Household water treating method and system with antioxidant reverse osmosis film

A technology of reverse osmosis membrane and treatment system, which is applied to the treatment method of domestic water purification and the system field designed by applying the method, which can solve the problems of troublesome water pretreatment, easy blockage of reverse osmosis membrane, waste of water resources, etc. low cost, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

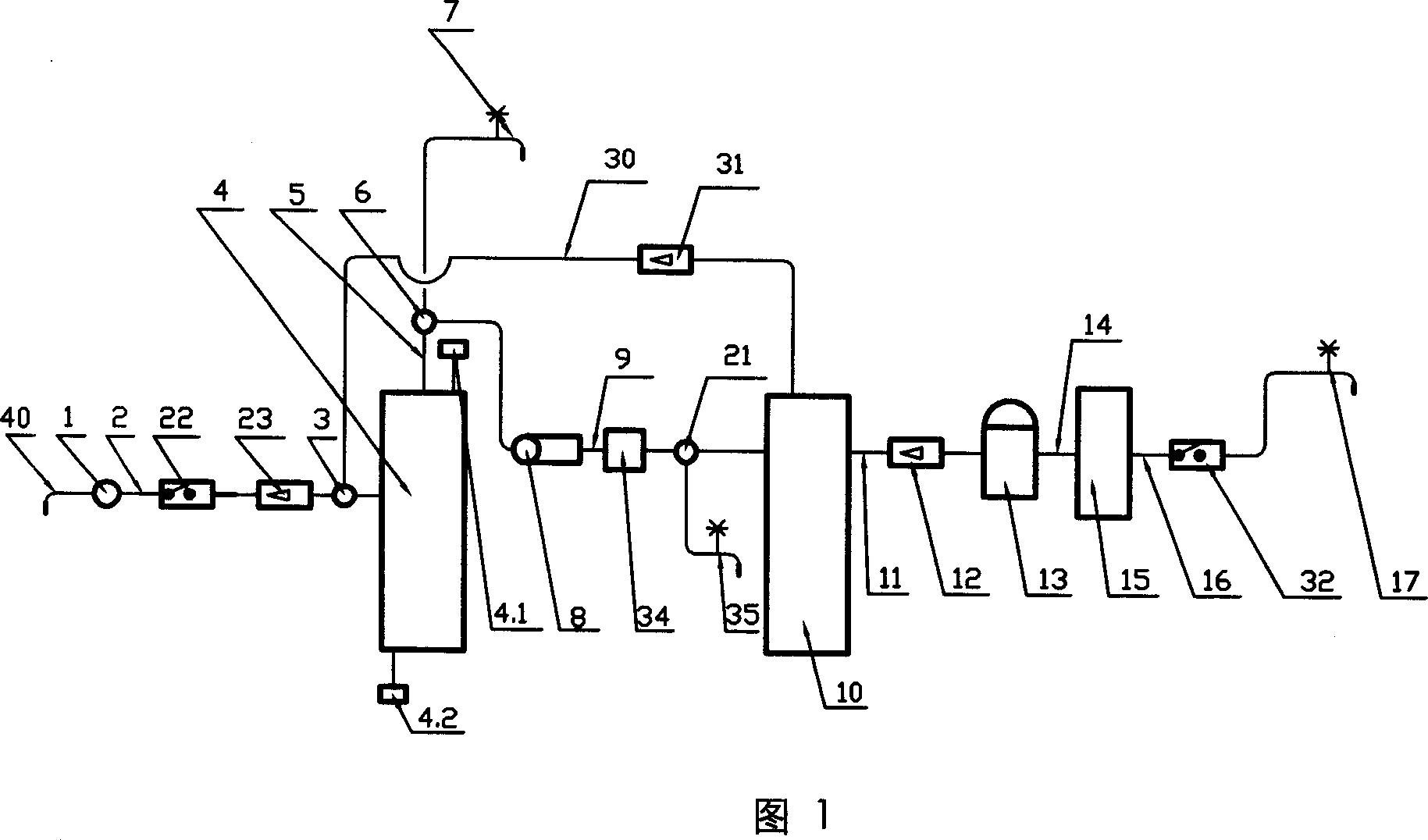

[0047]As shown in FIG. 1, the present invention mainly includes a pressure limiting valve 1, an ultrafiltration water purifier 4, and an anti-oxidative reverse osmosis unit 10. The pressure limiting valve 1 has a water cutoff function and is installed at the front end of the system, and is connected with the water inlet pipe. 40 is connected, and its water outlet is water pipe A2. On the water pipe A2, a first pressure switch 22 and a second check valve 23 are connected in series in sequence, and a first three-way 3 is also installed at the outlet end of the second check valve 23. One of the first three-way 3 The outlet is communicated with the ultrafiltration water purifier 4 , and the other outlet is connected with the concentrated water outlet of the anti-oxidation reverse osmosis unit 10 through a communication pipe 30 . The ultrafiltration water purifier 4 is respectively connected with the flush valve 4.1 and the drain valve 4.2, and its opening and closing can be contro...

