Wet-process open treatment method of arsenic in copper ashes

A treatment method, copper soot technology, applied in the direction of improvement of process efficiency, etc., can solve problems such as difficulty in opening roads, air pollution, etc., and achieve the effects of simple process, low production cost, and high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

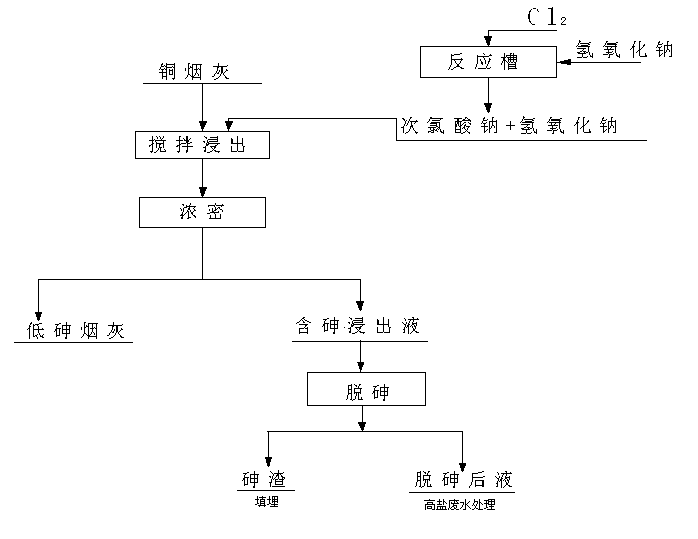

Method used

Image

Examples

Embodiment 1

[0021] Copper soot chemical weight composition: lead 50%, arsenic 4.3%, nickel 0.03%, copper 5.6%, zinc 6.2%, iron 0.86%, antimony 3%, bismuth 2.18%, sulfur and oxygen, carbon 30%.

[0022] Add sodium hypochlorite and sodium hydroxide solution to the copper soot, the concentration of sodium hypochlorite solution is 8%, sodium hydroxide is 2%, the liquid-solid ratio is 15:1, the reaction is stirred for 1.5 hours, the reaction temperature is 50°C, and the dearsenized slag and dearsenized residue are obtained by filtration. After liquid, the liquid after arsenic removal is used in the next step.

[0023] The slag after arsenic removal is sent to the current soot plant to recover valuable metals such as copper, lead, zinc, and bismuth. Chemical composition of slag after arsenic removal: lead 56.99%, arsenic 0.18%, nickel 0.06%, copper 6%, zinc 6.85%, iron 0.96%, antimony 3.40%, bismuth 2.32%, sulfur 0.5%, oxygen, chlorine, sodium 20% .

[0024] The arsenic solution is used to pr...

Embodiment 2

[0026] Copper soot chemical composition: lead 10%, arsenic 5%, nickel 0.01%, copper 20%, zinc 2%, iron 1.5%, antimony 5%, bismuth 15%, sulfur and oxygen, carbon 40%.

[0027] Add sodium hypochlorite and sodium hydroxide solution to the copper soot, the concentration of sodium hypochlorite solution is 12%, sodium hydroxide is 2%, the liquid-solid ratio is 10:1, the reaction is stirred for 1 hour, and the reaction temperature is 80°C. After the arsenic removal, the solution will be used in the next step.

[0028] The slag after arsenic removal is sent to the current soot plant to recover valuable metals such as copper, lead, zinc, and bismuth. Chemical composition of slag after arsenic removal: lead 10.99%, arsenic 0.19%, nickel 0.02%, copper 23%, zinc 2.15%, iron 1.7%, antimony 5.6%, bismuth 17%, sulfur 0.9%, oxygen, chlorine, sodium 39% .

[0029] The arsenic solution is used to precipitate arsenic by ferrite method after arsenic removal, the arsenic slag is buried, and the ...

Embodiment 3

[0031] Chemical composition of copper soot: lead 60%, arsenic 2, nickel 0.1%, copper 2, zinc 7%, iron 0.5%, antimony 0.1%, bismuth 1%, sulfur and oxygen carbon 36%.

[0032] Add sodium hypochlorite and sodium hydroxide solution to the copper soot, the concentration of sodium hypochlorite solution is 4%, sodium hydroxide is 10%, the liquid-solid ratio is 20:1, the reaction is stirred for 2 hours, the reaction temperature is 60°C, and the dearsenized slag and dearsenic are obtained by filtration After liquid, the liquid after arsenic removal is used in the next step.

[0033] The slag after arsenic removal is sent to the current soot plant to recover valuable metals such as copper, lead, zinc, and bismuth. Chemical composition of slag after arsenic removal: lead 67%, arsenic 0.1%, nickel 0.06%, copper 2.3%, zinc 7.85%, iron 0.6%, antimony 1.02%, bismuth 1.12%, sulfur 0.3%, oxygen, chlorine, sodium 30% .

[0034] The arsenic solution is used to precipitate arsenic by ferrite me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com