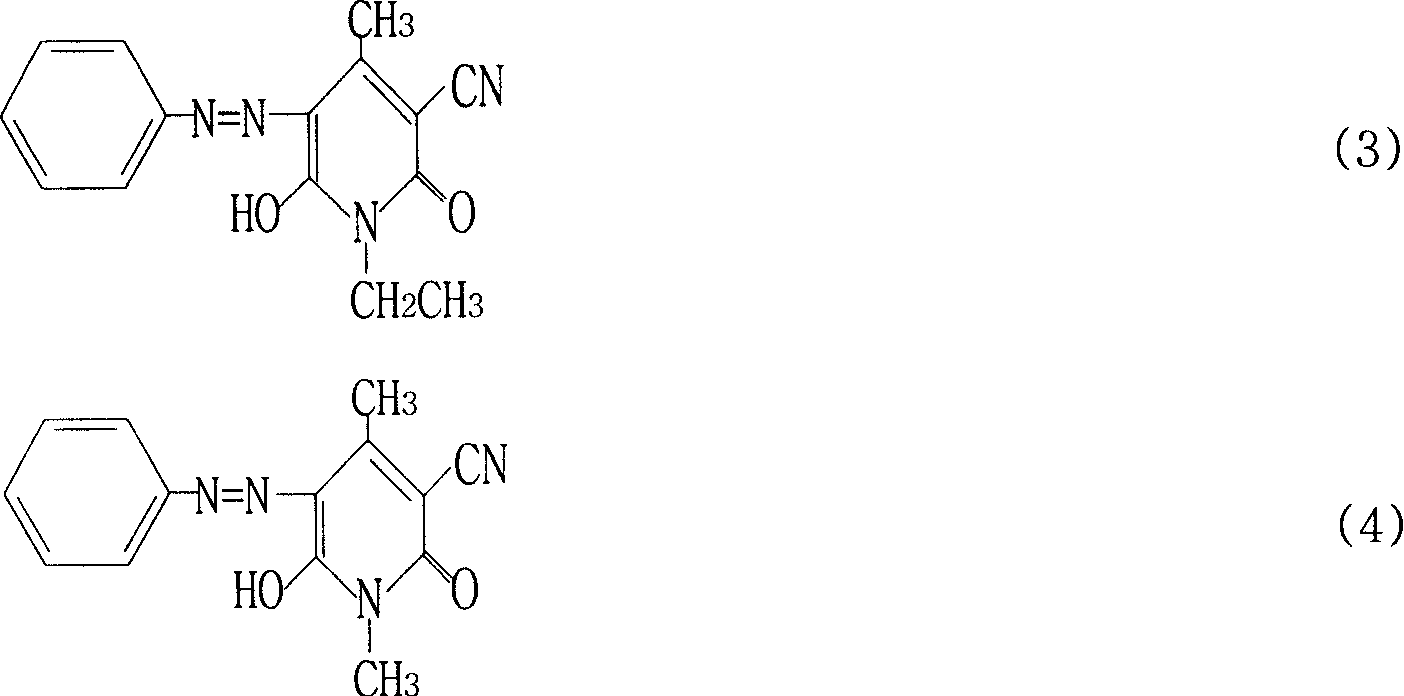

Brightyellow combined dispersible dye

ActiveCN1850913AEasy to liftGood dyeing rateOrganic dyesDyeing processDisperse dyeHigh concentration

The invention discloses a compounding dispersing dye that is suitable for dye printing polyester material. The invention could make the bright yellow product that has high concentration, and reduce polluted water. It has good dyeing repeatability and good color fastness.

