Ink composition with high-weather-resistance black dye for ink-jet printing

A black dye, high weather resistance technology, used in inks, applications, household appliances, etc., to achieve the effect of high ozone resistance, excellent dyeing performance, and excellent image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

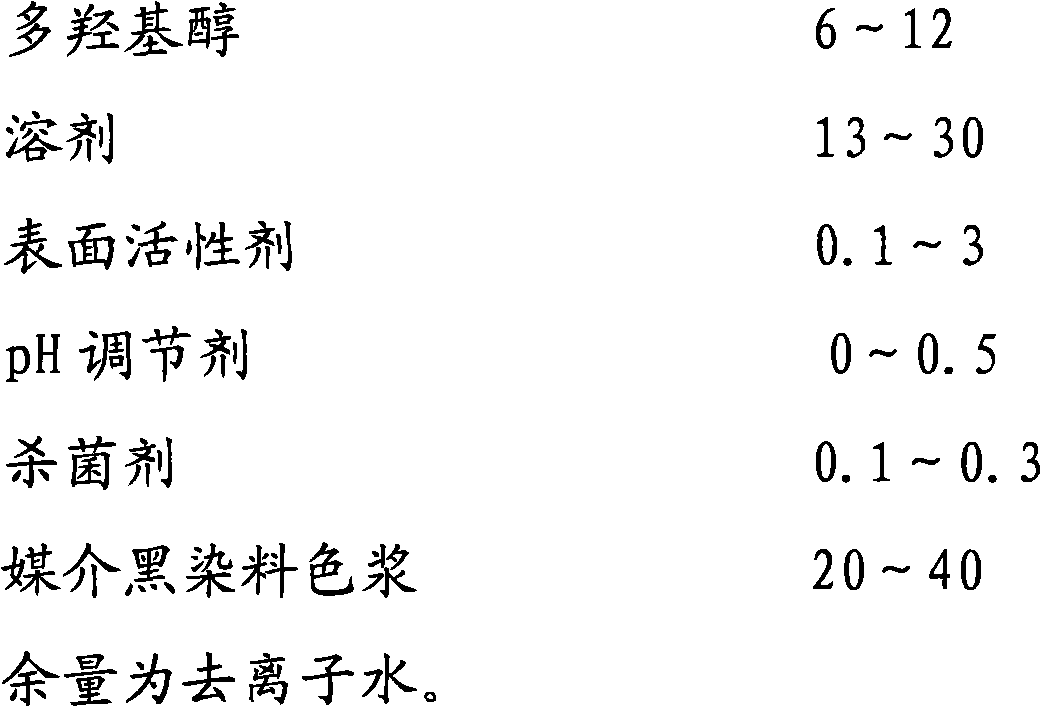

Method used

Image

Examples

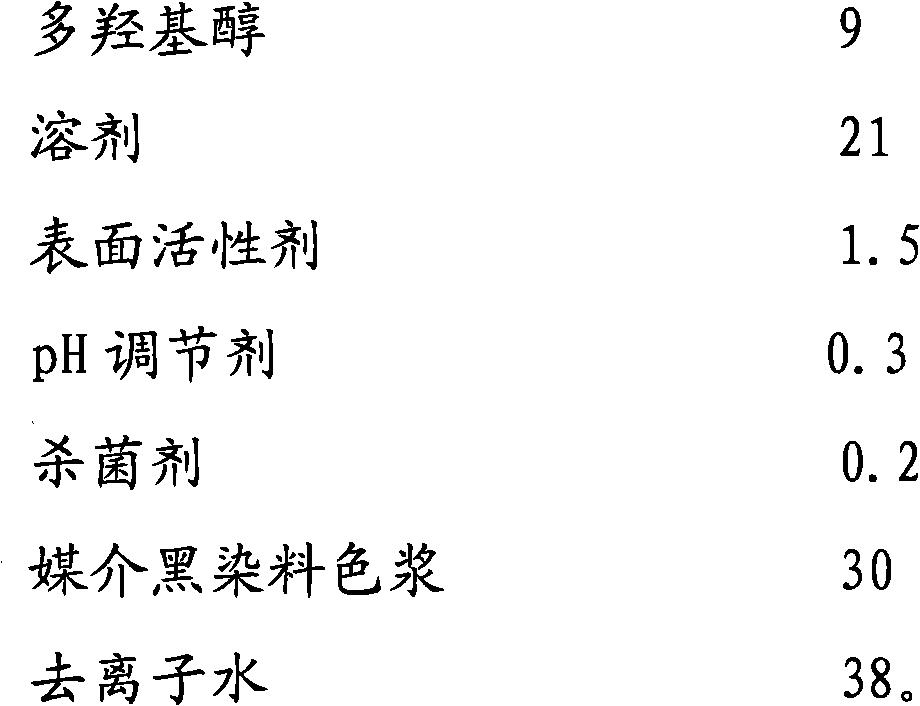

Embodiment 1

[0024] 1. Purification of medium black dye paste

[0025] Take 30 kg of medium black PV original powder, add it to an electric heating stirring kettle containing 270 kg of deionized water, heat while stirring, and stir for 1 hour after the temperature reaches 80 degrees to ensure that all the dye powder added After dissolving, use a 5-micron PP filter element for coarse filtration, and when the temperature is lower than 60 degrees, use an ultrafiltration membrane and a nanofiltration membrane combination filter that can remove sodium chloride for filtration to remove molecular weight above 30,000. Substances by-products and sodium chloride. Supplement deionized water in the purification process to ensure the permeability of the membrane, and detect the conductivity of the filtered liquid. When the conductivity is below 20ms / cm, stop adding deionized water, continue nanofiltration and add color paste. The volume of the product is controlled at about 200 liters, that is, the re...

Embodiment 2

[0033] 1. Purification of medium black dye paste

[0034] Take 30 kg of the original powder of medium black P2B, add it to an electric heating stirring kettle containing 270 kg of deionized water, heat while stirring, and stir for 1 hour after the temperature reaches 80 degrees to ensure that all the dye powder added is After dissolving, use a 5-micron PP filter element for coarse filtration, and when the temperature is lower than 60 degrees, use an ultrafiltration membrane and a nanofiltration membrane combination filter that can remove sodium chloride for filtration to remove molecular weight above 30,000. Substances by-products and sodium chloride. Supplement deionized water in the purification process to ensure the permeability of the membrane, and detect the conductivity of the filtered liquid. When the conductivity is below 20ms / cm, stop adding deionized water, continue nanofiltration and add color paste. The volume of the product is controlled at about 200 liters, that...

Embodiment 3

[0042] 1. Purification of medium black dye paste

[0043] Take 30 kg of medium black T original powder, add it to an electric heating stirring kettle containing 270 kg of deionized water, heat while stirring, and stir for 1 hour after the temperature reaches 80 degrees to ensure that all the dye powder added is After dissolving, use a 5-micron PP filter element for coarse filtration, and when the temperature is lower than 60 degrees, use an ultrafiltration membrane and a nanofiltration membrane combination filter that can remove sodium chloride for filtration to remove molecular weight above 30,000. Substances by-products and sodium chloride. Supplement deionized water in the purification process to ensure the permeability of the membrane, and detect the conductivity of the filtered liquid. When the conductivity is below 20ms / cm, stop adding deionized water, continue nanofiltration and add color paste. The volume of the product is controlled at about 200 liters, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com