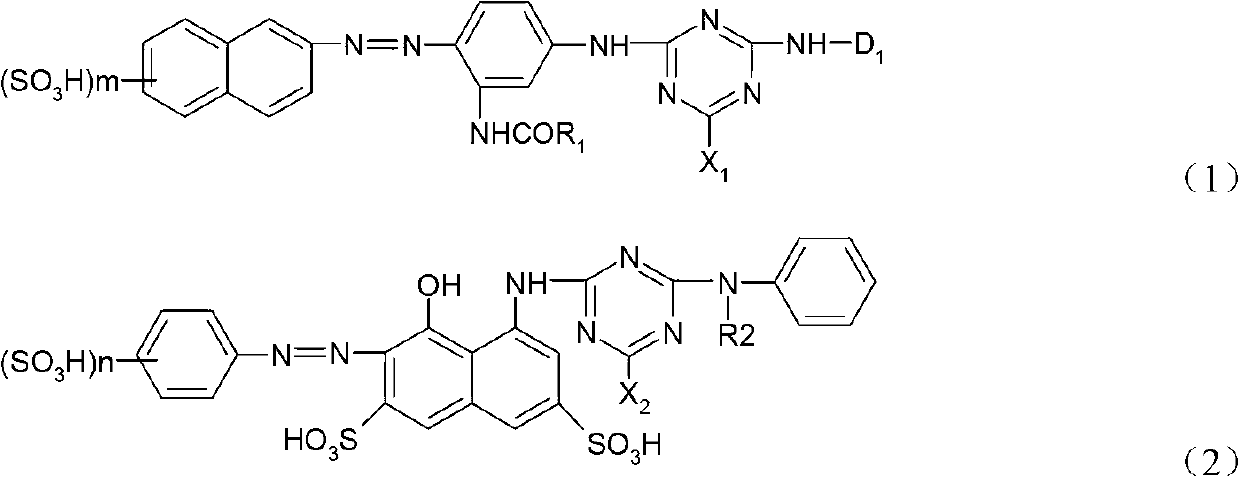

Red reactive dye mixture and preparation and application thereof

A technology of reactive dyes and mixtures, applied in the field of dyes, to achieve the effect of solving the problem of coloring and staining, low-cost formula, and good dyeing reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