Owner:ZHEJIANG RUNTU

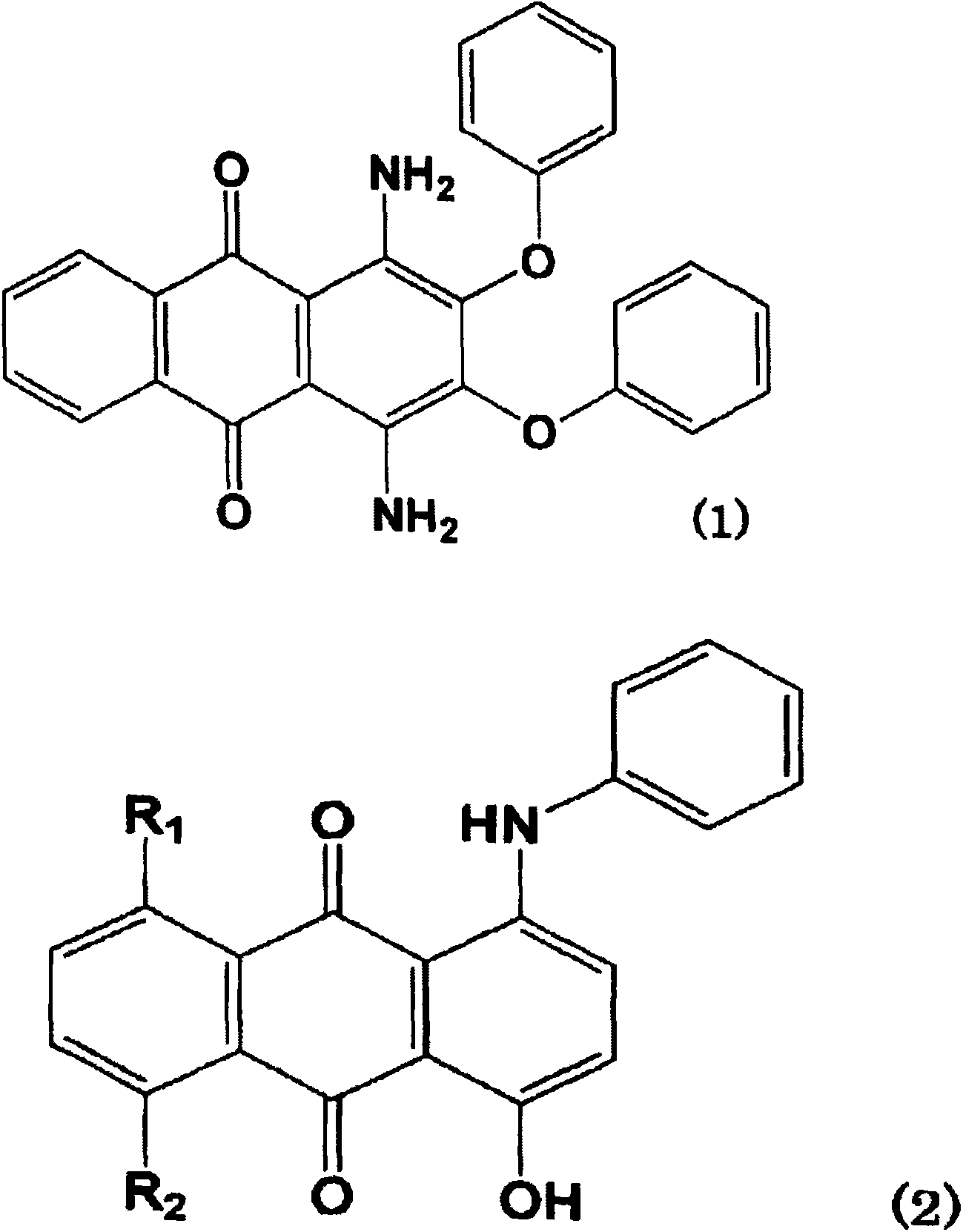

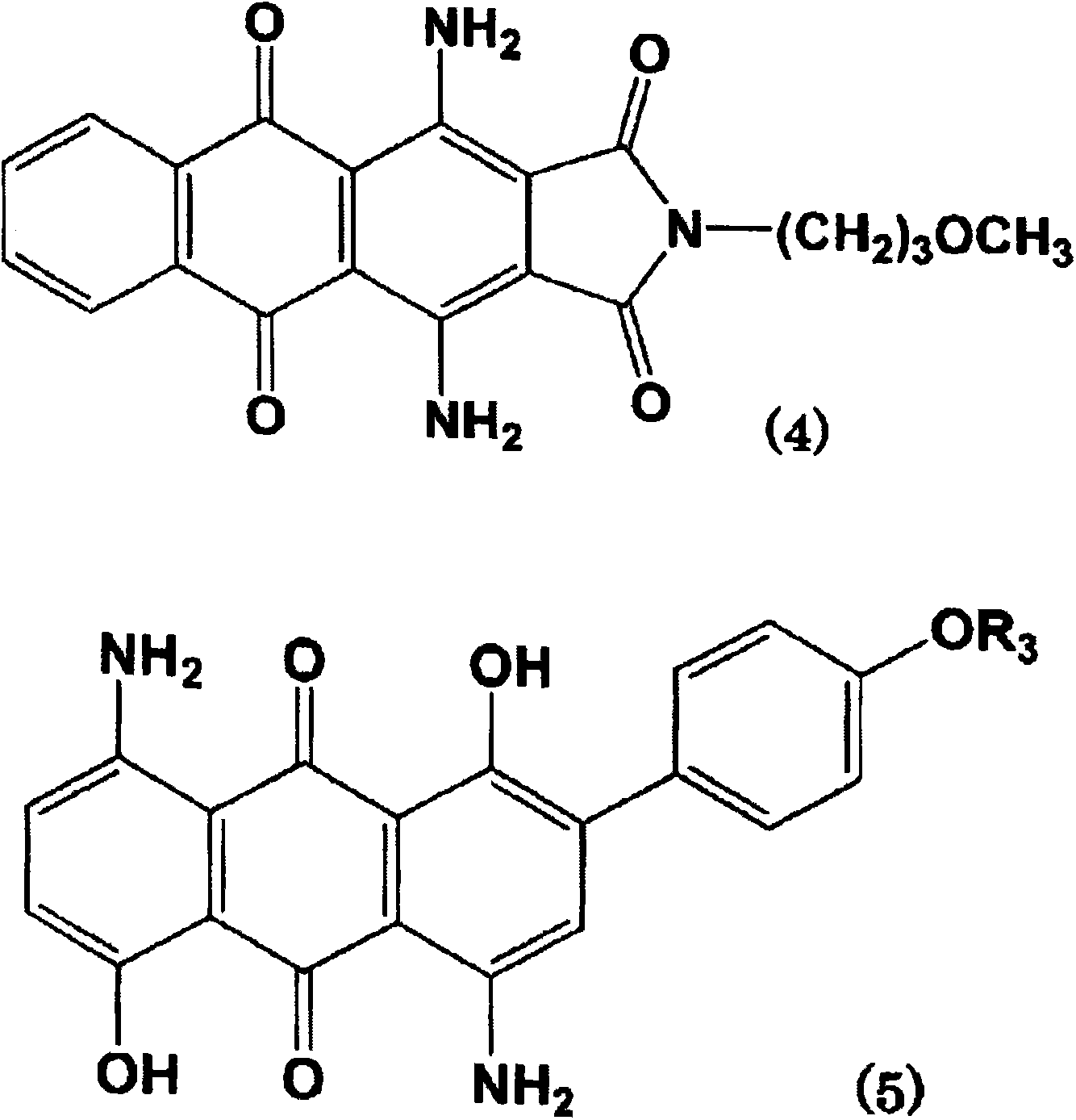

Disperse dye composition and dyeing method for hydrophobic fiber material using same

