Steam curing method and device for PC components

A technology for steam maintenance and components, applied in the field of construction, can solve the problems of large land occupation, high operating costs, large pollution, etc., and achieve the effects of high utilization rate of thermal energy, increased supply time, and convenient access to warehouses and warehouses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

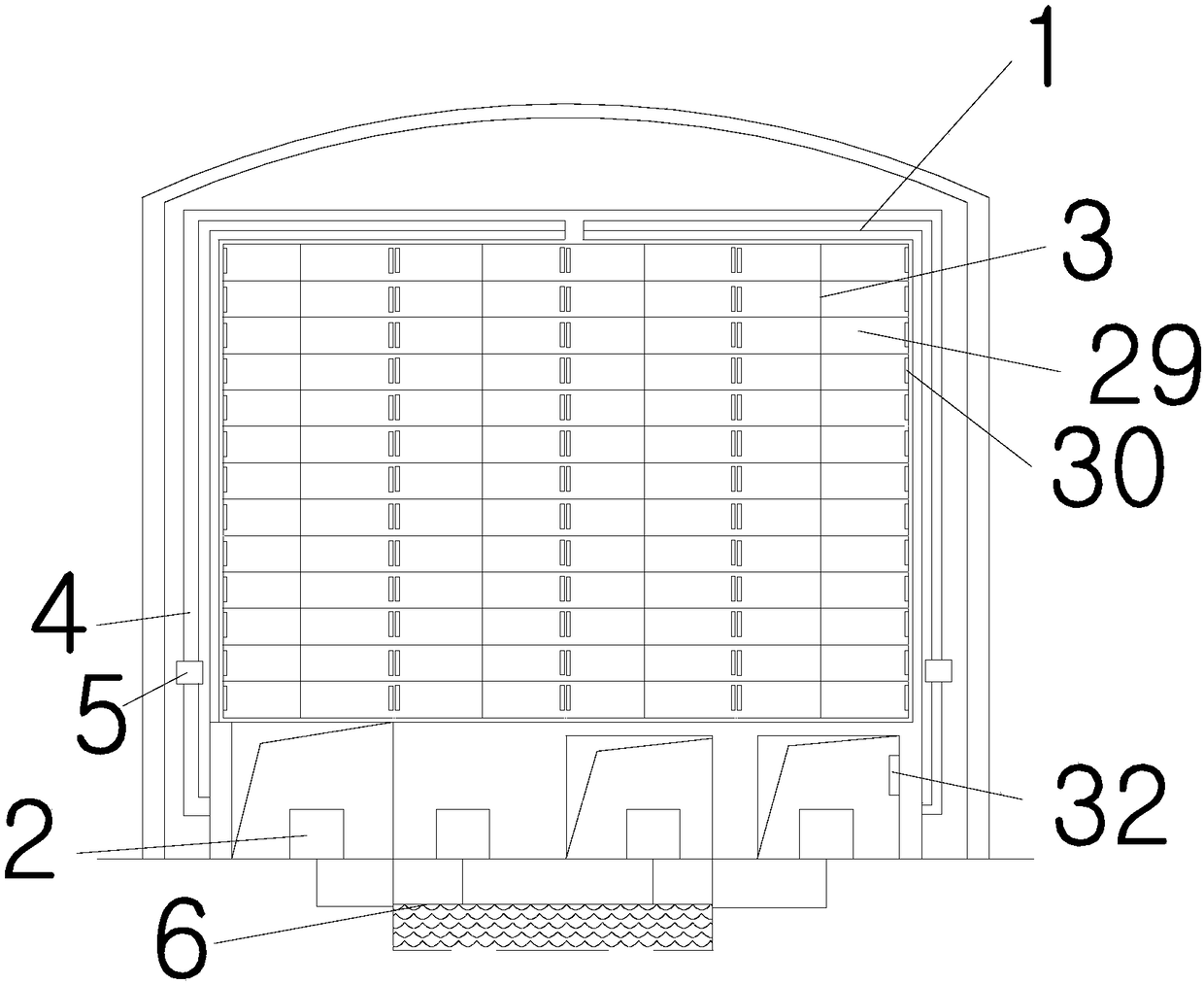

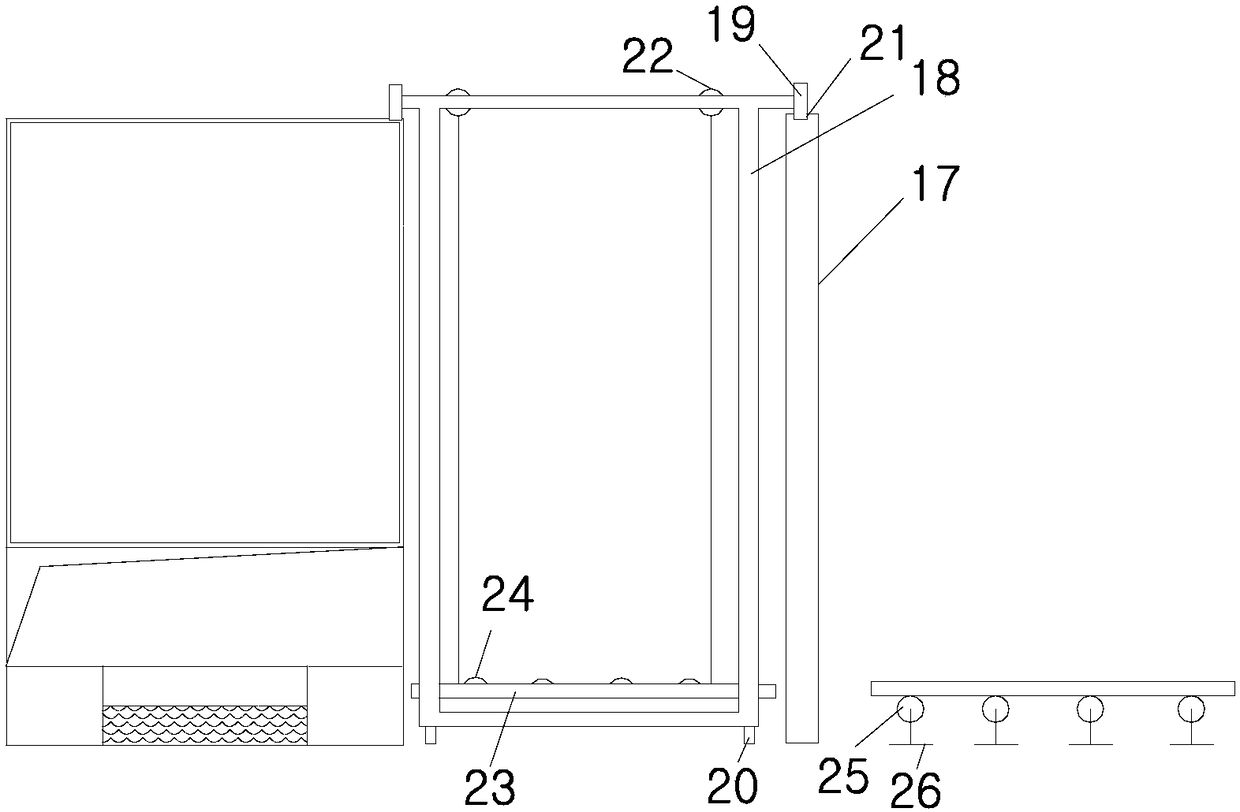

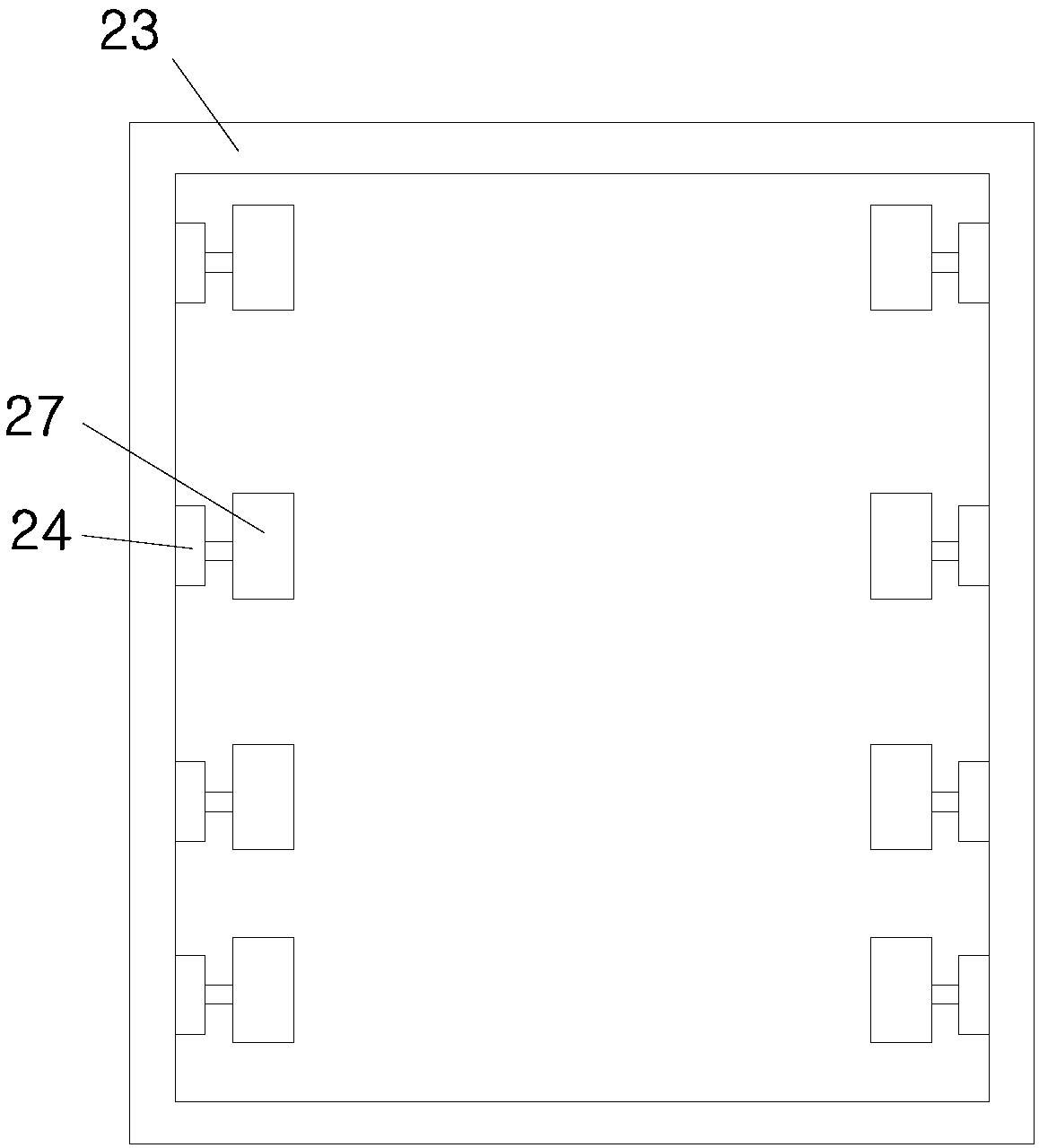

[0029] refer to Figure 1-Figure 4 , a steam curing device for PC components, comprising a thermal insulation steam curing bin 1 and self-climbing transfer equipment, the thermal insulation steam curing bin 1 is provided with a humidifier 2, a temperature and humidity sensor 32 and a multi-layer steam curing kiln 