Reactive dye mixture

A technology of reactive dyes and mixtures, applied in the field of dyes, can solve the problems of low solubility, easy staining, poor color fastness, etc., and achieve the effect of good storage stability, not easy to stain each other, and easy to clean

Active Publication Date: 2014-10-15

HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the problems of easy staining, low solubility and poor color fastness when printing navy blue and black dyes are washed with water, the invention provides a reactive dye mixture. The dye has excellent solubility, and is easy to wash and wash. Not easy to stain each other, excellent perspiration fastness, washing fastness and rubbing fastness, good storage stability of color paste, very suitable for printing of cellulose fibers, suitable for steaming or baking process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~20

[0040] Dye A, Dye B, Dye C and auxiliaries according to the amounts shown in Table 1 were dry-blended through a blender to obtain dye products 1-20 of reactive dye mixtures.

[0041] Table 1:

[0042]

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Relating to the technical field of dyes, the invention provides a reactive dye mixture to solve the problems of easy staining, low solubility and undesirable color fastness of printing navy blue and black dyes during washing. The reactive dye mixture is made of, by weight, 1-80% of a dye A, 20-99% of a dye B, and 0-50% of a dye C. The dye has excellent dissolution performance, is easy to wash off and difficult to stain each other, and has excellent perspiration fastness, washing fastness and rubbing fastness, as well as good color paste storage stability, thus being very suitable for printing of cellulose fiber, and the steaming or baking curing process.

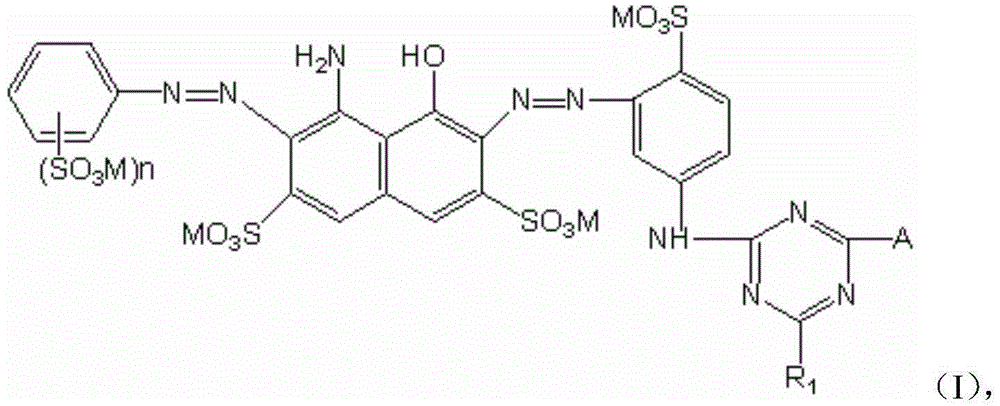

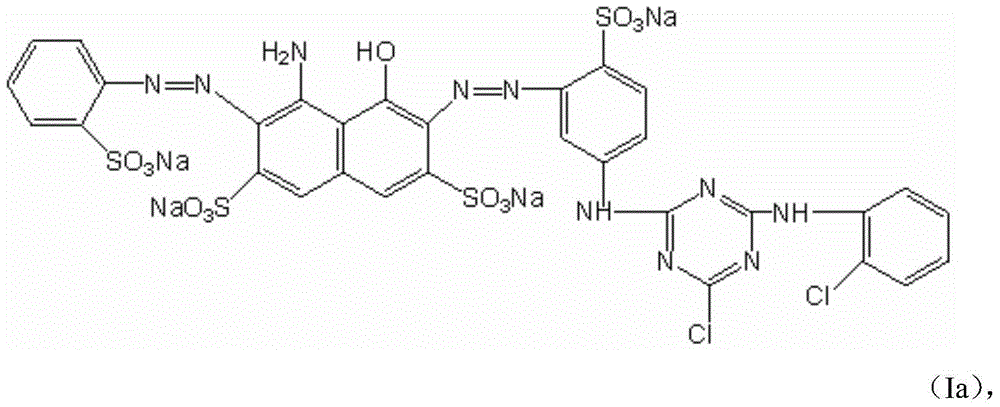

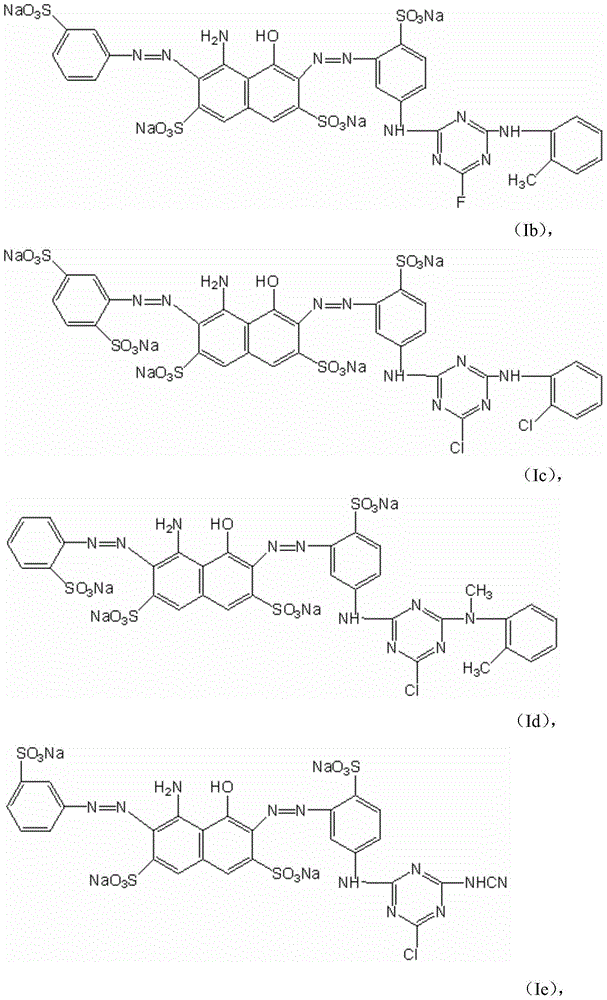

Description

technical field [0001] The invention relates to the technical field of dyes, in particular to the preparation of a reactive dye mixture. Background technique [0002] Among the reactive printing dyes, navy blue and black are the ones with a large amount of consumption. The three primary colors of traditional printing dyes are reactive brilliant orange K-G, reactive red K-2BP (C.I.Reactive Red24), and reactive dark blue K-R (C.I.Reactive Blue13). Navy blue and black can be obtained by mixing. Although the color paste is stable in storage, the bright orange K-G stains the white ground more seriously when washed with water, and the bright orange K-G and dark blue K-R have low solubility, so it is not easy to stain when washed with water. Printed navy blue and black dyes with stable storage and good color fastness have become the goals of various dye companies. [0003] Publication number is that the Chinese patent of CN101100559B discloses a kind of composite reactive black pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09B67/22C09B67/24D06P3/66D06P1/38

Inventor 陈美芬商李金孙岩峰简卫

Owner HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com