ActiveCN103649232AUniform dyeing propertiesGood dyeing reproducibilityMonoazo dyesNaphtholactam dyesDisperse dyeHigh humidity

An object of the present invention is to provide a disperse dye composition that has the light fastness required of synthetic fiber materials for automotive interiors that are exposed to sunlight at high temperature and high humidity, and that has good blue, red, and yellow dyeability. This object is achieved by a mixed disperse dye composition containing a blue disperse dye composition having a specific composition ratio of five specific types of disperse dyes, and other specific yellow and / or red disperse dyes. The invention makes it possible to provide a disperse dye composition having not only high fastness of each color but light fastness with a favorable balance of the three primary colors, with the dye properties of each color equal during dyeing, and good dye color reproducibility, as well as by a dyeing method using this dye.

Owner:NIPPON KAYAKU CO LTD

Brightyellow combined dispersible dye

Owner:ZHEJIANG RUNTU

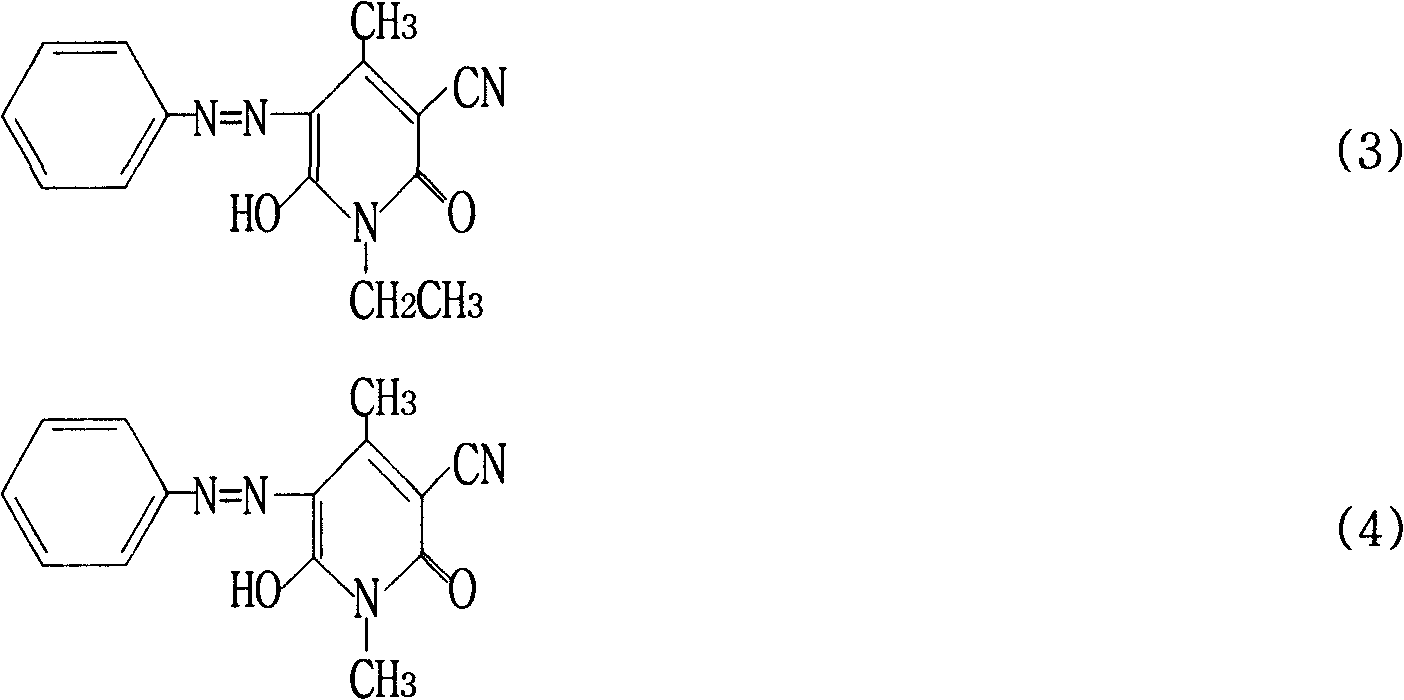

Environment-friendly combined yellow disperse dye

ActiveCN100374512CIncrease concentrationEasy to liftOrganic dyesDyeing processCompound aDisperse dye