Embodiment 2

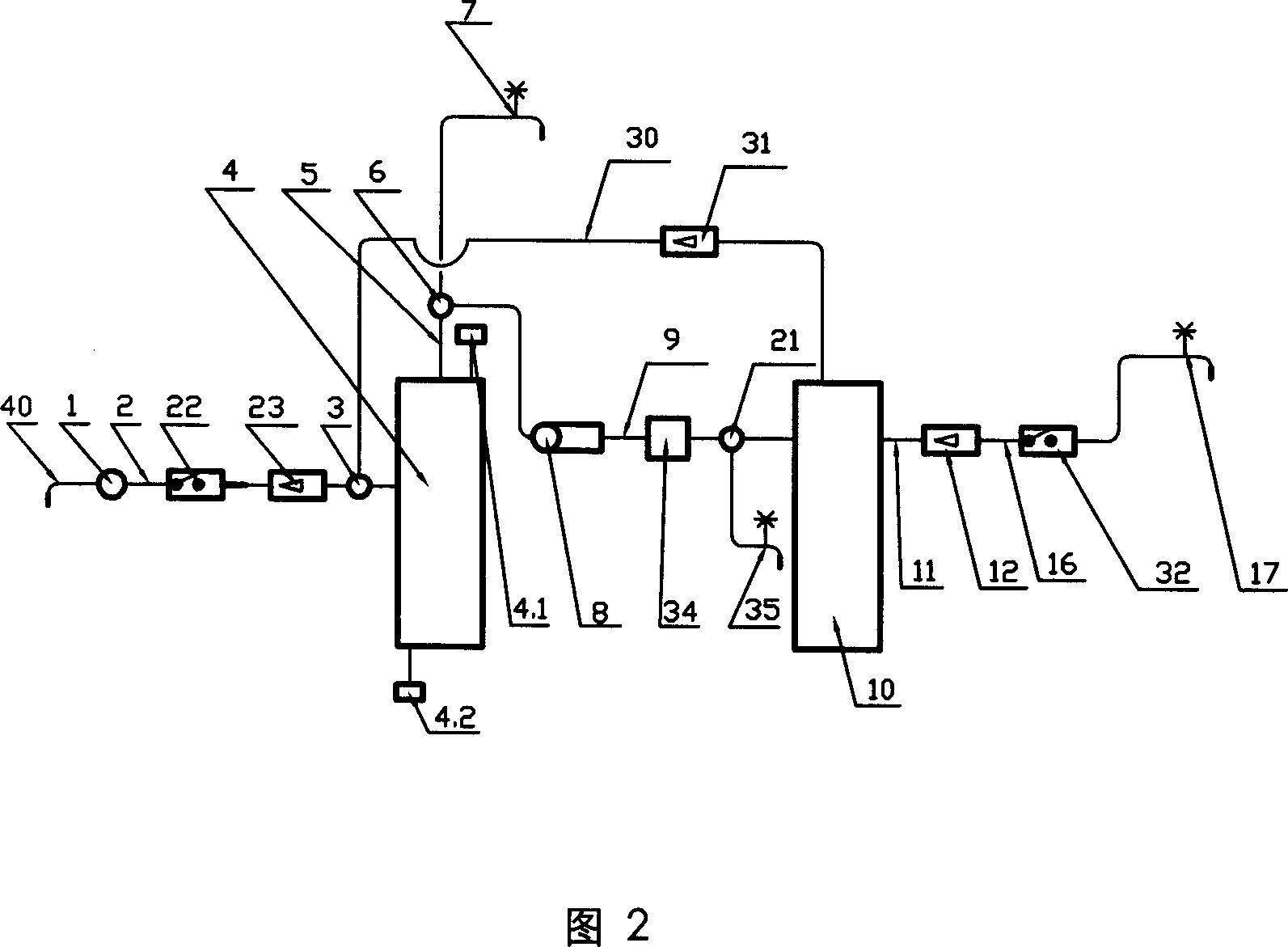

[0055] As shown in Figure 2, this embodiment is basically the same as the first embodiment, the difference is that the anti-oxidation reverse osmosis unit 10 with a large water flow rate is selected to meet the requirements of users for immediate use, so it is not necessary to equip a water storage system, and the anti-oxidation reverse osmosis unit 10 is not equipped with a water storage system. The outlet end of the permeation unit 10 is connected to the pure water tap 17 through the water pipe D11, the first check valve 12, and the second pressure switch 32 of the water pipe F16. When the user uses water, after opening the pure faucet 17, the water pressure of the water pipe F16 drops, the pressure switch 32 gives a signal, and starts the water pump 8; Turn off the water pump.