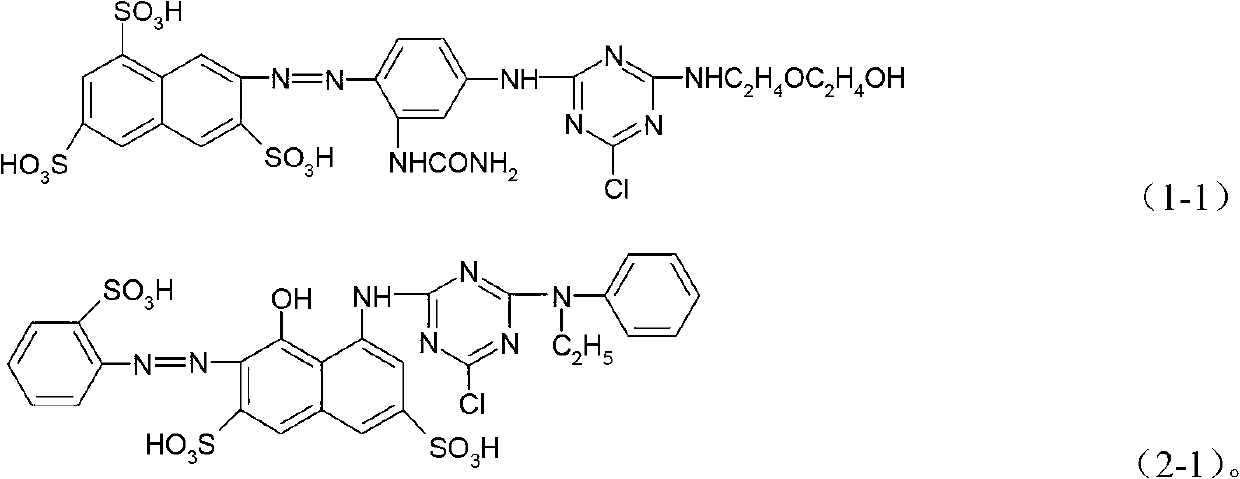

Embodiment 1

[0042] Embodiment 1, dyestuff preparation

[0043] After beating 38.3 parts of 2-naphthylamine-3,6,8-trisulfonic acid for 1 hour, add hydrochloric acid and cool down to 6°C with ice, then add 30% sodium nitrite solution dropwise and carry out diazotization reaction under stirring, 2 After 1 hour, add 18.75 parts of m-semicarbazide through fully beating, and maintain T=14 ℃, pH=4.5 to carry out coupling reaction, until not detecting diazonium salt is reaction complete, obtains a kind of coupled compound, then the coupled compound is in Add 18.45 parts of fully ice-ground cyanuric chloride within 30 minutes for condensation reaction, maintain T=10°C, PH=3.5 for 4 hours, and finally add 10.5 parts of hydroxyethylethanolamine to the system, maintain T=45°C , pH=5 to react for 4 hours, then nano-membrane filtration, first filter with a plate and frame filter press, remove most of the inorganic salts and water and a small part of by-products, you can obtain the dyestuff (1) that mee...

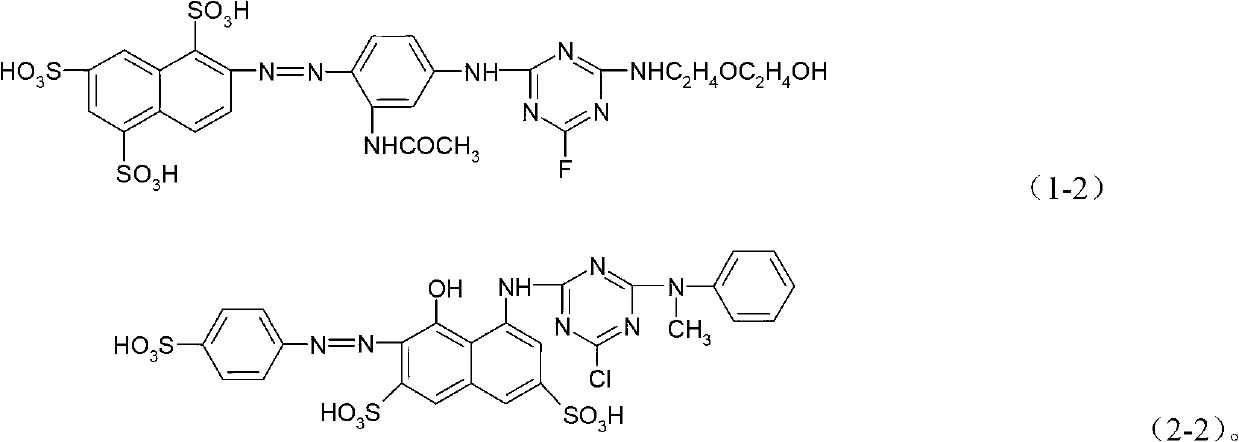

Embodiment 2

[0045] Embodiment 2, dyestuff preparation

[0046] After beating 38.3 parts of 2-naphthylamine-1,5,7-trisulfonic acid for 1 hour, add hydrochloric acid and cool down to 6°C with ice, then add 30% sodium nitrite solution dropwise and carry out diazotization reaction under stirring, 2 After 1 hour, add 18.65 parts of m-acetamidoaniline through fully beating, and maintain T=14 ℃, pH=4.5 to carry out coupling reaction, until not detecting diazonium salt is reaction complete, obtains a kind of coupling compound, subsequently coupling compound in Add 13.6 parts of fully ice-ground cyanuric fluoride within 30 minutes for condensation reaction, maintain T=10°C, pH=3.5 for 4 hours, and finally add 10.5 parts of hydroxyethyl alcohol amine to the system to maintain T= React at 4.5°C and pH=5 for 4 hours, then filter with nano-membrane, first filter with a plate and frame filter press, remove most of the inorganic salts and water and a small part of by-products, and you can get the dye th...

Embodiment 3

[0048] Embodiment 3, dyestuff preparation

[0049]Beat 30.3 parts of 2-naphthylamine-3,6,-disulfonic acid for 1 hour, add hydrochloric acid and cool down to 6°C with ice, then add 30% sodium nitrite solution dropwise and carry out diazotization reaction under stirring for 2 hours Add 18.75 parts of metasemicarbazide through fully beating afterward, and maintain T=14 ℃, pH=4.5 to carry out coupling reaction, until detecting that diazonium salt is not reacted completely, obtain a kind of coupled compound, then the coupled compound is in 30 Add 18.45 parts of fully ice-ground cyanuric chloride within minutes to undergo condensation reaction, maintain T=10°C, pH=3.5 for 4 hours, and finally add 6.1 parts of ethanolamine to the system, maintain T=4.5°C, pH=5 React for 4 hours, then filter with nano-membrane, first filter with a plate and frame filter press, remove most of the inorganic salts and water and a small part of by-products, you can get the dye (1-3) that meets the general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com