Method for preparing bright yellow active dye stuff K-6G

A technology of reactive dyes and bright yellow, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of poor chlorine bleaching fastness, color supply, color fixation rate and low solubility, so as to eliminate the discharge of sewage, Excellent color giving power and high profit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

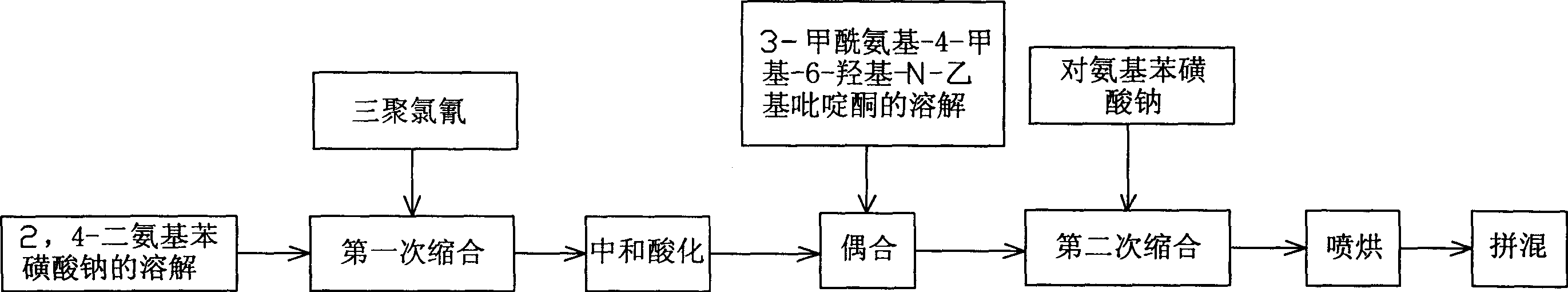

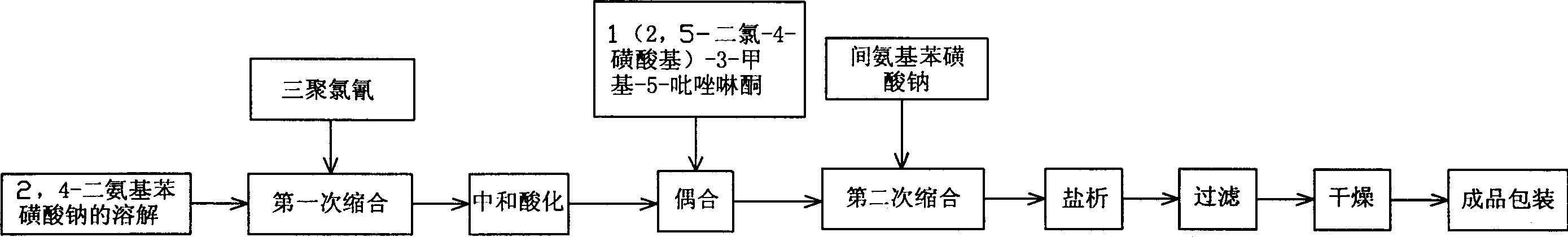

Method used

Image

Examples

Embodiment 1

[0031] raw material name

[0032] 2. The K-6G preparation process of the present invention operates as follows:

[0033] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0034] Put 2000L of bottom water in the dissolving pot, add 162.97kg of sodium 2,4-diaminobenzenesulfonate, stir and clarify, adjust pH=5.5 with dilute hydrochloric acid, temperature is 18°C, volume is 3200L, C%=6 in the solution.

[0035] b. The first condensation reaction: add 200L of water and crushed ice into the shrinkage tank, add 150kg of industrial 99.5% cyanuric chloride by weight, beat for 45 minutes, adjust the pH to 2.0 with dilute hydrochloric acid, and the temperature is 0°C. Add the sodium 2,4-diaminobenzenesulfonate solution into a shrink pot within 1.5 hours, stir and react for 2 hours after the addition, and control the solution temperature at 5°C after the reaction.

[0036] c. Neutralize acidification

[0037] Quickly add 10% soda water within 10 minutes to adjust the pH ...

Embodiment 2

[0055] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0056] Put 2000L of bottom water in the dissolving pot, add 162.97kg of sodium 2,4-diaminobenzenesulfonate, stir and clarify, adjust pH=6.0 with dilute hydrochloric acid, temperature is 20°C, volume is 3200L, C%=7 in the solution.

[0057] b. The first condensation reaction: add 200L of water and crushed ice to the shrinkage tank, add 150kg of industrial 99.5% cyanuric chloride, beat for 45 minutes, adjust the pH to 2.5 with dilute hydrochloric acid, and the temperature is 5°C. Add the sodium 2,4-diaminobenzenesulfonate solution into the shrink pot within 2 hours, stir and react for 2 hours after the addition, and control the solution temperature at 8°C after the reaction.

[0058] c. Neutralize acidification

[0059] Quickly add 10% soda water within 10 minutes to adjust the pH of the condensate to 6.5, stabilize for 2 minutes, add crushed ice, quickly add hydrochloric acid, increase the volume to 4500L, add disso...

Embodiment 3

[0071] a. Dissolution of sodium 2,4-diaminobenzenesulfonate

[0072] Put 2000L of bottom water in the dissolving pot, add 162.97kg of sodium 2,4-diaminobenzenesulfonate, stir and clarify, adjust pH=5.0 with dilute hydrochloric acid, temperature is 15°C, volume is 3200L, C%=6 in the solution.

[0073] b. The first condensation reaction: add 200L of water and crushed ice to the shrinkage tank, add 150 kg of industrial 99.5% cyanuric chloride, beat for 45 minutes, adjust the pH to 1.5 with dilute hydrochloric acid, and the temperature is 0°C. Add 2,4-diaminobenzenesulfonate sodium solution into a shrink pot within 1.5 hours, stir and react for 2 hours after the addition, and control the solution temperature at 2°C after the reaction.

[0074] c. Neutralize acidification

[0075] Quickly add 10% soda water within 10 minutes to adjust the pH of the condensate to 5.5, stabilize for 2 minutes, add crushed ice, quickly add hydrochloric acid, increase the volume to 4500L, add dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com