3, and the steam curing The kilns 3 are connected to each other; the lower part and the top of the heat preservation and steaming warehouse 1 are connected through the pipeline 4, and the air pump 5 is arranged on the pipeline 4 to form a circulating air system; the bottom of the heat preservation and steaming warehouse 1 is provided with a pool 6, which is connected with solar energy Hot water engineering system, cold water pipe 33 and humidifier 2; described climbing type transfer equipment includes fixed support 17 and mobile support 18, the top both sides of mobile support 18 are connected with first roller 19, the bottom end of mobile support 18 is connected with ...

Embodiment 2

[0040]The PC component is finished on the PC component carrying plate 26, and then the PC component carrying plate 26 is pushed down on the feeding frame 23 by the second feeding roller 25, and the climbing transfer equipment sends the PC component carrying plate 26 to the corresponding position of the steam curing kiln 3. A feeding roller 24 sends the PC component bearing plate 26 into the steam curing kiln 3 to steam the PC components.

[0041] When the outside temperature is lower than 25°C, the solar hot water engineering system heats the thermal insulation steaming storage bin 1 to keep the curing temperature in the thermal insulation steaming storage bin 1 between 5-25°C, preferably 19°C-25°C; When the temperature is higher than 25°C, cold water is introduced through the cold water pipe 33, and the cold water is scattered into the warm steaming bin 1 to cool down through the humidifier 2, so that the curing temperature in the heat preservation steaming bin 1 is kept betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com