A kind of circulation gas stripping distillation method for extracting EPA&DHA from fish oil

A technology for circulating gas and fish oil, applied in chemical instruments and methods, steam distillation, preparation of organic compounds, etc., can solve problems such as difficulty in meeting actual production, low separation efficiency, residual organic solvents, etc., and achieve significant industrialization prospects, Wide application prospects, mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

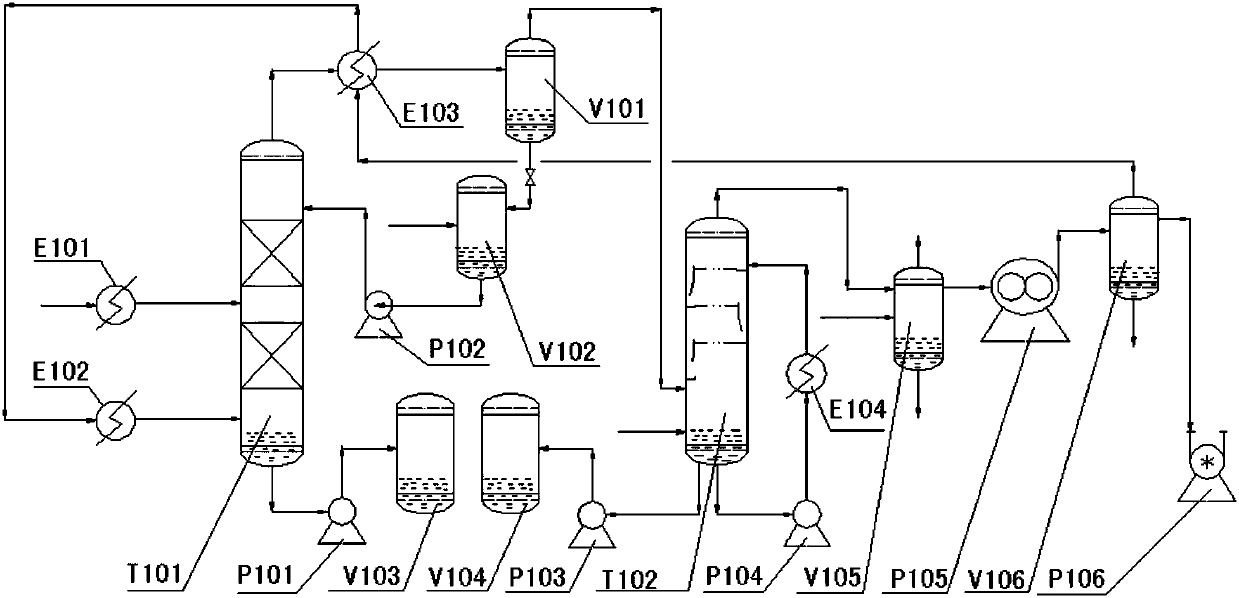

Image

Examples

Embodiment 1

[0037] The gas stripping distillation tower T101 has a diameter of DN400mm and a height of 15 meters. The top temperature of the tower is 142℃, and the bottom temperature of the tower is 178℃; the system is evacuated to 4KPa, and the nitrogen is circulated through the gas compressor P105, and then preheated to 250 by the nitrogen heater E102 ℃, nitrogen flow rate is 1500m 3 / h;

[0038] The raw material fish oil feed rate is 25L / h (the EPA&DHA content in the raw material is 24%, of which EPA contains 13%, mass percentage content). After being preheated to 140℃ by the raw material preheater E101, it is fed from the middle of the gas lift distillation tower T101 The top of the gas-lifting rectification tower T101 is refluxed by the gas-lifting tower reflux pump P103, the reflux temperature is 110°C, and the reflux flow rate is 15L / h (the composition of the reflux liquid is the liquid phase collected when reflux is not under this condition, The EPA content is less than 2%, mass perc...

Embodiment 2

[0040] The gas stripping distillation tower T101 has a diameter of DN400 and a height of 15 meters; the system is evacuated to 4KPa, the top temperature of the tower is 142°C, and the bottom temperature of the tower is 178°C. After nitrogen is circulated through the gas compressor P106, it is preheated to 250 by the nitrogen heater E103 ℃, nitrogen flow rate is 1500m 3 / h;

[0041] The raw material fish oil feed rate is 25L / h (the EPA&DHA content in the raw material is 27%, the mass percentage content), after being preheated to 140°C by the raw material preheater E101, it is fed from the middle of the gas lift distillation tower T101 for gas lift distillation The top of the tower T101 is refluxed through the stripping tower reflux pump P103, the reflux temperature is 110°C, and the reflux flow rate is 15L / h (the composition of the reflux liquid is about 6% EPA, 0 DHA, and mass percentage), The EPA&DHA mixture is extracted from the T101 tower bottom of the gas-lifting rectificatio...

Embodiment 3

[0043] The gas stripping distillation tower T101 has a diameter of DN400mm and a height of 15 meters; the system is evacuated to 4KPa, the top temperature of the tower is 142°C, and the bottom temperature of the tower is 177°C. After nitrogen is circulated through the gas compressor P106, it is preheated to 230 by the nitrogen heater E103 ℃, nitrogen flow rate is 1400m 3 / h;

[0044] The raw material fish oil feed rate is 23L / h (the EPA&DHA content in the raw material is 25%, the mass percentage content), after being preheated to 120°C by the raw material preheater E101, it is fed from the middle of the gas lift distillation tower T101 for gas lift distillation The top of the tower T101 is refluxed through the stripping tower reflux pump P103, the reflux temperature is 100°C, and the reflux flow rate is 13L / h (the composition of the reflux liquid is about 6% EPA, 0 DHA, and mass percentage), The EPA&DHA mixture is extracted from the T101 tower bottom of the gas-lifting rectificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com