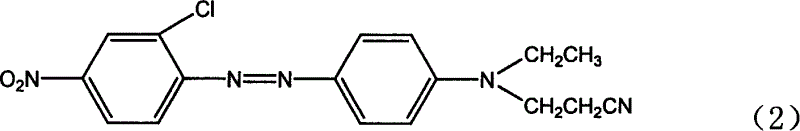

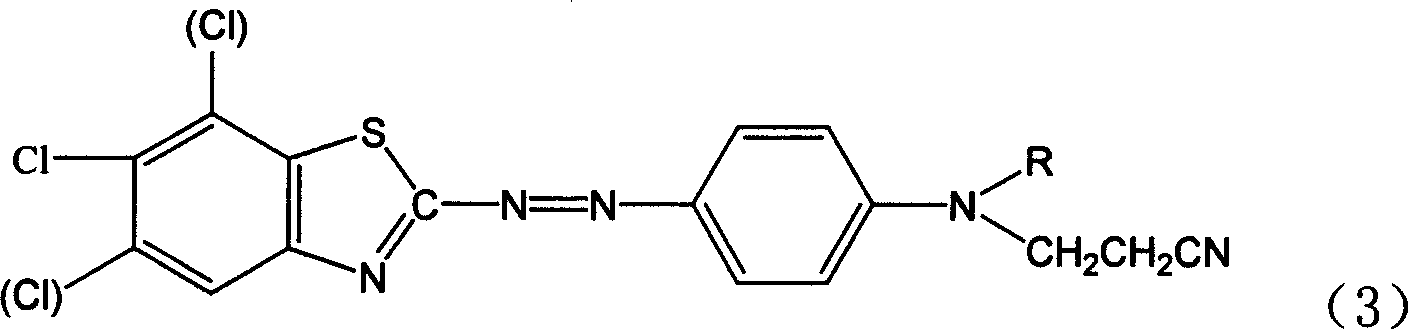

The invention discloses an environment-friendly combination yellow dispersion dye, which comprises the components (by weight percent) of 15.0-50.5% of compound A represented by formula (1) and 0.2-30.5% of at least one or more compounds B represented by formula (2), and balancing auxiliary agent.

Owner:ZHEJIANG RUNTU

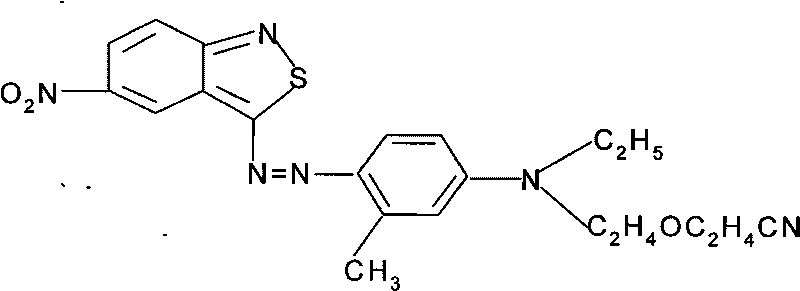

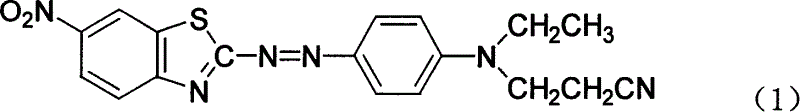

Red reactive dye mixture and preparation and application thereof

ActiveCN101565560BGood Dark Lifting PowerHigh color fixing rateOrganic dyesDyeing processDark colorPhotochemistry

The invention relates to a red reactive dye mixture and preparation and application thereof, which are characterized in that: the red reactive dye mixture comprises dye of general formula (1) and dye of general formula (2), the proportion by weight between the two dyes is 63.6-60:28.7-30. The compound dye has excellent lifting power for dark colors, low-cost formula, and better dyeing reproducibility than ordinary commercial dyes, thus being suitable for a plurality of application processes.

Owner:HUBEI COLOR ROOT TECH CO LTD

Low-salt dyeing method of reactive dye

ActiveCN111005245AHigh affinityIncrease color depthDyeing processCotton fibrePulp and paper industry

The invention relates to a low-salt dyeing method of a reactive dye. The dyeing method does not change the conventional dyeing equipment and basic dyeing process of cotton textiles, and is easy to implement and control. Compared with a traditional dyeing method of a reactive dye to cotton textiles, the dyeing method can reduce the dosage of a dyeing electrolyte by 50% or above, and the cotton textile dyed by adopting the low-salt dyeing method of the reactive dye disclosed by the invention has obviously higher color rendering depth, high dyeing fastness and excellent dyeing reproducibility, and can be used for reactive dye dyeing processing of various cotton fibers and products thereof, so that the use amount of the dyeing electrolyte is remarkably reduced, the environment is protected, and the dyeing method has good application effect and bright market prospect.

