Dip dyeing equipment capable of maintaining stable dye liquor concentration and dyeing method

A technology of dye liquor concentration and dyeing equipment, which is applied in the direction of processing textile material equipment configuration, textile material processing, textile and paper making, etc. cost, the effect of improving the quality of dyed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

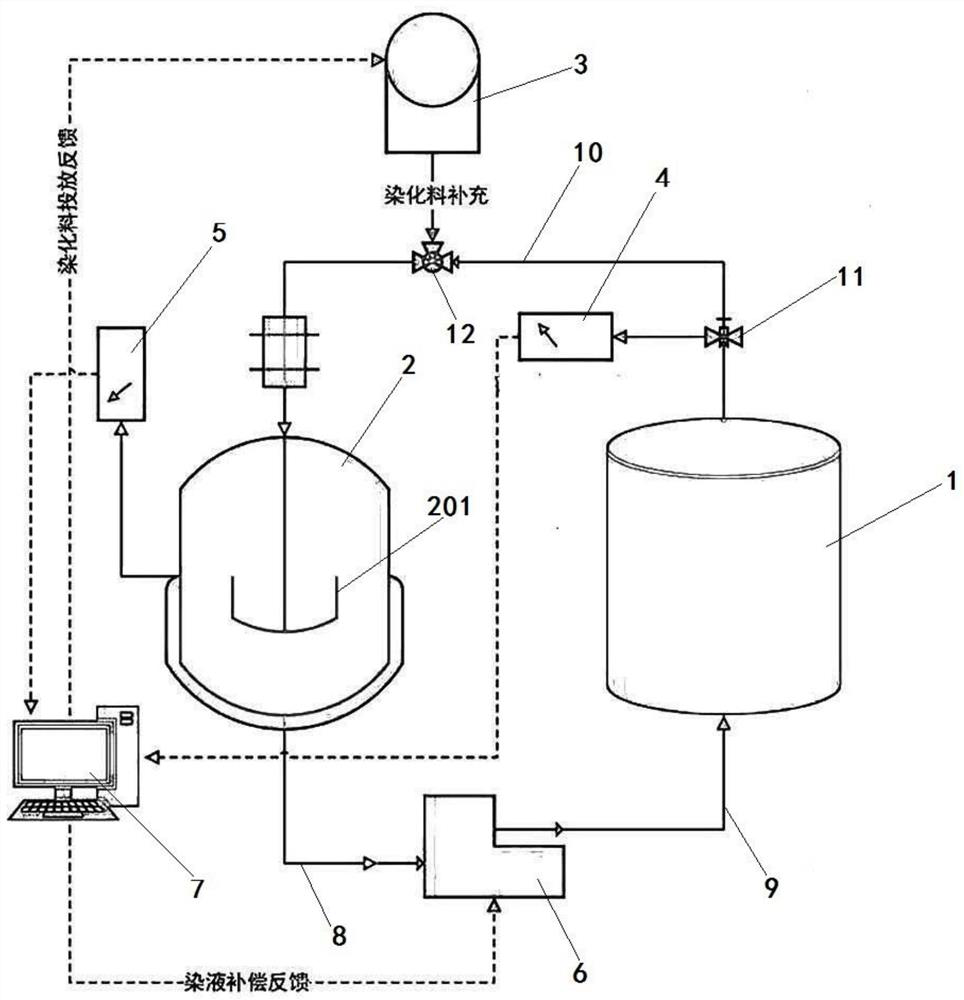

[0029] Such as figure 1 As shown, the immersion dyeing equipment provided in Example 1 that can maintain a stable dye liquor concentration includes a dye vat 1, a dye liquor storage tank 2, an automatic feeding device 3, a dye liquor concentration data acquisition device 4, and a storage liquor concentration data acquisition device. device 5, metering pump 6 and terminal server 7;

[0030] The dye liquor concentration data acquisition device 4 is connected with the dye vat 1, and is used to collect the dye liquor concentration data in the dye vat 1, and the output end of the dye liquor concentration data acquisition device 4 is connected with the terminal server 7 signal; the terminal server 7 The output end of the metering pump 6 is connected to the metering pump 6, the inlet of the metering pump 6 is connected to the outlet of the dye solution storage tank 2 through a liquid outlet pipeline 8, and the outlet of the metering pump 6 is passed through a liquid inlet pipeline 9 ...

Embodiment 2

[0043] The difference between this embodiment 2 and embodiment 1 is that: the dipping dyeing equipment is not provided with a circulation pipeline connected with the dye solution outlet of the dye vat, and a storage solution concentration data acquisition device connected with the dye solution storage tank is not provided; The feeding device is directly connected with the dye liquor storage tank through a valve.

[0044] Utilize the dip dyeing equipment of embodiment 2 to carry out the method for dip dyeing, may further comprise the steps:

[0045] (1) Store the prepared dye solution in the dye solution storage tank, and the initial concentration of the dye solution in the dye solution storage tank is equal to the preset concentration, and inject a certain amount of dye solution into the dye tank by using a metering pump;

[0046] (2) The fabric is immersed in the dye vat for dyeing. During the dyeing process, the dye liquor concentration data acquisition device collects the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com