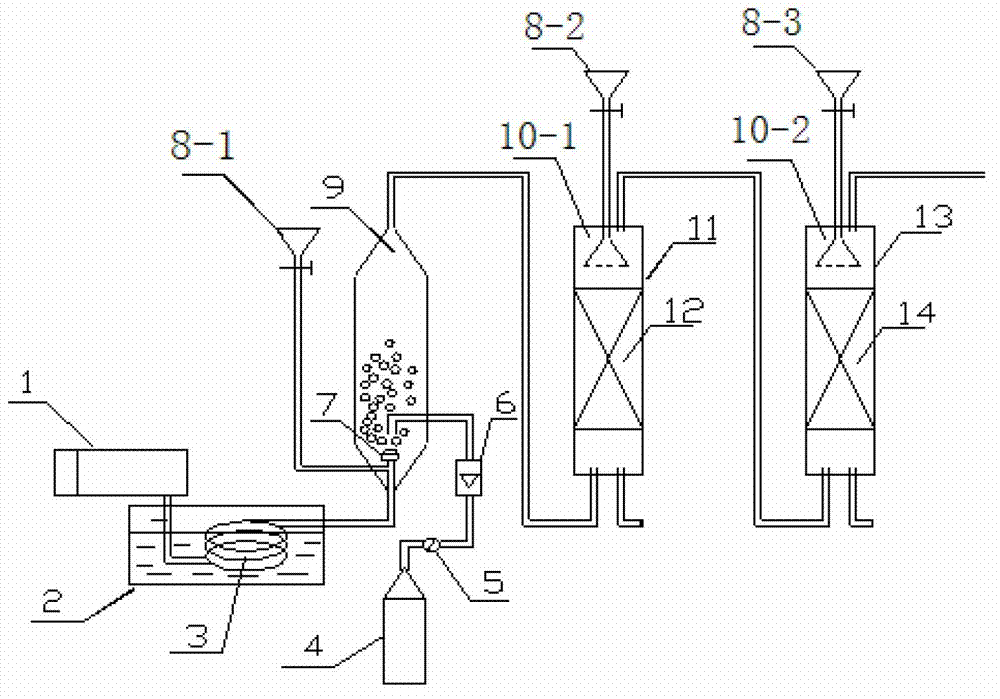

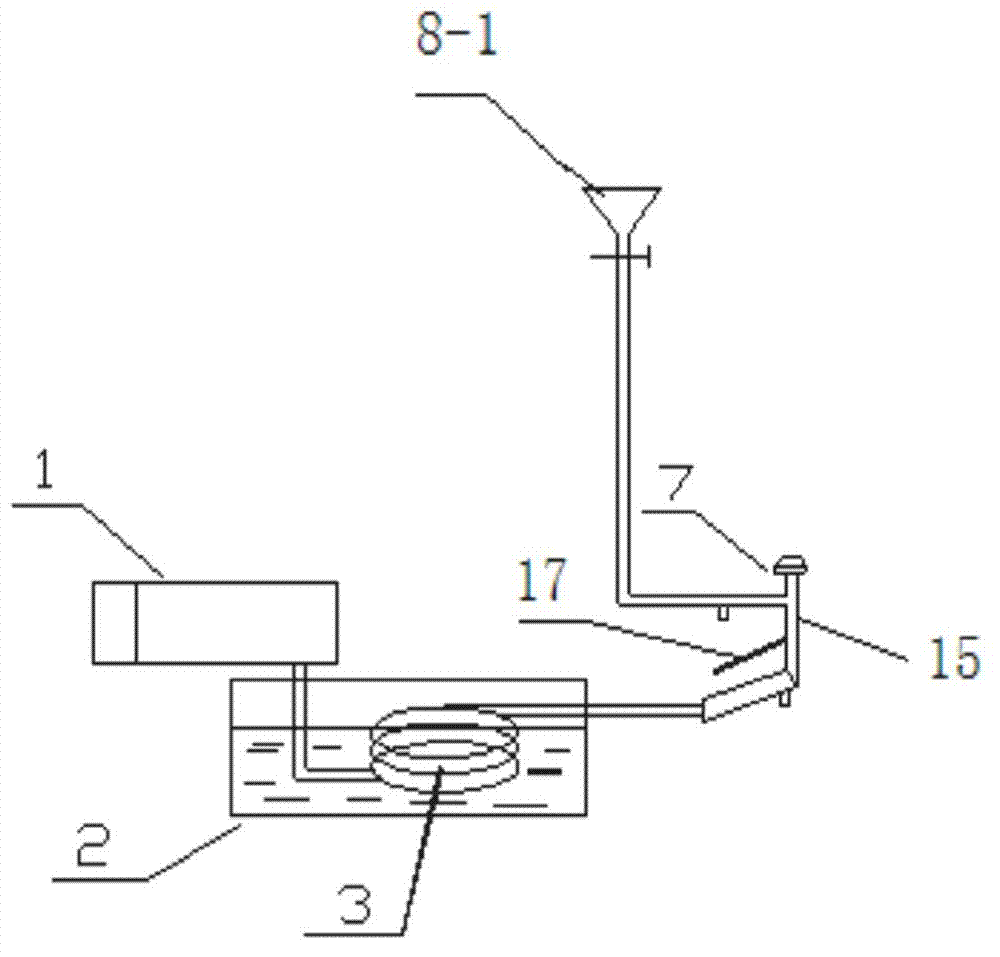

Device and operation method for removing malodorous gas such as methyl mercaptan by chlorine dioxide