Owner:WUHAN TEXTILE UNIV

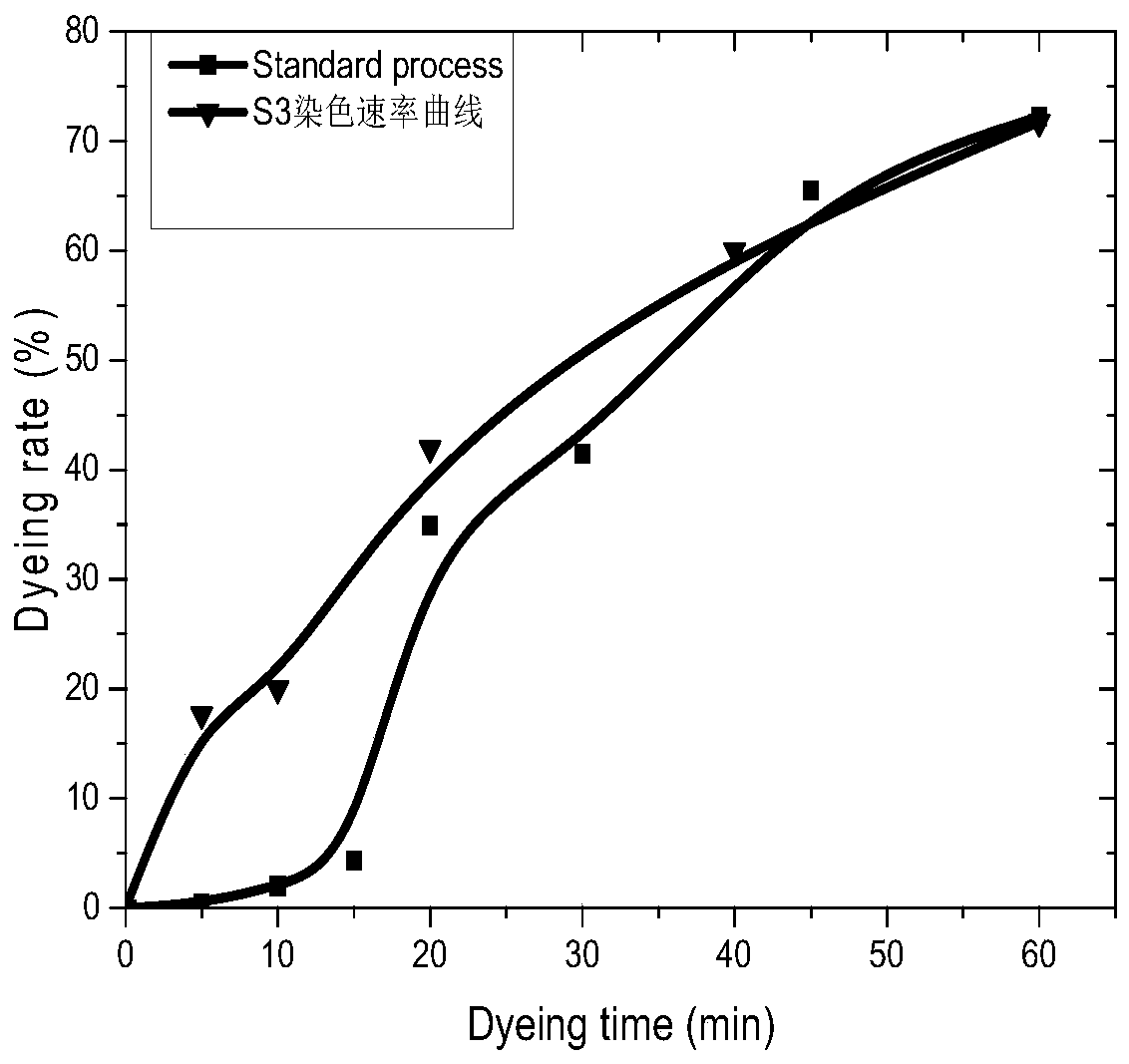

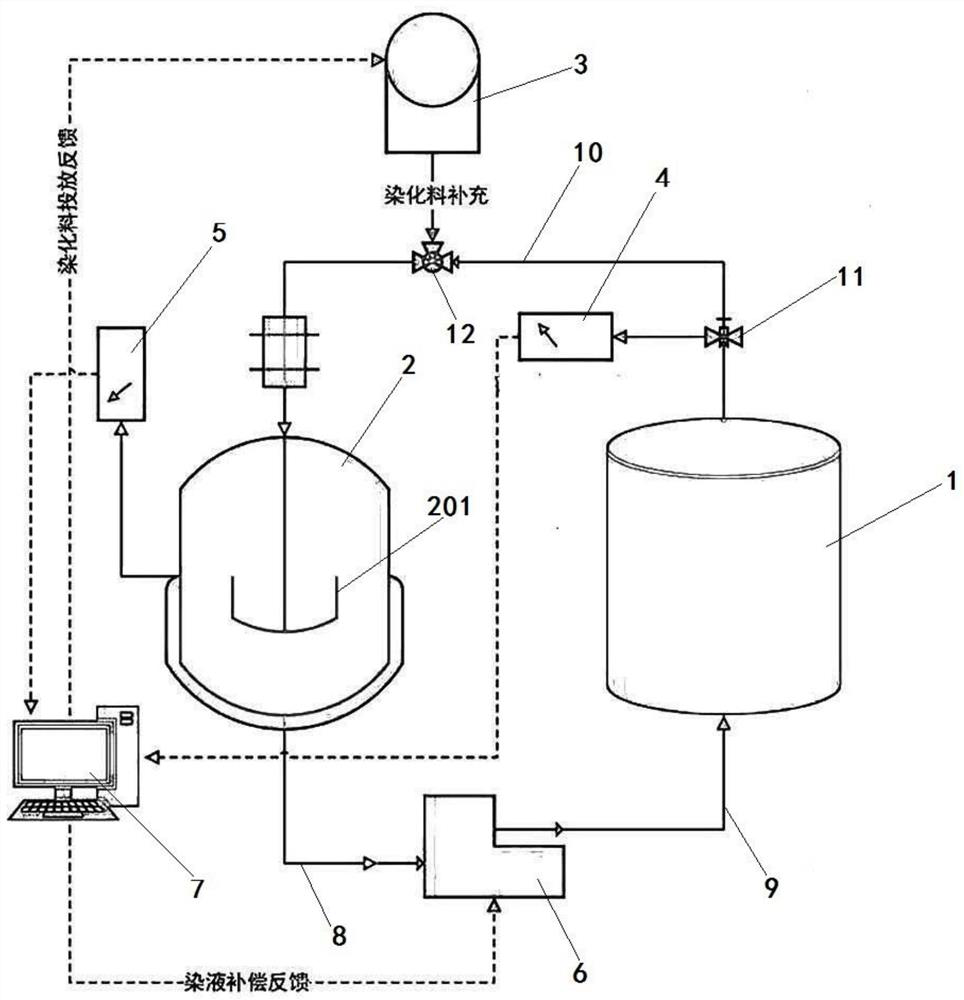

Dip dyeing equipment capable of maintaining stable dye liquor concentration and dyeing method

