Dyeing technology of wool/polyester blended fabric

A technology of blended fabrics and wool, applied in the field of textile printing and dyeing, can solve the problems of deterioration of tensile properties, difficulty in grasping dyeing effect, and easy embrittlement, etc., and achieve simple dyeing process steps, good dyeing reproducibility, and high color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

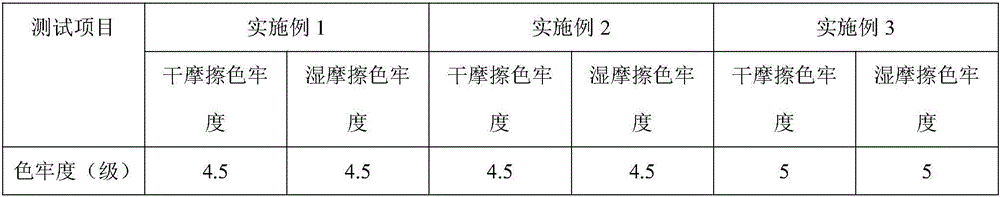

Examples

Embodiment 1

[0021] A kind of wool / polyester blended fabric dyeing process of the present invention comprises steps:

[0022] (1) Preparation of pretreatment solution: place acetic acid-sodium acetate buffer solution and fatty acid methyl ester ethoxylate in the mixed solution of ethanol and water, mix it into pretreatment solution after stirring evenly, wherein, the liquor ratio of pretreatment solution 1:7, the volume ratio of ethanol and water in the pretreatment solution is 19:1, the pH of the pretreatment solution is 4, and the concentration of fatty acid methyl ester ethoxylate is 1g / L;

[0023] (2) Pretreatment of wool / polyester blended fabrics:

[0024] The wool / polyester blended fabric to be dyed is placed in the pretreatment liquid prepared in step (1) and soaked, the liquid-carrying rate of the wool / polyester blended fabric after soaking is 50%, and the weight ratio of wool fiber in the wool / polyester blended fabric is 30%;

[0025] (3) Preparation of dyeing solution: put reac...

Embodiment 2

[0028] A kind of wool / polyester blended fabric dyeing process of the present invention comprises steps:

[0029] (1) Preparation of pretreatment solution: place acetic acid-sodium acetate buffer solution and fatty acid methyl ester ethoxylate in the mixed solution of ethanol and water, mix it into pretreatment solution after stirring evenly, wherein, the bath ratio of pretreatment solution 1:20, the volume ratio of ethanol and water in the pretreatment solution is 1:1, the pH of the pretreatment solution is 6, and the concentration of fatty acid methyl ester ethoxylate is 5g / L;

[0030] (2) Pretreatment of wool / polyester blended fabrics:

[0031] The wool / polyester blended fabric to be dyed is placed in step (1) and soaked in the pretreatment liquid prepared, the liquid carrying rate of the wool / polyester blended fabric after soaking is 100%, and the weight ratio of wool fiber in the wool / polyester blended fabric is 40%;

[0032] (3) Preparation of dyeing solution: put react...

Embodiment 3

[0035] A kind of wool / polyester blended fabric dyeing process of the present invention comprises steps:

[0036] (1) Preparation of pretreatment solution: place acetic acid-sodium acetate buffer solution and fatty acid methyl ester ethoxylate in the mixed solution of ethanol and water, mix it into pretreatment solution after stirring evenly, wherein, the bath ratio of pretreatment solution 1:15, the volume ratio of ethanol and water in the pretreatment solution is 10:1, the pH of the pretreatment solution is 5, and the concentration of fatty acid methyl ester ethoxylate is 3g / L;

[0037] (2) Pretreatment of wool / polyester blended fabrics:

[0038] The wool / polyester blended fabric to be dyed is placed in the pretreatment liquid prepared in step (1) to soak, and the liquid-carrying rate of the wool / polyester blended fabric after soaking is 70%, and the weight ratio of wool fiber in the wool / polyester blended fabric is 50%;

[0039] (3) Preparation of dyeing solution: put reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com