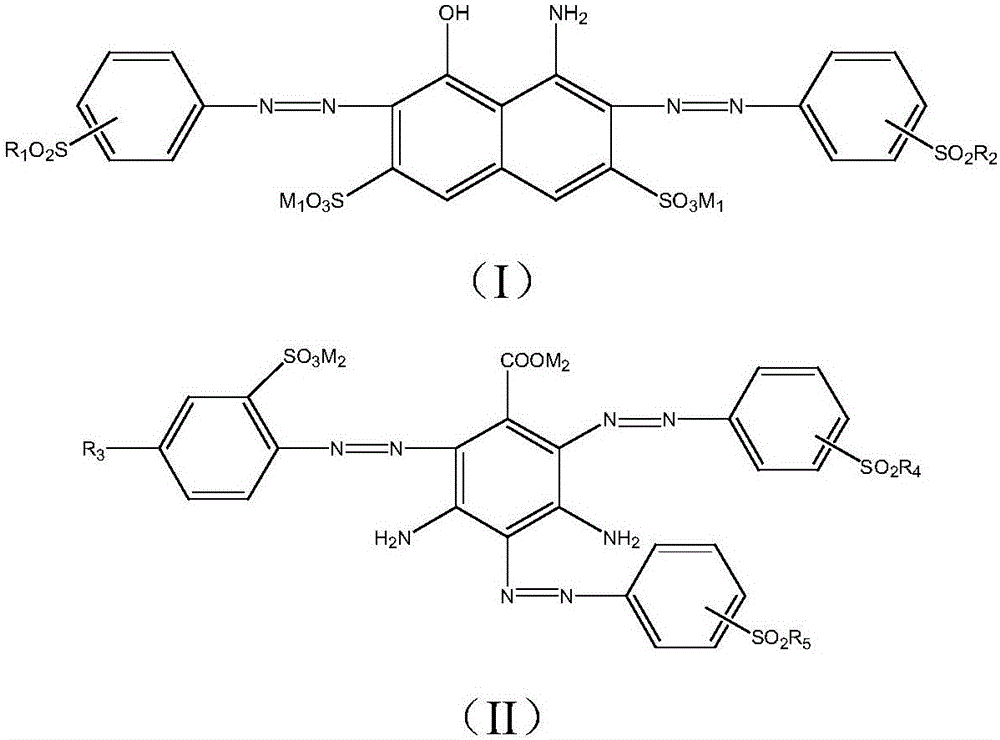

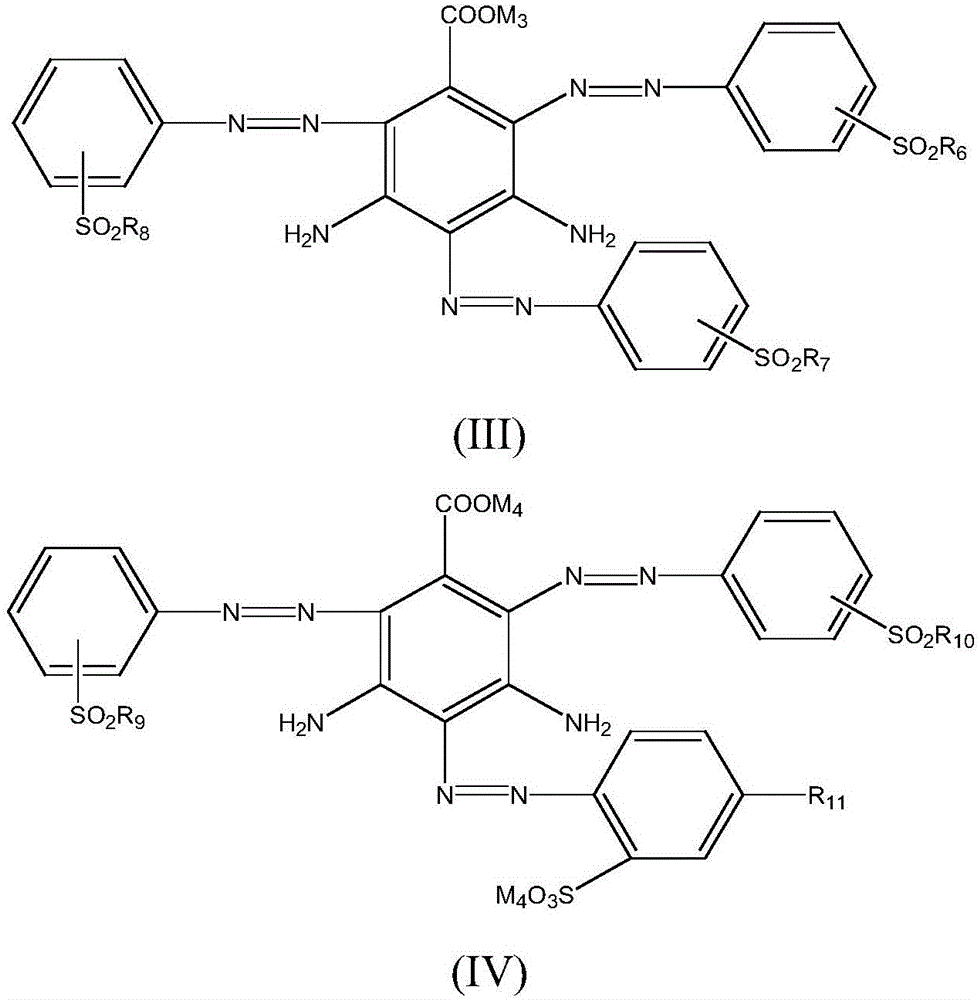

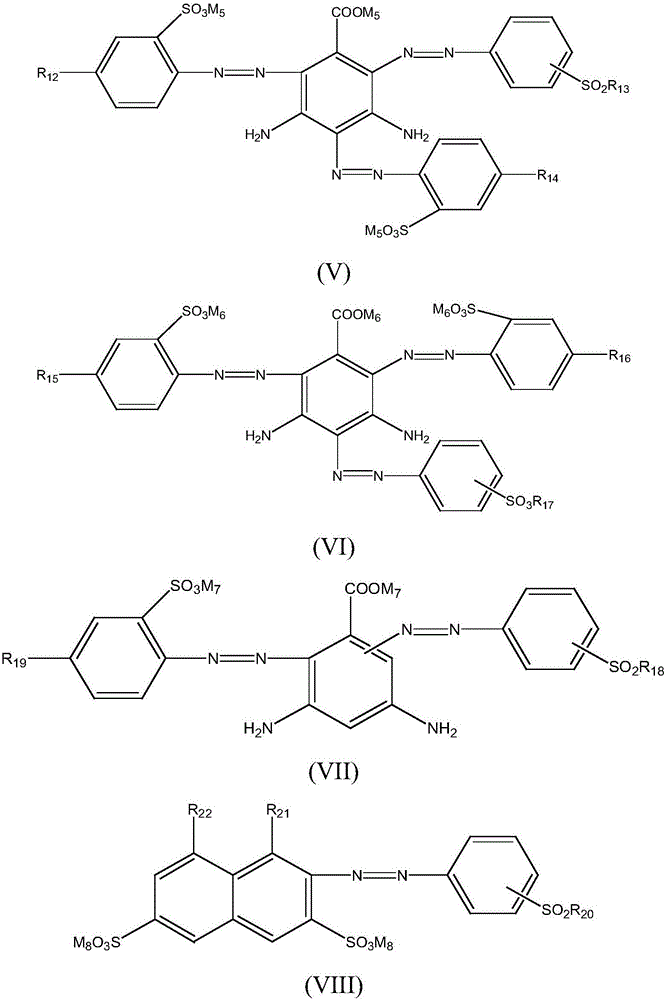

Black reactive dye composition and preparation method and application thereof

A technology of reactive dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., which can solve problems such as dyeing reproducibility, various color fastness defects, and difficulty in achieving comprehensive effects of reactive black dye compositions. Achieve the effect of high cost performance, high relative color fixation rate and good dyeing reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The component A of 79.5 parts by weight of formula (I-1) and the component B of 20.5 parts by weight of formula (II-1) carry out dry powder mixing by mixer to obtain black reactive dye composition 1, and said composition is used as Reactive black dye, which prints and dyes cotton fabrics black.

[0054]

[0055]

Embodiment 2

[0057] Component A of 56 parts by weight of formula (I-1) and component B of 44 parts by weight of formula (II-4) are carried out dry powder mixing by mixer to obtain black reactive dye composition 2, and said composition is used as Reactive black dye, which prints and dyes cotton fabrics black.

[0058]

Embodiment 3

[0060] Component A of 56 parts by weight of formula (I-1) and component B of 44 parts by weight of formula (II-5) are carried out dry powder mixing by mixer to obtain black reactive dye composition 3, and said composition is used as Reactive black dye, which prints and dyes cotton fabrics black.

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com