PendingCN112458672ASolve reunionQuality improvementTextile treatment machine arrangementsTerminal serverData acquisition

The invention discloses dip dyeing equipment capable of maintaining stable dye liquor concentration. The dip dyeing equipment comprises a dye vat, a dye liquor storage tank, an automatic feeding device, a dye liquor concentration data acquisition device, a metering pump and a terminal server. The dye liquor concentration data acquisition device is connected with the dye vat and used for acquiringdye liquor concentration data in the dye vat, and the dye liquor concentration data acquisition device is in signal connection with the terminal server. The output end of the terminal server is connected with the metering pump, an inlet of the metering pump is connected with an outlet of the dye liquor storage tank, and an outlet of the metering pump is connected with the dye vat. The output end of the terminal server is connected with an automatic feeding device. The automatic feeding device is connected with the dye liquor storage tank. The invention further provides a dyeing method by usingthe dip dyeing equipment. The dye liquor concentration in the dye vat can be kept within the preset interval all the time, the dye-uptake rate is controlled within the optimal range, the problems ofcolor spots and the like caused by dye agglomeration due to high dye concentration are solved, dyeing uniformity is ensured, and the quality of dyed products is improved.

Owner:SHENGHONG GRP CO LTD +1

Anhydrous printing liquid disperse dye and method for preparing same

The invention provides anhydrous printing liquid disperse dye. The anhydrous printing liquid disperse dye comprises, by weight, 10-15 parts of superfine disperse dye, 3-5 parts of sodium dodecylbenzene sulfonate, 3-5 parts of seconary alkane sulphonate sodium, 6-8 parts of hydroxymethyl celluloses, 5-10 parts of sodium citrate, 3-5 parts of sodium hydroxide, 5-8 parts of urea, 3-5 parts of sodiumlignin sulfonate, 3-5 parts of sucrose ester and 20-30 parts of deionized water. The anhydrous printing liquid disperse dye has the advantages that the anhydrous printing liquid disperse dye has smallparticle sizes, and textile products do not contain azo dye, which can be decomposed to generate carcinogenic aromatic amine, after normal printing is carried out by the aid of the anhydrous printingliquid disperse dye; the anhydrous printing liquid disperse dye does not contain carcinogenic dye or allergenic dye or banned aromatic amine or bioactive substances, and the heavy metal content conforms to allowed limited quantities; the anhydrous printing liquid disperse dye is high in color fixing rate after being applied to the textile products, low-chromaticity sewage can be reused, and accordingly sewage discharge can be effectively reduced.

Owner:JIANGSU NEW REBA TECH CO LTD

Low-salt and low-alkali dyeing process of cellulose fiber fabrics with medium-temperature reactive dyes

ActiveCN103556498BIncrease dye seatFacilitated DiffusionDyeing processVegetal fibresCellulose fiberPolymer chemistry

The invention relates to a low-salt and low-alkali dyeing process with a mesothermal type active dye of a cellulosic fiber fabric. The low-salt and low-alkali dyeing process comprises the following steps: modifying a cellulosic fiber fabric to be dyed by a fiber modifying agent to prepare a partially-aminated modified cellulosic fiber fabric to be dyed; modifying the mesothermal type active dye by a dye modifying agent to prepare an activated and modified mesothermal type active dye; and carrying out low-salt and low-alkali dyeing on the cellulosic fiber fabric, namely carrying out the low-salt and low-alkali dyeing on the partially-aminated modified cellulosic fiber fabric to be dyed by the activated and modified mesothermal type active dye in the presence of neutral electrolyte, inorganic alkalis and water. According to the dyeing technology, the use amount of the neutral electrolyte and the inorganic alkalis can be reduced and the dyeing temperature can be reduced by about 10 DEG C; the dyed cellulosic fiber fabric has high coloring depth, good dyeing fastness and excellent dyeing reproducibility; the low-salt and low-alkali dyeing process can be used for dyeing various cellulosic fiber fabrics by the mesothermal type active dye.

