Cutter wheel tail yarn processing device

A technology of processing device and cutter wheel, which is applied in thin material handling, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of affecting output, work errors, easy head breakage, etc., and achieve the effect of convenient control and cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

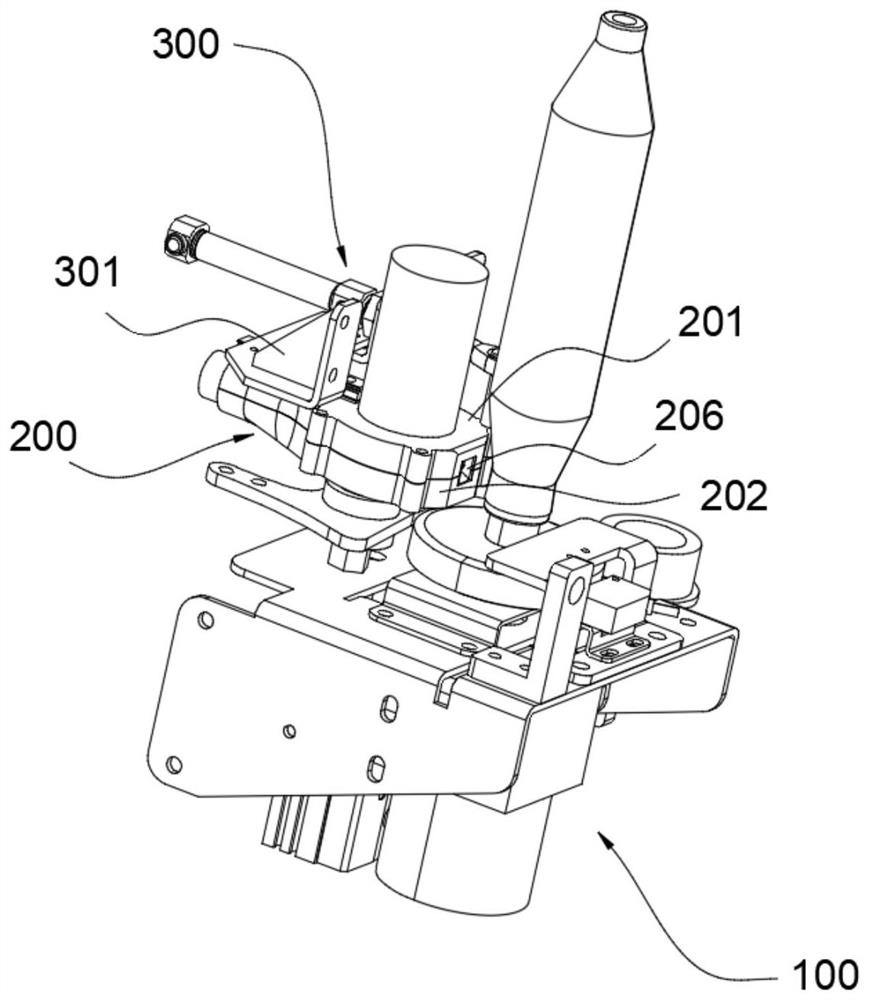

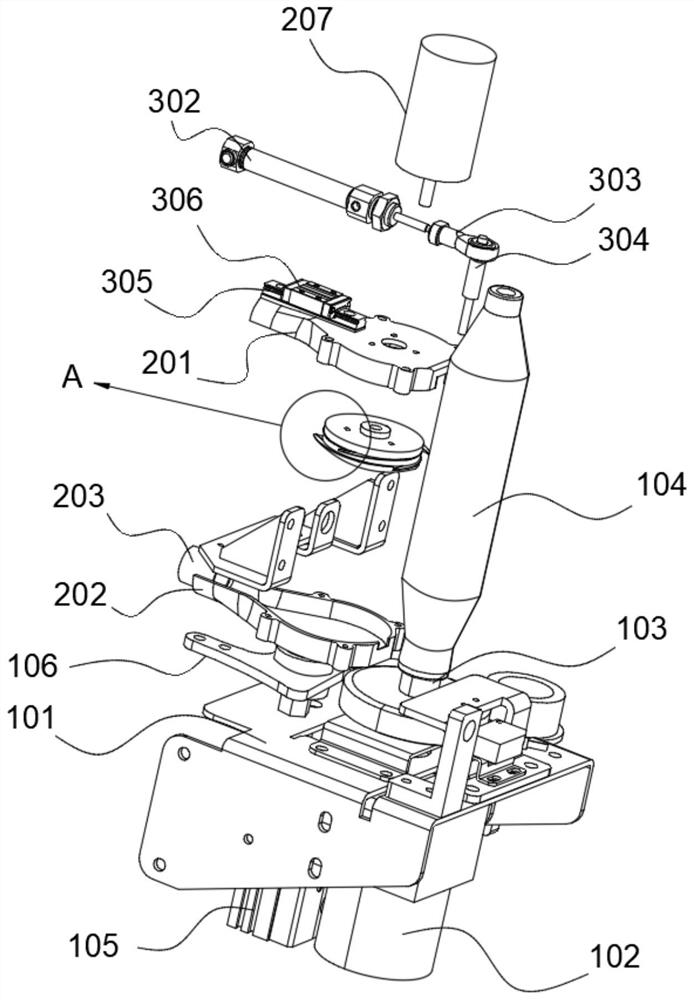

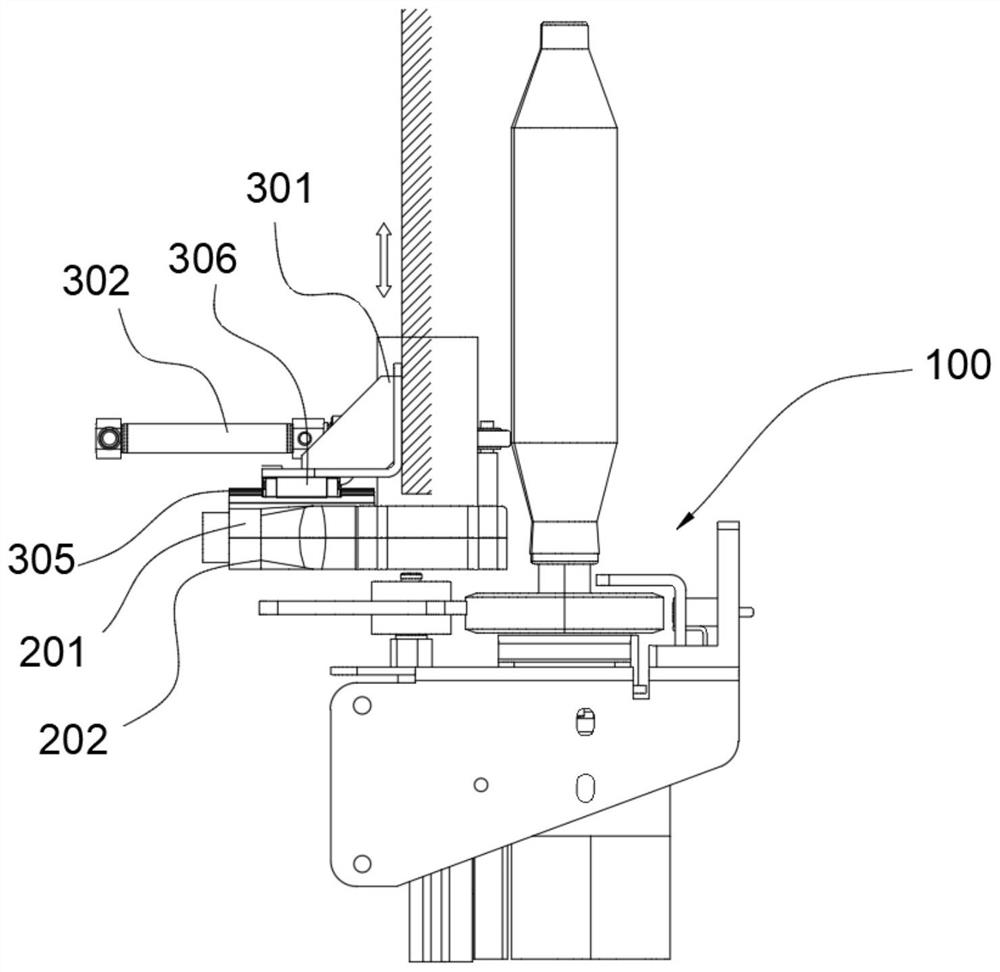

[0033] refer to Figure 1-2 , as an embodiment of the present invention, a cutter wheel tail yarn processing device is provided, and the device includes a main body mechanism 100 , an adsorption mechanism 200 and a driving mechanism 300 .

[0034] The main mechanism 100 includes a positioning machine 101, a bobbin tray 103 arranged on the positioning machine 101, and a bobbin 104 placed on the bobbin tray 103. The rotating stepper motor 102, the main mechanism 100 also includes a jacking cylinder 105 fixedly connected to the bottom side of the positioning machine 101, the telescoping end of the jacking cylinder 105 is fixedly connected with a jacking platform 106, and the jacking platform 106 is located on the lower cover plate Just below the 202 is used to control its up and down movement, which is convenient for the adjustment of the working position, and the top is set on the jacking platform 106, and it is noted that the top is not directly connected with the lower cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com