High-modulus and low-dielectric-constant basalt fiber enhanced PC (polycarbonate) material and preparation method thereof

A technology of basalt fiber and low dielectric constant, which is applied in the field of high modulus and low dielectric constant basalt fiber reinforced PC material and its preparation, can solve the problems of poor compatibility of basalt fiber, weakening effect of modification and poor toughness, etc. Achieve the effect of good surface finish, broaden the application field, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

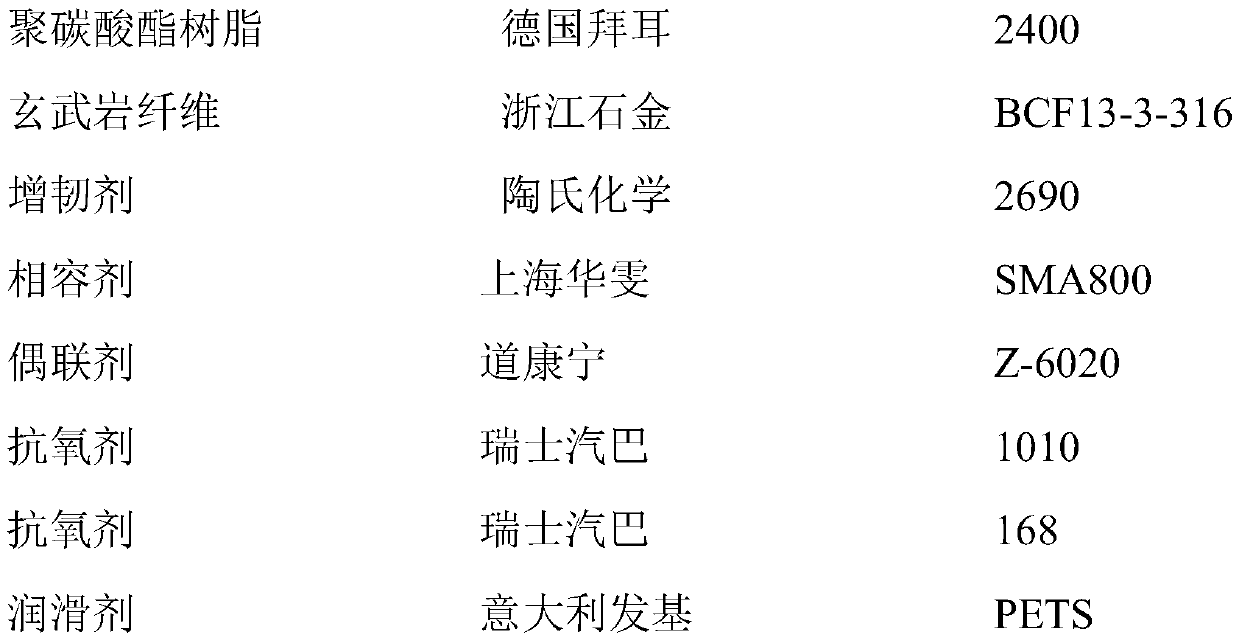

[0034] Adopt material and method of the present invention to make high modulus low dielectric constant basalt fiber reinforced PC material, preparation method steps are as follows:

[0035] 1) Put the PC resin into a drying oven for drying treatment, the process conditions are: temperature 120°C, time 4-8h;

[0036] 2) Weigh PC resin, basalt fiber, coupling agent, toughening agent, compatibilizer, antioxidant and lubricant according to the formula weight ratio;

[0037] 3) Add PC resin, coupling agent, toughening agent, compatibilizer, antioxidant and lubricant to the high-speed mixer, and mix for 20-30 seconds;

[0038] 4) Add the mixed raw materials into the twin-screw extruder. The basalt fiber is fed into the twin-screw extruder by side feeding, melted and extruded at 250°C-280°C, and pelletized after cooling to obtain high modulus and low modulus. Dielectric constant basalt reinforced PC material.

[0039]The processing temperature of the extruder is set to 230°C for zo...

Embodiment 4

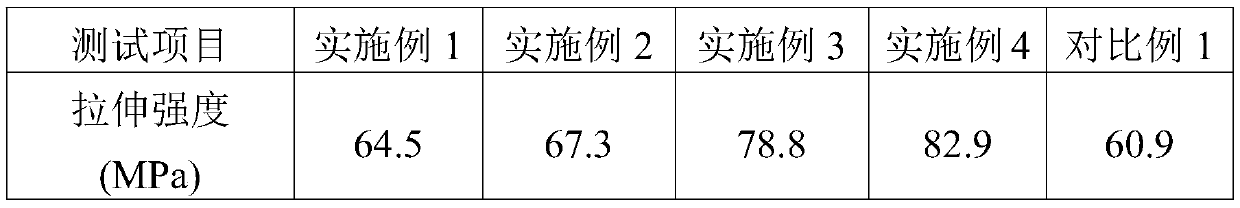

[0051] Example 4 (basalt reinforced PC with high modulus and low dielectric constant) has a flexural strength of 130.3MPa, a flexural modulus of 4323MPa, and a notched Charpy impact strength of 19.3kJ / m 2 , Dielectric constant 2.9. At the same time, the surface finish is good, and the overall performance is obviously better than that of the ordinary glass fiber reinforced PC material in the prior art (comparative example 1).

[0052] Draw the following conclusions from the test data of embodiment and comparative example:

[0053] 1. By adding the modified basalt fiber of the present invention instead of glass fiber, the strength and modulus of the product are greatly improved, and the dielectric constant of the material is reduced;

[0054] 2. By adding styrene-acrylonitrile-maleic anhydride random copolymer and methyl methacrylate-butadiene-styrene copolymer, the mechanical properties of the material are greatly improved;

[0055] 3. By adding γ-aminopropyltriethoxysilane, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com