Owner:佛山市马大生纺织有限公司

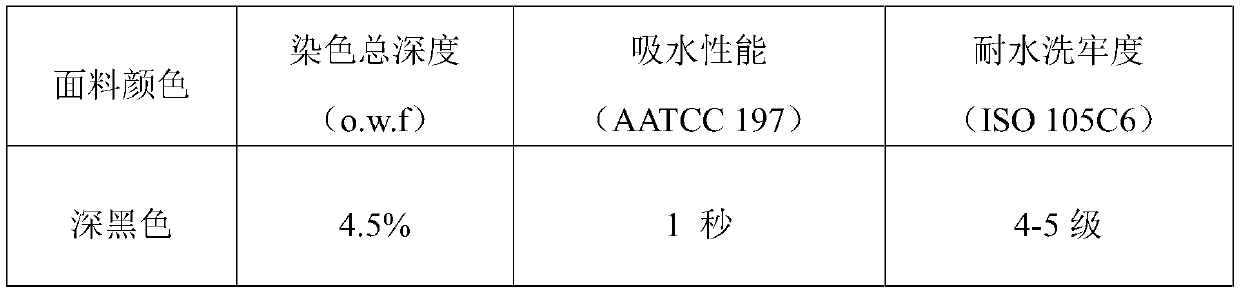

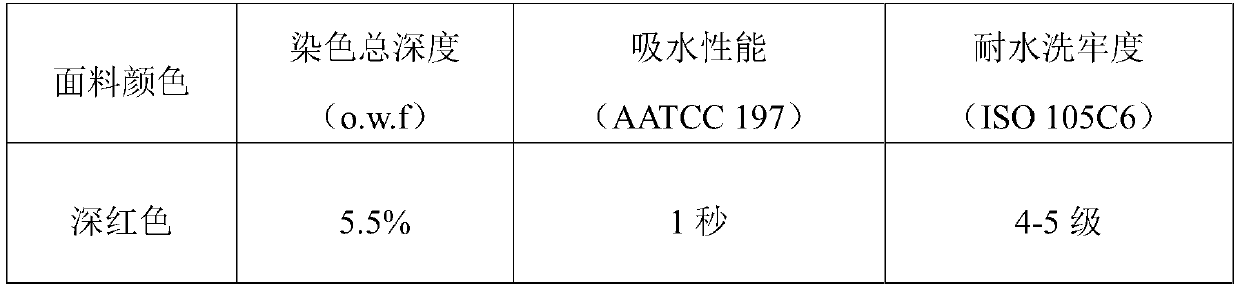

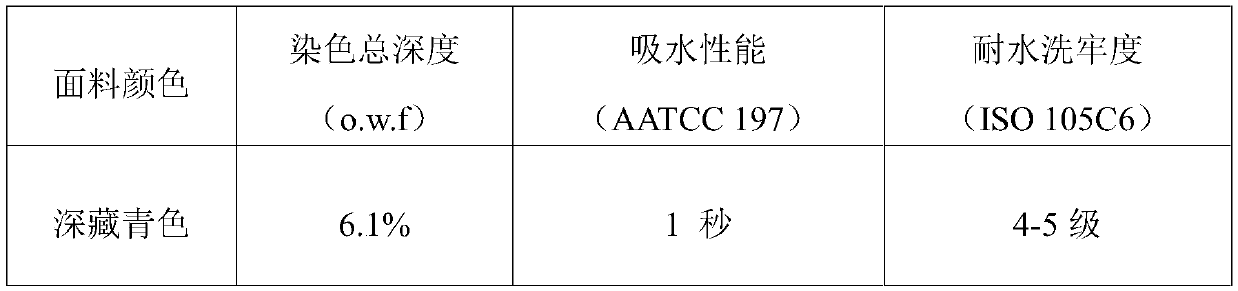

Dyeing technology of water-absorbing and quick-drying nylon-cotton interwoven knitted fabric with high washing fastness

InactiveCN111593586AGood water absorption and quick drying functionGood dyeing reproducibilityDyeing processVegetal fibresPolymer sciencePolymer chemistry

The invention discloses a dyeing technology of water-absorbing and quick-drying nylon-cotton interwoven knitted fabric with high washing fastness. The dyeing technology comprises the following steps of pretreatment, cotton dyeing, water washing, nylon dyeing, fixation and soaping. The dyeing technology of the invention can make the washing fastness of the dark nylon nylon-cotton interwoven knittedfabric reach 4-5 or more, and the nylon-cotton interwoven knitted fabric has good water-absorbing and quick-drying functions and good dyeing reproducibility, and is suitable for mass production and application.

Owner:NINGBO DAQIAN TEXTILE

Nanoscale liquid dispersion dye and preparation method thereof

InactiveCN109750525AHigh color fastnessGood dyeing reproducibilityOrganic dyesDyeing processCarcinogenic Aromatic AminePhotochemistry

The invention provides a preparation method of nanoscale liquid dispersion dye. The nanoscale liquid dispersion dye is prepared from following raw materials in parts by weight: 10-20 parts of nanoscale dispersion dye, 5-7 parts of a dispersion agent, 20-30 parts of ethanol, 3-5 parts of a deforming agent, 8-10 parts of starch, 5-7 parts of sodium chloride, 3-5 parts of sodium carbonate and 10-20 parts of deionized water. According to the preparation method of the nanoscale liquid dispersion dye, the particle size of the nanoscale liquid dispersion dye is small, after common printing, a textiledoes not contain azo dye which can decompose into carcinogenic aromatic amine, and does not contain carcinogenic dye, sensitizing dye, forbidden aromatic amine and a biological active substance, andthe heavy metal content meets permissible limits; and after the nanoscale liquid dispersion dye applied to textile, the fixation rate is high, low-color-degree waste water is reused, and the waste water discharge can be effectively reduced.

