Cleaning device for textile processing

A cleaning device and a technology for textiles, applied in textile processing machine accessories, textiles and papermaking, equipment configuration for processing textile materials, etc., can solve problems such as easy to re-adhere to textiles, affect cleaning effect, and difficult to clean, so as to prevent Wrinkles, improved cleaning efficiency, large contact surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

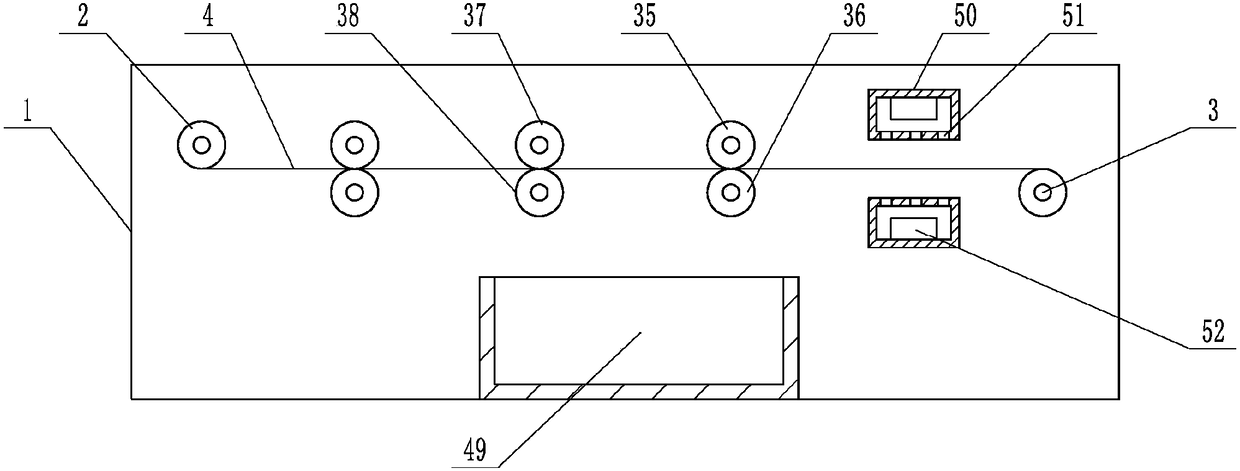

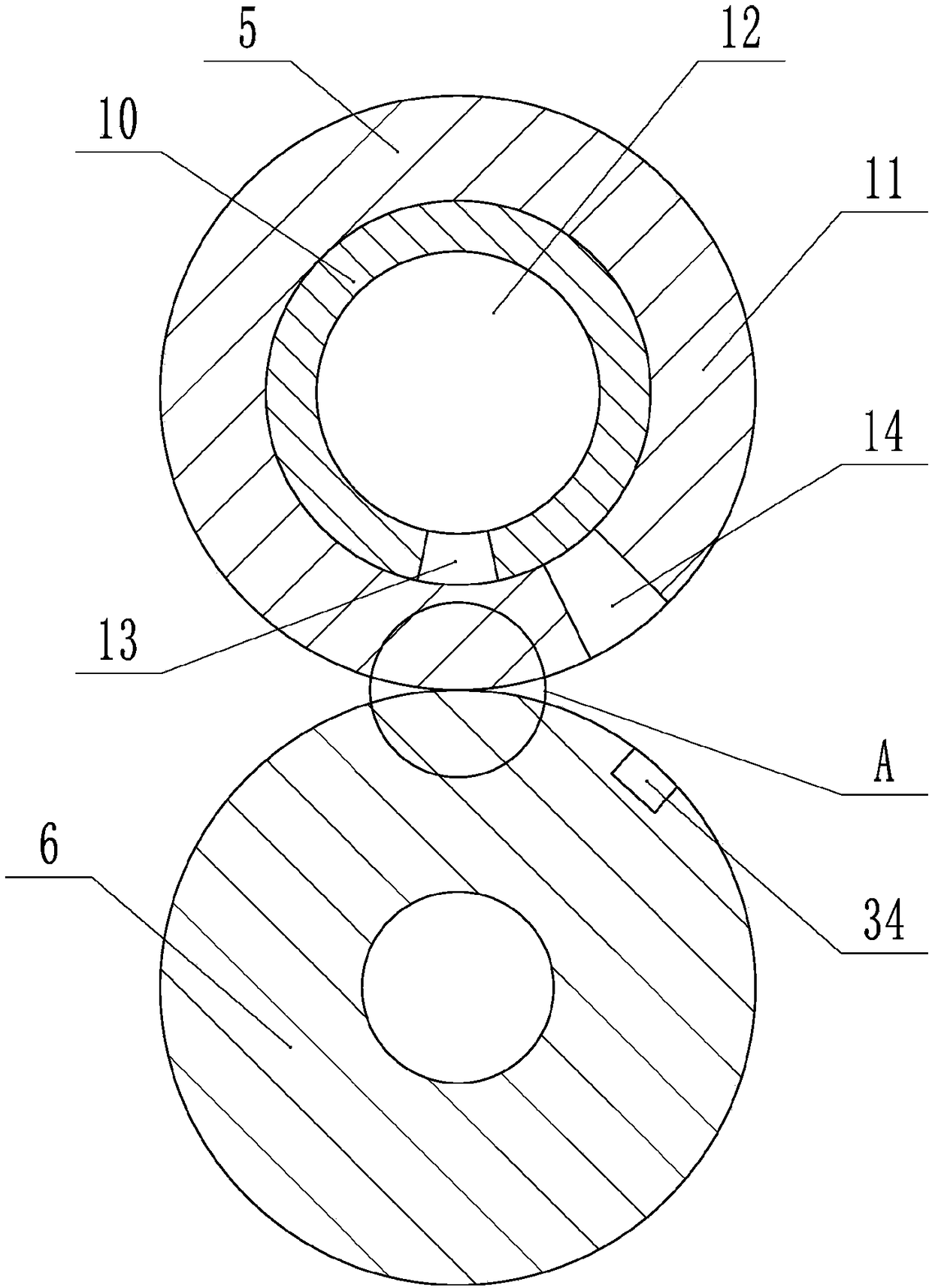

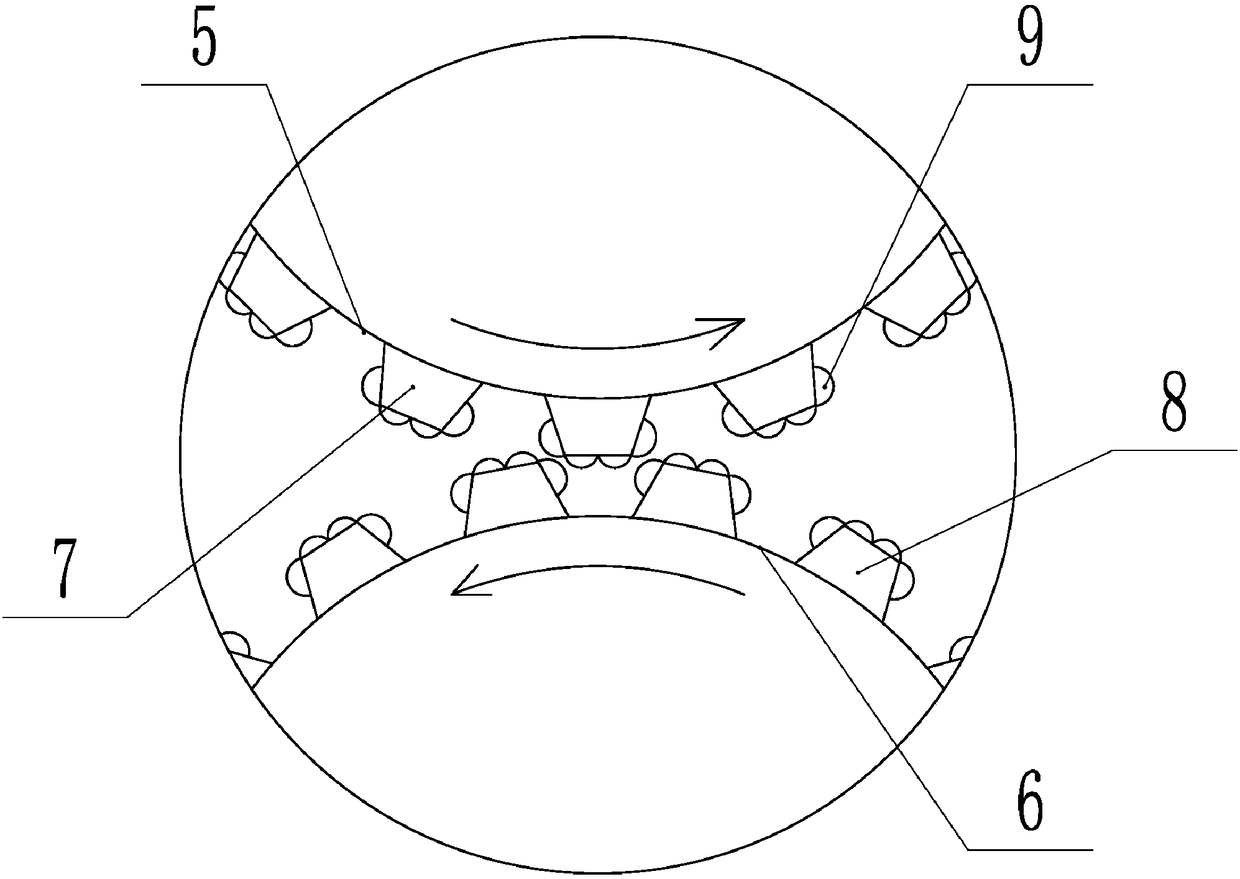

[0028] The reference signs in the accompanying drawings include: frame 1, feeding roller 2, receiving roller 3, belt 4, first roller 5, second roller 6, first protrusion 7, second protrusion 8 , elastic ball 9, the first inner roller 10, the first outer roller 11, the inner cavity 12, the first through hole 13, the second through hole 14, the chute 15, the first slider 16, the second slider 17, the first A gear 18, a second gear 19, a third gear 20, a first chamber 21, a first worm gear 22, a fan gear 23, a water tank 24, a water spray pipe 25, a fourth gear 26, a fifth gear 27, a first tooth Bar 28, second rack 29, first pull rod 30, second pull rod 31, first electromagnet 32, second electromagnet 33, touch delay switch 34, third roller 35, fourth roller 36, The fifth roller 37, the sixth roller 38, the second outer roller 39, the second inner roller 40, the water chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com