Preparation method of leveling agent for one-bath dyeing of polyester-cotton fabric

A technology of one-bath dyeing and leveling agent, which is applied in the preparation of organic compounds, dyeing methods, preparation of aminohydroxy compounds, etc., can solve problems such as uneven dyeing, and achieve the effect of low foaming and good dyeing reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0031] A preparation method of a leveling agent for polyester-cotton fabric dyeing in the same bath, comprising the steps of:

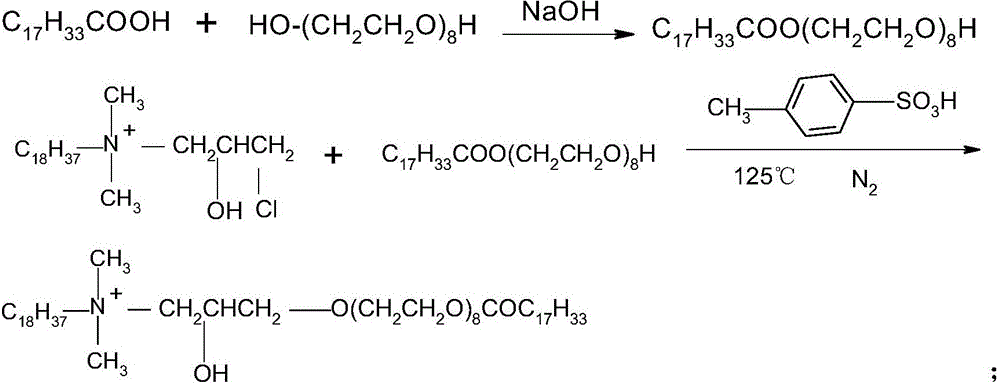

[0032] The first step, polyoxyethylene ether oleate hydroxypropyl dimethyl octadecyl ammonium chloride (N-EO 8 )Synthesis:

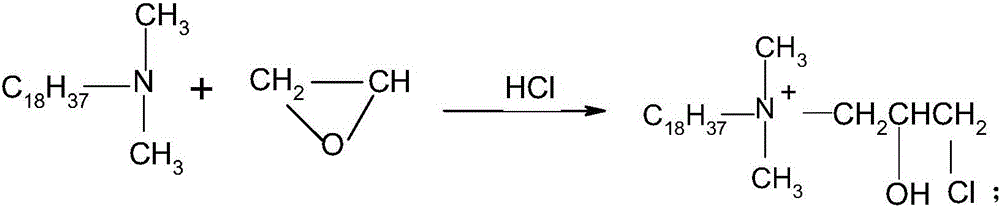

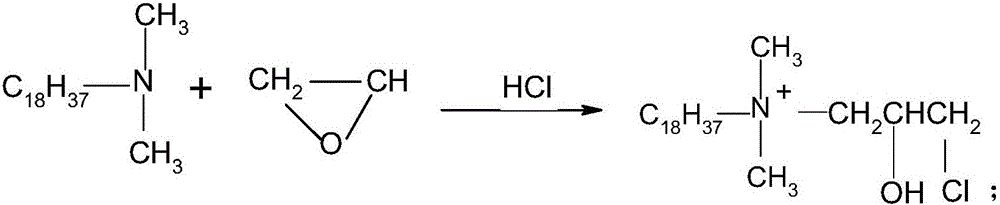

[0033] (1) Synthesis of 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride:

[0034]

[0035] At a constant temperature of 40°C, add 50.0 g of octadecyl tertiary amine and 100 g of distilled water to a 1000 mL four-neck flask with a condenser tube placed in a water bath, slowly add 36% HCl dropwise under stirring, and control the pH value to 2.5. After the dropwise addition is completed, slowly add 44g of epichlorohydrin, continue to stir, and control the temperature at 80°C. After the dropwise addition is completed, perform a constant temperature reaction for 3 hours to completely react the epichlorohydrin, and the reaction ends;

[0036] (2) Synthesis of polyoxyethylene ether oleate hydroxypropyl dimethyl octad...

specific Embodiment 2

[0049] A preparation method of a leveling agent for polyester-cotton fabric dyeing in the same bath, comprising the steps of:

[0050] The first step, polyoxyethylene ether oleate hydroxypropyl dimethyl octadecyl ammonium chloride (N-EO 8 )Synthesis:

[0051] (1) Synthesis of 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride:

[0052]

[0053] At a constant temperature of 40°C, add 50.0 g of octadecyl tertiary amine and 100 g of distilled water into a 1000 mL four-neck flask with a condenser placed in a water bath, slowly add 36% HCl dropwise under stirring, and control the pH value to 3. After the dropwise addition is completed, slowly add 44g of epichlorohydrin, continue to stir, and control the temperature at 85°C. After the dropwise addition, continue to react at a constant temperature for 3.5 hours to completely react the epichlorohydrin, and the reaction ends;

[0054] (2) Synthesis of polyoxyethylene ether oleate hydroxypropyl dimethyl octadecyl ammoniu...

specific Embodiment 3

[0066] A preparation method of a leveling agent for polyester-cotton fabric dyeing in the same bath, comprising the steps of:

[0067] The first step, polyoxyethylene ether oleate hydroxypropyl dimethyl octadecyl ammonium chloride (N-EO 8 )Synthesis:

[0068] (1) Synthesis of 3-chloro-2-hydroxypropyl dimethyl octadecyl ammonium chloride:

[0069]

[0070] At a constant temperature of 40°C, add 50.0 g of octadecyl tertiary amine and 100 g of distilled water into a 1000 mL four-neck flask with a condenser placed in a water bath, slowly add 36% HCl dropwise under stirring, and control the pH value to 3. After the dropwise addition is completed, slowly add 44g of epichlorohydrin, continue stirring, and control the temperature within the range of 83°C. After the dropwise addition, continue to react at a constant temperature for 3.2 hours to completely react the epichlorohydrin, and the reaction ends;

[0071] (2) Synthesis of polyoxyethylene ether oleate hydroxypropyl dimethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com