Owner:JIANGSU NEW REBA TECH CO LTD

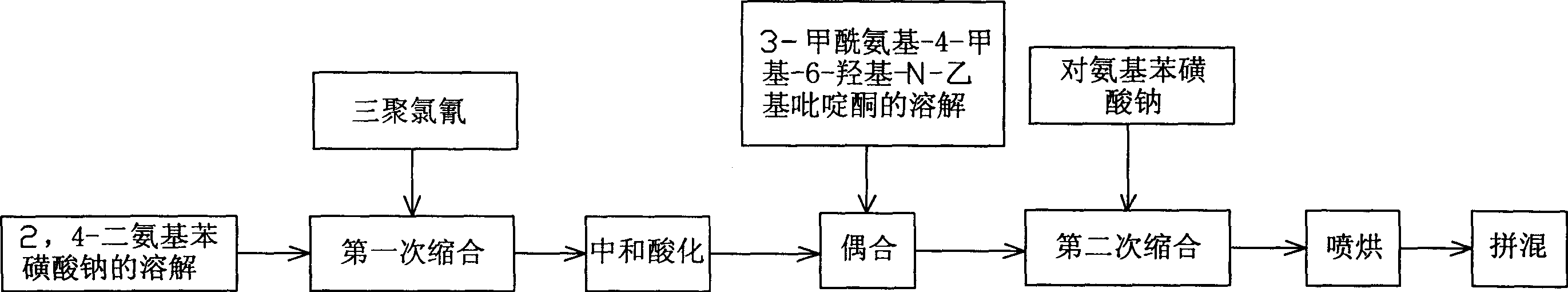

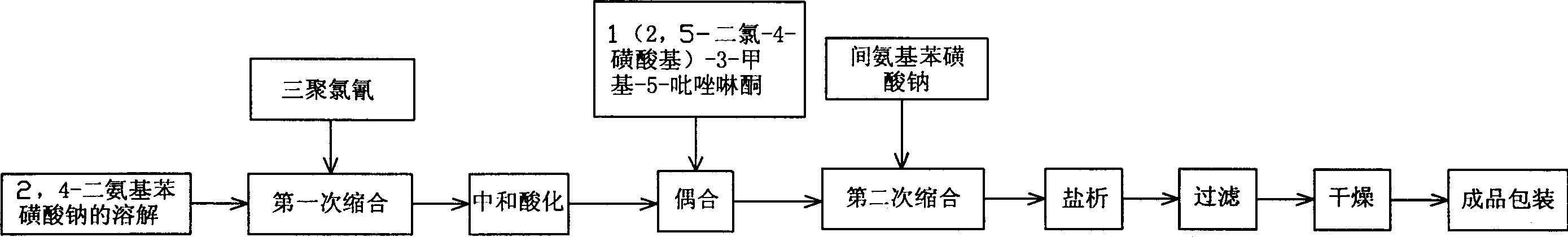

Method for preparing bright yellow active dye stuff K-6G

The related preparation method for bright-yellow reactive dyes K-6G for dyeing and printing to cotton, hair, silk, leather, polyamide synthetic fabric and other fibre mix-fabric comprises: with 2, 4-sodium biaminobenzoic sulfonate, cyanuric chloride, NaNO2, HCl, 3-carbamoyl-4-methyl-6- hydroxyl-N-acetaldehydepyridone, and sodium p-anilinesulfonate as materials; dissolving, first condensing, neutralizing, coupling, second condensing, spray drying, blending, and obtaining the target. This invention can reduce pollution and cost, and has high yield fit to industrial production.

Owner:泰州市姜堰区东风染料化工厂

Homochromatic dyeing process for chitin-containing viscose-fiber fabric

ActiveCN106087489AAvoid high levels of adsorptionGood dyeing reproducibilityDyeing processOrganic baseSolvent

The invention discloses a homochromatic dyeing process for a chitin-containing viscose-fiber fabric. The method comprises the following steps: (S1) carrying out pretreatment: submerging the chitin-containing viscose-fiber fabric into isopropyl alcohol, adding a sodium hydroxide solution, carrying out uniform stirring, then, adding an etherifying agent CTA, carrying out a reaction with stirring, pumping off a solvent, carrying out water washing, and carrying out baking; (S2) carrying out reactive dyeing: submerging the fabric into a reactive dye dyeing solution, heating the reactive dye dyeing solution to a primary dyeing temperature, adding an organic solvent B, heating the solution to a dyeing temperature, then, adding organic base and sodium carbonate according to the volume of the reactive dye dyeing solution, then, cooling the solution to a color fixation temperature, carrying out heat preservation, cooling the solution to room temperature; (S3) carrying out aftertreatment: washing the fabric by water, carrying out soaping, carrying out water washing again, and carrying out air-drying. According to the homochromatic dyeing process for the chitin-containing viscose-fiber fabric, the defect that the dyeing rate of chitin viscose fibers is relatively high can be overcome, a uniform and consistent dyeing effect is obtained, and the homochromatic dyeing process has the advantages of high color fastness and simple process.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

A high-temperature dyeing process for chemical fiber filaments

ActiveCN103938465BGuaranteed functionAvoid damageBiochemical fibre treatmentDyeing processCelluloseFiber

Owner:浙江锦瑞纤维科技有限公司

High fastness disperse dye

InactiveCN104212200AImprove good performanceGood dyeing reproducibilityOrganic dyesDisperse dyeColour fastness

The invention discloses a high fastness disperse dye. The high fastness disperse dye is prepared from the following components in parts by mass: 35-40 parts of component A, 20-25 parts of component B, 23-26 parts of component C, 30-32 parts of component D, 16-18 parts of component E and 3-5 parts of component F. The high fastness disperse dye is used for dyeing in the conventional manner in the industry, a dyed fabric with full hue, bright colour and excellent light fastness, washing fastness and rubbing fastness can be obtained, and the uplifting property and dyeing reproducibility of the high fastness disperse dye are improved.

Owner:ZHANGJIAGANG HUYI DYEING & FINISHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com