Dyeing technology of water-absorbing and quick-drying nylon-cotton interwoven knitted fabric with high washing fastness

A technology of fastness to washing, water absorption and quick drying, applied in the direction of dyeing, plant fibers, textiles and papermaking, etc., can solve the problems of unstable shade, fading, poor washing fastness, etc., and achieves good dyeing reproducibility, Good water absorption and quick drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

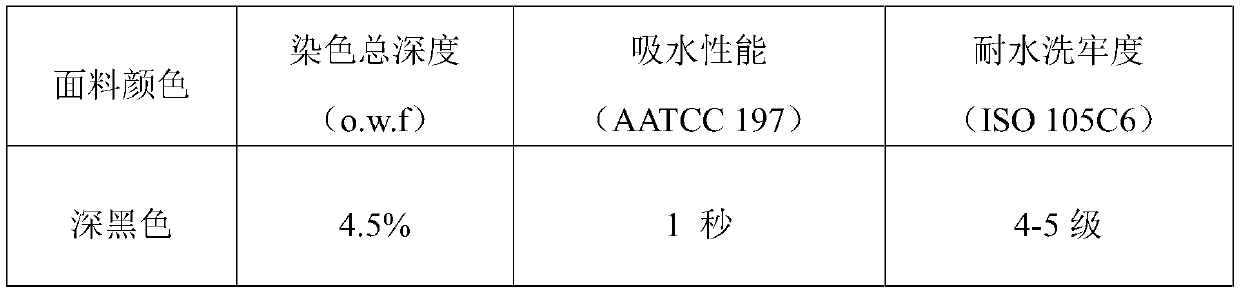

Embodiment 1

[0025] Provide a kind of dyeing process of water-absorbing and quick-drying nylon-cotton interwoven knitted fabric with high washing fastness, comprising the following steps:

[0026] S1. Pre-treatment: pre-treat the dyed fabric according to the conventional process;

[0027] S2, cotton dyeing: the cotton component is dyed dark black with reactive dyestuffs to the fabric after the pretreatment according to the conventional process;

[0028] S3. Washing: wash the fabric after dyeing cotton, the washing temperature is 90°C, the washing time is 20min, and the pH value is adjusted to 6.8;

[0029] S4. Dyeing nylon: use acetic acid / sodium acetate buffer solution to adjust the pH value to 4.1, add 1g / L leveling agent Abaig SET, 2% o.w.f dyeing accelerator CaCl 2 , Brilliant black reactive dye and 4% o.w.f moisture-absorbing and sweat-wicking finishing agent PR18, heat up to 100°C at a rate of 2.0°C / min, keep warm for 45min, then cool down to below 60°C at a rate of 2.0°C / min, and d...

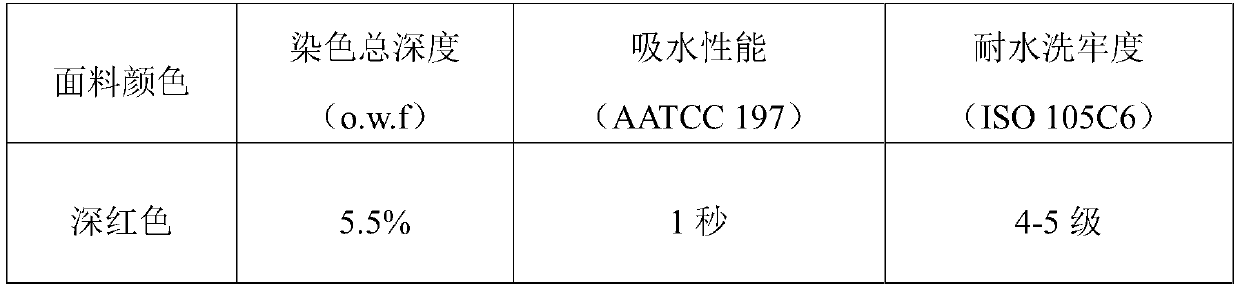

Embodiment 2

[0035] Provide a kind of dyeing process of water-absorbing and quick-drying nylon-cotton interwoven knitted fabric with high washing fastness, comprising the following steps:

[0036] S1. Pre-treatment: pre-treat the dyed fabric according to the conventional process;

[0037] S2, cotton dyeing: the fabric after the pretreatment is dyed dark red to the cotton component by conventional process with reactive dye;

[0038] S3. Washing: wash the fabric after dyeing cotton, the washing temperature is 95°C, the washing time is 20min, and the pH value is adjusted to 6.8;

[0039] S4. Dyeing nylon: use acetic acid / sodium acetate buffer solution to adjust the pH value to 4.1, add 1g / L leveling agent Abaig SET, 10% o.w.f dyeing accelerator CaCl 2 , Brilliant fast red reactive dye and 5% o.w.f moisture-absorbing and sweat-wicking finishing agent PR18, heat up to 95°C at a rate of 2.0°C / min, keep warm for 60 minutes, then cool down to below 60°C at a rate of 2.0°C / min, and drain;

[0040...

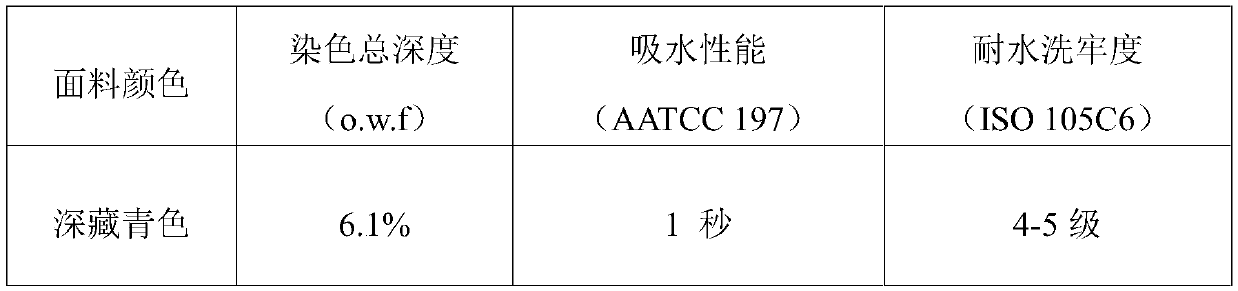

Embodiment 3

[0045] Provide a kind of dyeing process of water-absorbing and quick-drying nylon-cotton interwoven knitted fabric with high washing fastness, comprising the following steps:

[0046] S1. Pre-treatment: pre-treat the dyed fabric according to the conventional process;

[0047] S2, cotton dyeing: dye the cotton component with reactive dyes to deep navy blue according to the conventional process to the fabric after the pretreatment;

[0048] S3. Washing: wash the fabric after dyeing cotton, the washing temperature is 98°C, the washing time is 20min, and the pH value is adjusted to 7.0;

[0049] S4. Dyeing nylon: use acetic acid / sodium acetate buffer solution to adjust the pH value to 4.0, add 1.5g / L leveling agent UPS, 10% o.w.f dyeing accelerator CaCl 2 , Brilliant red, yellow and black reactive dyes and 4% o.w.f moisture-absorbing and sweat-wicking finishing agent PR18, heat up to 105°C at a rate of 2.0°C / min, keep warm for 30 minutes, and then cool down to below 60°C at a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com