A technology of chlorine dioxide and malodorous gas, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problem of high processing costs, the absence of chlorine dioxide to remove the odorous gas of methyl mercaptan, and the inability to remove odorous substances, etc. problems, to achieve low operating costs and equipment investment, easy operation, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

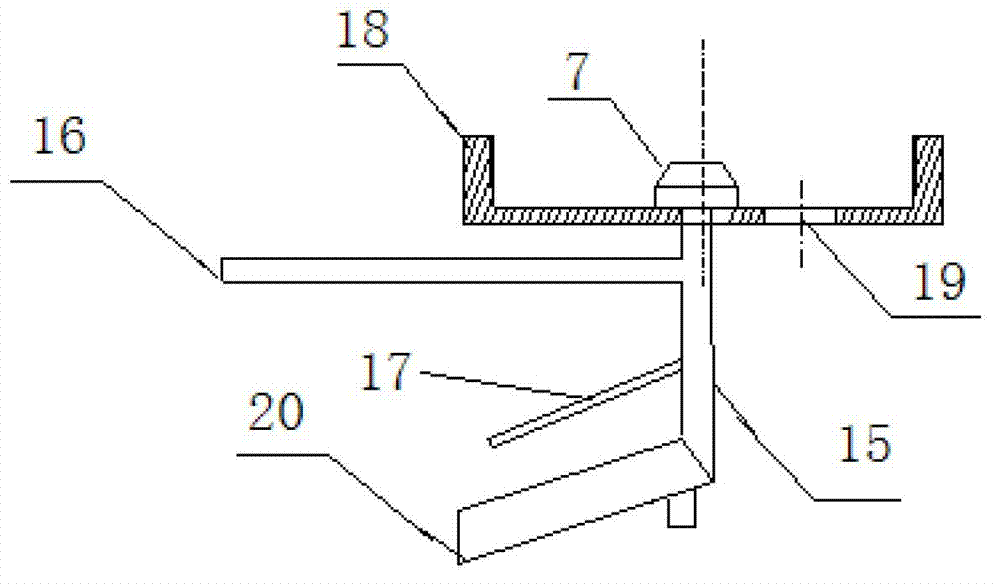

Method used

Image

Examples

Embodiment 1

[0036] 1) Measure 1000ml of absolute ethanol into the separatory funnel of the tail gas absorption tower; add 150ml of 5g / L NaOH and 5g / L NaOH into the alkali absorption tower 2 S mixed lye absorption liquid; 7.0g / L chlorine dioxide solution required for the reaction was added to the chlorine dioxide solution separatory funnel, wherein the molar ratio of chlorine dioxide solution to methyl mercaptan was 2:1.

[0037] 2) Open the intake switch of the compressed air first, and control the flow rate of the compressed air to 0.6m 3 / h, dehydrated alcohol is flowed in the methyl mercaptan absorption tower with the flow velocity of 250ml / min simultaneously, and mixed lye absorption liquid is flowed in the alkali absorption tower with the flow velocity of 40ml / min; The temperature of control odor reactor is 40 ℃, The pH of the chlorine dioxide solution is 2, then open the switch of the chlorine dioxide solution separating funnel, after the chlorine dioxide solution enters the reactor...

Embodiment 2

[0039] 1) Measure 1000ml of absolute ethanol into the separatory funnel of the tail gas absorption tower; add 150ml of 5g / L NaOH and 5g / L NaOH into the alkali absorption tower 2 S mixed lye absorption solution; 7.0g / L chlorine dioxide solution required for the reaction was added to the chlorine dioxide solution separatory funnel, wherein the molar ratio of chlorine dioxide solution to methyl mercaptan was 2.5:1.

[0040] 2) Turn on the intake switch of the compressed air first, and control the flow rate of the compressed air to 0.8m 3 / h, dehydrated alcohol is flowed in the methyl mercaptan absorption tower with the flow velocity of 250ml / min simultaneously, and mixed lye absorption liquid is flowed in the alkali absorption tower with the flow velocity of 40ml / min; Control odor reactor temperature is 30 ℃, two The pH of the chlorine dioxide solution is 3, and then the switch of the chlorine dioxide solution separating funnel is opened, so that the chlorine dioxide solution ent...

Embodiment 3

[0042] 1) Measure 1000ml of absolute ethanol into the separatory funnel of the tail gas absorption tower; add 150ml of 5g / L NaOH and 5g / L NaOH into the alkali absorption tower 2 S mixed lye absorption solution; 7.0g / L chlorine dioxide solution required for the reaction was added to the chlorine dioxide solution separatory funnel, wherein the molar ratio of chlorine dioxide solution to methyl mercaptan was 2.3:1.

[0043] 2) Turn on the intake switch of the compressed air first, and control the flow rate of the compressed air to 0.72m 3 / h, dehydrated alcohol is flowed in the methyl mercaptan absorption tower with the flow velocity of 250ml / min simultaneously, and the mixed lye absorption liquid is flowed in the alkali absorption tower with the flow velocity of 40ml / min; The control odor reactor temperature is 35 ℃, two The pH of the chlorine dioxide solution is 4, then open the switch of the chlorine dioxide solution separating funnel, after the chlorine dioxide solution enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com