Anti-corrosion cable having thermal-insulation shield with isolating bars

A technology of heat shield and isolation strip, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as hidden safety hazards, heat accumulation, and difficulty in cable installation, and achieve the effect of avoiding impact and reliable locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

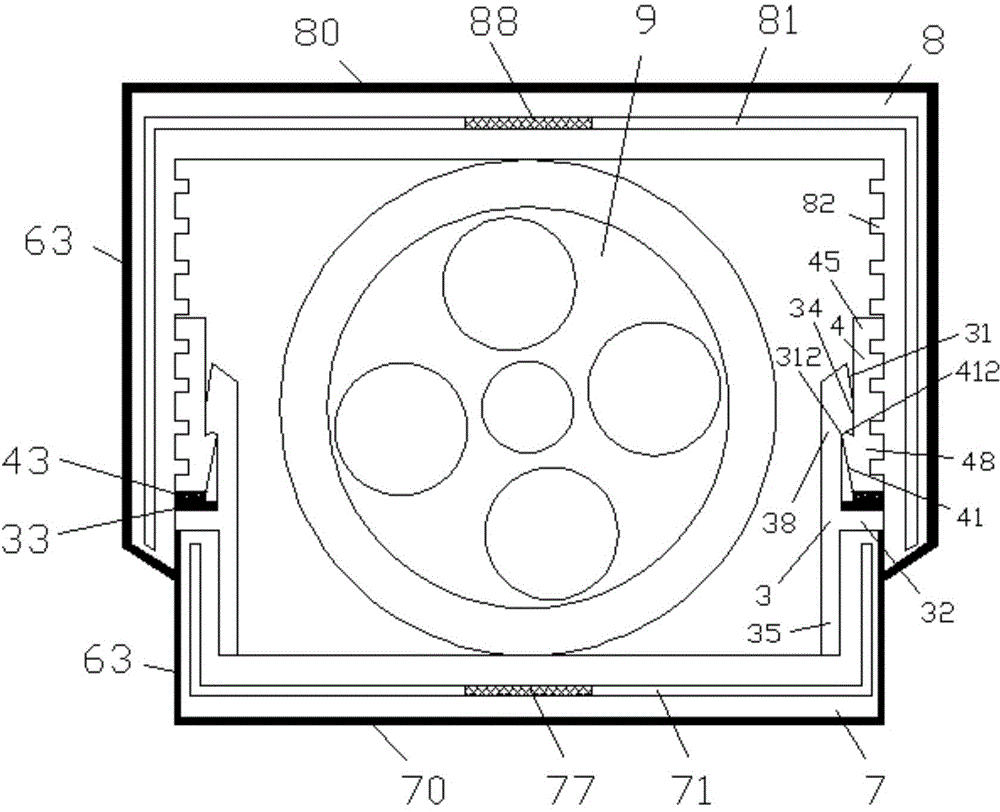

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] According to an embodiment, a cable with an anti-corrosion heat shield with insulating strips includes a cylindrical cable body 9 placed inside the heat shield and an upper heat shield 8 and a lower heat shield The heat shield of the shield 7, the cover walls of the upper heat shield 8 and the lower heat shield 7 all include respective bottom walls 80, 70 and side walls positioned on both sides of the bottom walls 80, 70 , the bottom walls 80, 70 are respectively in contact with the two diametrically opposite domes of the cable body 9, and cooling fluid passages 81, 81, 71, the outer surfaces of the walls of the upper heat shield 8 and the lower heat shield 7 are sprayed with a corrosion-resistant material layer 63, and the corrosion-resistant material layer 63 is used to prevent the heat shield from being corroded Therefore, the cable body 9 has been protected against corrosion to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com