Method for recycling aluminum electrolysis waste cathode carbon blocks

A technology for recycling waste cathode carbon blocks and aluminum, applied in chemical instruments and methods, aluminum fluoride, aluminum halide, etc., can solve the problems of difficult quality assurance, large amount of waste water, and difficult recycling of carbon materials, so as to solve equipment corrosion. , the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

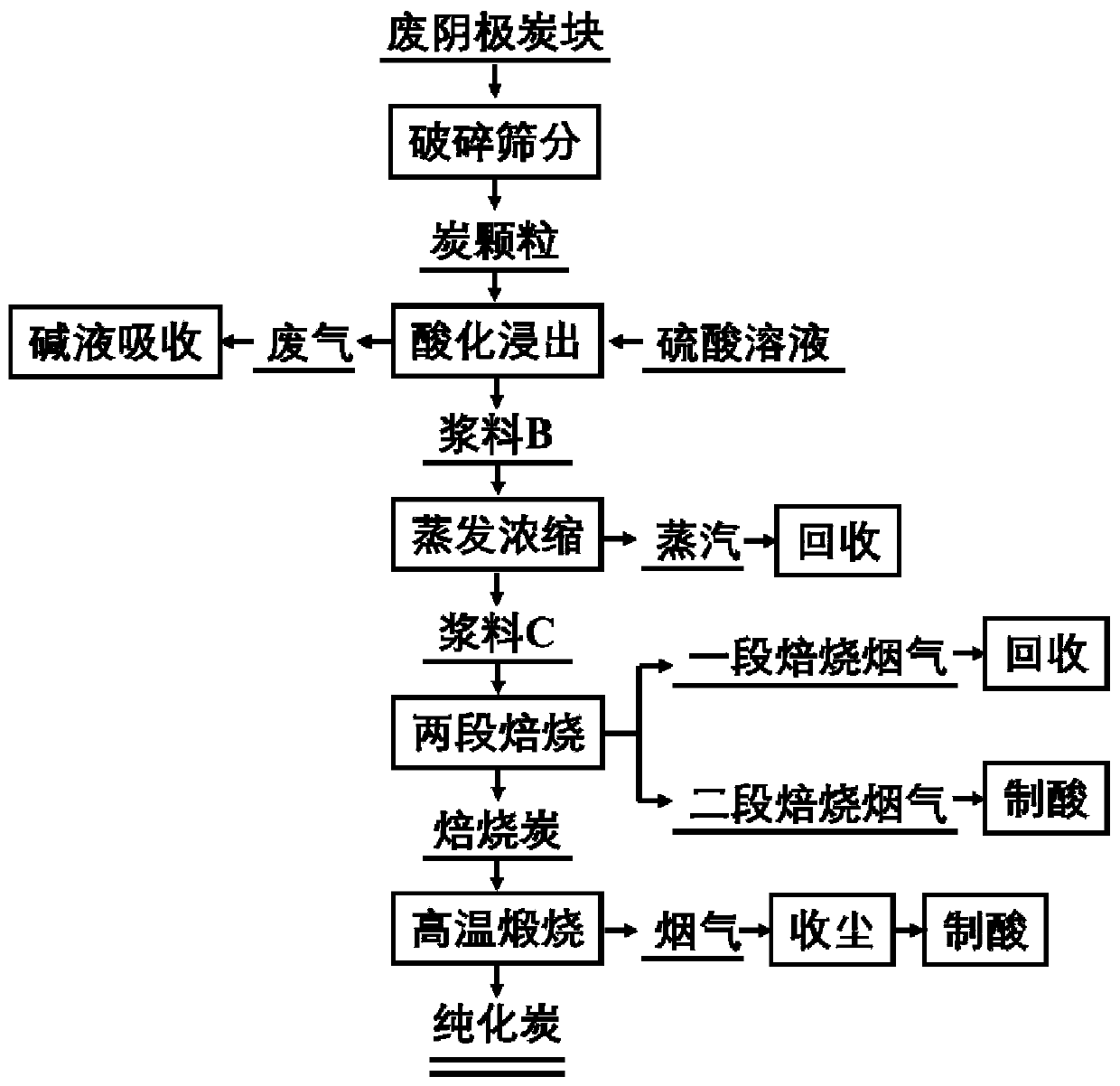

Image

Examples

Embodiment 1

[0056] (1) The cathode carbon block is crushed and sieved to obtain carbon particles;

[0057] (2) Taking the Si element in the carbon particles and the S element in the sulfuric acid solution as the target, after adding the sulfuric acid solution, the Si and S molar ratio in the slurry A is 1:2.10, and the concentration of the sulfuric acid solution is 3mol / L, soaking The time is 5 hours, the temperature is 150°C, the pressure is 0.4MPa, and the gas generated during the process is absorbed with lye.

[0058] (3) Slurry B was evaporated and concentrated at a temperature of 120° C., and the obtained slurry C had a water mass percentage of 8%, and the generated steam was collected to obtain slurry C.

[0059] (4) With the element F in the slurry C and the sulfur element in the concentrated sulfuric acid and the slurry C as the target, after adding the concentrated sulfuric acid, the molar ratio of F and S in the slurry D is 1:1.0, and the concentration of the concentrated sulfur...

Embodiment 2

[0062] (1) Crushing and screening the waste cathode carbon blocks to obtain carbon particles;

[0063] (2) Taking the Si element in the carbon particles and the S element in the sulfuric acid solution as targets, after adding the sulfuric acid solution, the Si and S molar ratio in the slurry A is 1:2.15, and the concentration of the sulfuric acid solution is 2mol / L. The time is 3 hours, the temperature is 200°C, and the pressure is 1.6MPa. The gas generated during the process is absorbed with lye.

[0064] (3) Slurry B was evaporated and concentrated at a temperature of 160° C., and the obtained slurry C had a water mass percentage of 7%, and the generated steam was collected to obtain slurry C.

[0065] (4) The element F in the slurry C, the concentrated sulfuric acid, and the sulfur element in the slurry C are targeted. After adding the concentrated sulfuric acid, the molar ratio of F and S in the slurry D is 1:2.0, and the concentration of the concentrated sulfuric acid is ...

Embodiment 3

[0068] (1) Crushing and screening the waste cathode carbon blocks to obtain carbon particles;

[0069] (2) Taking the Si element in the carbon particles and the S element in the sulfuric acid solution as targets, after adding the sulfuric acid solution, the Si and S molar ratio in the slurry A is 1:2.20, and the concentration of the sulfuric acid solution is 1mol / L, soak The time is 1 hour, the temperature is 250°C, and the pressure is 4MPa. The gas generated during the process is absorbed with lye.

[0070] (3) Slurry B was evaporated and concentrated at a temperature of 180° C., and the obtained slurry C had a water mass percentage of 6%, and the generated steam was collected to obtain slurry C.

[0071] (4) The element F in the slurry C, the concentrated sulfuric acid, and the sulfur element in the slurry C are targeted. After adding the concentrated sulfuric acid, the molar ratio of F and S in the slurry D is 1:3.0, and the concentration of the concentrated sulfuric acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com