Cable having fire-proof-layer-contained heat shield

A heat shield and fireproof layer technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as potential safety hazards, heat accumulation, difficult cable installation, etc., and achieve the effect of avoiding impact and locking reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

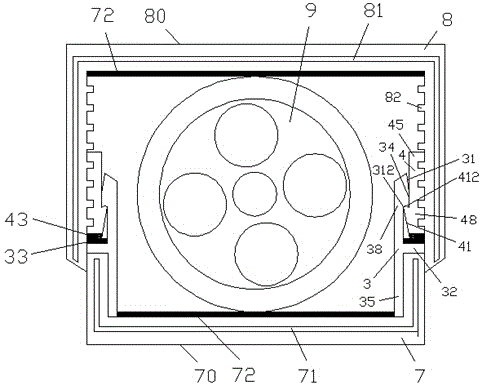

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] According to an embodiment, a cable with a heat shield with a fireproof layer comprises a cylindrical cable body 9 placed inside said heat shield and an upper heat shield 8 and a lower heat shield 7 The heat shield, the walls of the upper heat shield 8 and the lower heat shield 7 all include respective bottom walls 80, 70 and side walls located on both sides of the bottom walls 80, 70, the The bottom walls 80, 70 are respectively in contact with the two diametrically opposite domes of the cable body 9, and the contact surfaces of the bottom walls 80, 70 and the two diametrically opposite domes of the cable body 9 Fireproof layers 72 are arranged on them, and the fireproof layers 72 are made of fireproof materials to play the role of fireproof and heat insulation for the cable body 9. Extended cooling fluid channels 81, 71, wherein the two side walls of the lower heat shield 7 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com