Quality-improving process and apparatus for high-ash low rank coal

A low-rank coal, high-ash technology, applied in the petroleum industry, dry gas layout, solid fuel, etc., can solve the problems of no separation of ash, limited application range, and inability to separate dust, so as to expand the use, reduce production costs, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

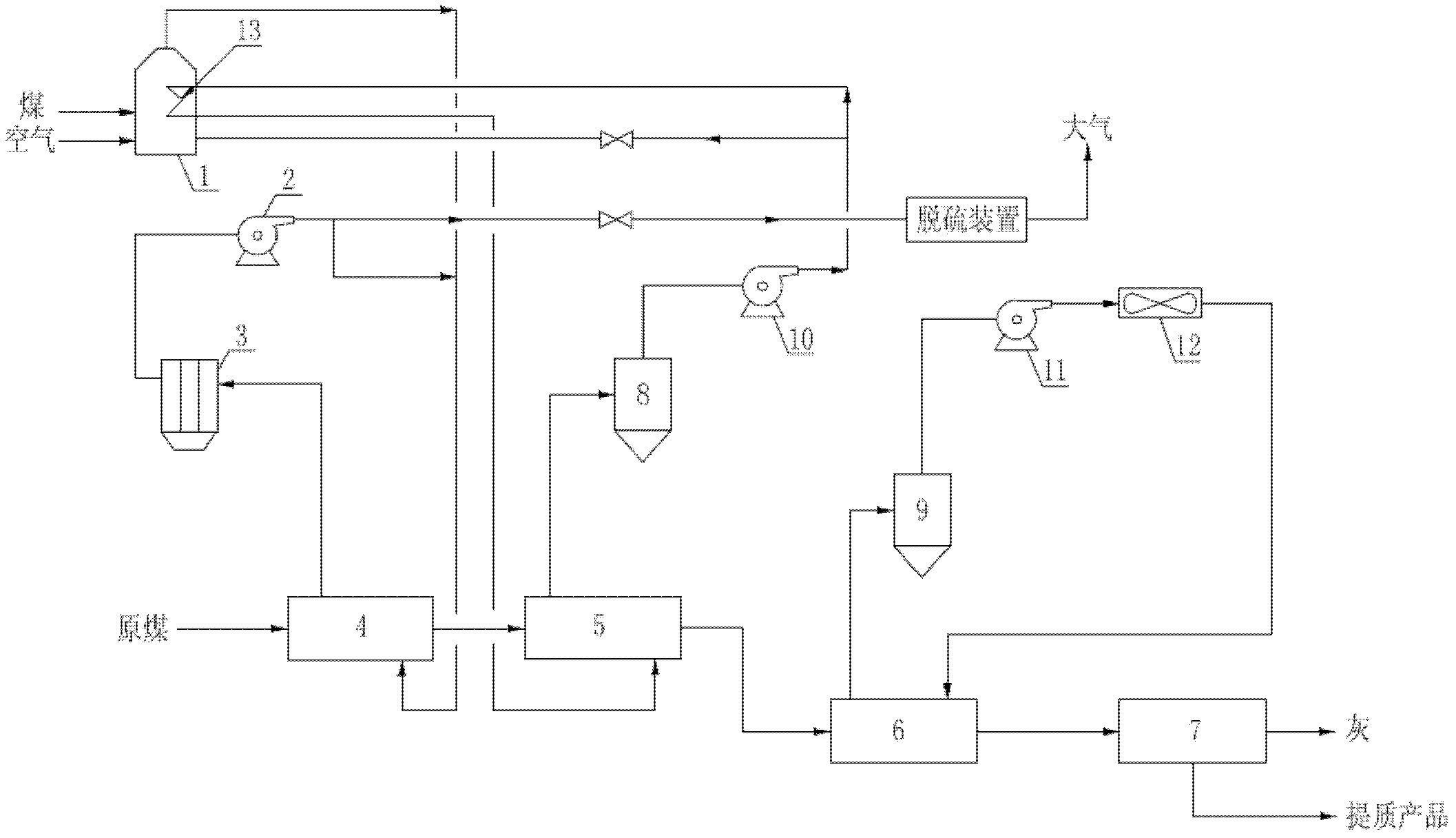

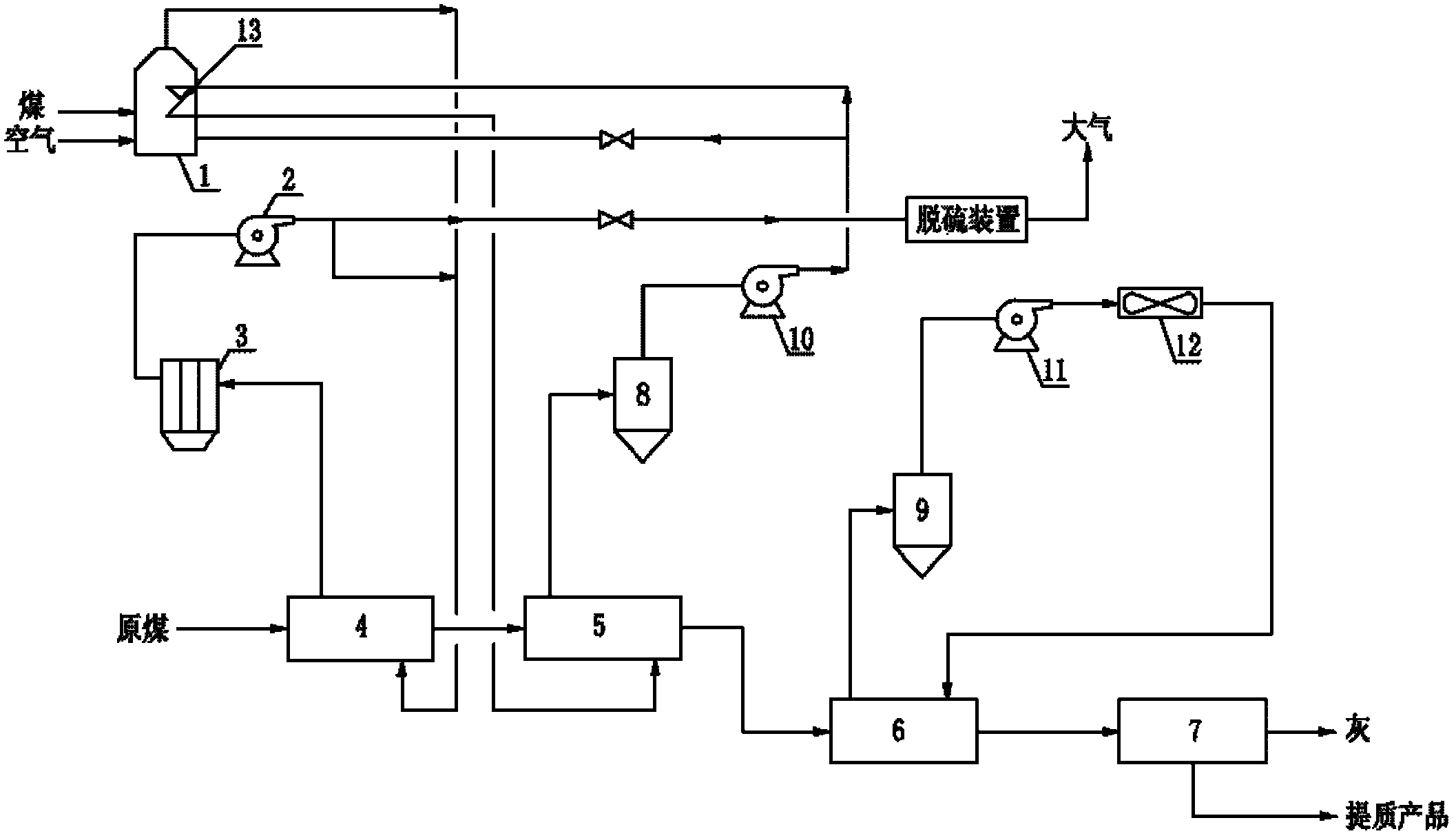

[0040] The present invention will be further explained below in conjunction with the drawings:

[0041] The device of the present invention includes a drying system, a cooling system and a winnowing dust removal system connected in sequence. The drying system includes a primary fluidized bed dryer 4 and a secondary fluidized bed dryer 5, which are used to dry the low-rank coal in a primary drying process to remove the external water, and then dry the low-rank coal to remove internal water; the cooling system It includes a fluidized bed cooler 6 for cooling and dewatering coal; the air separation and dust removal system includes an air separator 7 for separating the ash from the cooled coal by air separation; the drying system is also connected to the flue gas The supply system is connected, and the flue gas supply system includes a primary flue gas supply system and a secondary flue gas circulation system.

[0042] The first-level flue gas supply system includes a coal-fired hot b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com