Embodiment 3

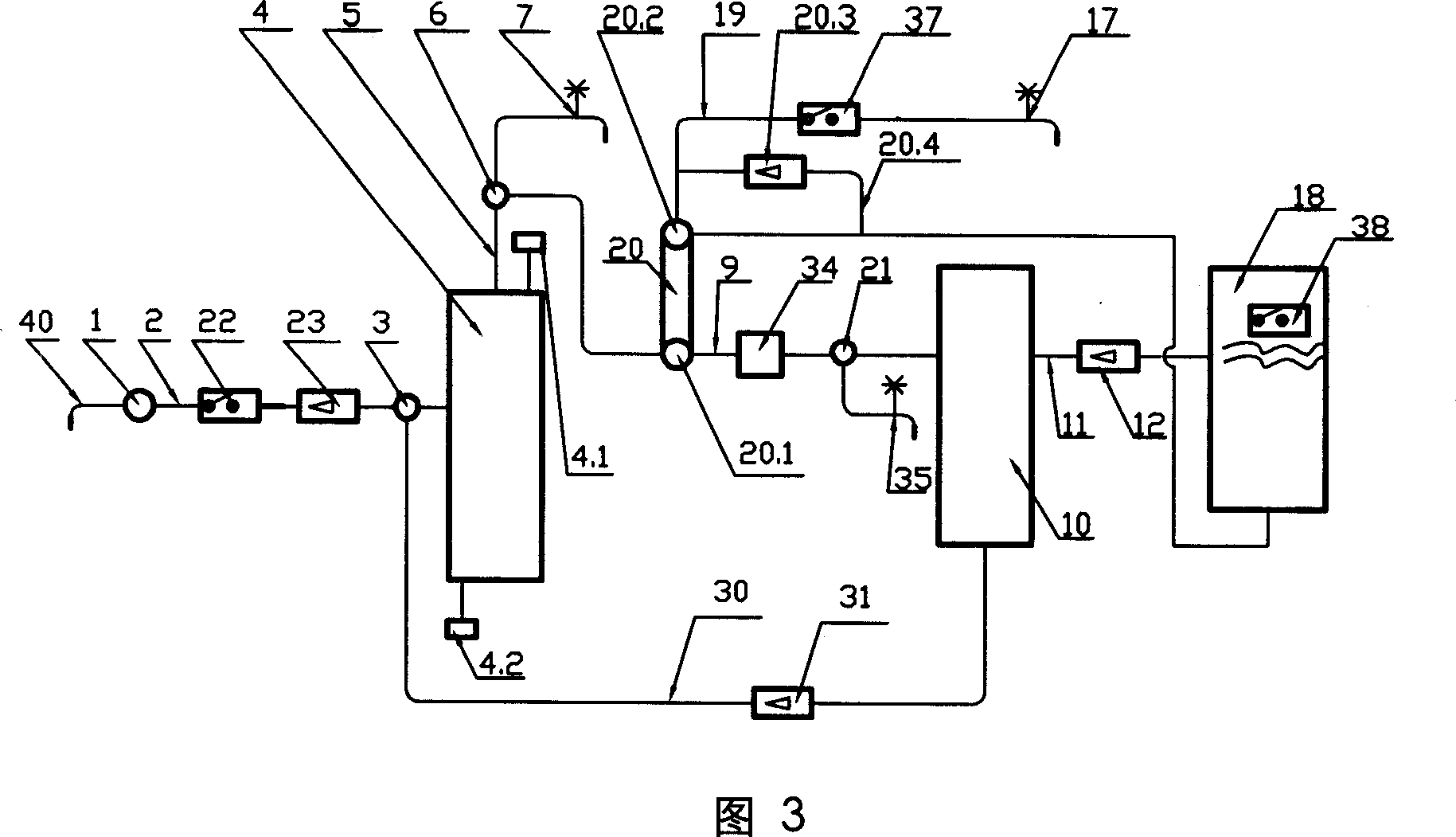

[0057] As shown in FIG. 3 , this embodiment is basically the same as the first embodiment, the difference is that a sterile water tank 18 is used to replace the pressure barrel 13 and the rear charcoal barrel 15 in the first embodiment. Described aseptic water tank 18 is the improved substitute product of pressure barrel 13, it is characterized in that it does not need to configure rear activated carbon, if it is installed on the top of pure water tap 17, it can flow out water; Provide power source. As shown in the figure, the sterile water tank 18 in this embodiment is located below the pure water faucet 17, and a power source is required to supply water to the outside. The double-head dual-purpose pump 20 is arranged on the water pipe C9 that communicates with the second three-way 6, the water outlet of the pump filter head 20.1 is placed on the water pipe C9, and an outlet of the water delivery head 20.2 is communicated through the water pipe G19 The pure water tap 17 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com